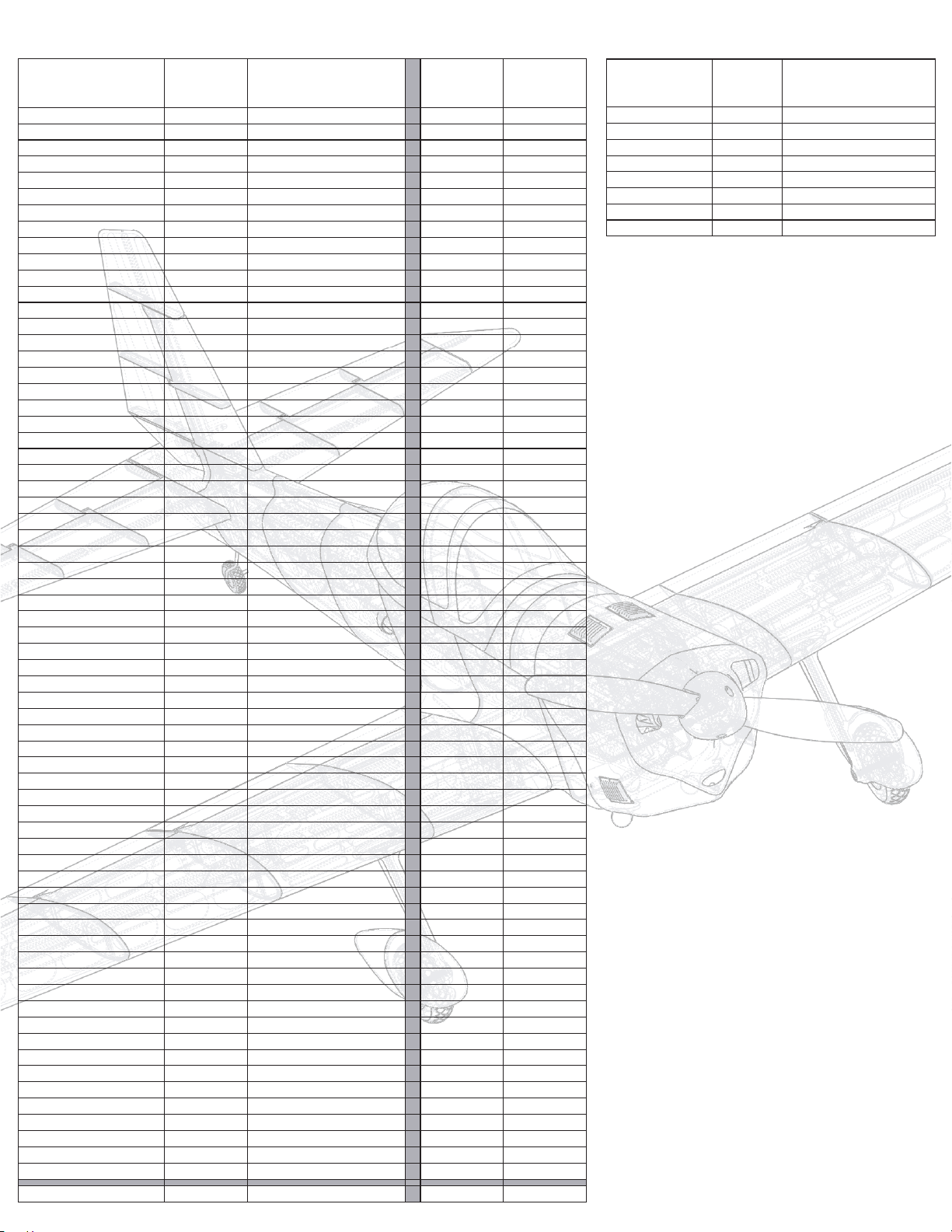

Estimated Part Weights by Material Type (Grams):

Hardware Needed:

- 5mm O.D x 3mm Thick Rare Earth Magnets for Removable Canopy.........................................

