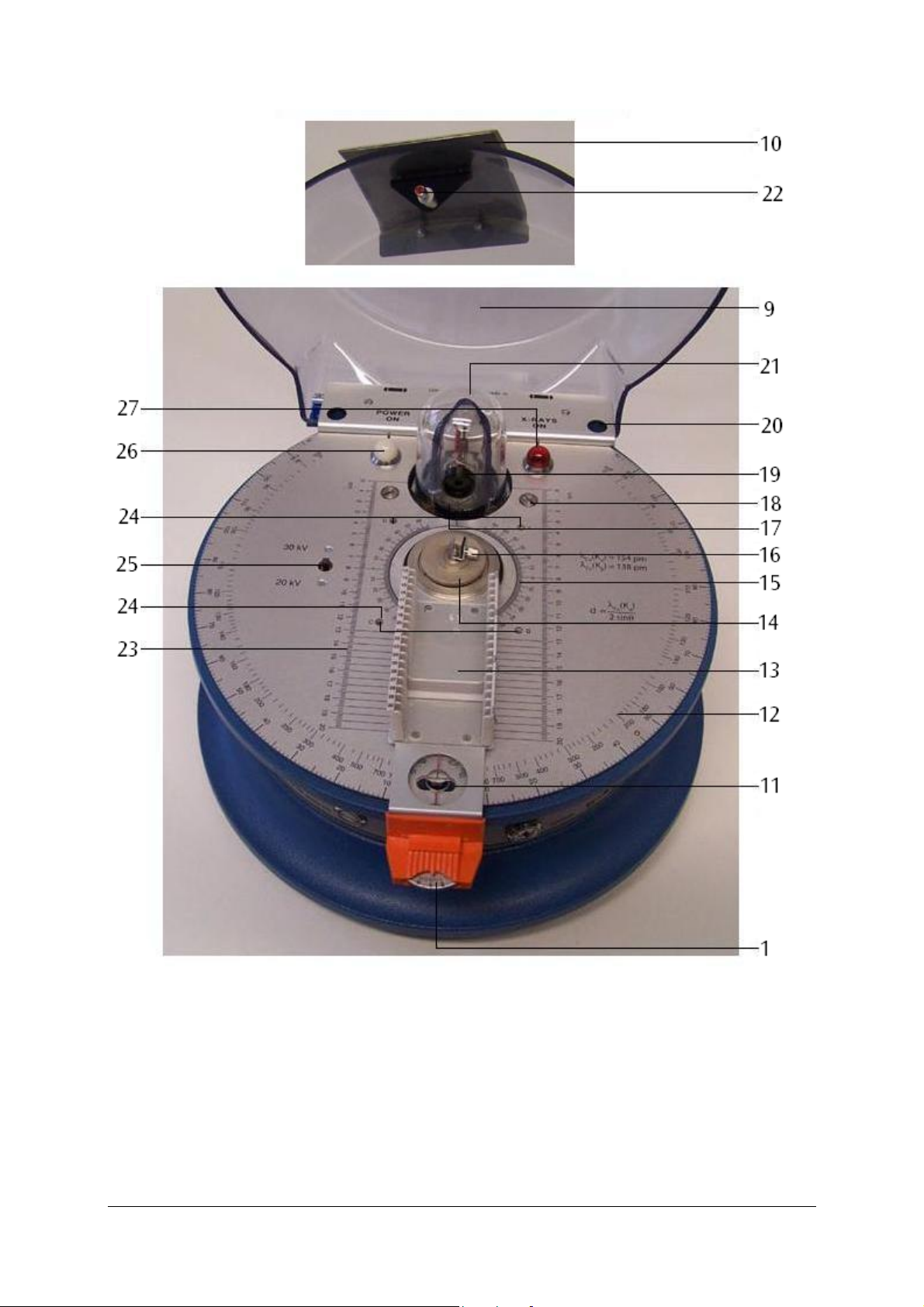

9

•Read of the relative angle from the vernier (accu-

rate to about 5 minutes of arc).

