Table o Contents

Safety........................................................................................................................................................3

Installation................................................................................................................................................3

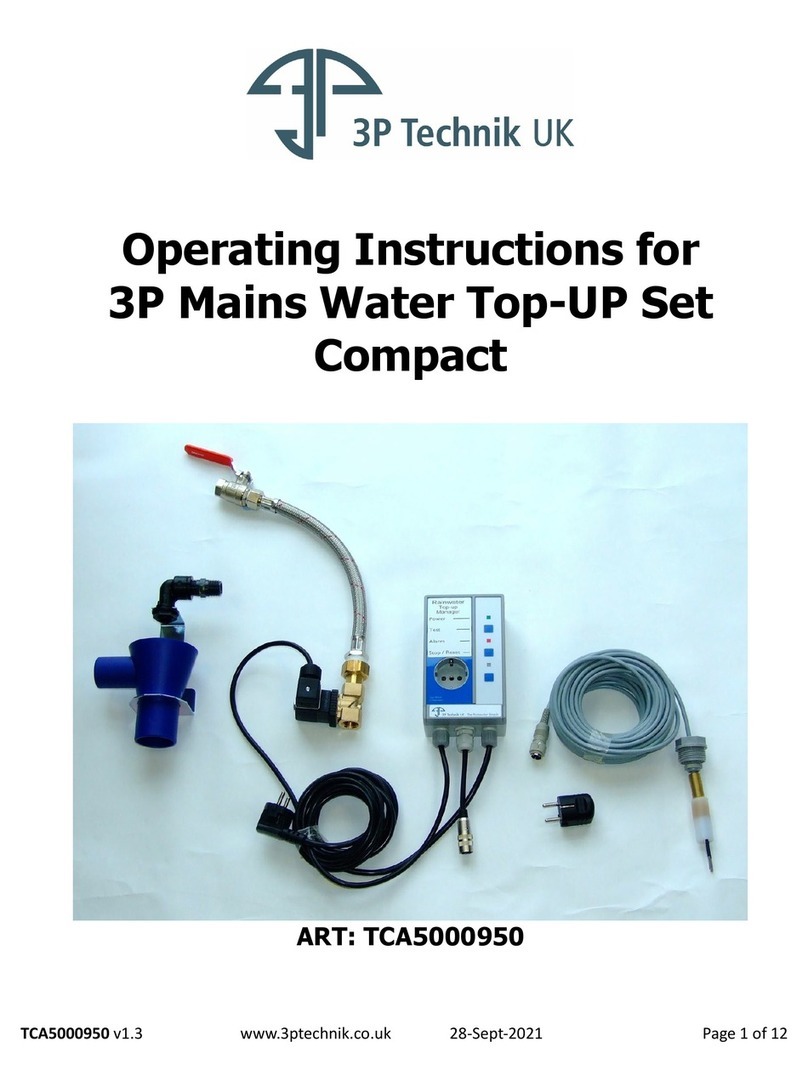

Included Components....................................................................................................................................3

Layout.............................................................................................................................................................4

Control Panel Mounting.................................................................................................................................6

Mains Power Connection...............................................................................................................................6

Output Power Connections............................................................................................................................7

Switch Input Connections..............................................................................................................................7

Tank Level Sensor Connections......................................................................................................................7

BMS connection.............................................................................................................................................7

Troubleshooting........................................................................................................................................7

Fuse Listing.....................................................................................................................................................9

Inputs (le t to right) – Con1...........................................................................................................................9

Pressure Sensor Inputs (le t to right).............................................................................................................9

BMS Output..................................................................................................................................................10

Output Control Outputs (le t to right).........................................................................................................10

Upgrades and Modifications....................................................................................................................10

Specifications..........................................................................................................................................11

Control Panel................................................................................................................................................11

Tank Level Sensor.........................................................................................................................................11

Switched Outputs (pump/solenoid/valve control)......................................................................................11

Operation................................................................................................................................................12

Description o Operation.............................................................................................................................12

Control Panel Operations.............................................................................................................................13

Menus and Functions..............................................................................................................................13

Water Level Display.................................................................................................................................14

Accessing the Menu Options...................................................................................................................14

Status Screen...........................................................................................................................................14

Main Menu..............................................................................................................................................14

Setup Menu (Menu>Setup)................................................................................................................14

Virtual Output Setup (Menu>Setup>Virtual).................................................................................14

Output Setup (Menu>Setup>Outputs)..........................................................................................15

Main Functions..........................................................................................................................15

Virtual Input Selection..............................................................................................................15

Levels.........................................................................................................................................15

Duty Cycle..................................................................................................................................15

Output Con iguration Examples................................................................................................16

Tank Alarms (Menu>Setup>Alarms)..............................................................................................17

Fault Diagnosis........................................................................................................................................17

Diagnostic Menu (Menu>Diags).........................................................................................................17

Input Options (Menu>Diags>Inputs).............................................................................................17

View Inputs (Menu>Diags>Inputs>View Input)........................................................................17

Adjust Probe Stability (Menu>Diags>Inputs>Adjust Probe Stability).......................................18

Activate Outputs (Menu>Diags>Outputs).....................................................................................18

View Logged Fault Codes (Menu>Diags>Faults)............................................................................19

TC Series Fault Codes (all models)......................................................................................................19

Clear Logged Fault Codes (Menu>Diags>Faults>Clear)............................................................21

Run..........................................................................................................................................................21

Stop.........................................................................................................................................................21

Menu (Stop>Menu)............................................................................................................................21

TC Series Controller v1.30 www.3ptechik.co.uk 09-August-2017 Page 2 o 28