DRILL AREA PREPARATION

The beadlock inner tube valve stem hole should be located about

20cm circumferentially from the standard valve stem hole in

either direction.

Although directly across from the standard valve stem hole seems

proper, with this, it is more difficult to mount the final outside

tire bead.

* Double check your measurements and positioning, before drilling the hole! *

Check exactly where you plan to drill the beadlock valve stem hole while checking for:

1) A flat spot to receive the O-ring, and

2) For rim thickness. The 8mm valve stem will accommodate any thickness of rim up

to 13mm and requires a 16mm diameter flat surface to receive the O-ring, washer

and nut.

We recommend 6mm or more of valve stem-to-inside- rim clearance and more may be

required to use your style air pressure gauge. With most rims, this is easily determined by

looking at the rim as normally mounted on the lugs. Again, check twice and drill once!

DRILLING PROCEDURE

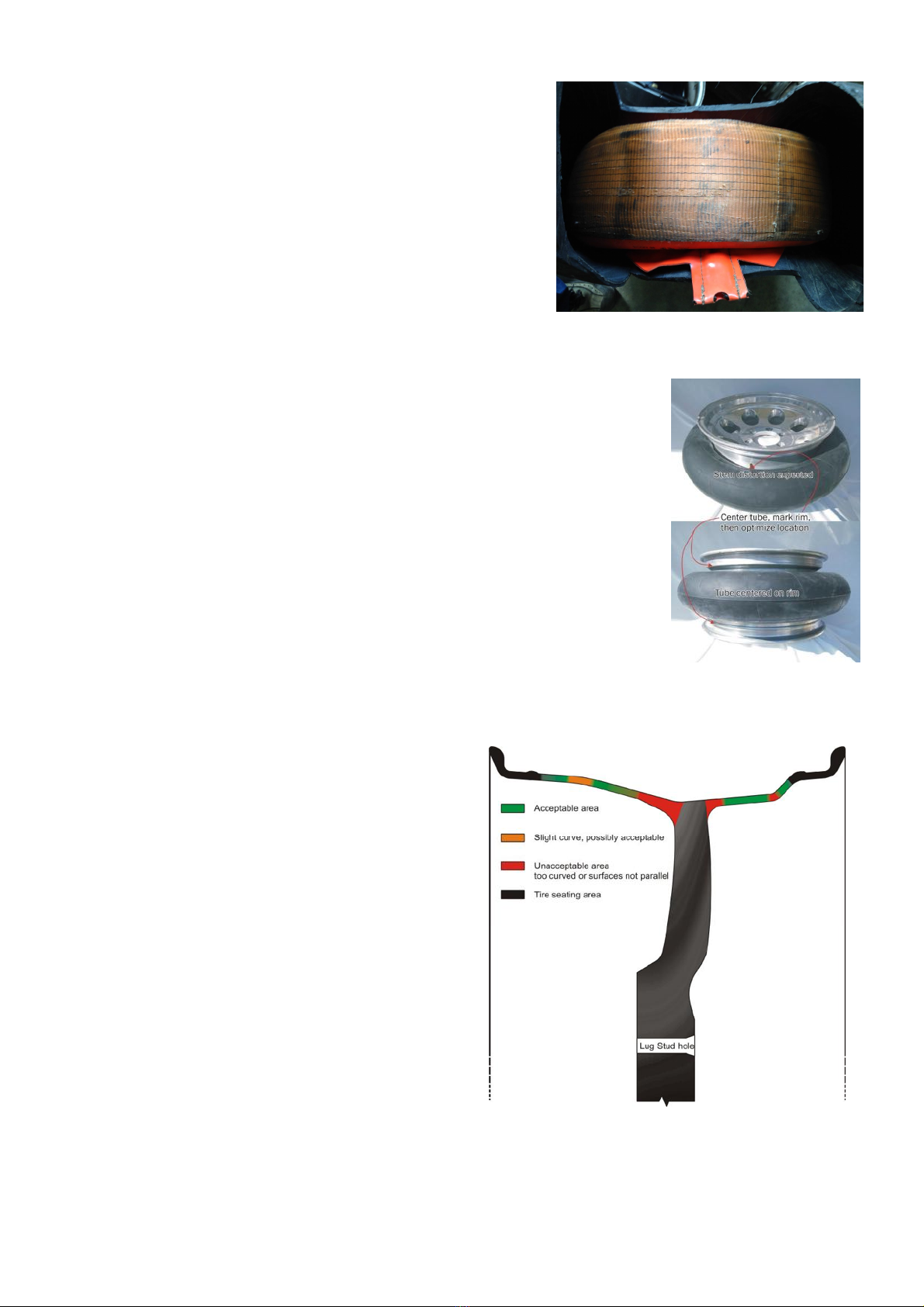

1) Use a center punch mark the hole.

