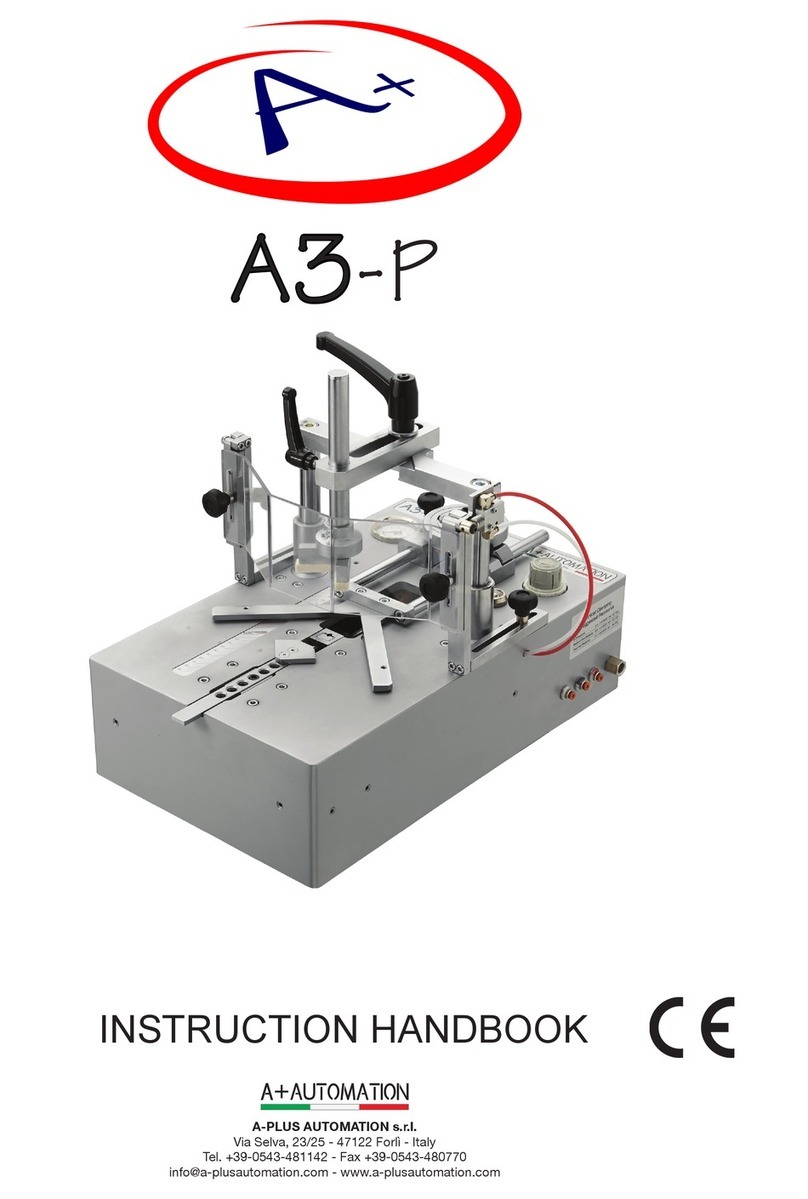

A-PLUS AUTOMATION A44-P manual

INSTRUCTION HANDBOOK

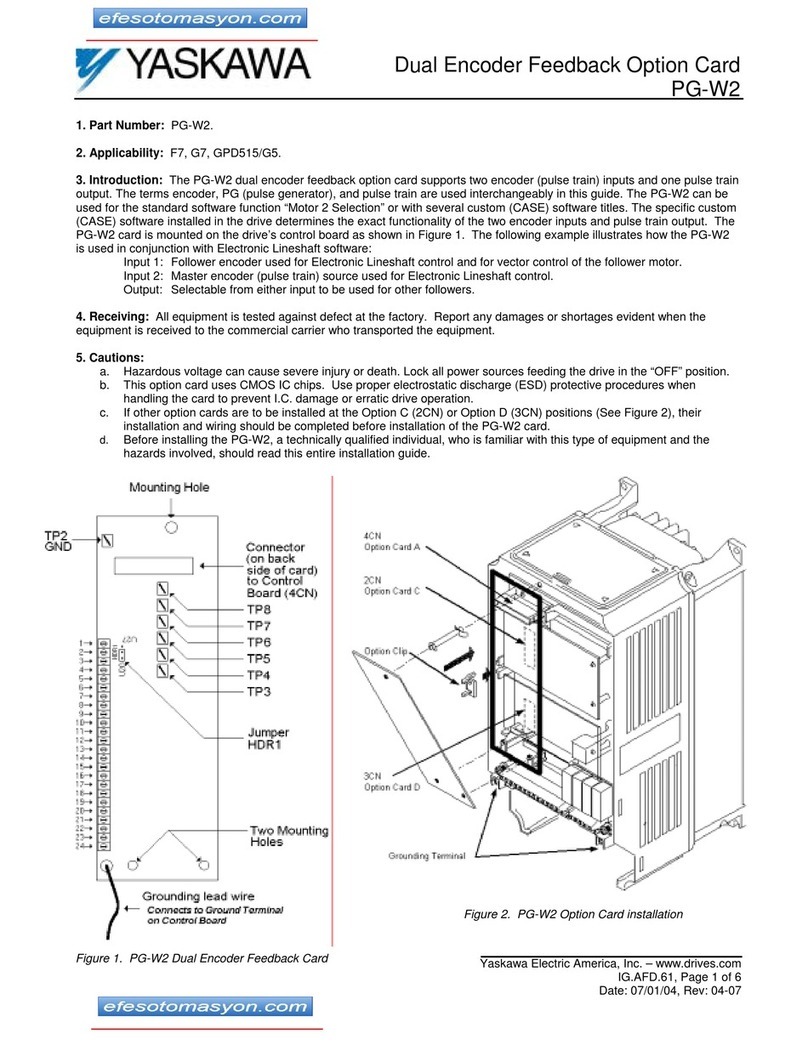

A-PLUS AUTOMATION s.r.l.

Via Selva, 23/25 - 47122 Forlì - Italy

Tel. +39-0543-481142 - Fax +39-0543-480770

A44-P

2

A44-P

INDEX

1. GENERAL INFORMATION .........................................................................................................4

2. MACHINE DESCRIPTION ...........................................................................................................6

3. SAFETY.....................................................................................................................................8

4. HANDLING AND INSTALLATION ................................................................................................9

5. OPERATING MODES .................................................................................................................16

6. MAINTENANCE ........................................................................................................................17

7. DIAGNOSTIC ............................................................................................................................ 18

8. SPARE PARTS............................................................................................................................20

9. MACHINE DEMOLITION............................................................................................................20

10. ATTACHMENTS.........................................................................................................................20

3

A44-P

4

A44-P

1. GENERAL INFORMATION

The idencaon plate illustrated is axed directly onto the machine. The plate contains all idencaon details and indicaons

necessary for safe operaon.

1.2 TECHNICAL SERVICE REQUEST PROCEDURES

For any requirement, please contact the Manufacturer’s Customer Service.

For any request for technical service, list the data on the idencaon plate, the approximate number of hours the machinery

has been used and the type of malfuncon.

1.3 CERTIFICATION

The machine is produced in conformity to the pertinent European Community Norms in force at the moment of its introduction

on the market.

1.4 WARRANTY

• The replacement of defective parts is warranted (counting from the date written on the delivery bill) for a period of:

• Mechanical components - 24 months

• Pneumatic parts - 12 months

• Electric and Electronic parts - 12 months

The driver blade is tested for about 1.000.000 working cycles.

The warrant does not include sending technical staff. The repair will be performed at A-Plus Automation's facility and the

freight of shipment will be entirely charged to the Customer.

