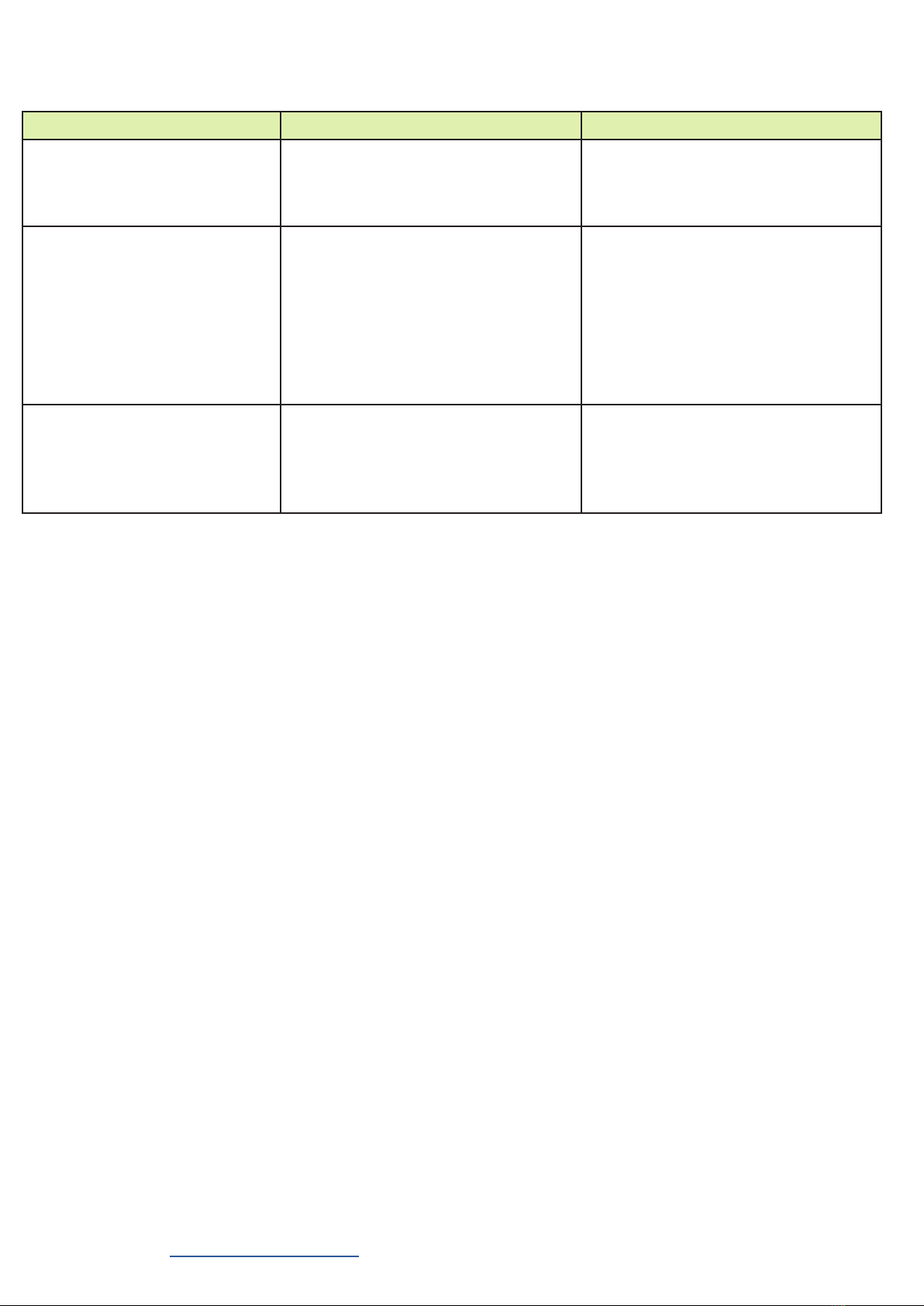

METHOD DESCRIPTION APPLICATION

Absolute Temperature (ABS)

An alarm is raised if the sensed

temperature exceeds the preset

trip point.

Simple bearing detection for over

heating, most commonly used.

Relative Temperature (REL)

An alarm is raised if the difference

between the sensed temperature

and the selected relative or

ambient source temperature is

greater than the preset trip point.

Used in addition to the rst method

and provides much earlier fault

detection. Especially useful in

cold weather as it is no longer

necessary to wait until the bearing

gets to a very high temperature

before a failure detected.

Rate of Rise (dR - delta R)

An alarm is detected if the bearing

starts to heat up at a rate higher

than the preset value in degrees

per minute.

Used in addition to the two

methods above, and provides for

an alternative fault detection for a

failing bearing.

HOT BEARING DETECTION -

The Watchdog Super Elite can monitor up to 8 NTC type temperature sensors (standard). This can be

expanded to a total of 20 NTC sensors with optional auxiliary boards. The supported alarm methods are:

AUXILIARY INPUTS -

The Watchdog Super Elite also has auxiliary inputs for pulley misalignment, plug condition or blocked chute

monitoring. These offer additional protection and prevent unnecessary costly downtime.

SETTINGS BACKUP & TRANSFER -

The controller is equipped with an SD card slot, and supports the ability to save and restore the system

settings from the memory card. This also allows system settings from one unit to be copied to another,

which is especially useful to duplicate settings on multiple controllers at the same location.

WDC4 CONFIGURATOR SOFTWARE -

The Watchdog Super Elite can be programed directly through the controller’s LCD menu screen, or by

using the WDC4 Congurator Software (Appendix C). The software tool makes programming the Watchdog

easier by providing all the system settings for each prole menu into one screen. Once a prole setup le

has been created, it can be saved to an SD card and then uploaded to the Watchdog. For remote sites,

the le can be emailed to an on-site technician, who can upload the le.

EVENT & ALARM LOGGING -

The last 40 events and alarms are logged and can be viewed directly from the Watchdog’s main LCD

screen. If an SD card is installed, all events and alarms (not just the last 40) are saved on the card. The

le can be imported into a spreadsheet program to create more detailed logging and trending reports.

HAZARDMON.COM CONNECTIVITY -

The Watchdog Super Elite has in-built network support for Hazardmon.com service connectivity. HazardMon

is a secure cloud based hazard monitoring solution providing status notications and data logging for

bucket elevators and conveyors. Live system status, graphs and historical data can be viewed on any

web-enabled device (smartphone, tablet PC, desktop or laptop computer). Emails can be sent to notify

users whenever a change in the system’s health is detected. An automated maintenance feature allows

site operators to verify that all sensors on the system are operational and working correctly.

To review of all the available features, and to see how the system works for yourself register for a free

demo account at: https://hazardmon.com.

PAGE 10