2) Drill at a right angle to the center-punched surface.

3) Drill in stages, first 4mm, then 8mm.

4) Deburr both the outside and inside of the hole.

5) Remove all chips from within the tire with a cloth, if you drill

with the tire half on the rim.

6) Do not use compressed air to blow the chips out, but rather

vacuum or wipe them out. Left inside the tire, these chips

can eventually chafe and wear through the beadlock casing,

inner tube or both. 4x4 Traction is not responsible for this

type of failure or product replacement. Keep everything

very clean and smooth.

RIM PREPARATION

1) Remove all dirt, flaking paint, rust, burrs and corrosion from the entire inside

surface and edge of the rim. Pay particular attention to the tire-bead-seating

surface. The condition of this surface sets the air seal integrity and rim-to-tire

anti-spin adhesion. We recommend wire brushing this entire surface along with the

rim’s bead bumps.

2) Next, remove the standard valve stem. Mark or remember this hole is for the

special air channel, which feeds the main tire.

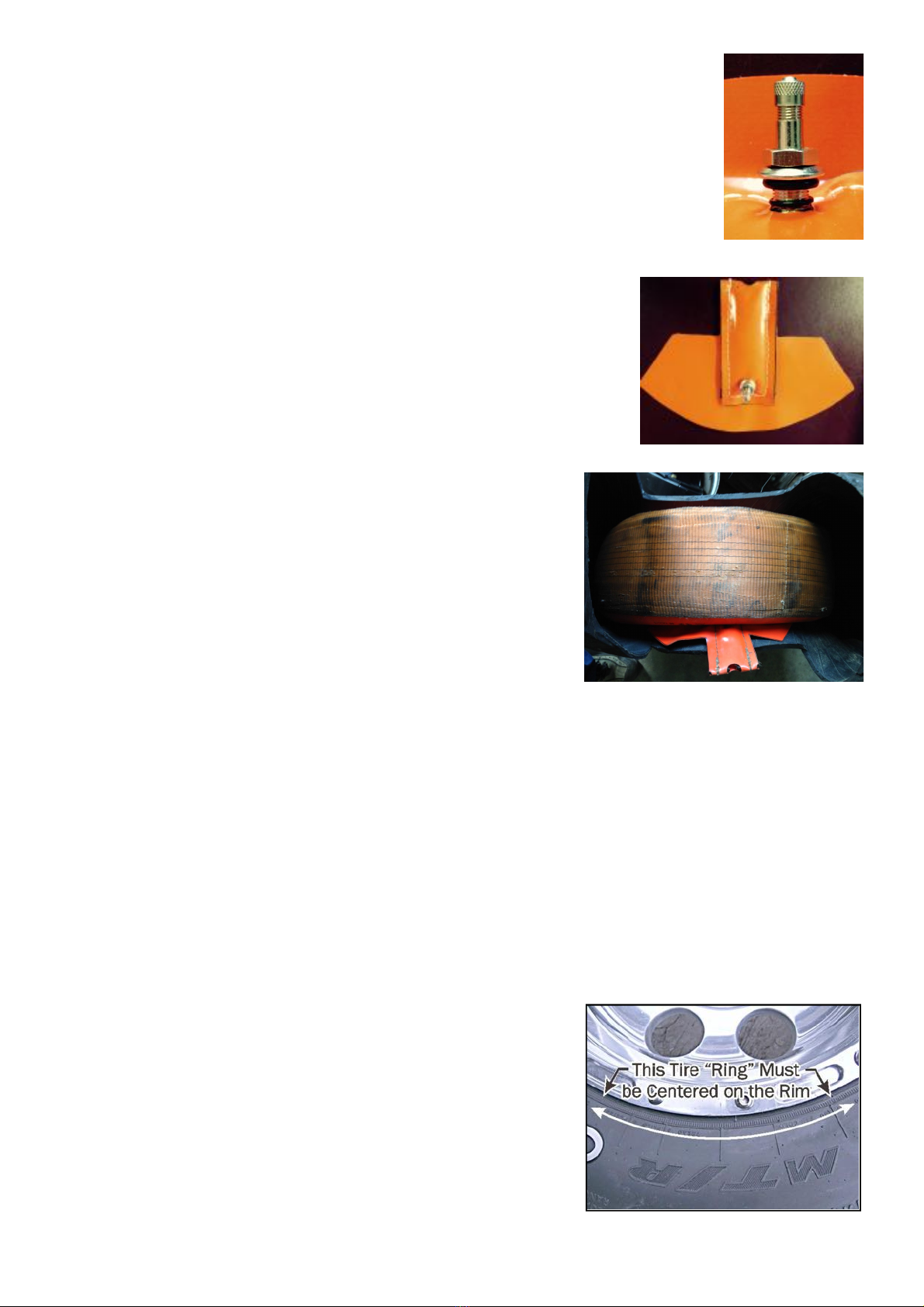

BEADLOCK PREPARATION

Using the powder supplied, generously “lubricate” 100% of the tube,

inside the casing and the inside of the rim. Both the inside and

outside of each beadlock bead must be dusted completely. The

lubricating powder makes it easier to move the tube within the

casing and for the beads to migrate to the correct position when

finally inflated.

