3SAE TECHNOLOGIES AS II User manual

AS II

User’s Guide

ASII Users Guide | 1/24/2019

Safety Information & Precautions ____________________________________________________ 5

Transportation & Storage ___________________________________________________________ 7

Introduction to the AS II_____________________________________________________________ 8

Operational Features_____________________________________________________________ 8

Safety Features__________________________________________________________________ 9

Unboxing the AS II________________________________________________________________ 10

The AS II at a Glance____________________________________________________________ 11

Accessories Included____________________________________________________________ 13

Optional Accessories____________________________________________________________ 13

Basics___________________________________________________________________________ 14

AS II Firmware Compatibility _____________________________________________________ 14

AS II Home Screen______________________________________________________________ 14

AS II Buttons ___________________________________________________________________ 15

AS II LEDs_____________________________________________________________________ 15

Heater Lock____________________________________________________________________ 16

Safety Shield___________________________________________________________________ 16

Providing Air ___________________________________________________________________ 16

Powering the AS II ______________________________________________________________ 17

Setting Heater Temperature______________________________________________________ 17

Zero Load Cell Response ________________________________________________________ 17

Clamp Pressure ________________________________________________________________ 18

General Use _____________________________________________________________________ 19

Loading the fiber________________________________________________________________ 19

Proof-Test Only_________________________________________________________________ 20

Programs________________________________________________________________________ 21

Selecting a Program_____________________________________________________________ 21

Editing a Program_______________________________________________________________ 21

Factory Program for SMF28______________________________________________________ 22

Program Parameters ____________________________________________________________ 23

3

ASII Users Guide | 1/24/2019

Global Parameters ______________________________________________________________ 27

Optimizing _______________________________________________________________________ 29

Introduction to Optimizing ________________________________________________________ 29

Optimizing a Fiber ______________________________________________________________ 29

Maintenance _____________________________________________________________________ 31

Replacing the Filter _____________________________________________________________ 31

Cleaning Linear Clamps _________________________________________________________ 33

Replacing Rubber Pads (optional)_________________________________________________ 35

Replacing Fuses________________________________________________________________ 37

AS II Errors ______________________________________________________________________ 38

Clamp Slipping _________________________________________________________________ 38

Fiber Too Tight _________________________________________________________________ 38

Broken Fiber ___________________________________________________________________ 38

PC Interface _____________________________________________________________________ 39

Tech Support_____________________________________________________________________ 40

4

ASII Users Guide | 1/24/2019

Copyright Notice

©2019 3SAE Technologies Inc. All rights reserved.

Reproduction of this manual in any form requires written permission from 3SAE Technologies,

Inc.

5

ASII Users Guide | 1/24/2019

Safety Information & Precautions

•The AS II must only be used for stripping optical fibers with a coating diameter up to

600um. Any attempts to use the device for any other purposes could cause injury to the

operator or impair the AS II

•For the AS II to work properly, clean air must be supplied. Unclean air can reduce the

cleanliness and strength of the stripped fiber and also can impair the operation of the AS II

•Always use eyeglasses to protect from fiber shatter

•The use of a ventilation system is recommended

•This device is plugged into a standard 115V or 230V outlet. As with any electrical device,

reasonable care is required to avoid electrical shock. If the fuses need to be replaced,

disconnect the unit from the wall outlet and used exact replacements

•Never remove any covers or parts from the unit. Only trained authorized personnel are

allowed to service the AS II

•The heated air generated by the AS II is extremely hot. It can reach temperatures up to

960°C (1760°F). It is hot enough to melt the coating on the fiber and cause severe burns to

the operator if reasonable care is not taken or instructions are not followed. The heater

nozzle and exhaust system are not accessible during normal operation. The surfaces of

these components can also cause burns

•3SAE does not recommend increasing the temperature past 960°C (1760°F); damage can

be done to the AS II and heater

•The AS II uses pneumatics and electrical actuators. Never operate the unit without the

covers, as this may cause injury to the operator

•Always dispose of fiber scraps properly

•Never use spray cleaner or compressed gas. Never pour liquid cleaner on the AS II

6

ASII Users Guide | 1/24/2019

•Use of the unit should be restricted to personnel that:

✓Have been appropriately trained in the handling of optical fiber and related materials.

