Contents

I. Safety rules for driving and operation of battery forklift................................................................................. 1

1.1 Overview ..................................................................................................................................................... 1

1.2 Forklift transportation.................................................................................................................................. 1

1.3 Precautions on Parking................................................................................................................................ 1

1.4 Preparations before use................................................................................................................................ 1

1.5 Precautions on operation.............................................................................................................................. 2

1.6 Charge of battery pack................................................................................................................................. 3

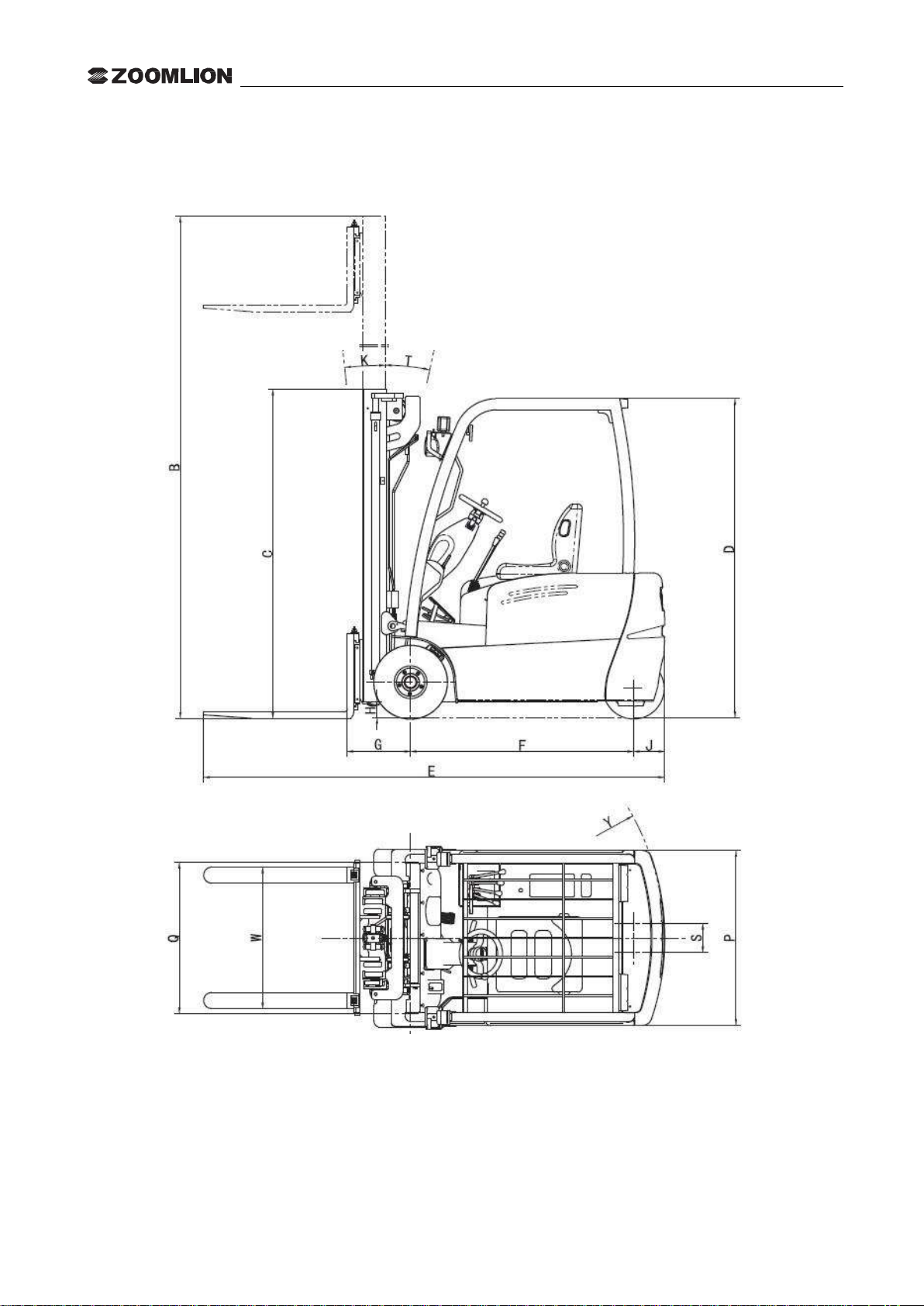

II. Dimension drawing of battery forklift.............................................................................................................. 4

