EVACreservestherighttomakealterationstothisspecificationwithout priornotice.

©CopyrightEvacOy.Allrightsreserved. 1

EVAC

CommercialMarineEquipment

VV

VV

VAA

AA

ACUUMCUUM

CUUMCUUM

CUUM TT

TT

TOILETOILET

OILETOILET

OILET

OPERATIONANDMAINTENANCE

Date: Doc.

20 Apr 2009 3:01012D

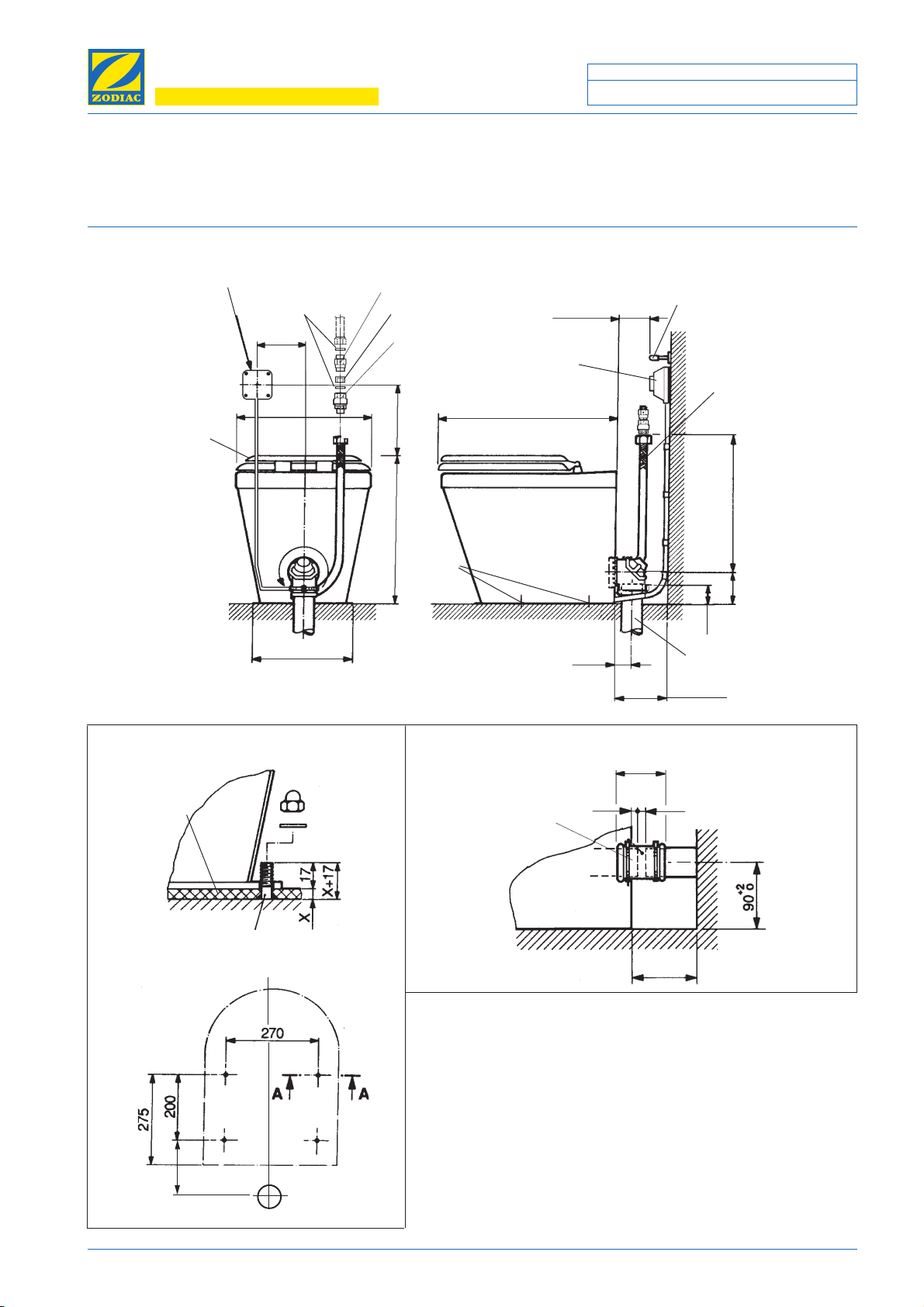

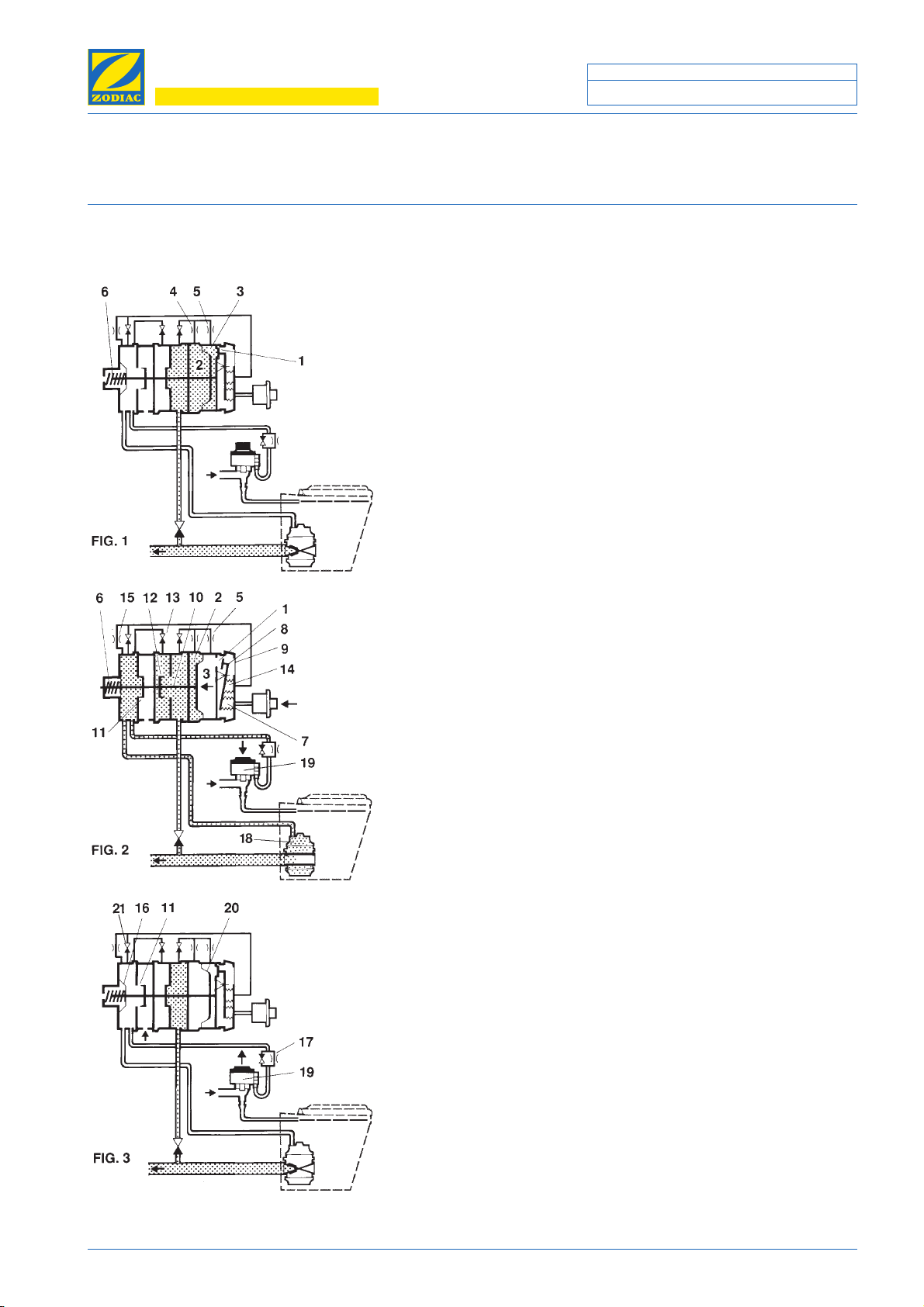

5775500 CONTROL MECHANISM, EVAC 90, STAINLESS STEEL, FLOOR MODELS

Description of flushing sequence

In the standby position FIG.1

Control valve 1 is closed. Vacuum in chambers 2 and 3 is

equalized by the jets 4 and 5. Spring force 6 holds the

mechanismin thenon-activated position.

In the just switched position FIG.2

Air pressure applied from the flush button to chamber 7 has

lifted the lever 8 and opened control valve 1.Atmospheric air

has entered chamber 3 through filter 9 and valve 1. The force

from the pressure difference between 2 and 3 has moved the

shaft 10 to the left and the following sequence of events has

occured:

The inlet valve 11 has closed. Vacuum valve 12 has opened.

Vacuumisdistributedvia checkvalve 13todischarge valve18

and water valve 19 which will both open. Chamber 14 is also

subjectedto vacuumthrough checkvalve21.

This vacuum will pull lever 8 and close valve 1 and the timer

function will start. Chamber 3 will be evacuated through jet 5

and the pressure difference 2-3 equalizes.At a certain level,

the counterforce from spring 6 will outweigh and the cycle will

go in the opposite direction:

Thevacuum valve12 willclose.Theair inletvalve 11will open

and atmospheric air enters discharge valve, water valve and

chamber14. Thedischarge valve 18will closeand somewhat

later(because ofthe jet 17),the watervalve 19closes whena

suitable water level has been reached at the bottom of the

bowl.

Returning to standby position FIG. 3

The whole system goes to standby position ready for another

VT-flush.

! NOTE: Diaphragm16 hasthe sameeffective area asthe air

inletvalve 11tobalance thevacuum forces. FIG.3

! NOTE: Check valve 13 ensures that connected valves in

activated position are unaffected by changes in the vacuum

supplylevel.

! NOTE: Ifvacuum istoo loworabsent thefunction isdelayed.

Control valve 1 stays open until chamber 14 is subject to

vacuum.