✓Have read, understood, and will follow all usage and safety instructions in this manual.

Note: It is the responsibility of the user to use this product for its intended purpose and

according to this manual. 3SAE Technologies cannot be responsible for damages or injury

resulting from failure to follow these instructions

7

ASII Users Guide | 1/24/2019

Transportation & Storage

The AS II must be protected against humidity, vibrations, and shock during transportation and

storage.

Save the packaging materials and locking screw for future use and always transport the AS II

in its original packaging material and secure the heater with the locking screw to prevent

damage.

Keep the AS II clean and dry.

8

ASII Users Guide | 1/24/2019

Introduction to the AS II

The use of chemicals for fiber stripping is past history

The AS II is a unique product utilizing the patented “Burst Technology” for fast and chemical

free window stripping of optical fibers with coatings up to 600um diameter.

The AS II was developed to meet the industry’s needs for variable window strip lengths with

high strength and ultra cleanliness.

The Burst Technology instantly vaporizes the fiber coating; the result is a stripped fiber,

perfectly clean, with high strengths.

The AS II is equipped with a built in tensile tester, which can pull up to 20N.

To ensure high quality, repeatability, and a high production yield, all critical processes and

parameters such as stripping distance, burst temperature, burst speed, and strength test are

controlled by built in microprocessors.

The fibers are easily placed in the correct position by guided linear clamps and a “One Touch”

go button that starts the stripping process automatically.

Operational Features

•Chemical free stripping

•Easy low maintenance bench top design

•Fast cycle time

•High 1st pass yield

•Accommodates fibers with coatings up to 600um

•Accommodates ribbon fibers from 4, 8, and 12 (with optional nozzle)

•Software adjustable parameters

•RS232 interface

9

ASII Users Guide | 1/24/2019

•Automated linear fiber clamps

•Variable strip length from 3mm to 150mm

•Built in high force linear tensile test

Safety Features

•All stripping processes are done inside the unit. Exposure to moving parts, hot gases, and

surfaces by user is extremely limited

•Safety shield to protect the operator from broken fiber shatter

•Exhaust systems with air filter for organic vapors

•Built in battery driven cooling fan allows the heater temperature to cool down slowly even if

the unit is disconnected from the wall outlet

•Fused for electrical protection

10

ASII Users Guide | 1/24/2019

Unboxing the AS II

1 Begin by opening the box.

2 Remove the AS II unit.

3 Remove all of the included accessories.

4 Compare the contents of the package with the Accessories Included list and the packing

slip to verify that everything has been received.