- M3 x 0.5mm Thread x 12mm Long Screws for Cowling and Landing Gear.................................

- M3 x 0.5mm Thread x 25mm Long Screws for Spinner.............................................................

- M4 x 0.7mm Thread x 16mm Long Screws for Motor Mount and Wing Mount...........................

- M5 x 0.8mm Thread x 40mm Long Screws for Landing Gear.....................................................

- M3 x 0.5mm Thread Lock Nut for Spinner................................................................................

- M3 x 0.5mm Thread Heat-Set Threaded Inserts for Cowling and Landing Gear.........................

- M4 x 0.7mm Thread Lock Nut for Motor Mount........................................................................

- M4 x 0.7mm Thread Heat-Set Threaded Inserts for Wing Mounts............................................

- M5 x 0.8mm Thread Lock Nut for Landing Gear........................................................................

- Steel washer for M5 Screw Size for Landing Gear.....................................................................

- M2 or #2 Thread Forming or Tapping Screws for mounting servo covers.................................

- 3mm O.D. (or 1/8” O.D) x 10mm Long Dowel Pins (cut from scrap carbon tube/rod)..................

- 6mm O.D. Carbon Fiber Tubes

- 600mm (or 24“) Long for Wings (x6).............................................................................

- 500mm Long for Horizontal Stab.................................................................................

- 220mm Long for Vertical Stab......................................................................................

- 1mm - 1.5mm O.D. Carbon fiber rod or Steel Wire

- 650mm Long for Aileron Hinges (x2)............................................................................

- 550mm Long for Elevator Hinge...................................................................................

- 220mm Long for Rudder Hinge.....................................................................................

- 2mm (or 2-56) diameter steel wire with threaded ends for servo control rods

- 30” for elevator and rudder..........................................................................................

- 12” for ailerons.............................................................................................................

- 1.8mm - 2mm diameter steel wire for tailwheel wire................................................................

- Nylon or Steel Kwik-Links........................................................................................................

- Adjustable Pushrod Connectors (optional)..............................................................................

- Wheel Collars to fit 5mm rod (main landing gear)....................................................................

- Wheel Collar to fit 2mm rod (tailwheel)...................................................................................

- 4” servo extensions for aileron servos....................................................................................

- 6” servo extensions for aileron ports in receiver.....................................................................

