Zip HydroTap G4 Series User manual

1

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

®

Installation instructions

Zip

HydroTap G4

Tap range.

Model number:

(See table of contents for specific models).

02 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Tap options

The G4 series offers a range of interchangeable taps to suit the customer's needs.

Classic range

Arc / Cube range

Elite range

Classic All-in-One

Mixer range

These standalone taps offer instant boiling, chilled

and sparkling water* and are directly compatible

with the G4 Command-Centre.

The All-in-One taps may be used as alternatives to

the above HydroTap and mixer tap combinations*.

The mains and vented mixer tap range may be

used in conjunction with any of the above to

provide mixed hot and cold water for sanitary

use*.

Celsius range

The Celsius range offer instant boiling, chilled

and sparkling / boiling and chilled / boiling and

ambient / chilled and sparkling / chilled or boiling*

water together with the an integral mixer to

provide mixed hot and cold water from the mains.

*Dependant upon model purchased.

Celsius All-in-One

03

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Table of contents

Tap options .............................................................................................................................................2

Generic installation instructions .............................................................................................................4

Min / Max water supply pressure requirements .....................................................................................4

Special tool requirements .......................................................................................................................4

Hole & tap positioning ............................................................................................................................5

Clearance envelope.................................................................................................................................6

Command Centre connection table .......................................................................................................6

Tap installation

Section 1 - Classic and Elite HydroTap G4 installation.............................................................................7

Section 2 - Arc / Cube HydroTap G4 installation ....................................................................................8

Section 3 - Vented Classic Mixer tap installation ....................................................................................11

Section 4 - Mains Arc & Cube Mixer tap installation...............................................................................12

Section 5 - Vented Arc & Cube Mixer tap installation .............................................................................13

Section 6 - Mains All-in-One tap installation ..........................................................................................15

Section 7 - Vented All-in-One tap installation ........................................................................................18

Section 8 - Mains Celsius tap installation ................................................................................................21

Section 9 - Mains All-in-One Celsius Arc tap installation........................................................................24

Product information

End of life disposal ..................................................................................................................................27

Contact details ........................................................................................................................................28

04 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Generic installation instructions

Arc / Cube

Elite Classic Classic

All-in-

One

Celsius

Min / Max water supply pressure requirements

HydroTaps and Mains All-in-One & Celsius taps sparkling models.............0.30 MPa (3.0 bar) - 0.7 MPa (7.0 bar)

HydroTaps and Mains All-in-One & Celsius taps non-sparkling models........0.17 MPa (1.7 bar) - 0.5 MPa (5.0bar)

Vented All-in-One sparkling models............................................................0.25 MPa (2.5 bar) - 0.5 MPa (5.0 bar)

Mixer taps and Vented All-in-One non-sparkling model taps.....................0.25 MPa (2.5bar) - 0.5 MPa (5.0 bar)

Using these instructions

These instructions are provided primarily to demonstrate how to install HydroTap G4 taps

and do not provide sufficient information to install and commission complete HydroTap G4

systems.

Please refer to all safety and installation requirements detailed in the Quick start guide

provided with the Command-Centre, and Command-Centre installation instructions found

online prior to any change to the complete system.

Arc Cube

All-in-One

Celsius Arc

!

HydroTaps All in One taps Mixer taps

Before commencing the installation, download & read the Command Centre

installation instruction manual, which can be found online at:

(Australia) www.zipwater.com

(UK) www.zipwater.co.uk

Tap installation special tool requirements In addition to normal tools, the following

(or equivalent equipment) will be required.

For the HydroTap G4, Celsius and mixer taps (for All-in-One Celsius Arc see below).

• 35mm diameter sheet metal hole punch for sinks (not supplied).

• 35mm diameter hole saw for worktops (not supplied).

• Nut runner tube spanner (supplied for all but Celsius & mixer taps) for fixing the tap assembly.

For the All-in-One tap & All-in-One Celsius Arc.

•50mm diameter sheet metal hole punch for sinks (not supplied).

•50mm diameter hole saw for worktops (not supplied).

•Nut runner tube spanner (not supplied for All-in-One Celsius Arc) for fixing tap assembly.

Font installation special tool requirements

•Hole saw or equivalent to suit surface being cut. Ø140m for Arc / Cube and Ø108mm for Classic and Elite.

!

Be aware of the risks of hazards which could cause harm when using tools.

Assess the risks before starting the installation.