11

ASII Users Guide | 1/24/2019

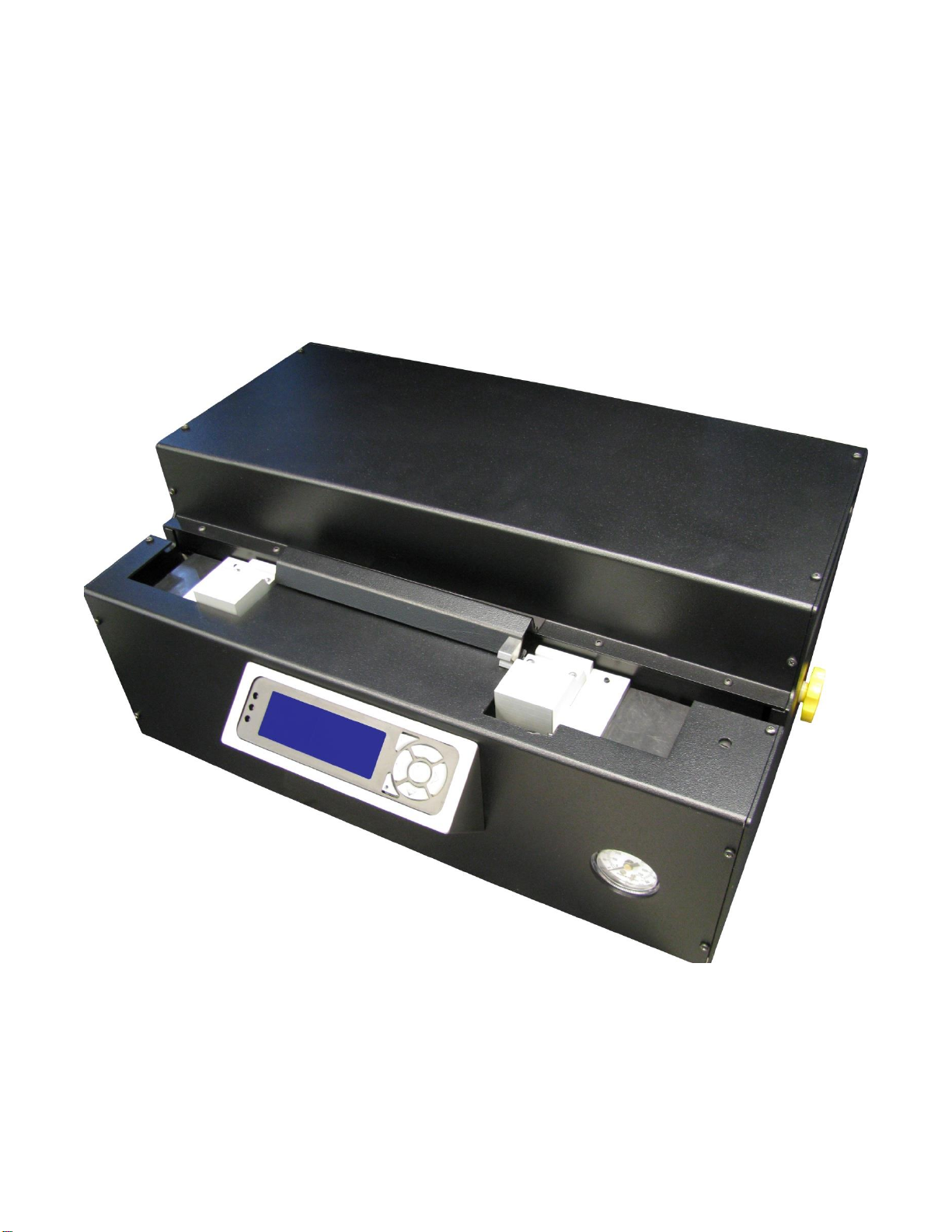

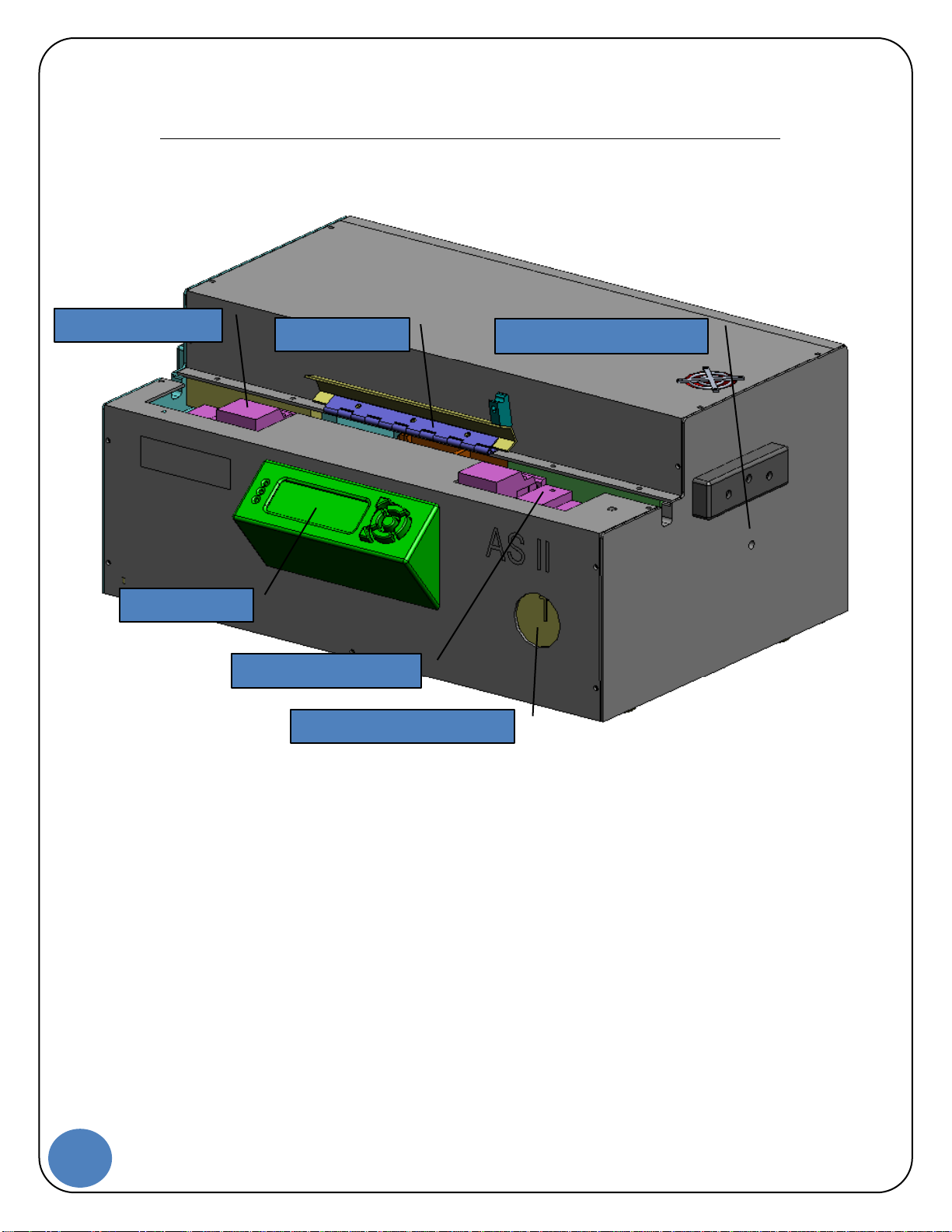

The AS II at a Glance

The AS II comes standard with the following features & add-ons.

