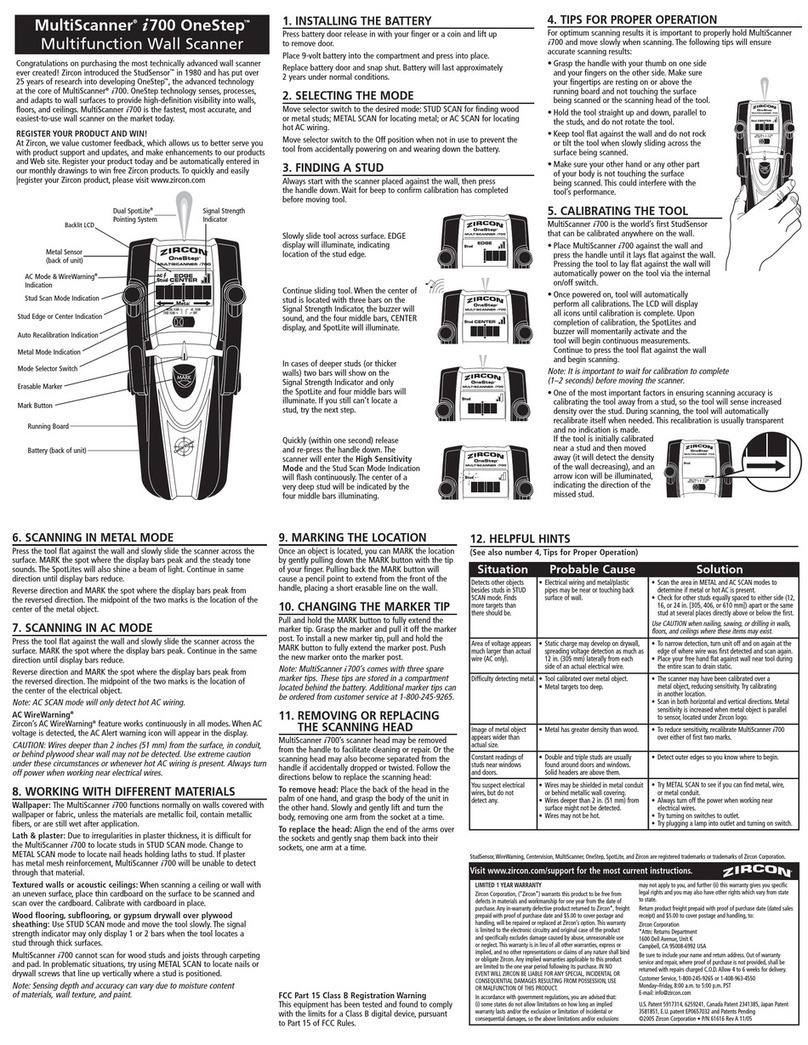

Textured walls or acoustic ceilings: When scanning a ceiling or wall with an uneven surface,place thin

cardboard on the surface to be scanned and scan over the cardboard. Calibrate with cardboard in place.

Wood flooring, subflooring, or gypsum drywall over plywood sheathing: Use STUD SCAN mode and

move the tool slowly.The signal strength indicator may only display 1 or 2 bars when the tool locates a stud

through thick surfaces.

MultiScanner i700 cannot scan for wood studs and joists through carpeting and pad. In problematic

situations, try using METAL SCAN to locate nails or drywall screws that line up vertically where a stud

is positioned.