05

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Tap Recommended

dispensing

distance (mm)

Elite 116

HydroTap Classic 116

HydroTap Arc/Cube 171 (-174 extended)

All-in-One 211

Celsius All-in-One

Arc 220

Celsius - Arc/Cube 220

Mixer - Arc 220

Mixer - Classic 270

Mixer - Cube 220

HydroTap G4 Classic

116

Note

• Celsius, All-in-One and mixer taps have spouts that swivel.

• All images are for illustrative purposes, to aid understanding

of the system configuration, and are not prescriptive of tap

positioning.

• Ensure that the taps are mounted in a position that allows the

water to safely drain to waste throughout the positional range.

Hole positioning

• Position the tap such that it dispenses into the sink bowl with ample clearance for a cup or tea pot.

Alternatively, the tap could be mounted away from the sink using a Zip Font, available as an accessory.

Tap positioning

125

225 with extension

Generic installation instructions

!

Ensure that taps are positioned to minimise the risks of scalding by dispensing

boiling water while using the mixer tap.

06 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Generic installation instructions

Clearance envelope

• See adjacent diagram.

• A clearance envelope around all Command-Centres must be

provided to allow adequate ventilation for the safe and effective

use of the HydroTap G4 system.

• The tap must have adequate clearance to correctly dress tubes

and hoses without kink or sagging.

• Allow space for the threaded boss and the connection pipes.

Clearance

envelope

535mm

min. 300mm

335mm

All plastic pipes / silicone tubes must be trimmed to size. They must have a constant fall to the Command-

Centre.

The connection tubes supplied with the tap head assembly CANNOT be lengthened.

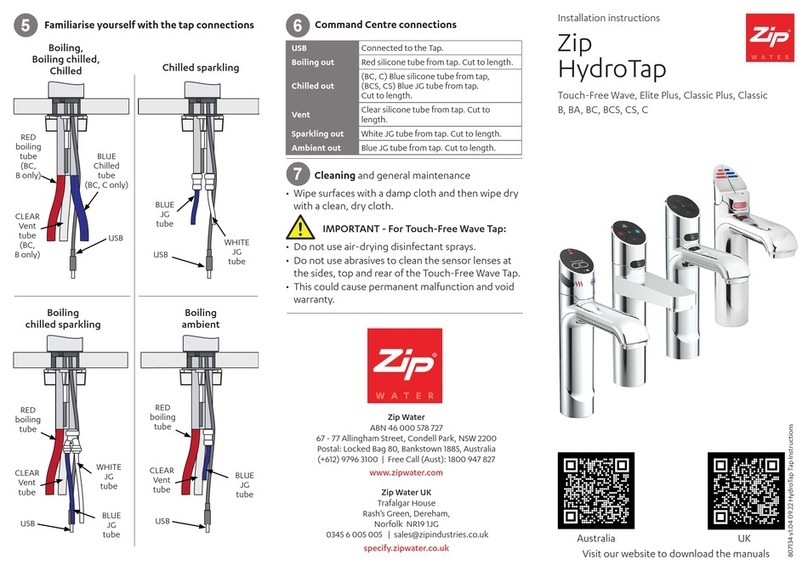

Command Centre connection table - for reference

Mains In Mains water supply. Wholesome (cat 1).

Mains power IEC power lead, 230V AC 50Hz 13A socket.

USB Connect to the Tap—make sure they click together and are secured up off

the floor of the cupboard.

CO2IN Connect the 1/4’ connection from the CO2cylinder.

Boiling out Cut to length Red hose from tap. No kinks, bends or loops. Must fall from tap

directly to Command Centre.

Chilled out Connect the JG 1/4’ pipe to this push fit outlet. There is another push fit JG

fitting for the tap.

Vent Cut to length clear hose from tap. No kinks, bends or loops. Must fall from

tap directly to Command Centre.

Sparkling out Connect a piece of JG 1/4’ pipe to this outlet. Fit the carbonation valve to the

pipe, then connect valve to tap.

Bypass in Only used for Booster (supplied with 240/175 models) & scale filter. Braided

hose from Booster outlet (or scale filter).

Bypass out Only used for Booster (supplied with 240/175 models) & scale filter. Braided

hose from Booster inlet (or scale filter).

Mixer in

Only used when supplied with a special 3 hose mixer tap from Zip. Leave the

red dust caps on if not used.

If using a mixer tap connect to the blue marked braided hose from mixer tap.

Mixer out

Only used when supplied with a special 3 hose mixer tap from Zip. Leave the

red dust caps on if not used.