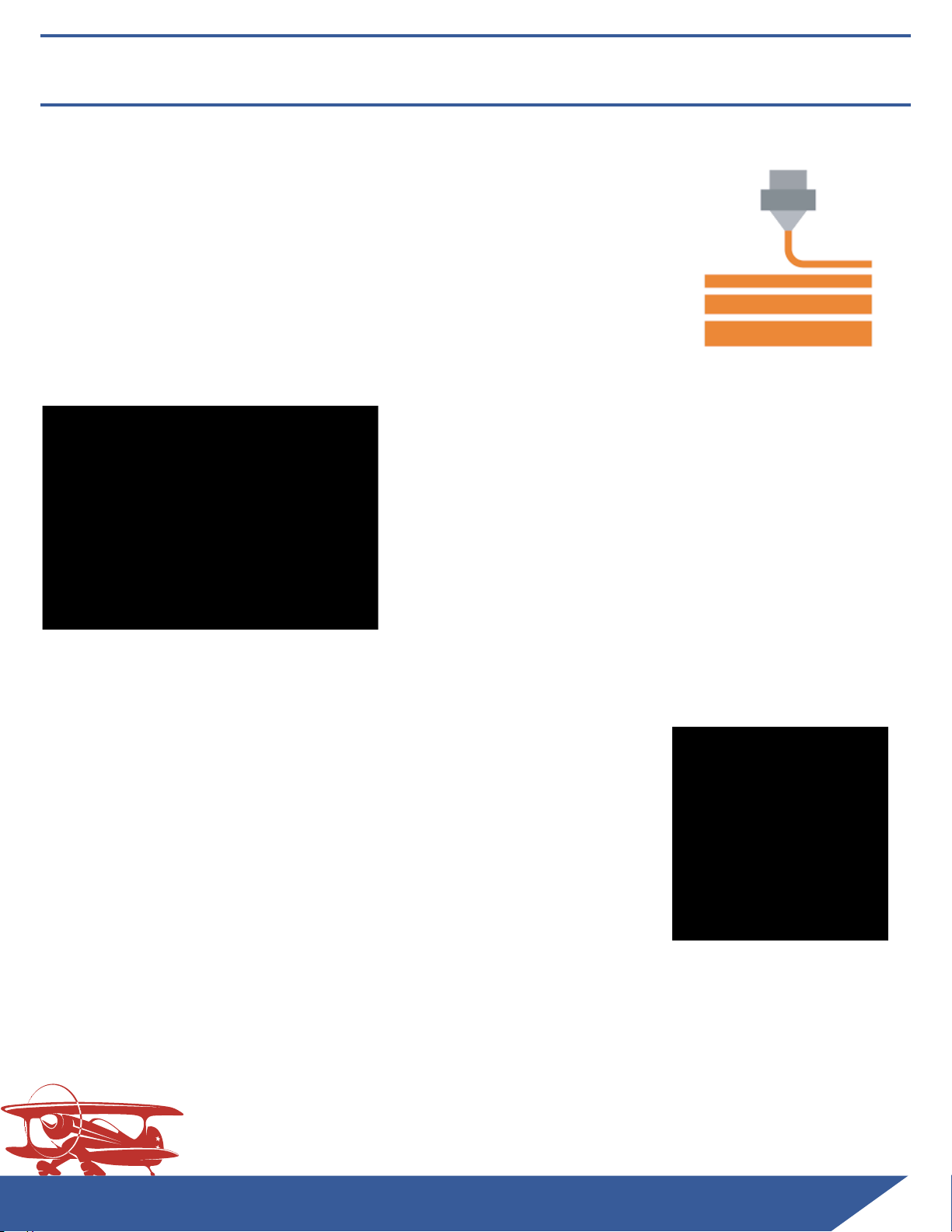

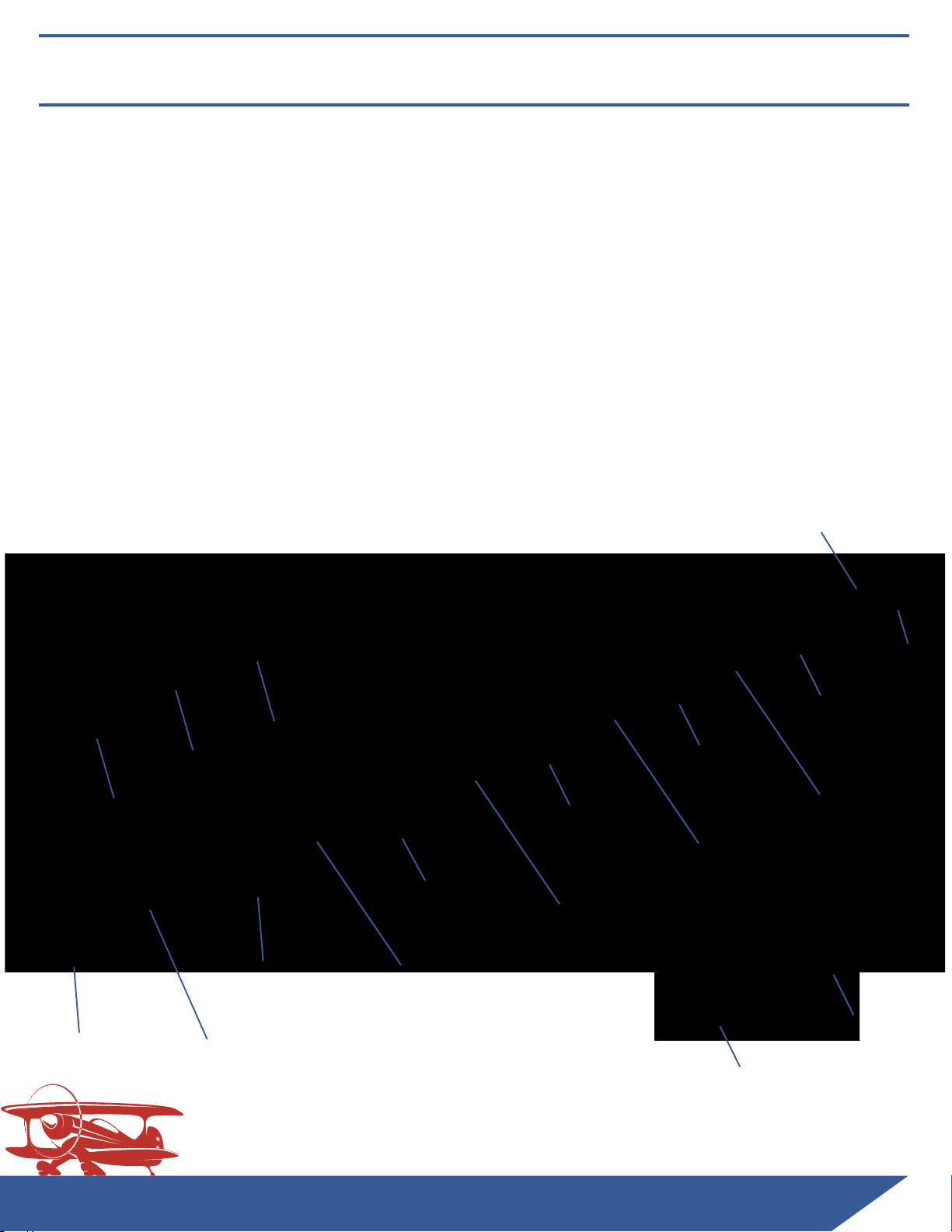

Part Name

PLA/LW-PLA Recommended Material

for Hybrid

PLA/PETG

ABS/ASA

149

1

37

137

134

134

100

100 88

100

100 88

Wing Trailing Edge R 13 LW-PLA 23 20

Wing Trailing Edge L 13 LW-PLA 23 20

Wing Tip R 8 LW-PLA 16 14

Wing Tip L 8 LW-PLA 16 14

Wing Servo Covers 15 PLA 15 15

Aileron R1 14 LW-PLA 24 21

Aileron R2 14 LW-PLA 24 21

Aileron R3 14 LW-PLA 24 21

Aileron R4 14 LW-PLA 24 21

Aileron L1 14 LW-PLA 24 21

Aileron L2 14 LW-PLA 24 21

Aileron L3 14 LW-PLA 24 21

Aileron L4 14 LW-PLA 24 21

HorizStab R1 14 LW-PLA 27 24

HorizStab R2 13 LW-PLA 22 19

10

HorizStab L1 14 LW-PLA 27 24

HorizStab L2 13 LW-PLA 22 19

HorizStab L3 10 LW-PLA 1917

41

41

43

43

41

41

43

43

65

ABS, ASA, or PETG 65 (PETG) 57

Vert Stab 1 10 LW-PLA 17 15

Vert Stab 2 11 LW-PLA 1917

Control Horns 11 PLA, ABS, ASA, or PETG 11 11

1938 2817 2507

OPTIONAL

PARTS

Estimated

Weights Recommended Material

Tire 20 TPU/TPE

Tire Hub 1 7 PLA, ABS, ASA, or PETG

Tire Hub 2 7 PLA, ABS, ASA, or PETG

Tailwheel Tire 2 TPU/TPE

Tailwheel Hub 1 1 PLA, ABS, ASA, or PETG

Tailwheel Hub 2 1 PLA, ABS, ASA, or PETG

Spinner 1 25 PLA, ABS, ASA, or PETG

Spinner 2 9 PLA, ABS, ASA, or PETG

Weights