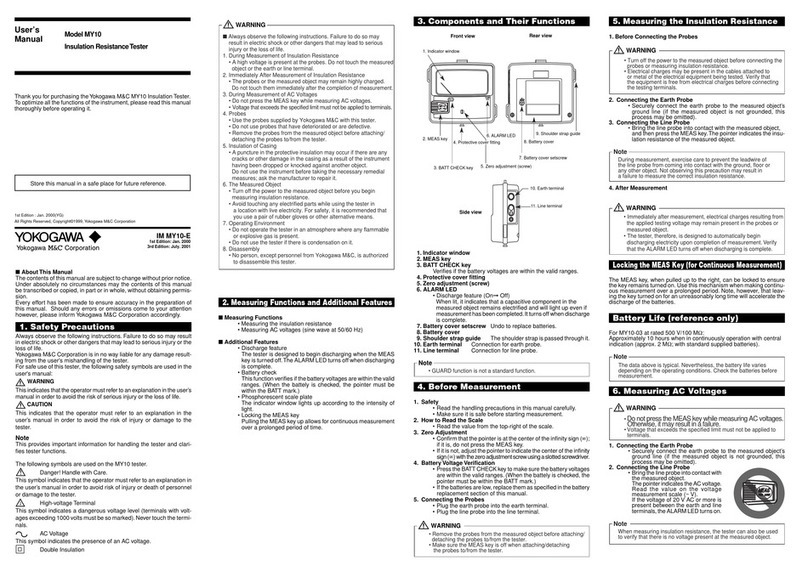

Warnings

Read the documentation and fully assimilate the

information it contains before use

Do not use the appliance on voltages greater than 230

V.inspect the appliance before use. Do not use the

appliance if it is damaged.

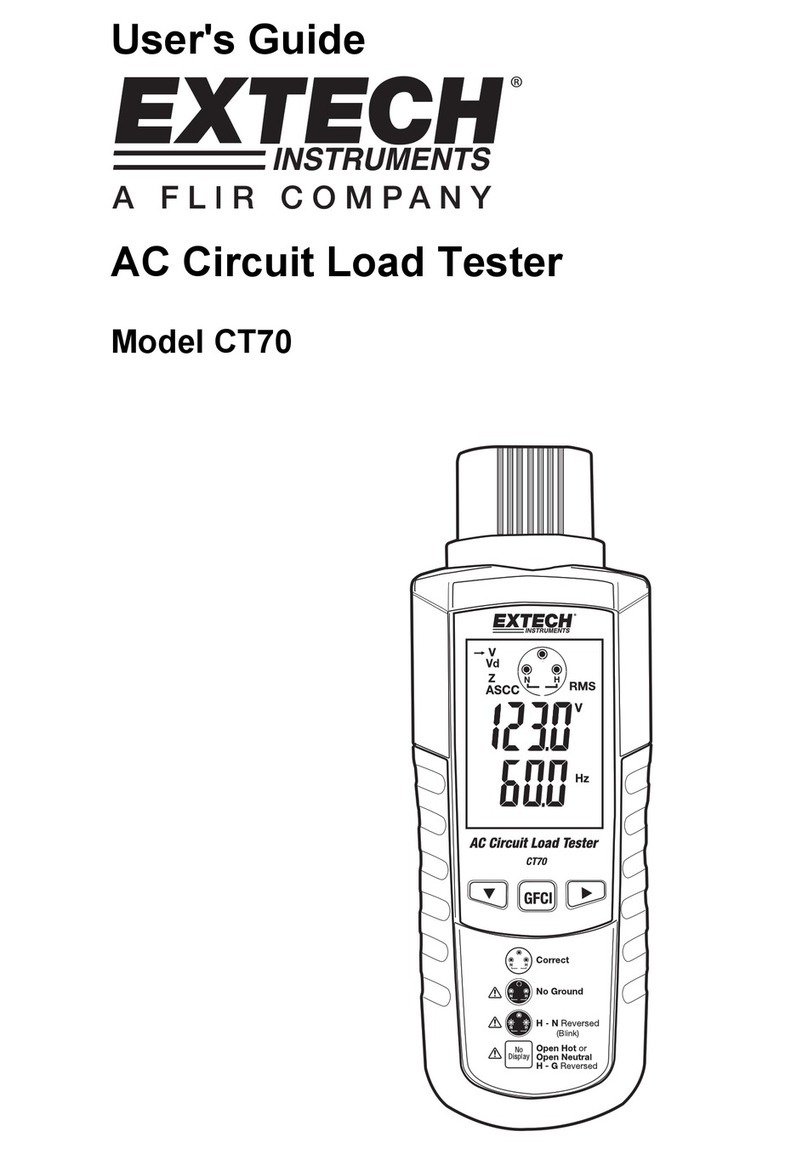

If a 400 V pictogram is displayed, disconnect the appliance

immediately and check the installation.

The nature of the test is to trip differential protection

mechanisms. At the end of the test, there is therefore no

power on the tested port of the installation.

Before using the appliance, you must therefore ensure

that the absence of power will not harm any

People or damage equipment (medical,

computers ,industrial plant, etc.).

The tester is not a No Voltage Tester (nvt).

Use an appliance designed for this purpose.

The manufacturer must carry out the after-sales

operations.

Do not attempt to continue the tests if the default voltage

(50V) is displayed (calculated for I-

△n); then check the installation.