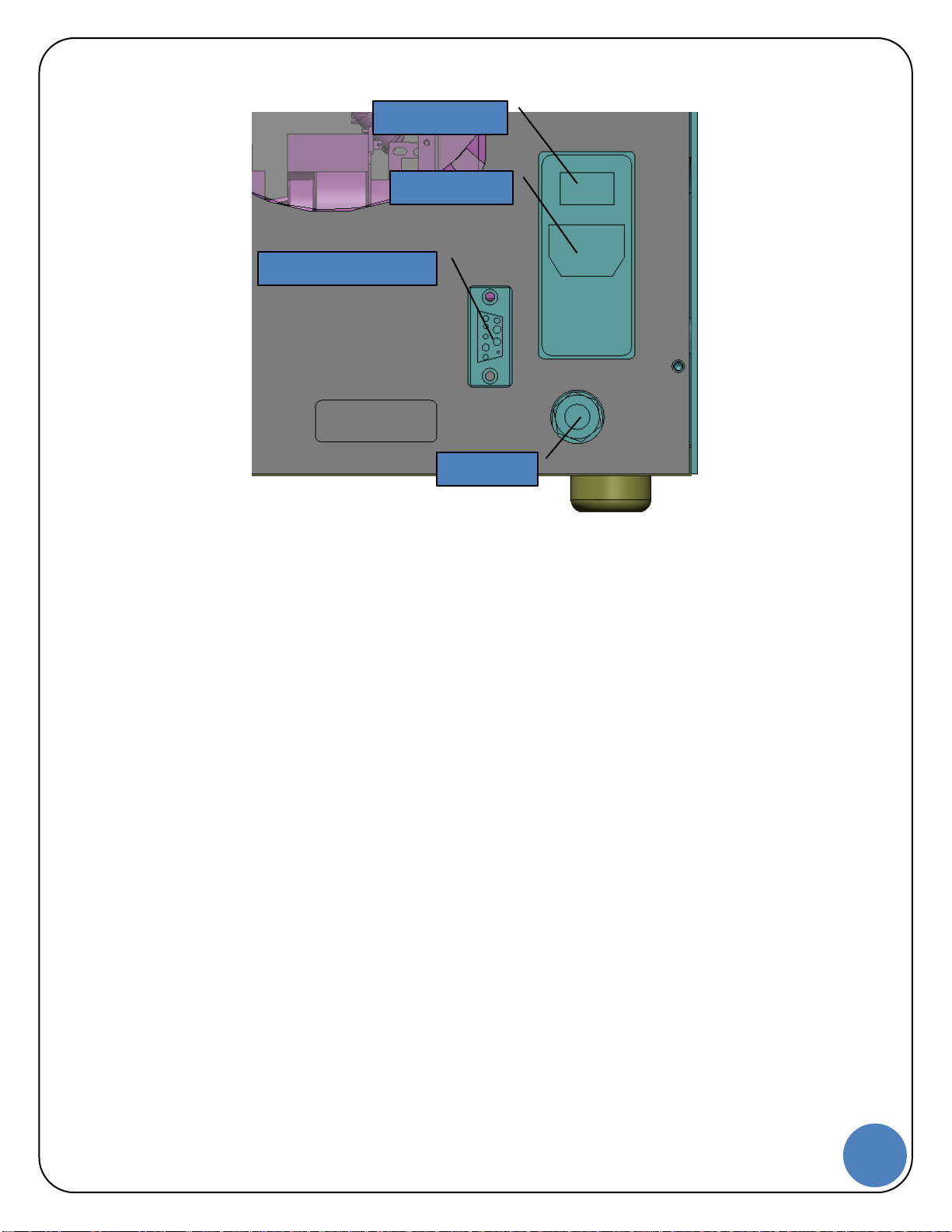

Left clamp/button

Safety shield

Heater locking system

LCD display

Right clamp/button

Clamp pressure gauge

12

ASII Users Guide | 1/24/2019

Power switch

Power input

Power

RS232 connection

Air input

Power

13

ASII Users Guide | 1/24/2019

Accessories Included

The AS II comes standard with the following accessories.

Item What it’s used for

Power cord Connect the power cord to the AS II, then plug

into a standard power outlet

Air-line (8mm) w/fitting Connect the air-line to the AS II, then plug the fitting

to an air supply

Quick start guide Quick setup guide and operation guide for the ASII

Hex shank bit Used to adjust the clamp pressure

(SPT-10-1326)

Rubber pad (x2) Used to help secure fiber coatings during stripping

(SPT-10-0898)

Optional Accessories

Load cell validation kit Used to verify/adjust the AS II load cell system

(ACC-01-0601)

14

ASII Users Guide | 1/24/2019

Basics

The AS II LCD provides access to all user controls.

AS II Firmware Compatibility

This manual is compatible with the following firmware and above: v1.7

AS II Home Screen

The AS II home screen provides the end user with the following information

•Current program number

•Current status

•Edit option

•Zero option

•Current set temperature

•Real time load cell reading

15

ASII Users Guide | 1/24/2019

AS II Buttons

The AS II buttons allow the end user the ability to

•Access new programs

•Make changes to programs

•Access global parameters

•Zero the load cell

AS II LEDs

The AS II LEDs indicate to the end user the following:

Top LED

•This will be solid green to represent that the unit is on and waiting on the operator. Red

indicates that the unit is in use and the clamps are closed

Middle LED

•Not used

Bottom LED

•Red during heater ramping up and will flash green when the heater is at temperature

Button 2

Power

Button 1

Power

Go button

Power

16

ASII Users Guide | 1/24/2019

Heater Lock

The heater locking system is a new safety feature. The lock secures the heater assembly

during shipping.

