BLDC motor driver NSPBLDS4810 manual

Address:No.271,West Hehai Rd, Xinbei District ,Changzhou Jiangsu China,213125

Tel:0086-519-88123456 Fax:0086-519-85152560

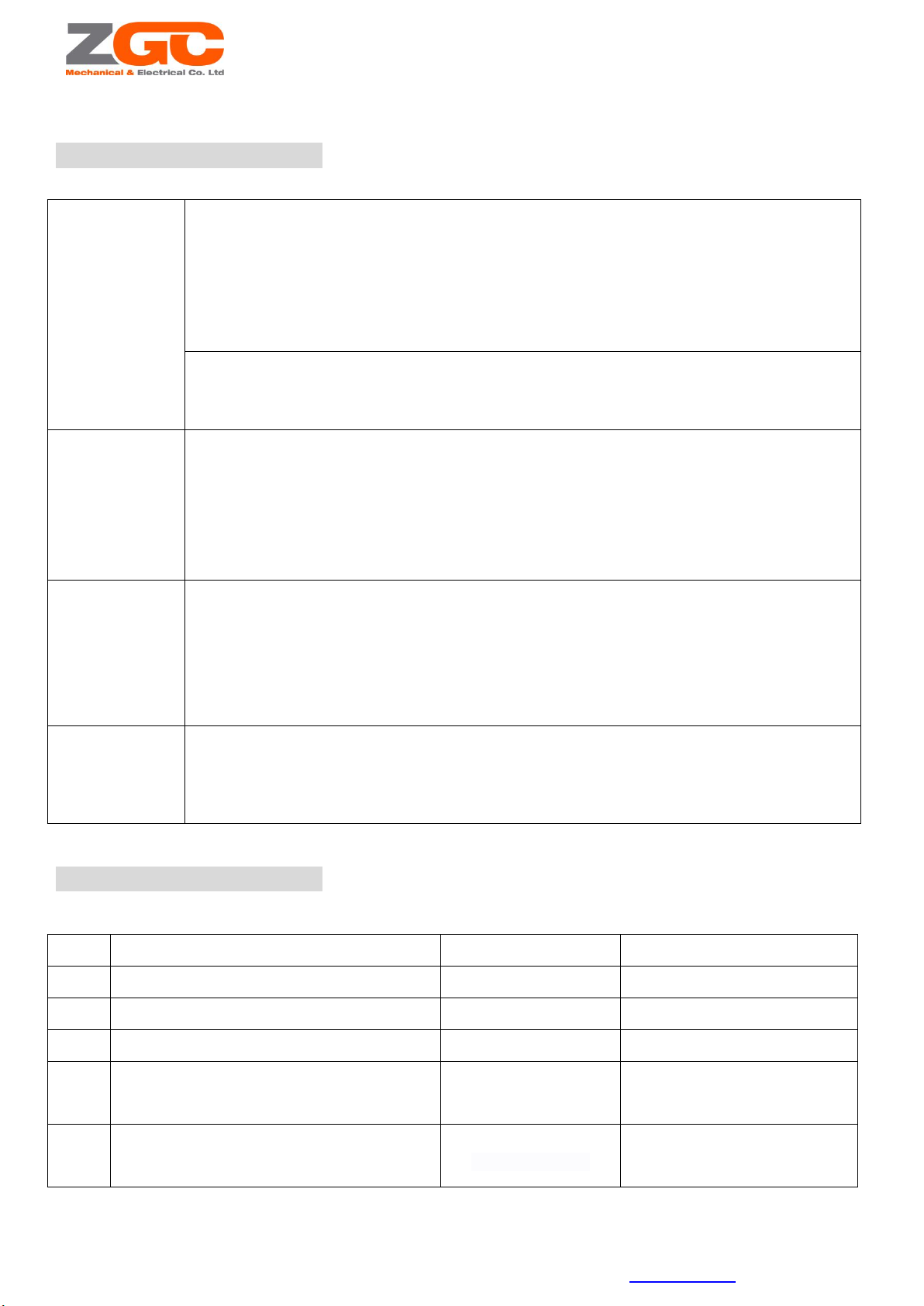

Safety Precautions

★Connecting motor and driver should be carried out under the condition of power failure

★Connect the power cable, motor winding wire and hall signal cable correctly according to the figure. Order of

the UVW phases must be consistent.

★Do not disassemble the driver without instruction to prevent device damage

★Do not touch all terminals during power-on operation

★Do not operate the drive without housing

★Impacting the drive may cause damage

Q&A

1. How to use the drive for the first time?

After properly connecting the power cable, motor cable and Hall wire, the external potentiometer slowly

accelerates. After the motor rotates correctly, it will test the functions such as enable and direction. If you are not

familiar with this product, please install it to the actual occasion after test in initial use.

2. What happens if the power supply is reversed?

The Driver will be broken.

3. What is the maximum voltage of the upper control signal?

The maximum voltage of the speed control signal is 5V. The drive will be broken with voltage above 5V.

4. Housing of the driver is heated after long period of work, is it normal?

It is normal. At normal temperature, the housing reaches 90 degrees after a long period of work, which will not

affect the performance.

5. The motor does not turn but shake when the power LED is on, what is the reason?

The phase wires and the hall wires may be connected incorrectly. Please test after wiring according to the motor

manual.

6. Can I adjust my motor speed to 6000 with this driver?

The maximum speed of the brushless motor is determined by the parameters of the motor itself. Driver can

control the motor speed from 0 to the max speed.

7. How can I connect this driver to my own motor?

Please make sure that the phase wires and Hall wires of the motor are defined before connecting. If you are not

sure, please consult the motor manufacturer. Improper connect will cause damage to the driver.

8. Is it possible to add more function to this driver or develop new product?

Yes, please feel free to contact us.