If using a mixer tap connect to the red marked braided hose from mixer tap.

Cut hoses to length, no clamps are required on silicone hoses.

07

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

SECTION 1 Classic & Elite HydroTap G4 installation

• Apply a light smearing of silicone sealant on the

underside of the spacer to ensure a watertight fit.

1.2 Cut the hole & fit the spacer

• Cut a Ø35mm hole in the worktop / sink.

Note Make sure the tap location will allow the tap

spout to drain into the sink.

Ø35mm

EliteClassic

1.1 Configure the tap

All thread rod

Stainless steel

spacer

Spider

clamp

Nut

Black plastic

spacer

Blue chilled pipe

(chilled models)

Red boiling pipe

USB lead

Clear vent pipe

(boiling models)

Black

plastic spacer

1.3 Mount the tap

• Pass the tubes and USB cable through

the Ø35mm hole.

Ø35mm hole

1.4 Secure the tap

• Fit the stainless steel washer & spider clamp.

• Secure with nut.

• Feed each of the tubes and USB cable evenly

in between the legs of the spider clamp during

installation.

Nut

Spider clamp

Stainless steel

washer

1.5 Connect the water supply (detail shown,

assembled and disassembled)

Note correct filter orientation. Valves and

fittings must be sealed with PTFE tape.

!

Filter

(supplied)

via Isolation valve

(not supplied)

Incoming mains

ambient water

supply

Male - Female

adaptor

(supplied)

Braided hose

to Command

-Centre

(supplied)

Connect together Isolation valve

1/2” BSP

(G 1/2)

Australia UK

15mm

- 1/2” BSP

(G 1/2)

Ambient mains water supply

08 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Scalding risk, Position *A should not be selected with boiling water models.

!

2.2 Adjust the height & angle (fixed position options, see below)

225mm

175mm

*A *A

2.3 Cut the hole & mount the tap

• Cut a Ø35mm hole in the worktop / sink.

Ø35mm

• Slide o-rings in place.

• Mount tap in position on Ø35mm hole.

• Slide lower rubber washer & metal washer over

threaded boss, tighten the tap nut to secure in place.

• Do not over tighten.

Upper o-ring

Base ring

Lower o-ring

Rubber washer

Metal washer

Nut

Spout locating

screws

Undercut

for USB

Upper locating

positions

Spring clip

Lower locating

positions Dimples

Spring clip

The Arc / Cube have spouts that may be fixed in 1 of 6 angular positions and 1 of 2 height

positions. The spout is fixed and does not swivel.

Arc / Cube

2.1 Configure the tap (see diagram below)

• Remove spout locating screws, lower spout to expose the plastic spring clip.

• To reposition spout, prise open spring clip.

• Slide spring clip up/down to engage selected holes.

• Ensure dimples engage simultaneously with the two selected holes.

• Raise the spout (ensure USB lead fits in undercut and open ends of the clip).

• Align clip with locating holes, & refit the 2 x locating screws.

SECTION 2 Arc & Cube HydroTap installation

09

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

2.5 John Guest fittings (insertion and removal)

• Ensure cut tube has a clean, square & straight edge.

• Remove any residual material.

• Ensure tube remains round, without distortion.

• See adjacent diagram for fitting & removal.

2.4 Fit the tube kit (The L/H & R/H positions of the three way silicone tube are interchangeable) refer to

instruction supplied with the tube kit, and the configuration diagrams below .

SECTION 2 Arc & Cube HydroTap installation

Blue / White

LLDPE

Red

Silicone

Boiling, chilled

& sparkling

Boiling &

ambient

Blue

LLDPE

Red

Silicone Clear

Silicone

Chilled and

sparkling

Blue / White LLDPE

Chilled

Blue

Silicone

Red

Silicone Clear

Silicone

Blue

Silicone

Boiling

Red

Silicone Clear

Silicone

Three way

silicone tube

S/S tube

20mm

insertion

Clamp Herbie

clip near the

end of the

three way

silicone tube

• Check the insertion depth as shown above.

• Ensure the Herbie clip is clamped close to the end of the three way silicone tube and aligned with the

central axis, as shown above.

• Compress with pliers for tight fit.

Axial alignment

of clips

Herbie clip

orientation:

align with axis

2.7 Attach the label Area 1

Area 2

BOILING

CHILLED

SPARKLING

BOILING

CHILLED

BOILING

AMBIENT BOILING CHILLED

SPARKLING CHILLED

• Clean tap, select correct label.