Note: Do not power on the unit prior to removing the locking screw, THIS CAN damage the AS

II

1 Spin the locking screw CCW to remove.

2 Insert the protective cap where the locking screw was.

3 Save the locking screw for future shipping.

Safety Shield

The AS II safety shield has a sensor installed for additional security.

•If the safety shield is open, the AS II will not perform an operation

•During a cycle, if the safety shield is opened, the AS II will stop the cycle immediately

Providing Air

Use of an external pressure regulator is required if the line pressure is greater than 95psi. Set

input pressure to 90-95ps before connecting compressed air line to the AS II.

•The AS II is equipped with an 8mm instant push-in fitting

•Push the supply hose into the fitting, making sure that the hose is fully inserted. When the

hose reaches the bottom of the fitting, it will be locked in place

•To remove the hose, push the locking ring in and pull the hose out

17

ASII Users Guide | 1/24/2019

Powering the AS II

1 Connect the power cord to AS II and then plug it into a standard power outlet.

2 Toggle the power switch from off to on.

Upon power-up, the AS II will perform a number of internal tests; if successfully completed, the

top LED on the AS II LCD will become solid green. If unsuccessful, the top LED will become

solid red.

Setting Heater Temperature

The heater temperature is displayed on the front of the unit in real time.

To change the heater temperature:

1 Select the program number that the temperature needs to be changed on.

2 Press Button 2 (labeled Edit).

3 Cycle the Right Arrow Button until ‘Heater temp’ is displayed.

4 Using the Up and Down Arrow Buttons, the temperature can be changed. The Go Button

changes the value from 1 to 100 to accommodate a larger change.

5 Press Button 2 (labeled Save) to keep the current change.

•Allow some time for the heater to adapt for the new temperature setting

Note: If the heater value is set to 0°, then the heater will be turned off

Zero Load Cell Response

•Press Button 2 to zero out the load cell

•If the tension fluctuates 10%, zero out the load cell

Verify the correct voltage is selected, 115V or 230V before powering

on the unit; selecting the incorrect voltage will damage the unit

18

ASII Users Guide | 1/24/2019

Clamp Pressure

The clamp pressure is factory set to 50.

It may be necessary to adjust the clamp pressure for:

•A smaller or larger diameter fiber

•Specialty coated fibers

•When ‘Fiber Slipping’ occurs

•Hex shank bit

1 Adjust the clamp pressure as needed (hex shank bit).

a Turn the dial CW to increase the clamp pressure.

b Turn the dial CCW to decrease the clamp pressure.

c DO NOT over tighten the dial when making adjustments.

Clamp pressure adjustment

Power

19

ASII Users Guide | 1/24/2019

General Use

This section describes the standard operation procedures for using the AS II.

