5

5/8" ZP Hex Nut 1 ea.

Loctite Tube 1 ea.

Module Mounting Hardware ( x # of modules ) Quantity

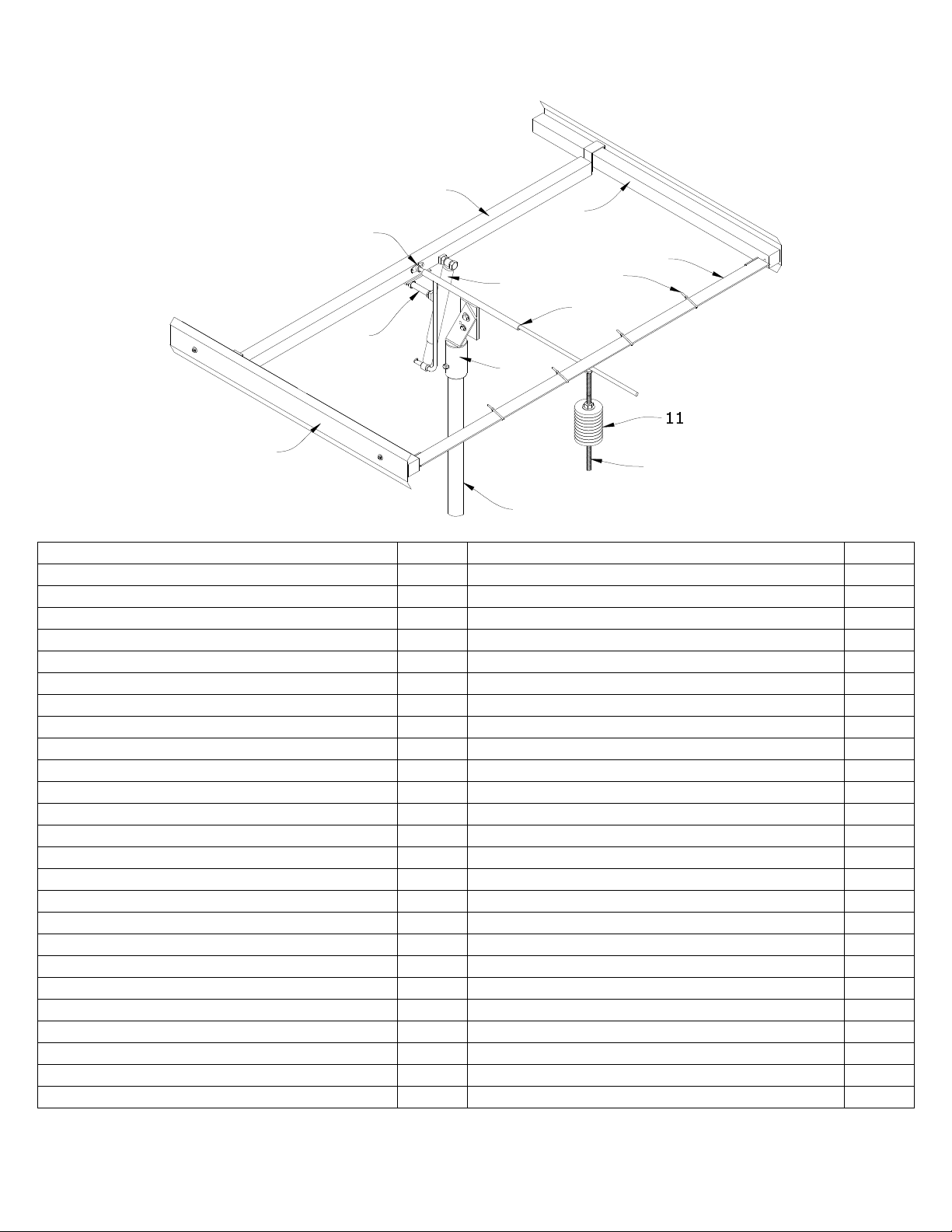

Counterweight Bar & Counterweights ( #11 & 12 ) Quantity

2" Stainless Steel J-Clip 4 ea. 5/8" ZP All Thread Bolt ( 17 1/4" long ) 1 ea.

1/4"-20 x 5/8" SS Hex Bolt 4 ea. Rubber Hose ( 5 1/2" long ) 1 ea.

1/4"-20 x SS Hex Flange Lock Nut 4 ea. 5/8" ZP Hex Nut 2 ea.

1/4" SS Flat Washer 4 ea. 5/8" ZP Flat Washer 2 ea.

5/8" ZP Lock Washer 2 ea.

5/8" ZP Jamb Nut 1 ea.

2 1/2lb Disk Weight 8 ea.

RECOMMENDED TOOLS:

•(2) 15/16” combination wrenches •(2) ¾” socket or combination wrenches

•(2) 9/16” combination wrenches •(1) flathead screwdriver

•(2) ½” combination wrenches •(1) 7/16” socket or combination wrench

NOTE TO INSTALLER: The installer MUST provide the schedule 40 steel pipe. Before assembling your

Track Rack™, use the list above to assure that you have all of your components. In the event that you may have

missing parts, contact Zomeworks Customer Service @1-800-279-6342.PLEASE have your SALES ORDER

NUMBER,SERIAL NUMBER,DATE OF PURCHASE, along with your DEALER NAME when calling.