• Trim to size if required & fit to tap as indicated, see adjacent diagram.

2.6 Secure the tube kit

Vent connector

Note Fit the vent connector in ALL installations (to stabilise the tube assembly)

Boiling &

chilled

10 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

SECTION 2 Arc & Cube HydroTap installation

Filter

(supplied)

Incoming mains

ambient water

supply

Male - Female

adaptor

(supplied)

Connect together

Braided hose to

Command -Centre

(supplied)

2.8 Connect the water supply (detail shown, assembled and disassembled)

Note correct filter orientation. Valves and

fittings must be sealed with PTFE tape.

!

via Isolation valve

(not supplied)

Isolation valve

1/2” BSP

(G 1/2)

Australia UK

15mm

- 1/2” BSP

(G 1/2)

Ambient mains water supply

11

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

SECTION 3 Vented Classic mixer tap installation

3.1 Configure the tap

Braided

hose x 3

Nut

Lower rubber

washer

Upper rubber washer

Washer

Classic

3.2 Cut the hole & mount the tap

Nut

Lower rubber

washer

Upper rubber

washer

Washer

White or plain marking -

mains supply

Blue marking - MIXER IN

on Command-Centre

Red marking - MIXER OUT

on Command-Centre

Note Make sure the tap location will allow the

tap spout to drain into the sink.

• Slide upper rubber washer in place.

• Mount tap in position on Ø35mm hole.

• Slide lower rubber washer, metal washer then tap

nut over thread extension.

• Tighten the tap nut to secure in place, do not

over tighten.

• Match the braided hose and tap extension colour

markings, attach the braided hoses.

• Ensure the seals on the end of the hoses are

lubricated, do not over tighten.

• Cut a Ø35mm hole in the worktop / sink.

Ø35mm

3.3 Fit the braided hoses (see 3.2)

3.4 Connect the water supply (detail shown,

assembled and disassembled)

Note correct filter orientation. Valves and

fittings must be sealed with PTFE tape.

!

Isolation valve

1/2” BSP (G 1/2)

Australia UK

15mm - 1/2” BSP(G 1/2)

Flow restrictor

(supplied)

T-piece

(supplied)

Male - male

adaptor

(supplied)

Incoming

mains ambient

water supply

Connect together

via Isolation valve

(not supplied)

Ambient mains water supply

Plain braided

hose to mixer

tap

Braided hose

to Command

-Centre mains

inlet

12 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Arc Cube

4.1 Configure the tap

Braided

hose x 2

Nut

Lower rubber

washer

Upper rubber

washer

Washer

4.2 Cut the hole & mount the tap

Note Make sure the tap location will allow the

tap spout to drain into the sink.

• Slide upper rubber washer in place.

• Mount tap in position on Ø35mm hole.

• Slide lower rubber washer, metal washer then

tap nut over threaded boss, then tighten the

tap nut to secure in place, do not over tighten.

• Match the braided hose and tap extension

colour markings. Attach the braided hoses.

• Ensure the seals on the end of the hoses are

lubricated.

• Do not over tighten.

• Cut a Ø35mm hole in the worktop / sink.

Ø35mm

Nut

Lower rubber

washer Upper rubber

washer

Washer

Section 4 Mains Arc & Cube mixer tap installation

Blue marking - Ambient

mains supply

Red marking - Hot mains

supply

4.3 Fit the braided hoses (See 4.2)

4.4 Connect the water supply (detail shown,

assembled and disassembled)

Note correct filter orientation. Valves and

fittings must be sealed with PTFE tape.

!

Isolation valve

1/2” BSP

(G 1/2)

Australia UK

15mm

- 1/2” BSP

(G 1/2)

Incoming

mains water

supply

Male - Female

adaptor

(supplied)

Blue marking -

Braided

hose

to tap

Red marking -

Braided

hose

to tap

Connect together

HotAmbient

13

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 5 Vented Arc & Cube mixer tap installation

Arc Cube

5.1 Configure the tap

• See adjacent diagram.

5.2 Low pressure installation

Replace the supplied Aerator with a 94732 flow

straightener in the spout of the v

ented Zip mixer tap.

Replacement

94732

Supplied

aerator

Braided

hose x 3

Nut

Lower rubber

washer

Upper rubber washer

Washer

5.3 Cut the hole & mount the tap, fit the braided hoses

Note Make sure the tap location will allow the

tap spout to drain into the sink.