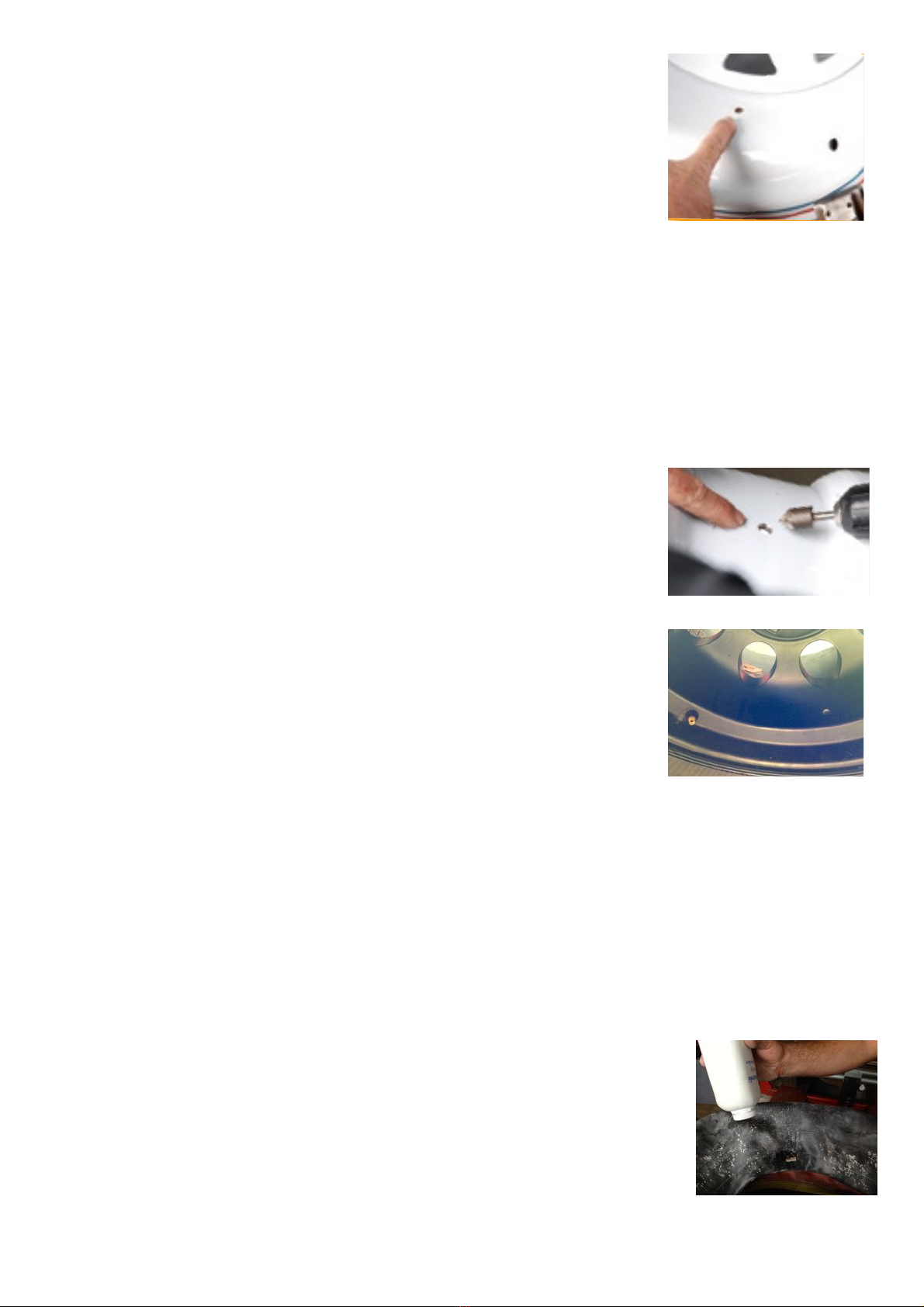

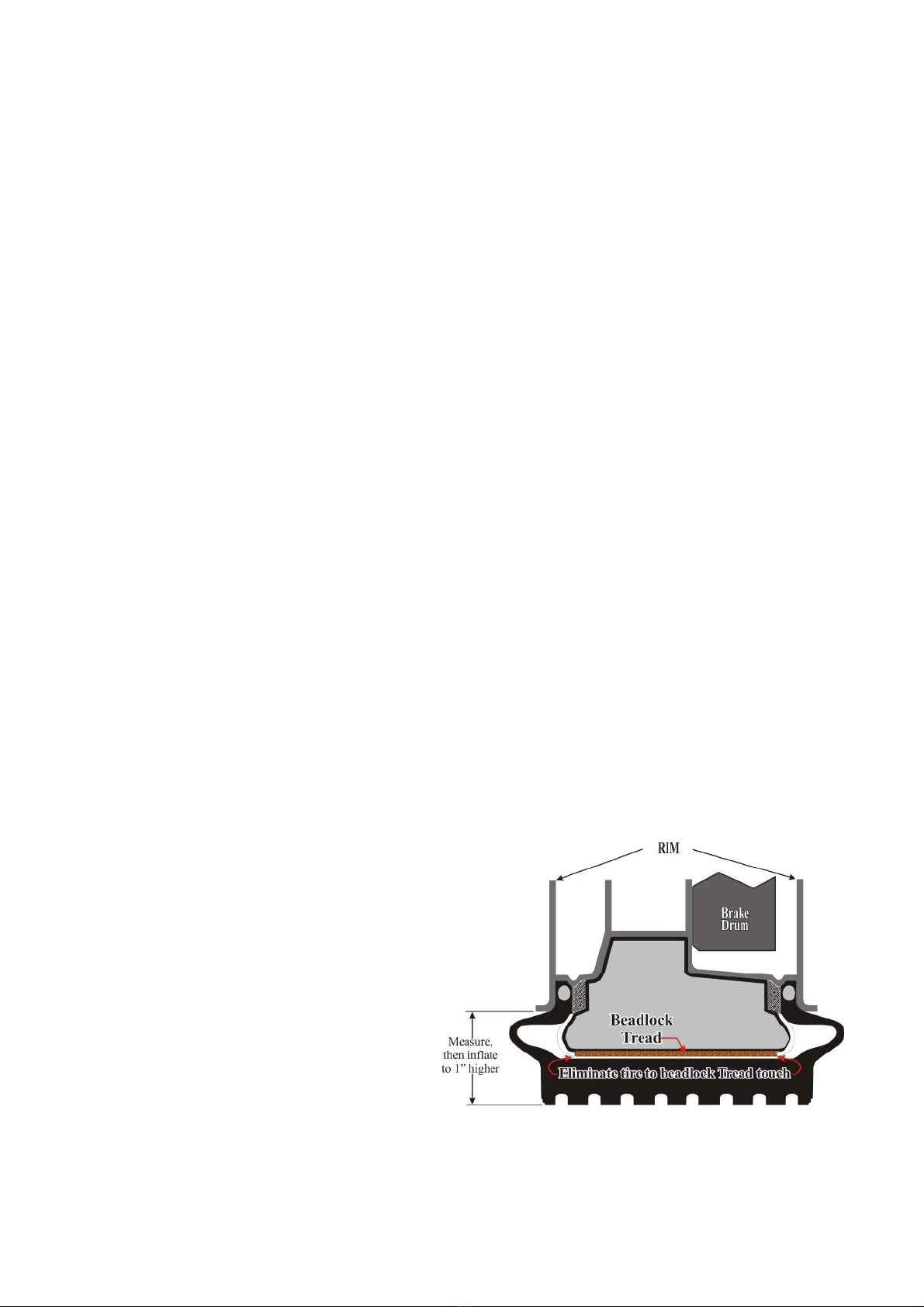

installation

1) Locate position for the tube valve

stem hole: The beadlock tube valve stem

hole should be 150 to 200 mm (5.905 to

7.874”) clockwise from the standard valve

stem hole and as near to the center of the

rim as practical without interfering with the

brakes and associated components if the

tube valve stem is located inboard/brake

side of the rim. Ensure that the proposed

inside and outside rim tube valve stem

hole surfaces are flat, parallel (to

accommodate both tube valve stem

O-rings) and less than 13mm (0.519”)

thick. (If your new Staun Internal Beadlocks

are being fitted to Staun manufactured

rims, the tube valve stem hole has been

predrilled. Proceed to step 3).