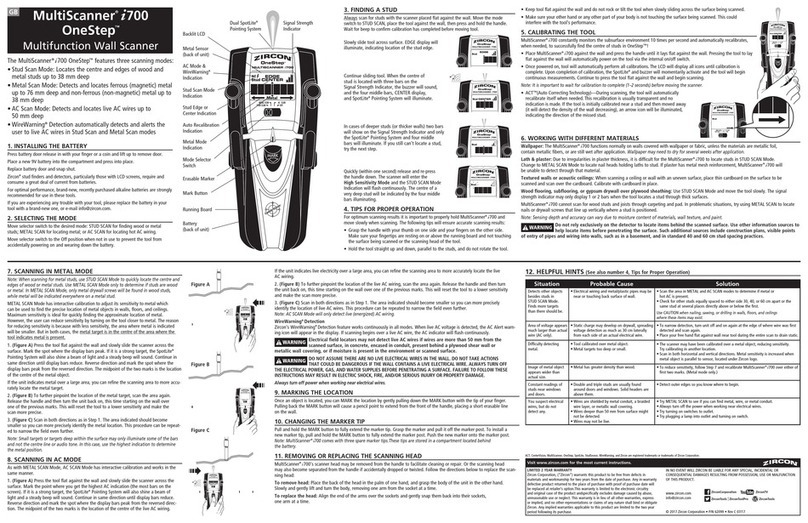

10. MARKING THE LOCATION

Once an object is located, you can MARK the location by gently pulling down the MARK button with the tip

of your finger. Pulling back the MARK button will cause a pencil point to extend from the front of the handle,

placing a short erasable line on the wall.

11. CHANGING THE MARKER TIP

Pull and hold the MARK button to fully extend the marker tip.Grasp the marker and pull it off the marker

post.To install a new marker tip,pull and hold the MARK button to fully extend the marker post.Push the

new marker onto the marker post.

Note: MultiScanner

i

700 comes with three spare marker tips. These tips are stored in a

compartment located behind the battery.

12. REMOVING OR REPLACING THE SCANNING HEAD

MultiScanner i700’s scanner head may be removed from the handle to facilitate cleaning or repair.Or the

scanning head may also become separated from the handle if accidentally dropped or twisted. Follow the

directions below to replace the scanning head:

To remove head: Place the back of the head in the palm of one hand, and grasp the body of the unit in

the other hand. Slowly and gently lift and turn the body, removing one arm from the socket at a time.

To replace the head: Align the end of the arms over the sockets and gently snap them back into their

sockets,one arm at a time.

FCC Part 15 Class B Registration Warning

This equipment has been tested and found to comply with the limits for a Class B digital device,pursuant

to Part 15 of FCC Rules.

LIMITED 1 YEAR WARRANTY

Zircon Corporation, (“Zircon”) warrants this product to be free from defects in materials and workmanship for

one year from the date of purchase.Any in-warranty defective product returned to Zircon*, freight prepaid with

proof of purchase date and $5.00 to cover postage and handling, will be repaired or replaced at Zircon’s option.

This warranty is limited to the electronic circuitry and original case of the product and specifically excludes

damage caused by abuse,unreasonable use or neglect.This warranty is in lieu of all other warranties,express

or implied, and no other representations or claims of any nature shall bind or obligate Zircon.Any implied

warranties applicable to this product are limited to the one year period following its purchase. IN NO EVENT

WILL ZIRCON BE LIABLE FORANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM

POSSESSION,USE OR MALFUNCTION OF THIS PRODUCT.

In accordance with government regulations,you are advised that: (i) some states do not allow limitations on

how long an implied warranty lasts and/or the exclusion or limitation of incidental or consequential damages,

so the above limitations and/or exclusions may not apply to you, and further (ii) this warranty gives you specific

legal rights and you may also have other rights which vary from state to state.

Return product freight prepaid with proof of purchase date (dated sales receipt) and $5.00 to cover postage

and handling, to:

Zircon Corporation

*Attn: Returns Department

1600 DellAvenue,Unit K

Campbell, CA 95008-6992 USA

Be sure to include your name and return address.Out of warranty service and repair, where proof of purchase

is not provided, shall be returned with repairs charged C.O.D.Allow 4 to 6 weeks for delivery.

Customer Service,1-800-245-9265 or 1-408-963-4550

Monday–Friday, 8:00 a.m. to 5:00 p.m. PST

U.S. Patents 5619128, 6259241,and Patents Pending

©2005 Zircon Corporation • P/N 60449 • RevA 04/05

Questions? Check our Web site at www.zircon.com and click “Support.”