• Slide upper rubber washer in place.

• Mount tap in position on Ø35mm hole.

• Slide lower rubber washer, metal washer then

tap nut over threaded boss, then tighten the

tap nut to secure in place, do not over tighten.

• Match the braided hose and tap extension

colour markings. Attach the braided hoses.

• Ensure the seals on the end of the hoses are

lubricated.

• Do not over tighten.

• Cut a Ø35mm hole in the worktop / sink.

Ø35mm

Nut

Lower rubber

washer

Upper rubber

washer

Washer

Plain hose, no marking -

Ambient mains supply

Blue marking - MIXER IN

on Command-Centre

Red marking - MIXER OUT

on Command-Centre

14 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 5 Vented Arc & Cube mixer tap installation

5.4 Connect the water supply (detail shown, disassembled and assembled)

Plain braided

hose to mixer

tap

Braided hose

to Command

-Centre

inlet

T-piece

(supplied)

Male - female

adaptor

(supplied)

Incoming

mains ambient

water supply

Connect together

Filter

(supplied)

Filter

(supplied)

Male - female

adaptor

(supplied)

Flow restrictor

(supplied)

Note correct filter orientation. Valves and

fittings must be sealed with PTFE tape.

!

Isolation valve

1/2” BSP (G 1/2)

Australia UK

15mm - 1/2” BSP(G 1/2)

via Isolation valve

(not supplied)

Ambient mains water supply

15

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 6 Mains All-in-One tap installation

O-ring

Base block

spider

Base block nut

Note Make sure the tap location will allow the tap

spout to drain into the sink.

6.2 Cut the hole & mount the tap

6.1 Configure the tap

• See adjacent diagram.

• Cut a Ø50mm hole in the worktop / sink.

Ø50mm

• Fit the o-ring to the underside of the tap.

• Pass tubes and cable through the Ø50mm hole.

• Feed each of the tubes and USB cable evenly between the legs of

the base block spider (see section 6.3).

• Locate the base block spider to the underside of the tap.

• Clamp in position using the base block nut.

• Do not over-tighten.

Note All silicone tubes must be cut to size. They must

have a constant fall back to the Command-Centre.

All-in-One

mains

USB cable

16 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 6 Mains All-in-One tap installation

6.4 Connect the tap

6.3 Position tubes, hoses & base block spider

Blue marking Red marking

USB cable

Red silicone

tube

Clear silicone tube

Blue marked

braided hose

(viewed from underneath)

Red silicone tube -To

BOILING OUTLET on

Command-Centre

Clear silicone

tube - To VENT on

Command-Centre

Blue silicone

tube -To

CHILLED

OUTLET on

Command-

Centre

Blue marked

braided hose to

blue marked pipe

on tap

USB plug, connect

to Command-

Centre

Blue silicone

tube

Red marked

braided hose

Red marked

braided hose to

red marked pipe

on tap

• Connect the tap using the

adjacent diagram.

• Match the braided hoses &

extension tubes colour markings.

• Attach the braided hoses

(lubricate seals).

• Do not over tighten.

• For sparkling HydroTaps, connect

the supplied Y connector to the

blue silicone tube, then 1/4” blue

and white pipes as shown.

• For ambient HydroTaps, connect

the supplied connector to the

blue silicone tube, then 1/4” blue

pipe as shown.

• Attach the USB connector to the

Command-Centre.

White pipe

to SPARKLING

OUTLET on

Command-

Centre

Blue pipe

to CHILLED

OUTLET on

Command-

Centre

Blue pipe to

AMBIENT

OUTLET on

Command-

Centre

SPARKLING

models

OR

OR

AMBIENT

models

Red marked braided

hose to hot mains

water supply

Blue marked braided

hose to ambient mains

water supply

17

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 6 Mains All-in-One tap installation

6.5 Connect the water supply (detail shown, disassembled and assembled)

Blue marked

Braided hose

to mixer tap

Braided hose

to Command

-Centre inlet

Male - Female

adaptor

(supplied)

T-piece

(supplied)

Male - Male

adaptor

(supplied)

Incoming

mains ambient

water supply

Red marked

Braided hose

to mixer tap

Filter

(supplied)

Connect together

Note correct filter orientation. Valves and

fittings must be sealed with PTFE tape.

!

