3DAeroventures

https://www.facebook.com/groups/3daeroventurespilots

mailto: eric@3daeroventures.com

Included in Your Download:

1. STL Files

2. Simplify3D Factory Files (for the recommended materials)

3. Cura and PrusaSlicer Profiles and Recommended Slicer Settings for different materials

4. Generic Gcode for i3 style printers (for the recommended materials)

5. PDF Build Guide

Please Read A Note from the Designer:

First of all, thank you so much for your interest and support of 3DAeroventures. I can’t tell you how

much joy I get out of designing and testing these aircraft, and the fact that you can now get joy out of

my creations just makes this calling that much more special. I dove into the R/C aircraft hobby as a 12

year old kid with my dad and it’s a passion I’ve maintained into adulthood. Part of 3DAeroventures

mission is to encourage people to not let go of the thing they were most passionate about growing up.

That’s why our motto is “Never Stop Exploring. Never Stop Questioning. Never Stop Playing.” I hope

the building and flying of this model keeps your passion for model aviation ignited. More importantly,

I encourage you to share your build and flying process with young people, hopefully igniting a fire in

them and helping to maintain and grow this wonderful hobby.

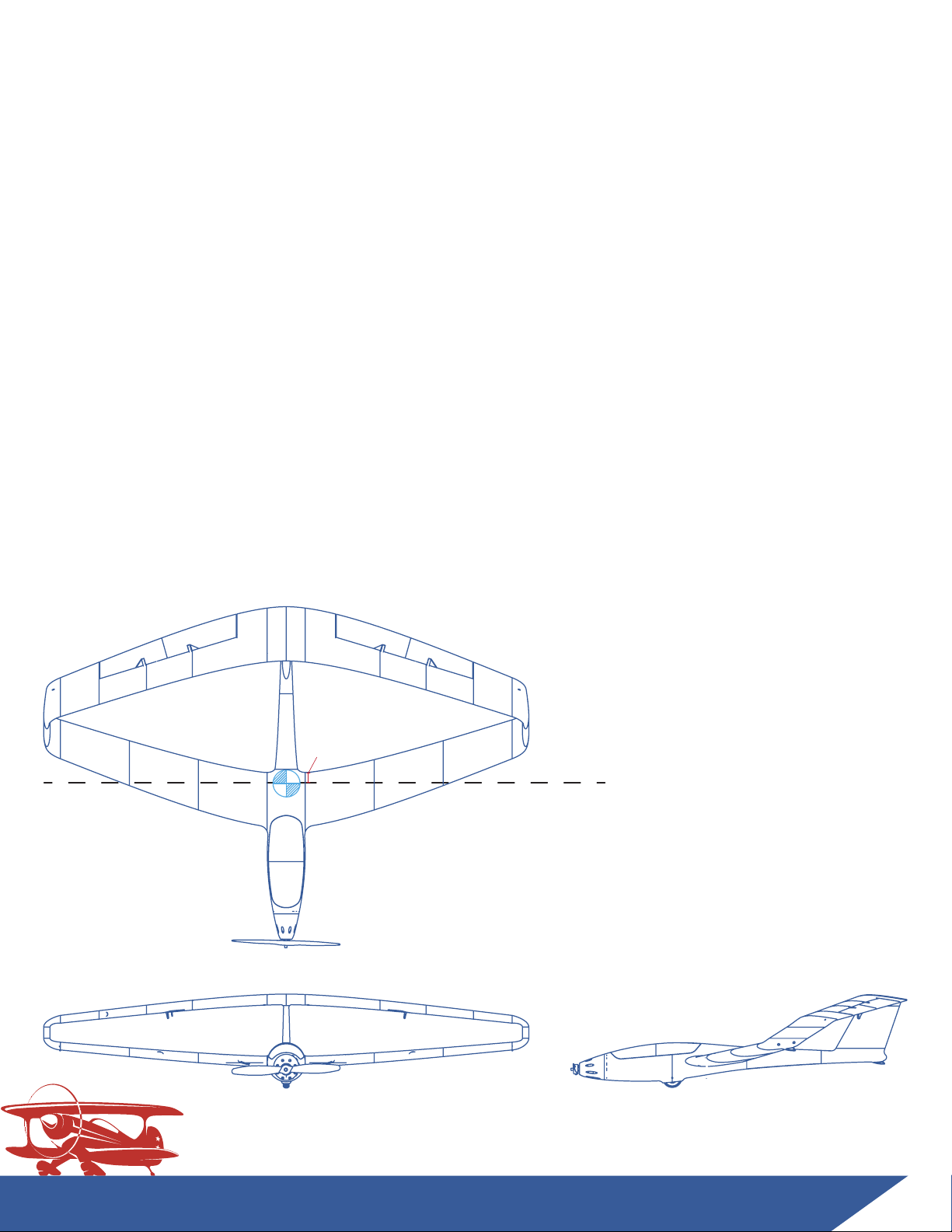

Now, on to the technical stuff. The X-100 Infinity Wing has been re-designed into this V2 version to meet

several goals: Improved stall performance, better printability/surface quality, increased part strength,

the ability to print the parts in any material - PLA, ABS, ASA, PETG, and especially LW-PLA or LW-ASA, and

much simpler slicing and the ability to use any slicer (like Prusa Slicer). I am now a big proponent of using

multiple material types to build a good performing and long-lasting craft. So you should find this style of part

design to be simpler to slice on your own and print in many different materials. The outer walls of the parts

now print like a corrugated plastic - two single perimeter walls filled with a very low infill, anywhere between

3 - 7%. The downside is, printing this style of design in standard PLA leads to a heavier aircraft, though not

too heavy to fly well. That’s why I am particularly excited about the results I've gotten printing this aircraft

as a hybrid with LW-PLA. I recommended at least printing some of the parts in LW-PLA to keep the weight as

low as possible and for the ideal weight distribution. The hybrid version balances perfectly at the new

recommended CG position with a 3S 2200mah battery located in the middle of the battery compartment. A

standard PLA version may require a larger battery or a small amount of nose weight to properly balance. If

you do only print a few of the parts in LW-PLA I recommend printing the Back Wing parts in LW-PLA for better

weight distribution.

I’d love to hear about your build and flight experience with this aircraft. You may contact me directly at

eric@3daeroventures.com with any feedback or troubleshooting questions. Or post your experiences on

the 3DAeroventures Pilots Alliance Facebook Group.

Thanks again and enjoy your flight!

Eric Haddad

Pilot in Command