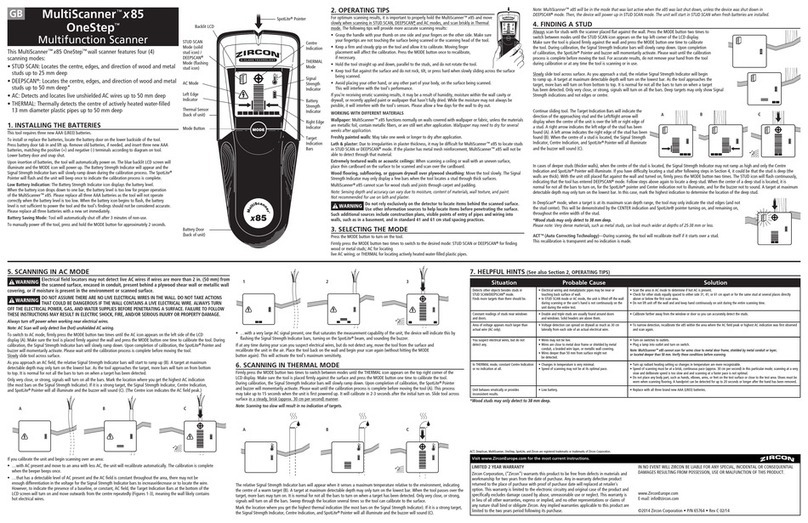

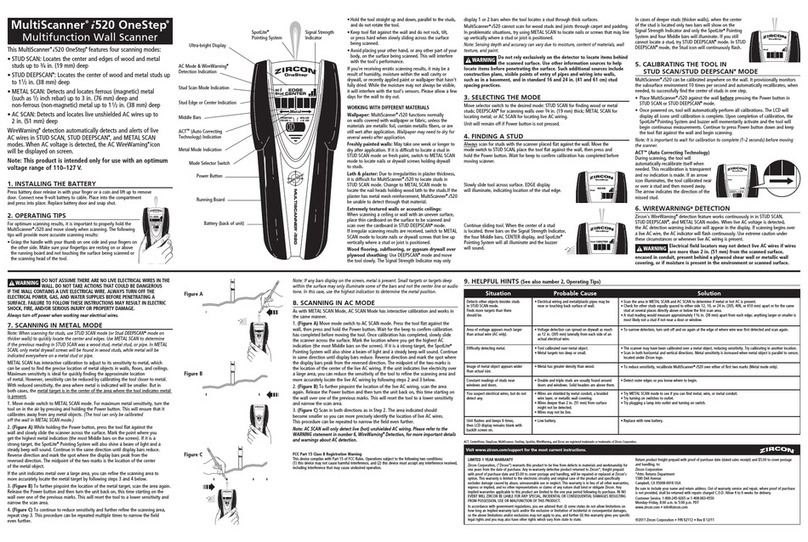

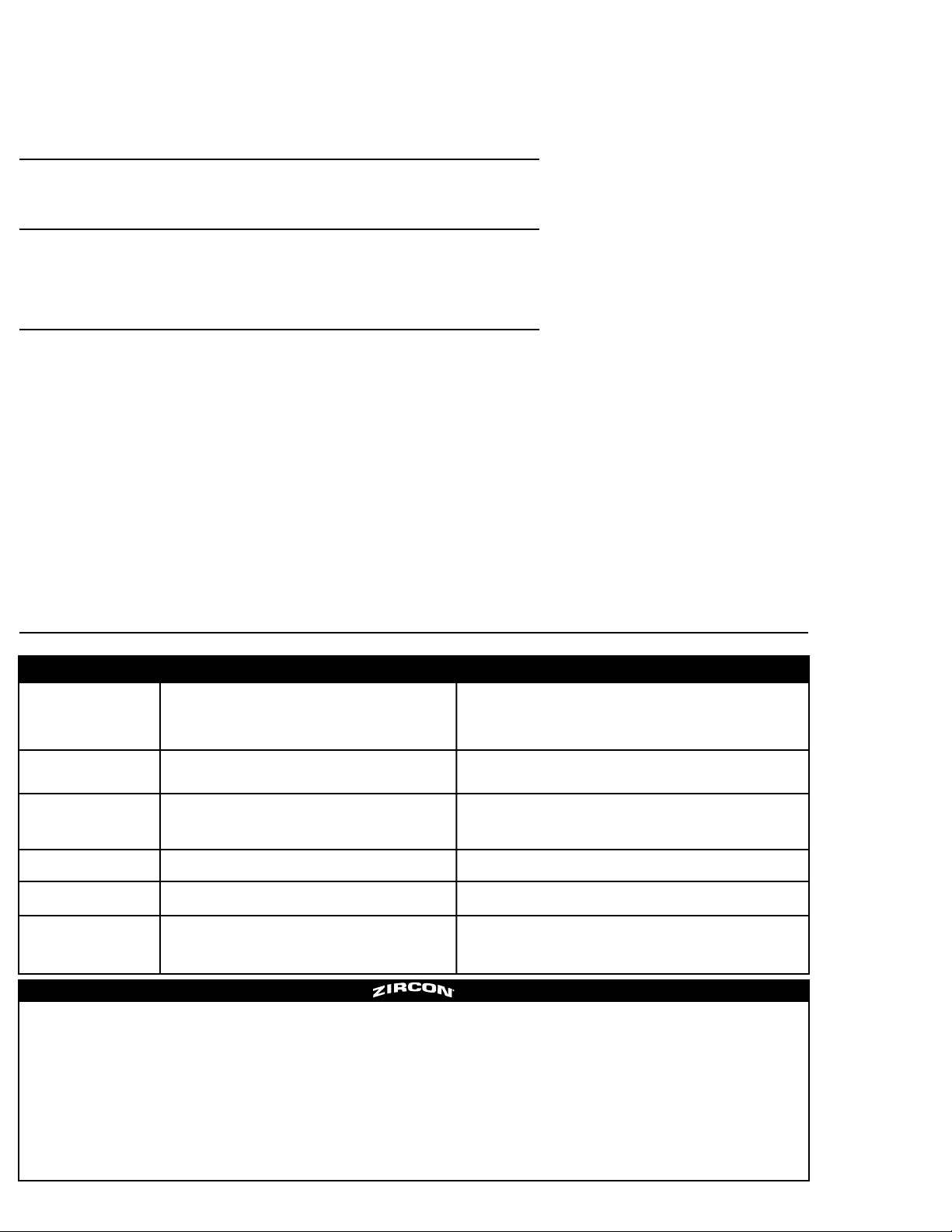

Detects other objects besides

studs in STUD SCAN mode. Finds

more targets than there should be.

Area of voltage appears much

larger than actual wire (AC only).

Difficulty detecting metal.

Image of metal object appears

wider than actual size.

Constant readings of studs near

windows and doors.

You suspect electrical wires, but

do not detect any.

•Electrical wiring and metal/plastic pipes may be near or touching back

surface of wall.

•Static charge may develop on drywall,spreading voltage detection

as much as 12 inches (305 mm) laterally from each side of an actual

electrical wire.

•Tool calibrated over metal object.

•Metal targets too deep.

•Metal has greater density than wood.

•Double and triple studs are usually found around doors and

windows.Solid headers are above them.

•Wires may be shielded in metal conduit or behind metallic wall covering.

•Wires deeper than 2 inches (51 mm) from surface might not be detected.

•Wires may not be hot.

•Scan the area in METAL and AC SCAN modes to determine if metal or hot AC is present.

•Check for other studs equally spaced to either side (12, 16,or 24 inches [305, 406,

or 610 mm]) apart or the same stud at several places directly above or below the first.

Use CAUTION when nailing, sawing, or drilling in walls, floors, and ceilings

where these items may exist.

•To narrow detection, turn unit off and on again at the edge of where wire was first

detected and scan again.

•Place your free hand flat against wall near tool during the entire scan to drain static.

•The scanner may have been calibrated over a metal object, reducing sensitivity.

Try calibrating in another location.

•Scan in both horizontal and vertical directions.Metal sensitivity is increased when

metal object is parallel to sensor, located under Zircon logo.

•To reduce sensitivity, recalibrate MultiScanner i700 over either of first two marks.

•Detect outer edges so you know where to begin.

•Try METAL SCAN to see if you can find metal, wire, or metal conduit.

•Always turn off the power when working near electrical wires.

•Try turning on switches to outlet.

•Try plugging a lamp into outlet and turning on switch.

13. HELPFUL HINTS

(See also number 3,Tips for Proper Operation)

Situation Probable Cause Solution