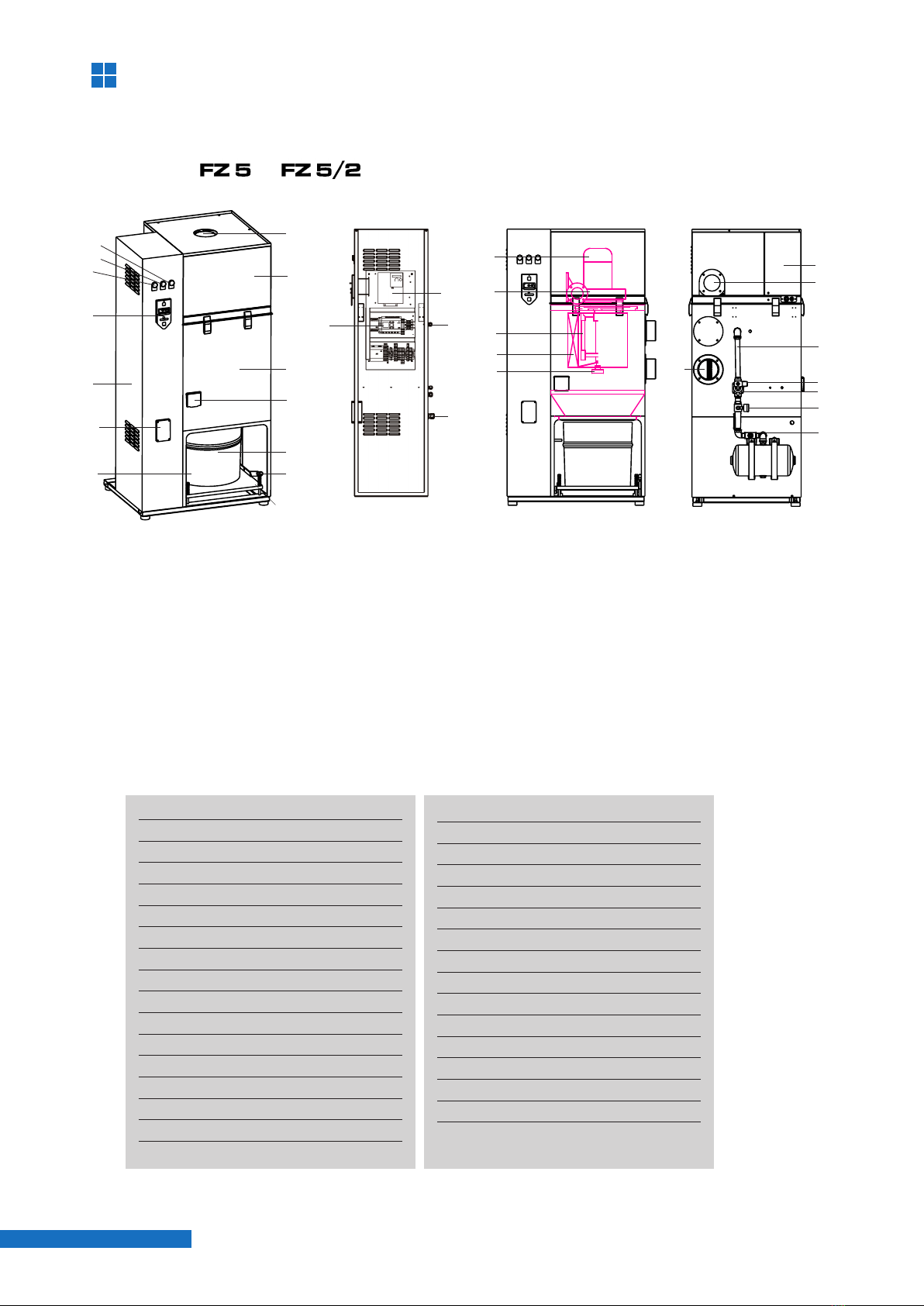

17 18 19 20 21

9

3. Operation

3.1 Connecting Up the Suction Machine

Installation of the machine and connection

to the piping system are normally performed

by specialised fitters when the extraction

system is installed. Connect the extraction

pipes coming from the laboratory to the

intake nozzles, item 31 (on the left and

right). Connect the exit air piping system

to the nozzle, item 29. Use the flexible

380 V, 16A connecting cable enclosed in

order to make the electrical connections

between the extraction system and your

building power supply. Plug the coupling

with plug (2) on the extraction side and

the cable connector into the socket of

the 380V building power supply.

