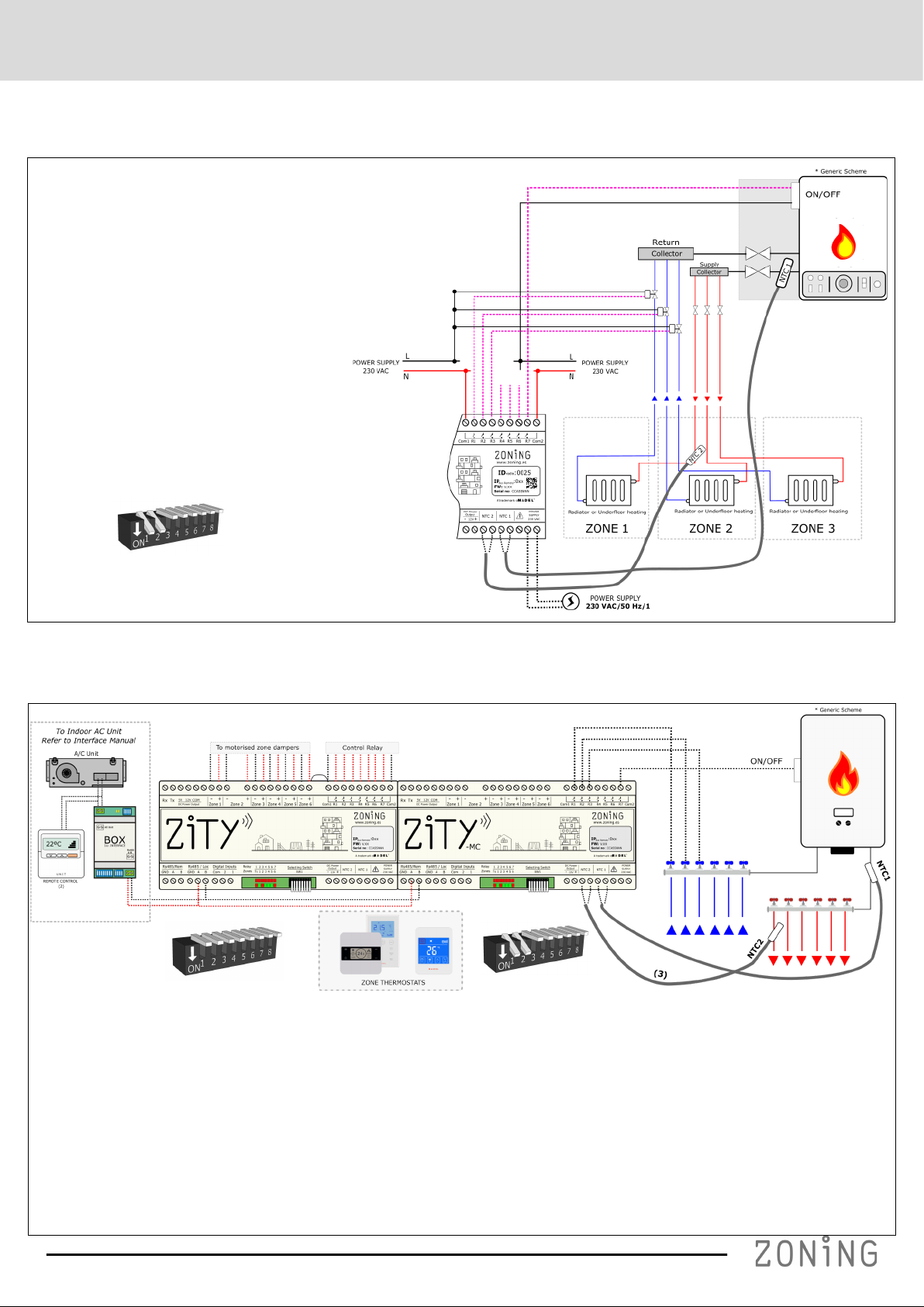

1 Connecting the system

All system components are wired to the control unit or to its

expansion modules.

It is advisable to locate the equipment preferably in a high

place away from metal masses and conductive elements;

place the control unit in a protected place that can only be

accessed by authorized personnel and with appropriate

Tools for opening and subsequent handling of the equip-

ment in question.

Place at a height of approximately 1.5 m, avoiding di-

rect heat sources and unwanted air currents

Avoid to location the thermostats near metal masses and

conductive elements.

1. Supply voltage, (230VAC/ 50 Hz/

1)

2. 10kOhm NTC temperature sen-

sors (see location according to

type of machine)

3. 12 VDC output voltage for wired

thermostats

4. Control LEDs, to monitor the

status of the control unit

5. 433/434 MHz Radio

transmission antenna (only

in ZITY-RC control units)

6. Digital inputs, potential-free inputs

7. RS485 local communication

bus. For wired thermostats and

expansion modules.

8. RS485 local communication

bus, for communication with

equipment interfaces (connect

in parallel with the previous

bus)

9. RS485 remote communication

bus for home automation com-

munication/ BMS or NetBox

(MODBUS RTU-SLAVE protocol)

10. 24 VDC outputs for control of

motorised zone dampers (maximum

2 dampers per zone) (24Vdc –200

mA)

11. Control relays of the climate-control

equipment (see connection

depending on the type of equipment).

Maximum current 6A

12. Thermostats: Wired or via radio

Fig.1 Connecting all ZONING SYSTEM components in the ZITY control unit.