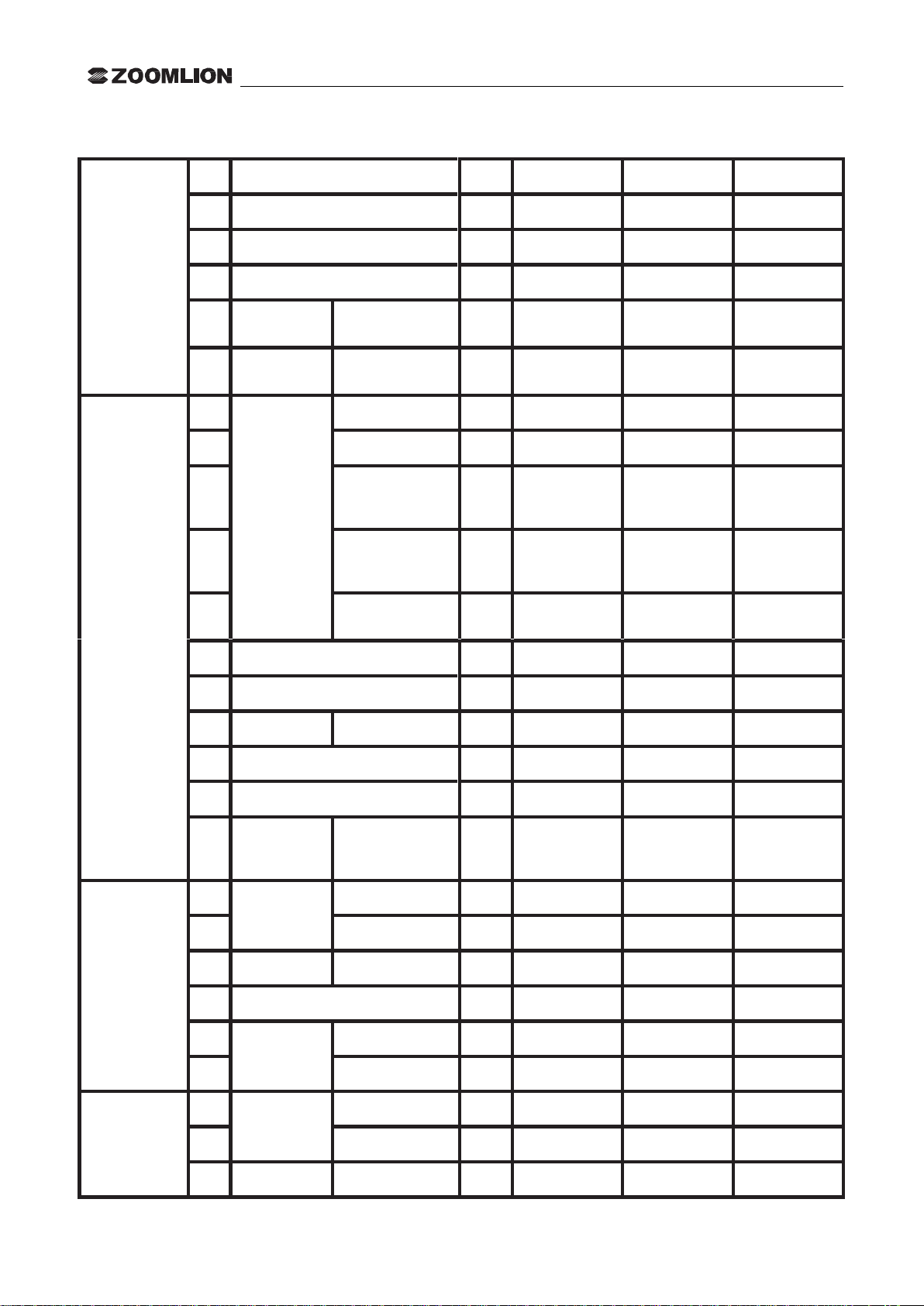

III. Main technical parameters of 1-12T triple-pivot battery forklift................................................................. 5