Isolation valve

1/2” BSP (G 1/2)

Australia UK

15mm - 1/2” BSP(G 1/2)

via Isolation valve

(not supplied)

Incoming

mains hot

water supply

via Isolation valve

(not supplied)

Ambient mains water supply

Hot mains water supply

18 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 7 Vented All-in-One tap installation

7.1 Configure the tap

• See adjacent diagram.

O-ring

Base block

spider

Base block nut

USB cable

Note Make sure the tap location will allow the tap

spout to drain into the sink.

7.2 Cut the hole & mount the tap

• Cut a Ø50mm hole in the worktop / sink.

Ø50mm

• Fit the o-ring to the underside of the tap.

• Pass tubes, hoses and cable through the Ø50mm hole.

• Feed each of the tubes and USB cable evenly between

the legs of the base block spider (see section 7.3).

• Fit the base block spider to the underside of the tap.

• Clamp in position using the base block nut.

• Do not over tighten.

Note All silicone tubes must be cut to size. They must

have a constant fall back to the Command-Centre.

All-in-One

vented

19

Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 7 Vented All-in-One tap installation

Red marked braided

hose to MIXER OUT

on Command-Centre

Blue marked

braided hose to

MIXER IN on

Command-Centre

7.3 Position tubes, hoses & base block spider

White marking Blue marking

USB cable

Blue silicone

tube

Red silicone

tube

Clear silicone tube

White marked

braided hose

Blue marked

braided hose

Red

marked

braided

hose

(viewed from underneath)

7.4 Connect the tap

• Connect the tap using the

adjacent diagram.

• Match the braided hoses

& extension tubes colour

markings.

• Attach the braided hoses

(lubricate seals).

• Do not over tighten.

• For sparkling HydroTaps,

connect the supplied Y

connector to the blue silicone

tube, then 1/4” blue and white

pipes as shown.

• For ambient HydroTaps,

connect the supplied

connector to the blue silicone

tube, then 1/4” blue pipe as

shown.

• Attach the USB connector to

the Command-Centre.

White pipe

to SPARKLING

OUTLET on

Command-

Centre

Blue pipe

to CHILLED

OUTLET on

Command-

Centre

SPARKLING

models

Red silicone tube -To

BOILING OUTLET on

Command-Centre

Clear silicone

tube - To VENT on

Command-Centre

Blue silicone tube

-To CHILLED

OUTLET on

Command-Centre

Blue marked

braided hose to

blue marked pipe

on tap

USB plug, connect

to Command-Centre

Red marked braided

hose to red marked

pipe on tap

Plain or white

marked Braided hose

- Flow restrictor

on ambient mains

supply

Plain or white

marked braided

hose to white

marked pipe on tap

AMBIENT

models

Blue pipe to

AMBIENT

OUTLET on

Command-

Centre

OR

OR

20 Installation instructions

803341 V3.00 June 2019 - Zip G4 tap range

Technical support

Australia Ph: 1800 460 222 , UK Tel: 0345 6 005 005 email: service@zipindustries .co.uk

Section 7 Vented All-in-One tap installation

7.5 Connect the water supply (detail shown, disassembled and assembled)

T-piece

(supplied)

Male - Female

adaptor

(supplied)

Filter

(supplied)

Incoming

mains ambient

water supply

Braided hose

to Command

-Centre

mains inlet

Male - Male

adaptor

(supplied)

Male - Male

adaptor

(supplied)

Filter

(supplied)

Flow restrictor

(supplied)

Male - Female

adaptor

(supplied)

Plain

Braided hose

to mixer tap

Connect together

Note correct filter orientation. Valves and

fittings must be sealed with PTFE tape.

!

Isolation valve

1/2” BSP (G 1/2)

Australia UK

15mm - 1/2” BSP(G 1/2)

Ambient mains water supply

via Isolation valve

(not supplied)

Other manuals for HydroTap G4 Series

5

This manual suits for next models

8

Table of contents

Other Zip Kitchen & Bath Fixture manuals

Popular Kitchen & Bath Fixture manuals by other brands

METHVEN

METHVEN Aio Shower Mixer with Fastflow installation guide

Stream33

Stream33 S331HKPO15-CH installation manual

Gessi

Gessi RIFLESSI 44879 manual

Hans Grohe

Hans Grohe Metris Select 2-Spray 73822 1 Series Installation/User Instructions/Warranty

Spectrum Brands

Spectrum Brands Pfister Saxton 016-GL1 Quick installation guide

Lefroy Brooks

Lefroy Brooks M1-5400 Installation, operating, & maintenance instructions