1 Power on the AS II.

2 Choose/verify the program for the fiber diameter/coating.

3 Allow the heater time to reach the operating temperature and stabilize (5 –10 min).

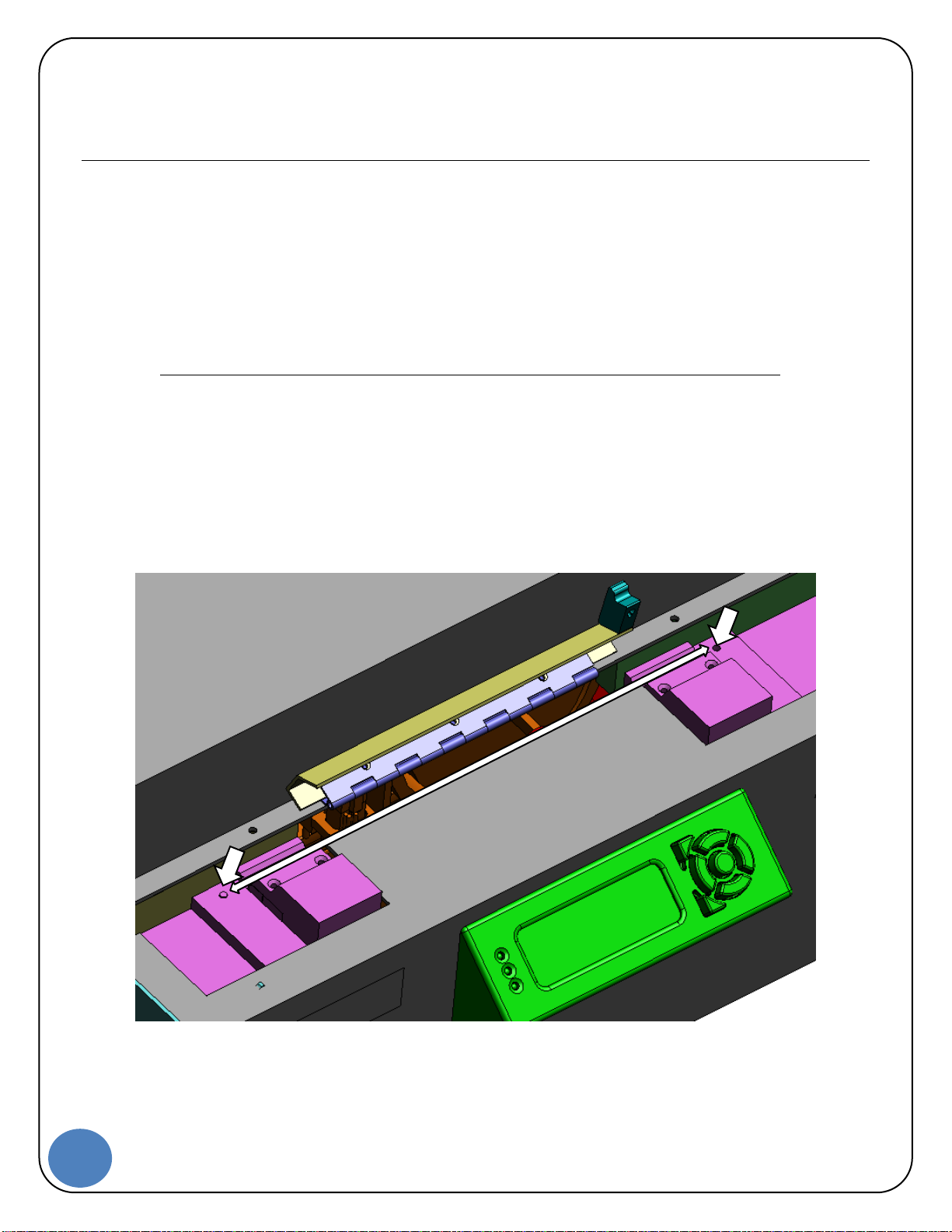

Loading the fiber

4 Open the safety shield to the AS II.

5 Load a fiber across both clamps.

a Make sure that the fiber is flat and taught.

b Make sure that the fiber length passes the buttons.

6 Press both buttons simultaneously.

7 Close the safety shield.

The display will read

Press Start

20

ASII Users Guide | 1/24/2019

8 Press the Go Button.

Note: The proof-test information will only be displayed if that feature is enabled

The display will read

ProofTest Ok (display value here)

The display will read

Done

The display will read

Release Fiber

9 Open the safety shield.

10 Remove the fiber by pressing both buttons simultaneously.

a Make sure to hold the fiber prior to pressing the buttons.

Proof-Test Only

1 Open the safety shield to the AS II.

2 Load a fiber across both clamps.

3 Press both buttons simultaneously.

4 Close the safety shield.

The display will read

Press Start

5 Press the Go Button.

The display will read

ProofTest Ok (display value here)

The display will read

Done

The display will read

Release Fiber

Table of contents