Operating Instructions

2K800/2K801/2K802 Preface

5

1Preface

This documentation is intended for specialists who

have experience to carry out maintenance and re-

pair work.

The ZF product is documented in accordance with

the design status as of the issue date.

The following safety notices are used in these op-

erating instructions:

NOTE

Used to highlight special sequences, methods, in-

formation, etc.

CAUTION

Used when incorrect and improper operating

procedures can cause damage to the product.

DANGER!

Used when due lack of care and attention

can cause injury to personnel and/or

damage to property.

ENVIRONMENTAL HAZARDS!

Lubricants and cleaning products must

not be poured onto the ground, into

groundwater or down the drain.

• Obtain and comply with the safety

regulations relevant to these products

issued by your local environmental au-

thority.

• Collect used oil in a suitably large con-

tainer.

• Dispose of used oil, clogged filters, lu-

bricants and cleaning products in ac-

cordance with local environmental

protection regulations.

• Always follow the instructions issued

by the manufacturer when handling

lubricants and cleaning products.

1.1 Safety instructions

•All persons repairing ZF units are responsible

for their own work safety.

•Every applicable safety regulation and legal

requirement must be complied with in order to

prevent injury to personnel and/or damage to

the product during the course of maintenance

and repair work.

•Repair staff should familiarize themselves with

these regulations before commencing work.

•Correct and proper repair of these ZF products

can only be assured by appropriately trained

specialists.

•The organization in charge of repairs is respon-

sible for ensuring that such training is given.

•Read these operating instructions carefully be-

fore commencing any testing or repair work.

