6

Mad in

G ramay

C

ZUBLER Gerätebau GmbH

Buchbrunn nw g 26

D-89081 Ulm

T l. +49(0)731 1452-0 / www.zubl r.d

Absauganlag

V6000

Spannung 230V

G samtl istung max. 1150W

Absaugung max. 700W

Automatikst ckdos 450W

V4010 00-11111-22

FP-R24

Netz

❶

❷

24V

Maschine

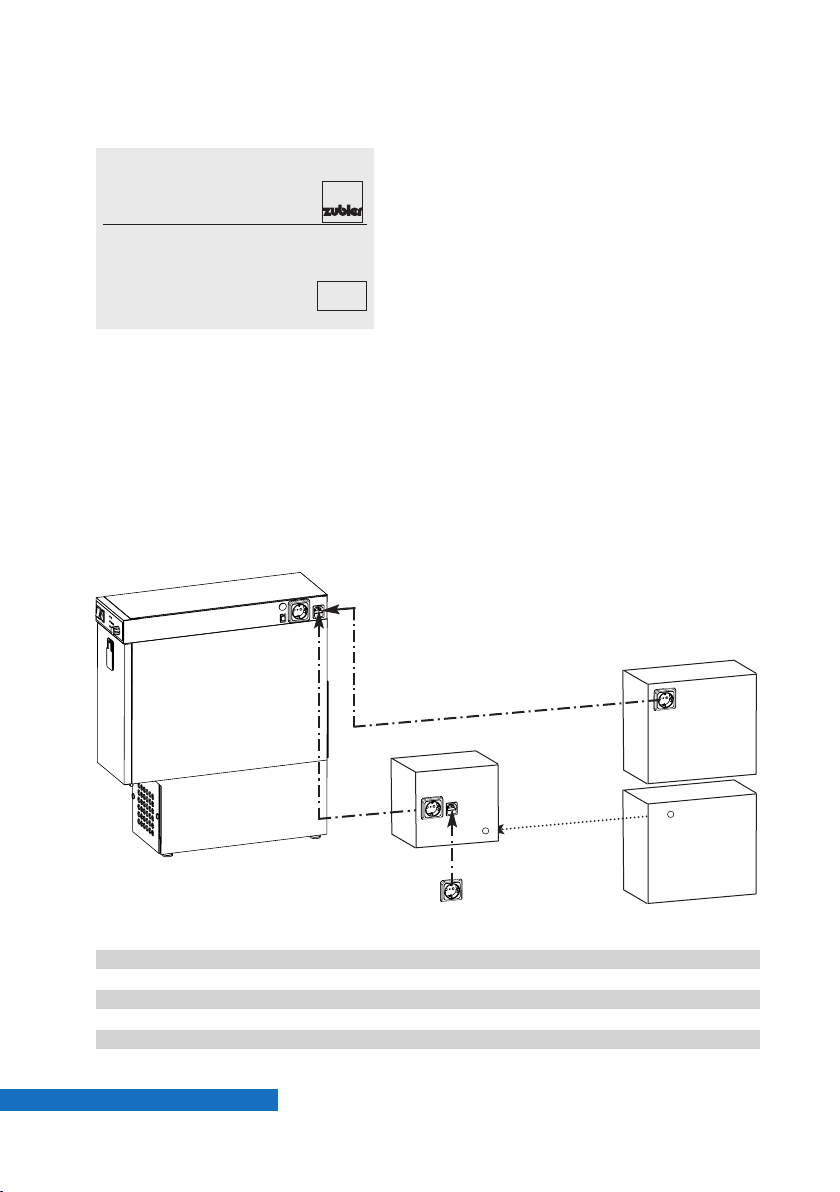

ig. 0.3: Remote switching

PagePage

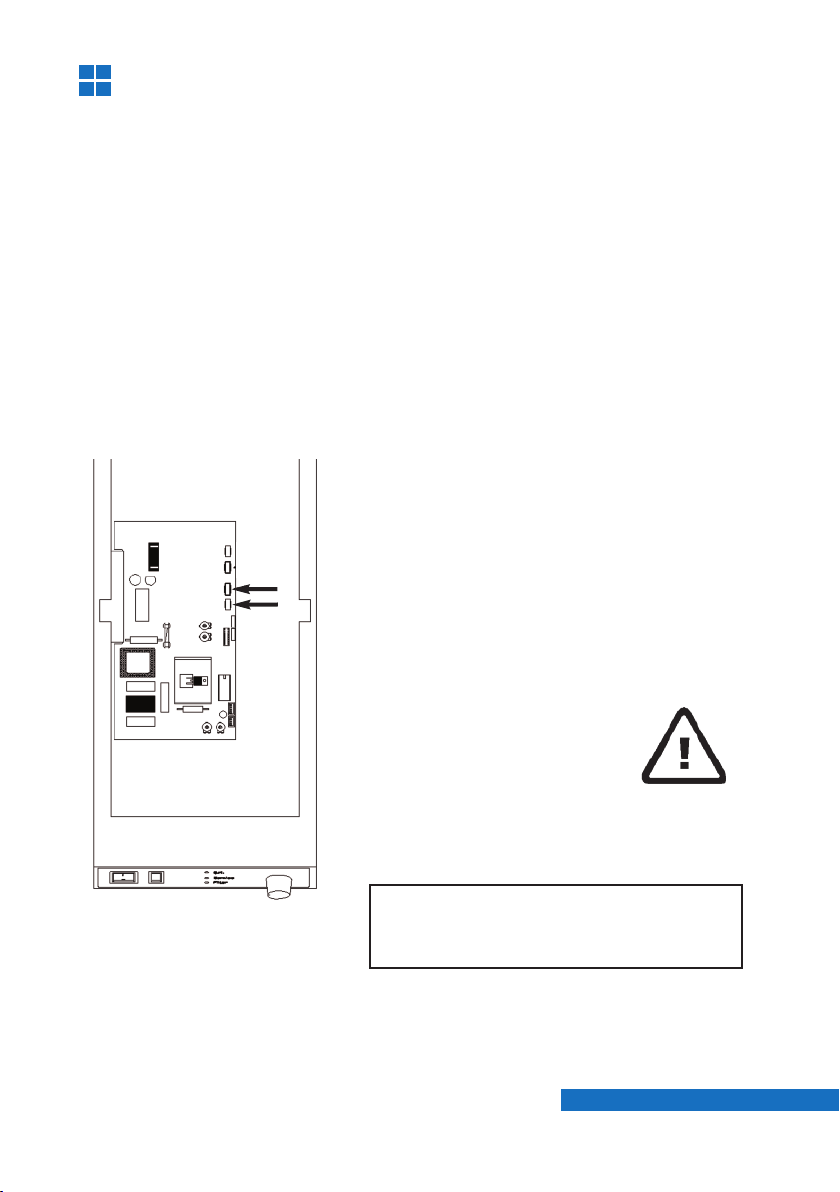

0.5.2 Connecting the technical gear

■Plug in the power cord of the working

tool (e.g. handpiece) into the autom.

power socket(7).

■The power consumption of the wor-

king tool may not exceed 450W !

■In order to make use of the automatic

operation mode the sensitivity must

be set. Choose the best matching

sensitivity setting with the sensitivity

swich (5).

■If the does not start/stop reliab-

le with one of the predefined 3 switch

positions, an internal sensitivity adjust-

ment is required (see chapter 2).

0.5.3 Remote switching (CAD/CAM)

❶If the remote machine offers a swit-

ched power socket, plug the

into the remote power socket.

❷If the remote machine offers a 24V

signal the optional P-R24 and a corre-

sponding connection cable is needed.

(see list below)

Order No.

FP-R24 825/257R24

Connection cable 24V length 2m:

SL-24 - DIN Round plug 4-pin vhf, wieland, shera 825/25600

SL-24 - DE9 D-sub-9 9-pin imes-icore, ammanngirrbach 825/25601

SL-24 - RS stereo phone jack 3,5mm roland 825/25602

SL-24 without plug other 825/25646

V6000

V6000