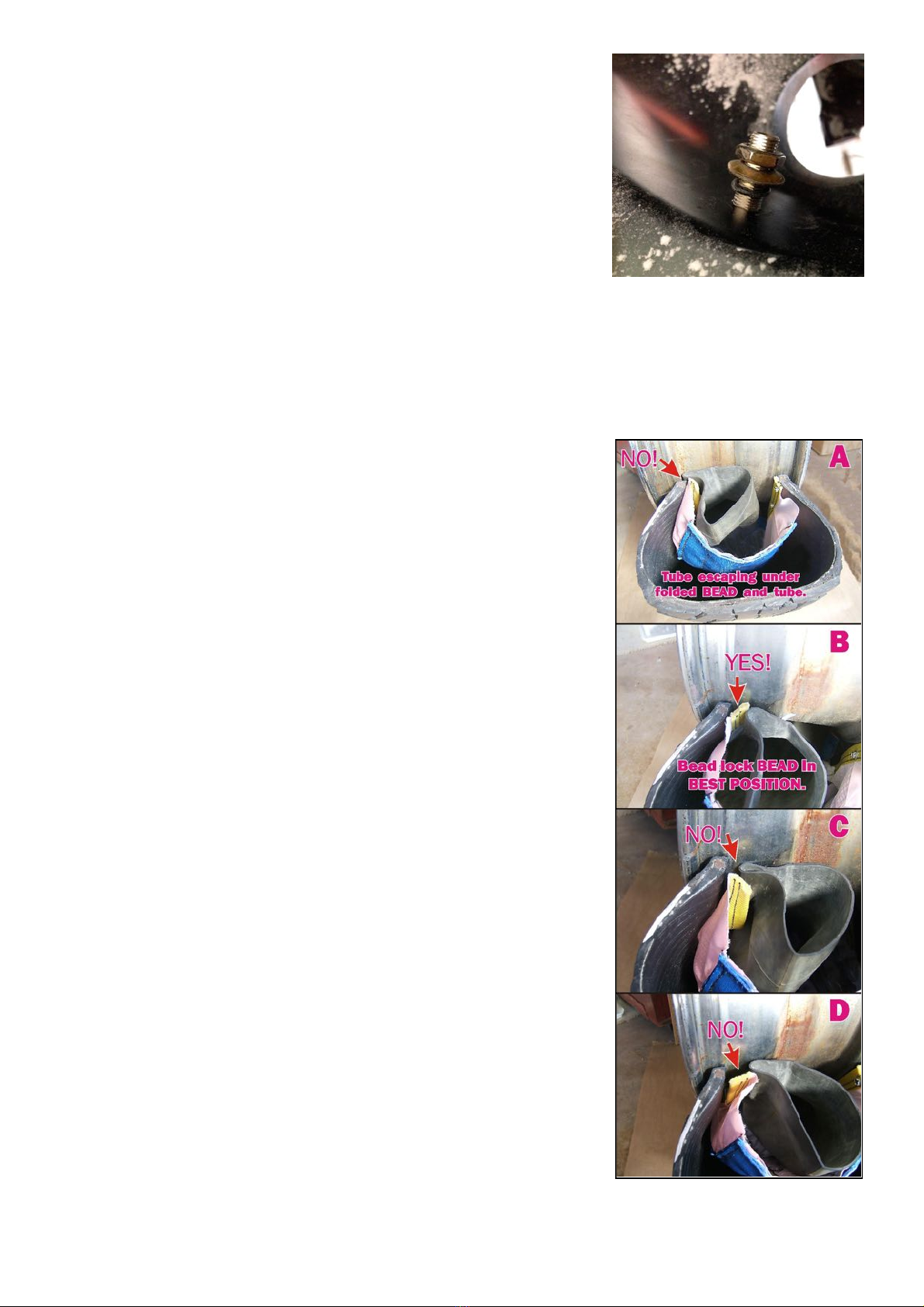

2) Drill and chamfer the tube valve

stem hole: Drill an 8 mm (0.315”) hole at

the chosen position. Chamfer the drop

center side of this hole to receive the

inner O-ring. The chamfer face should

be 2 to 3 mm (0.079 to 0.118”) wide. A

screw countersinking tool at slow rotating

speed is best to make the chamfer. Clean

all, metal chips off the rims, all beadlock

components and from within the tyres.

Chips can cause tube failure.

4

2

1

5

6

7

3) Prepare the rims: The rims should be

clean and free from all rough edges to

ensure that the tube is not damaged during

installation. All rust and labels, and their

adhesive should be removed from the rims.

4) Prepare the tyres: The inside edge of

the tyre bead should be checked for sharp

edges and buffed smooth as necessary.

This is particularly true of tyres 36 inches

and larger. This is mandatory for all tyres

with beads greater than 16 mm (0.629”)

regardless of diameter.

5) Powder all components: Powder

the beadlock cap, tube, air channel and

the rims’ drop center. Pay particular

attention to the inside and outside of both

beadlock beads (the black webbing at the

ID of the cap).

6) Contour the air channel: Select the

proper size rubber grommet for your rims’

tyre valve stem holes and discard the other.

Temporarily, and without force, hold an air

channel up to the existing valve stem hole

noting the shape necessary to fit to the

inside of the rim assuming the tyre bead is

in position. Without using the metal portion,

bend/pre-contour the air channels to the

shape if necessary. Set these aside for

step 12.

7) Mount the first tyre bead: Mount the

first tyre bead as normal. A Windex-like

product is recommended in place of

conventional tyre lubricants. This ensures

that if rewetted in actual use, the rim will not

spin within the tyre.

installation

1) Locate position for the tube valve

stem hole: The beadlock tube valve stem

hole should be 150 to 200 mm (5.905 to

7.874”) clockwise from the standard valve

stem hole and as near to the center of the

rim as practical without interfering with the

brakes and associated components if the

