804052US v1.27 06.21 CS75 Install Instructions Page 3 of 28

HydroTap Specifications

Installation Check List .................................................................................................................. 4

General Product Features............................................................................................................ 5

Important Safety Instructions ....................................................................................................... 6

Warnings and Regulatory Information.......................................................................................... 7

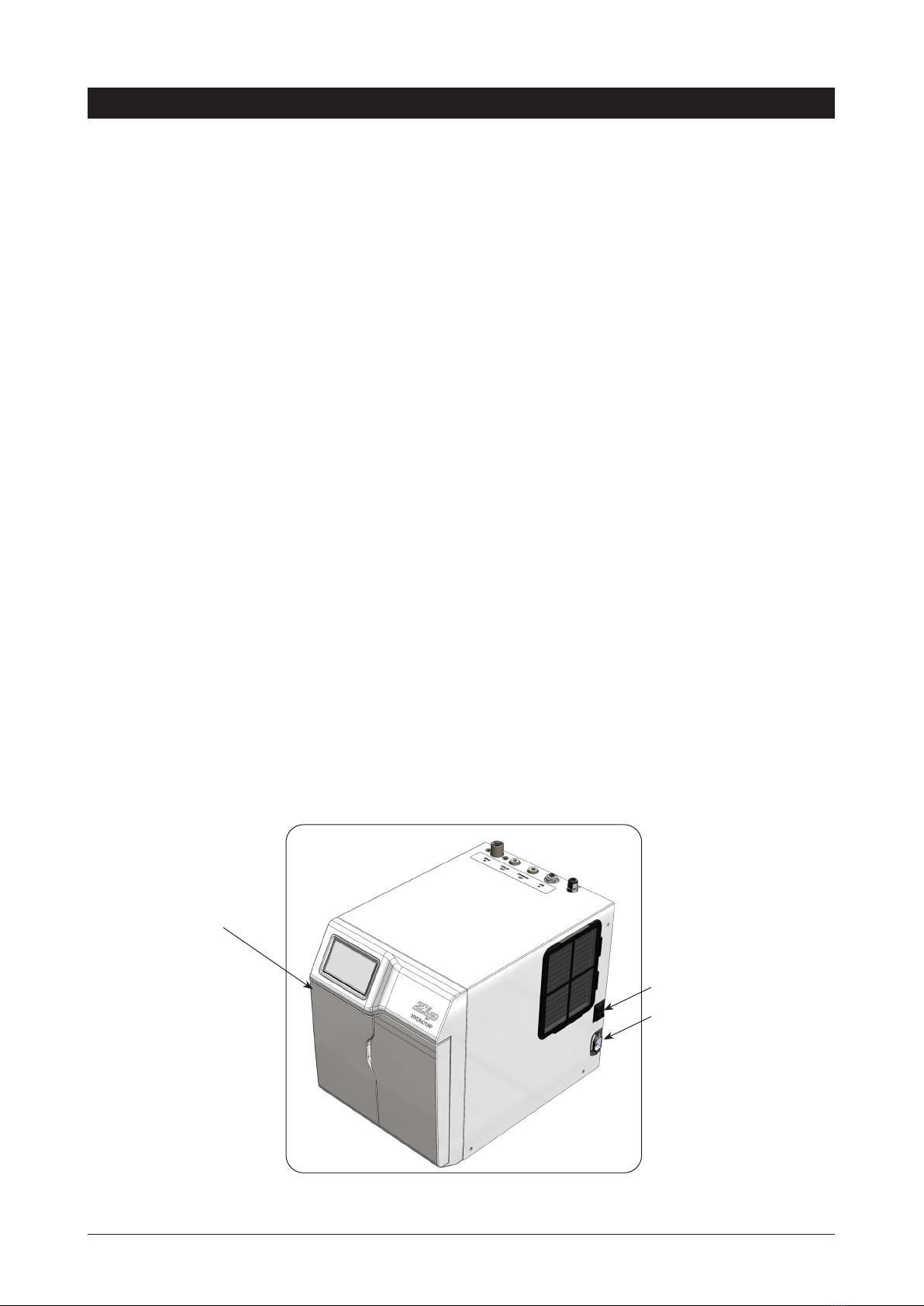

Major Components and Accessories ........................................................................................... 8

Technical Specification ................................................................................................................ 9

Before Installation and Site Requirements................................................................................... 10

Installation Procedure

STEP 1 - Measure and cut all the faucet holes before fitting the faucets

Section 1 - See Faucet Installation instructions (supplied with the faucet)

STEP 2 - Check for adequate ventilation

Section 2 - Ventilation

2.1 - Ventilation for All Models .......................................................................................... 11

2.2 - Cabinet Air Circulation .............................................................................................. 12

STEP 3 - Fit the CO2Gas cylinder

Section 3 - CO2Cylinder and regulator

3.1 - Secure the cylinder mounting ................................................................................... 14

3.2 - Connect the regulator ............................................................................................... 14

3.3 - Connect the gas hose............................................................................................... 14

STEP 4 - Install the Command Center

Section 4 - Command Center installation

4.1 - Electrical power supply ............................................................................................. 15

4.2 - Hose and tube fittings ............................................................................................... 15

4.3 - Test for gas leaks...................................................................................................... 16

4.4 - Installing carbonation valve....................................................................................... 17

4.5 - Model CS installation and connection....................................................................... 17

STEP 5 - Commission the HydroTap

Section 5 - Commissioning

5.1 - Select the language .................................................................................................. 18

5.2 - CO Purge.................................................................................................................. 18

5.3 - Filter Flush ................................................................................................................ 18

5.4 - Conditioning Procedure ............................................................................................ 19

5.5 - Carbonation Valve Flow Adjustment......................................................................... 19

5.6 - Backflow Prevention ................................................................................................. 20

Troubleshooting ........................................................................................................................... 21

End of life disposal....................................................................................................................... 21

Performance Data Sheets............................................................................................................ 22

Warranty....................................................................................................................................... 26

Index