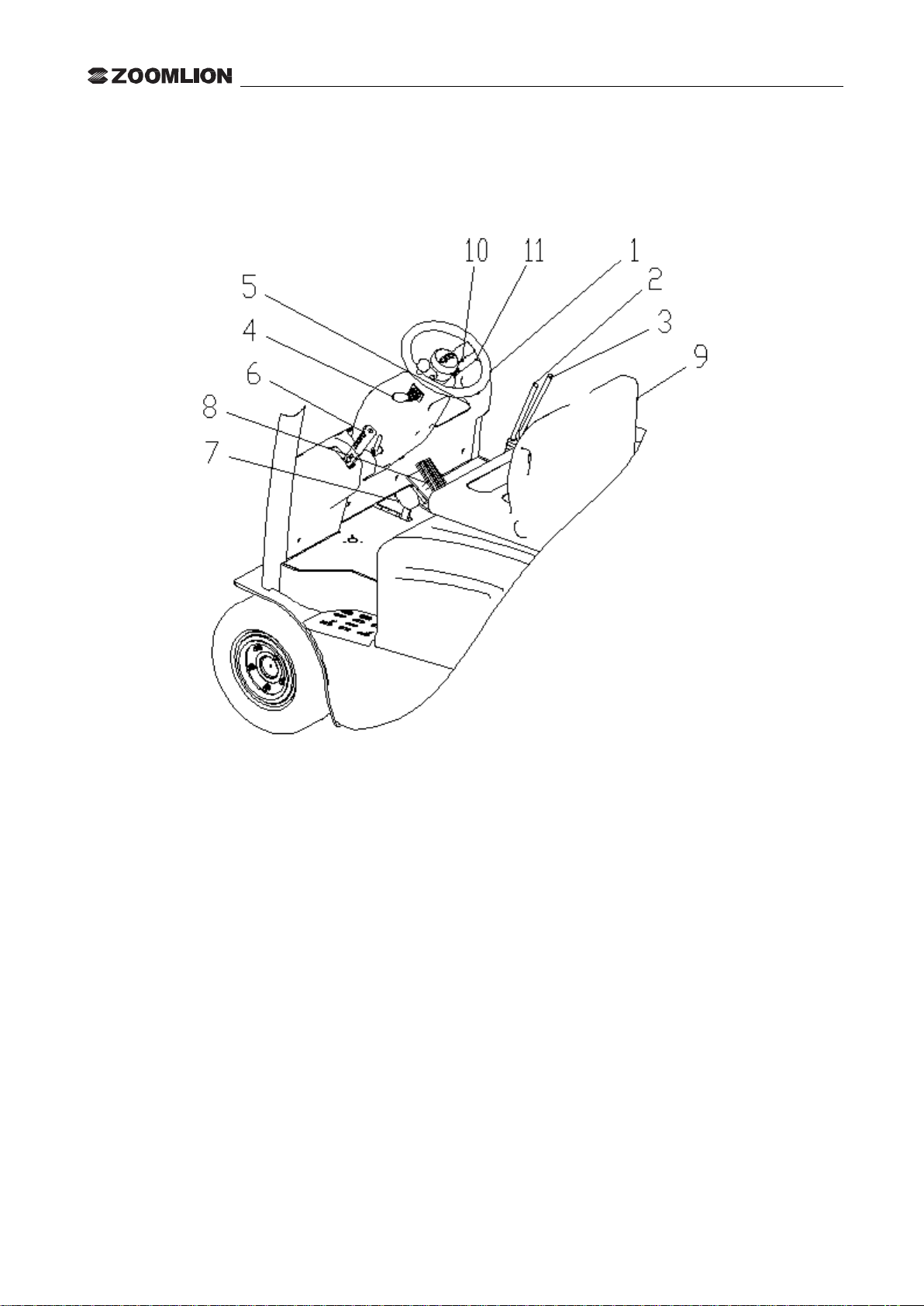

IV. Structure and working principle of forklift.................................................................................................... 8

4.1 Drive system (Fig.4-1)................................................................................................................................. 8

4.1.1 Drive axle.......................................................................................................................................... 8

4.2 Steering system............................................................................................................................................ 9

4.2.1 Full hydraulic steering gear ............................................................................................................ 10

4.2.2 Steering cylinder (Fig.4-4).............................................................................................................. 11

4.2.3 Steering axle (Fig.4-5).................................................................................................................... 11

4.3 Brake system (Fig.4-6) .............................................................................................................................. 13

4.3.1 Service brake .................................................................................................................................. 14

4.3.2 Brake master cylinder..................................................................................................................... 14

4.3.3 Adjustment of brake pedal.............................................................................................................. 15

4.3.4 Parking brake.................................................................................................................................. 16

4.4 Hydraulic system (Fig.4-11)...................................................................................................................... 18

4.4.1 Lifting oil pump and steering oil pump (Fig.4-12)......................................................................... 19

4.4.2 Multi-way valve (Fig.4-13)............................................................................................................. 20

4.4.3 Lifting cylinder (Fig.4-14).............................................................................................................. 21

4.4.4 Governor valve ............................................................................................................................... 22

4.4.5 Tilt cylinder (Fig.4-17)................................................................................................................... 23

4.4.6 Hydraulic system fault diagnosis.................................................................................................... 24

4.5 Lifting system............................................................................................................................................ 25

4.5.1 Inner/outer mast (Fig.4-18)............................................................................................................. 25

4.5.2 Pallet fork bracket and load backrest (Fig.4-19)............................................................................. 26

4.5.3 Position of roller (Fig.4-20)............................................................................................................ 27

4.5.4 Forklift fittings................................................................................................................................ 28

4.6. Electric System......................................................................................................................................... 29

4.6.1 Overview......................................................................................................................................... 29

4.6.2 Operating method ........................................................................................................................... 31