tube valve stem is located inboard/brake

side of the rim. Ensure that the proposed

inside and outside rim tube valve stem

hole surfaces are flat, parallel (to

accommodate both tube valve stem

O-rings) and less than 13mm (0.519”)

thick. (If your new Staun Internal Beadlocks

are being fitted to Staun manufactured

rims, the tube valve stem hole has been

predrilled. Proceed to step 3).

2) Drill and chamfer the tube valve

stem hole: Drill an 8 mm (0.315”) hole at

the chosen position. Chamfer the drop

center side of this hole to receive the

inner O-ring. The chamfer face should

be 2 to 3 mm (0.079 to 0.118”) wide. A

screw countersinking tool at slow rotating

speed is best to make the chamfer. Clean

all, metal chips off the rims, all beadlock

components and from within the tyres.

Chips can cause tube failure.

4

2

1

5

6

7

3) Prepare the rims: The rims should be

clean and free from all rough edges to

ensure that the tube is not damaged during

installation. All rust and labels, and their

adhesive should be removed from the rims.

4) Prepare the tyres: The inside edge of

the tyre bead should be checked for sharp

edges and buffed smooth as necessary.

This is particularly true of tyres 36 inches

and larger. This is mandatory for all tyres

with beads greater than 16 mm (0.629”)

regardless of diameter.

5) Powder all components: Powder

the beadlock cap, tube, air channel and

the rims’ drop center. Pay particular

attention to the inside and outside of both

beadlock beads (the black webbing at the

ID of the cap).

6) Contour the air channel: Select the

proper size rubber grommet for your rims’

tyre valve stem holes and discard the other.

Temporarily, and without force, hold an air

channel up to the existing valve stem hole

noting the shape necessary to fit to the

inside of the rim assuming the tyre bead is

in position. Without using the metal portion,

bend/pre-contour the air channels to the

shape if necessary. Set these aside for

step 12.

7) Mount the first tyre bead: Mount the

first tyre bead as normal. A Windex-like

product is recommended in place of

conventional tyre lubricants. This ensures

that if rewetted in actual use, the rim will not

spin within the tyre.