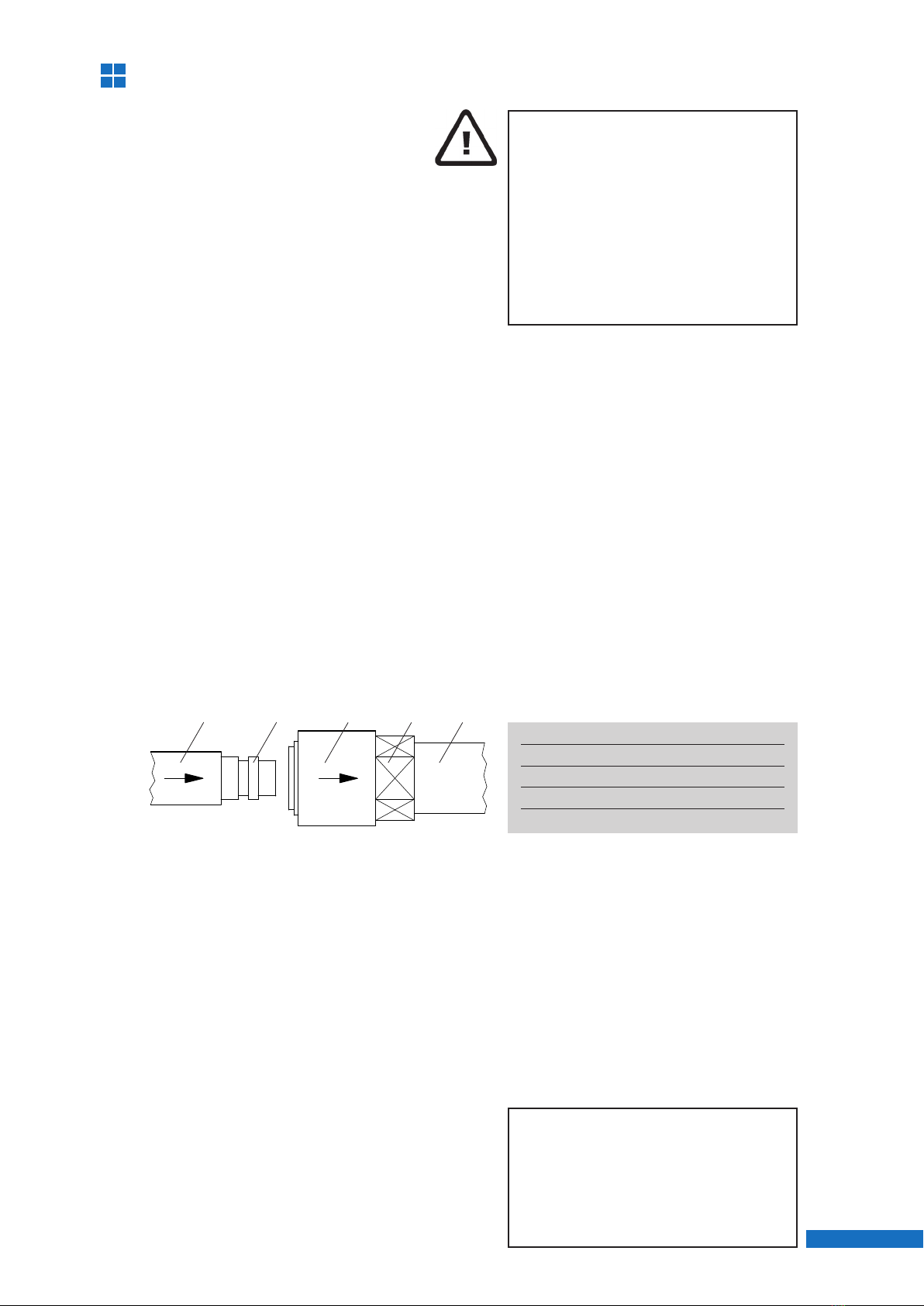

Press the connection nipple (18) with the

compressed-air hose (17) into the couling

17 Compressed-air hose

18 Connection nipple

19 Locking mechanism

20 Quick-release coupling

21 Compressed-air network

3.2 Switching On the Suction Machine

Put the Central Extraction System into

operation by turning on at the ON/OFF

power switch (5). Beforehand check to

make sure there is a supply of compressed

air in the extraction system and in the

laboratory. If the compressor system is

only started up at the same time as the

suction machine, the suction units in the

laboratory will be open because the

network is not pressurised. In addition,

make sure the dust container is positioned

correctly and the lever (11) is in a vertical

position. Only then is the extraction

system sealed tight. Before switching on,

please also check to make sure the vacuum

hose (14) is firmly inside the push-fit

coupling of the dust container (12).

Important: The seal (sealing lip) of the

dust filter cartridge is compressed

the first time it is screwed tight. On

account of "settling" the pressure

exerted decreases after a few days.

Therefore, 4 weeks after putting into

operation or changing the filter check

the star grip nut (see section 7.4 on

page 19) to make sure it is firmly in

place, and tighten up if necessary.

(20) of the compressed air network (21)

(5-8 bar). When disconnecting, hold the

connection nipple tightly and retract the

locking mechanism (19) in the direction

of the arrow.

The system must not be operated without

being connected to the compressed air

supply or else the dust filter cartridge

cannot be subjected to automatic

compressed-air dedusting.

To prevent the filter cartridge from

becoming clogged, the compressed air

from your compressed air system must

be oil and water-free. Modern cold air

dryers meet the requirements for

industrial compressed air in accordance

with ISO 8573.1

Filter dedusting start-up delay:

After switching on the extraction system

it takes approx. 5 min for the suction

motor to start up. The purpose of the

time delay is to ensure efficient filter

dedusting without any suction being

applied. During the first few minutes

before dedusting it also ensures that the

laboratory compressor can build up the

required air pressure. After three

dedusting surges the motor starts up and

the extraction system is ready

Note:

This function is not available on all

machines. Particular suction systems

e.g. for schools and universities,

with smaller dust accumulation, are

equipped with different control

systems. Page