8.2.8 Angle coupling 2:1

To photograph a Bragg spectrum the measuring arm

needs to be set to twice the crystal angle 2 θwhile

the sample holder is rotated by a given angle θ.

•Set both the measuring arm and the sample

holder to precisely θ= 0°.

•Carefully screw in the pressure plate.

Now when the measuring arm is moved, the sample

holder rotates by precisely half the angle (see Fig. 4).

•To decouple the two elements, unscrew the

pressure plate by one or two turns.

8.3 Changing fuses

•Disconnect the mains plug.

8.3.1 Mains fuse

•Unscrew the fuse holder for the mains fuse from

the bottom of the housing.

•Insert a new fuse of the correct value (T1A, 250 V).

•Screw the fuse holder back in.

8.3.2 High voltage fuse

•Unscrew the fuse holder for the high voltage fuse

from the bottom of the housing.

•Insert a new fuse of the correct value (T1A, 250 V).

•Screw the fuse holder back in.

8.4 Changing bulbs

•Disconnect the mains plug.

•Remove the plastic cover for the mains or high

voltage indicator as appropriate

•Unscrew the lamp with the help of a short sec-

tion of plastic tubing and replace the bulb:

Mains voltage indicator lamp: 6 V / 0.05 A

High voltage indicator lamp: 6 V / 0.1 A

•Screw the cover back on.

8.5 Adjustment of X-ray rube

The X-ray apparatus is supplied having been pre-

adjusted at the factory. There will usually be no need

to adjust it any more. However, it is possible for the

adjustment to have been lost during transport so

that re-adjustment becomes necessary.

8.5.1 Height adjustment of X-ray tube

•Insert the counter tube into slots 17 and 20 of

the measuring arm and rotate it to 0°.

•Take a 1-mm horizontal slot aperture (from

U19205) and insert it into slot 13.

•Position an aperture of 1 mm dia. (from U19205)

on the brass collimator of the leaded glass dome.

•Turn on the X-ray apparatus and select a high

voltage of 20 kV.

•Set the emitter current so that the counter tube

registers around 200 to 400 pulses per second

(see 8.2.4).

•Remove the rubber stopper from the bottom of

the apparatus at the rear to access the screw for

adjusting the height of the tube and set it up so

that the maximum rate of count is obtained.

•Replace the rubber stopper.

8.5.2 Sideways adjustment of X-ray tube

•Turn off the X-ray tube and open the cover.

•Insert a 1-mm slotted aperture (from U19205)

into slot 30 so that it is aligned vertically.

•Fix a 1-mm slotted aperture (from U19205) to the

brass collimator of the leaded glass dome so that

it is aligned vertically.

•Remove the clamp from the sample holder and

place the mounting clip for glass rods (from

U19205) in the sample holder (see Fig. 5).

•Turn on the mains.

•Aim the tube through the crossover between the

two slot apertures. The glass rod should be pre-

cisely in the middle of the cathode reflex on the

anode.

•If it is not in this position, release the securing

screws and rotate the leaded glass dome by a

small angle.

•Remove the glass rod and clip.

•For this fine adjustment, place a lithium fluoride

(LiF) miniature crystal in the sample holder.

•Turn the measuring arm and sample holder to

0°.

•Set up the 2:1 angle coupling (see 8.2.8).

•Move the measuring arm to an angle 2 θ= 45°.

You should select the side of the goniometer so

that impinging and reflected beams are on the

angled side of the sample holder (see Fig. 5).

•Set the high voltage to 30 kV, close the cover and

turn on the high voltage.

•Look for the Cu-Kαreflex maximum (quoted

value for LiF = 44°56’). The measured value

should be within 30’ of the quoted value.

•If the measured value is outside this tolerance,

check through the previous steps and repeat

them if necessary.

•If the measured value is still outside the toler-

ance, set the measuring arm to the average of

the measured and quoted values.

•Remove the rubber stopper at the top on the

rear of the housing to access the screw for chang-

ing the inclination of the tube and adjust it until

the counter rate reaches a maximum.