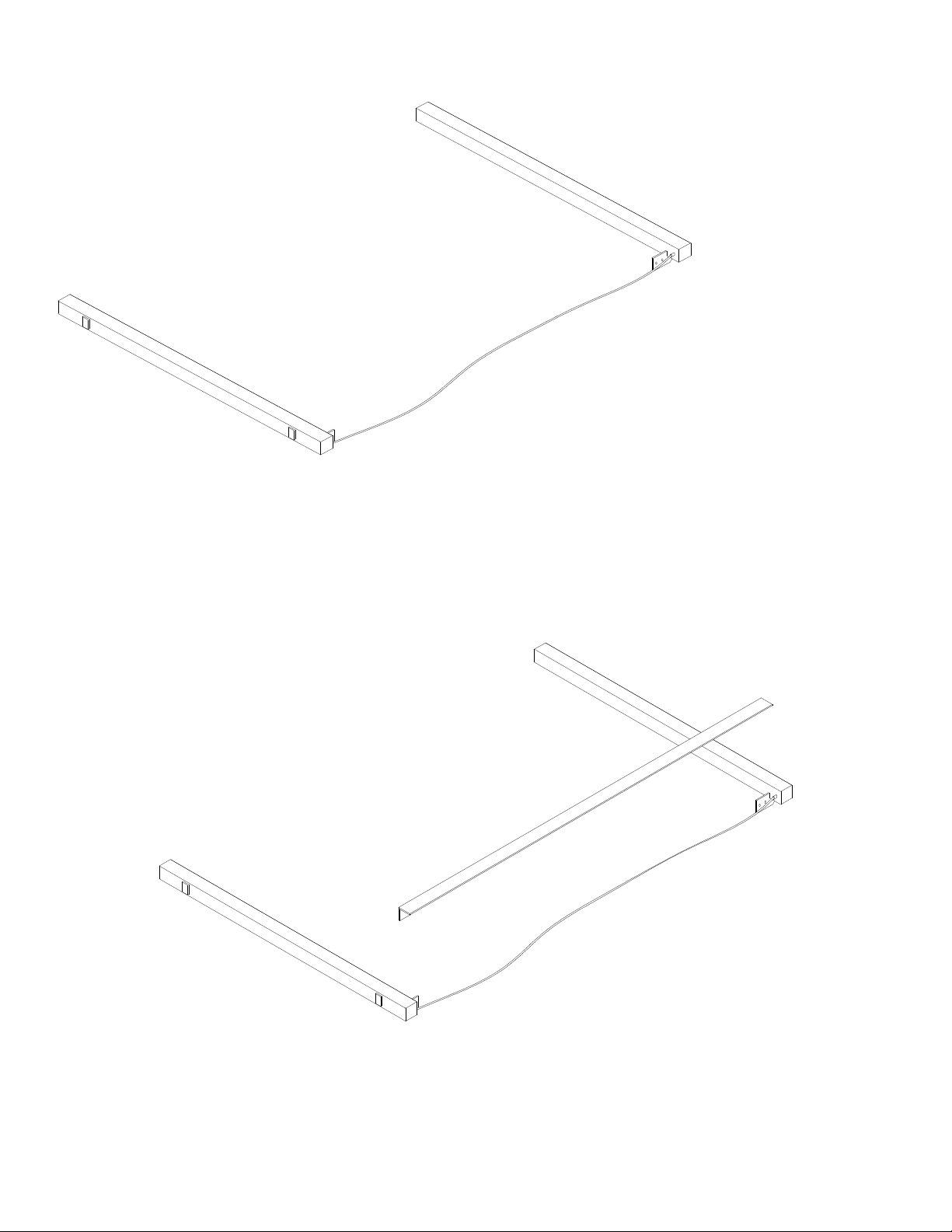

UTR-SERIES POLE INSTALLATION

IMPORTANT NOTE: ZOMEWORKS CORP. ASSUMES NO LIABILITY FOR THE STRUCTURAL

INTEGRITY OF THE POLE AND ITS INSTALLATION. SOIL AND WIND CONDITIONS VARY. IF THERE

IS ANY DOUBT, CONSULT WITH A LOCAL STRUCTURAL ENGINEER.

LOCATION CONSIDERATIONS:

For installations in sandy or muddy areas, for tall mounting poles, or for any mounting different from the

situations described in these instructions, you will need to consult a local structural engineer. Large TRACK

RACKScan receive significant wind loads, so a strong mounting pole and foundation is very important. Also,

be aware of turbulence near buildings or sudden changes in terrain. The site should receive the maximum

possible sunlight from AM to PM, in the winter and summer. Avoid shade from buildings and trees, including

shade that may occur in other seasons. The height of the pole should result in adequate ground clearance for the

mounted modules.

CAUTION – BE CAREFUL WORKING AROUND THE RACK AFTER INSTALLATION ON THE

POLE. SOME OF THE STRUCTURAL MEMBERS MAY BE AT HEAD LEVEL.

•The customer provided pole is a 2 1/2” (nominal) schedule 40 steel pipe with a 3” OD. Pole can be black or

galvanized steel pipe.

•Note: Heavier schedule steel pipe schedule 80, schedule 160 can be used as long as OD is 3”.

•Using the chart below, find the MINIMUM acceptable pole height above your finished grade. It is strongly

recommended that the pole height be to our minimum specifications.

•The minimum recommended hole depth is 1/3 the pole length, 1/3 in the ground, 2/3 above the ground.

Example: 5’ below grade, 10’ above grade, total of a 15’ pole.

•Center the pipe in the hole, and using a level, make sure pole is vertical.

•Fill the hole with concrete (3000-psi minimum strength), and check level of the pole.