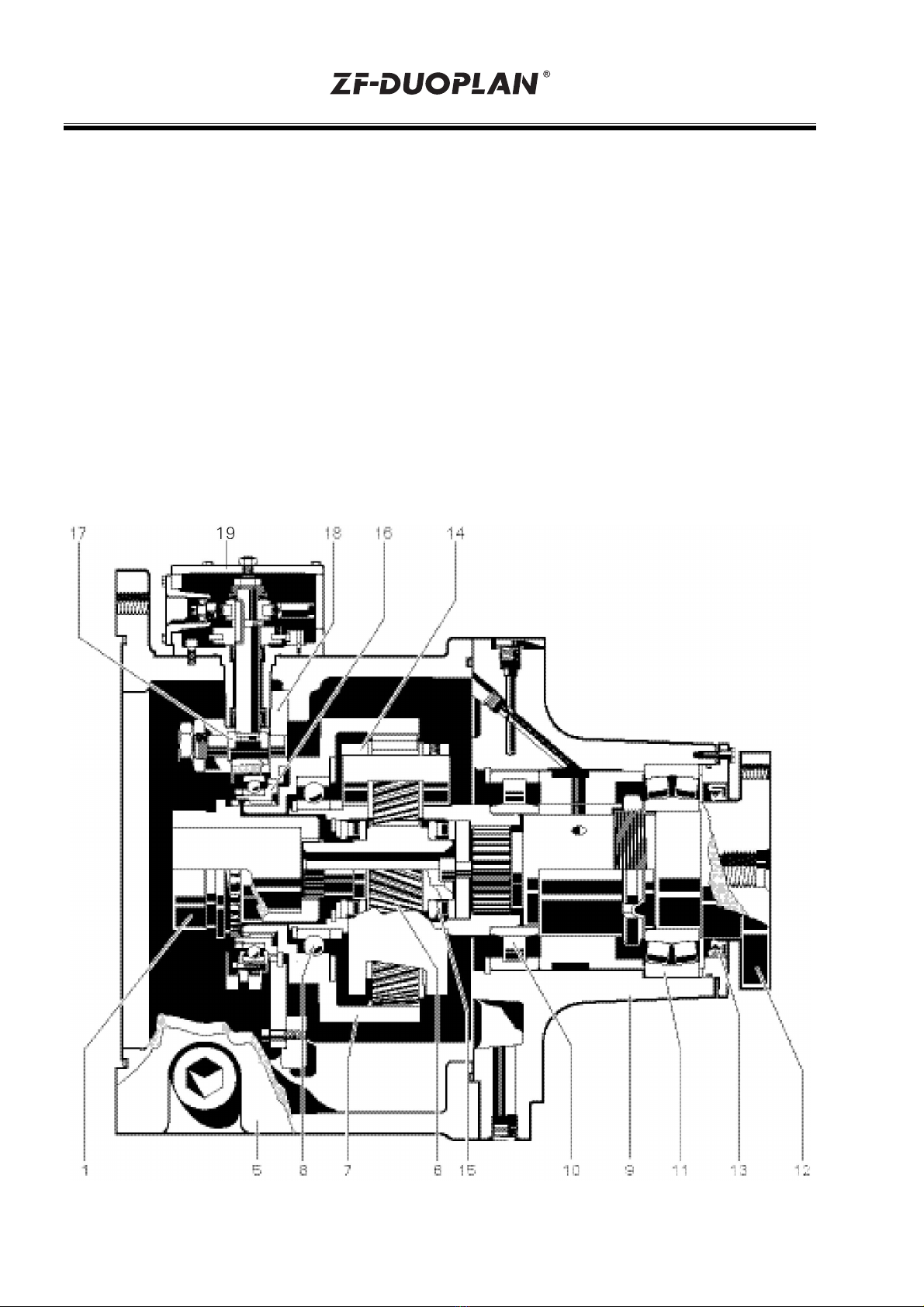

CAUTION

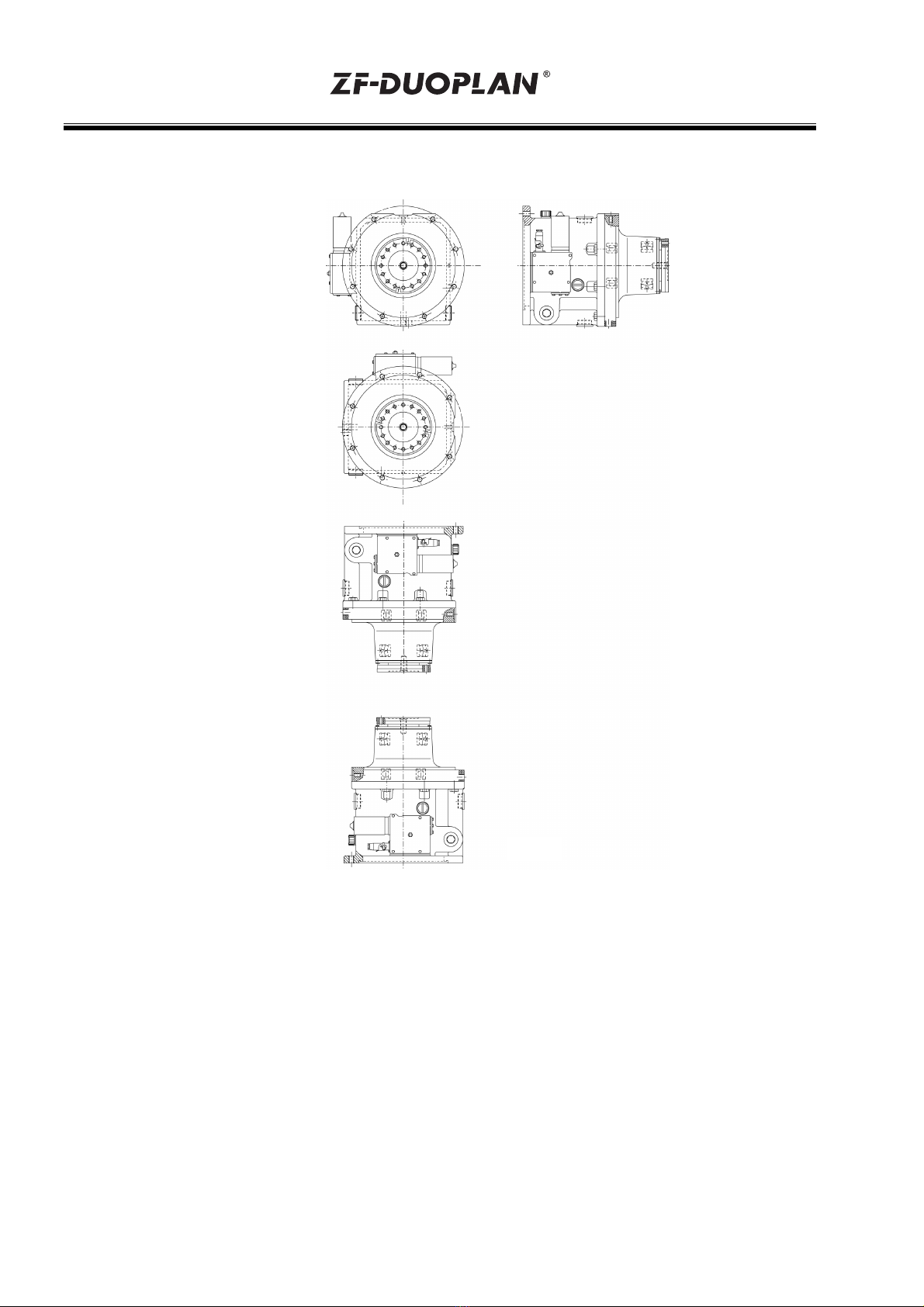

Pictures, drawings and components do not al-

ways represent the original object but are used

to illustrate working procedures.

The illustrations, diagrams and parts are not

drawn to scale and no assumptions should be

made regarding size and weight (including

within a single illustration or drawing).

Work must be performed as described in the

text.

Following the completion of repair work and test-

ing, the specialists must satisfy themselves that the

product will function perfectly again.

1.2 ZF instructions

•Remove any traces of old seals or gaskets from

mating faces. Use an oil stone to carefully re-

move any burrs or similar irregularities.

•Carefully cover or shield open gearboxes to

prevent the ingress of foreign matter.

!

!