3

This manual is designed to give you the correct information to assemble and install this swing door

operator to the current EN 16005 : 2012 regulations

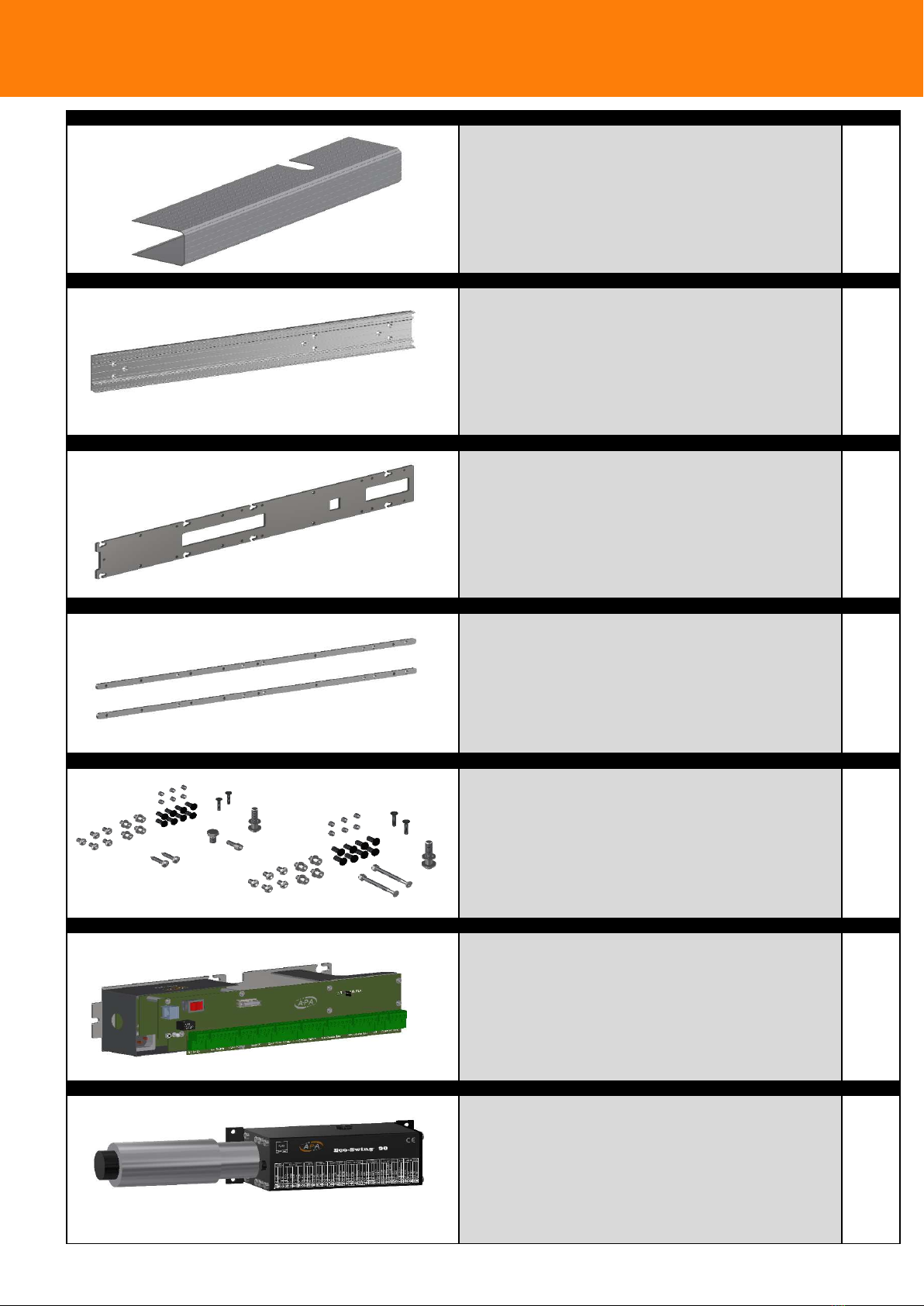

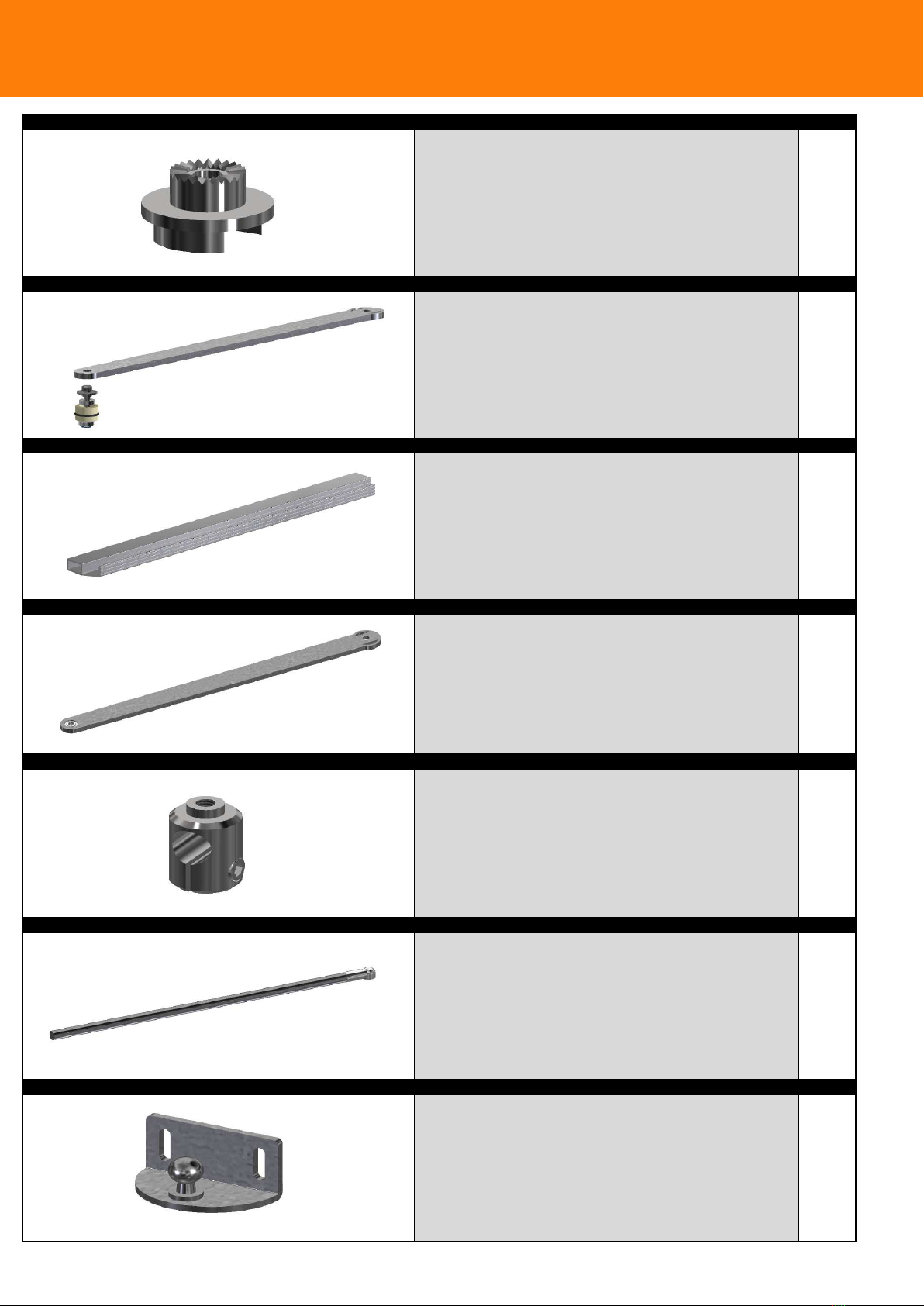

The ES-90 swing door operator has been designed by engineers with many years experience in the

automatic door industry and built on proven, reliable designs, incorporating the latest wireless

technology which interfaces the unit to any Wi-Fi browser for easy set-up and adjustment features.

An optional adjuster board can be added to give a certain level of manual adjustment / settings if

preferred.

This unit should be installed as per the instructions in this manual and with reference to the current EN 16005

regulations by a qualied engineer.

A badly or incorrectly installed unit can cause damage to both the equipment and possible injury to people.

As with all equipment installed in the workplace which falls under the Machinery At Work Act, this operator

should be routinely inspected and serviced according to the EN16005 : 2012 regulations.

We recommend this is carried out at least twice yearly by a EN16005 certied & trained engineer.

(Please note : Other regulations such as Building Regulations Part “P” or Disability Discrimination Act may

need to apply as well)

This unit is designed to be used indoors, in a dry environment only.

Safety First

Environmental Requirements

The Eco-Swing 90 contains electronics and batteries that may have materials that could be

hazardous to the environment. Please dispose of them responsibly & safely in accordance with your

countries laws

Safety