The warranty does not cover the damages caused by an inappropriate use of the machine or not corresponding to the

instructions described in this handbook.

The warranty decays in case of unauthorized modifications or because of accidental damages or tampering performed by

unqualified personnel.

The warranty also decays if you use wedges different from the original special steel A+ ones.

To take advantage of warranty services it is necessary, at the moment you receive your machine to completely fill out the

warranty card and send back as soon as possible to A-Plus Automation.

The warranty will be valid after it is received & recorded at A-Plus Automation.

1.5 PRE-ARRANGEMENTS CHARGED TO THE CUSTOMER RESPONSIBILITY

It is the customer’s duty, on times agreed with the producer, to execute what is indicated in the following documentation.

Things normally charged to the customer:

• Premises predisposition, included building works

• Pneumatic supply of compressed air (see at the paragraph 4.6.1)

• Machine power supply, observing the current norms of Country where the machine is installed (see at the paragraph 4.6.2)

1.6 PURPOSE OF THE MANUAL

The manual herein, part and parcel with the machinery, has been designed and built by the manufacturer with the purpose

to supply the necessary informaon to the persons authorized to operate the machinery during its useful life.

As well as adopng an appropriate ulizaon technique, the recipients of the informaon must read and strictly apply them.

This informaon is supplied by the manufacturer in its own language (Italian) and may be translated into other languages to

sasfy statutory and/or sales needs.

A lile me dedicated to the study of this informaon, will permit the user to avoid health and safety risks to personnel and

economic loss.

The translaon in the language of the country of use, supplied by the manufacturer, its representave or whoever brings

the machine to such linguisc area, must be carried out from the “ORIGINAL INSTRUCTIONS” and must display the phrase

“TRANSLATION OF THE ORIGINAL INSTRUCTIONS”.

5

A44-P

In the event that the manual herein contains addional informaon concerning the ngs of the machinery, said informaon

does not interfere with the reading of the manual.

Keep this manual for the enre duraon of its useful life in a well known and easy to access place, available for reference any

me the need should arise.

The manufacturer reserves the right to make modicaons with no obligaon to supply a prior nocaon.

1.7 SYMBOLS

SYMBOL MEANINGS

DANGER Indicates situations involving great hazard risks which, if overlooked, could put

people’s health and safety in great danger.

WARNING Indicates technical information of particular importance which must not be

overlooked.

INQUIRY The user is requested to check the proper positioning of any element of the machine,

before operating a certain command.

6

A44-P

2. MACHINE DESCRIPTION

2.1 GENERAL MACHINE DESCRIPTION

The A44-P Frame Assembling Machine have been realized to assemble any kind of frame.

The machine versions is equipped with a Wedges driver blade mounted on a movable carriage which, manually shifted by

the operator allows the quick insertion of Wedges in different positions.

The A44-P being of simple construction and extremely easy to use, make them possible to join with absolute precision any

kind of moulding by means of special steel A+ wedges.

2.2 CONSTRUCTIVE CONFIGURATION

The main components constung the machines are:

• Frontal clamping device to have a perfect joint

• Brake on posion to insert easily intermediate Wedges in any prole

• Pneumac balancing that allows to work easily when the working bench is lted

• Adjustable lng fences.

• Floor stand

• Fixed and magnec changeable pressure pads to have the proper clamping of any prole

• Dual funcons foot operang pedal for separate control of clamping and nail inseron

• Pneumac opening of wedges magazine for a very quick reloading

• Nail heads sizes 7, 10 and 15 mm.

2.3 AXIS

- X AXIS

Movement horizontal.

- Y AXIS

Movement vercal

Picture 2.3.A - Movement directions

2.4 AMBIENT CONDITIONS IN THE INSTALLATION AREA

The installaon area must have adequate environmental condions.

The installaon area must meet the following requisites.

• Adequate lighng to European standards (recommended 250÷650 lux)

• Well venlated rooms

• Adequate relave humidity and temperature. The permied temperatures go from 5° to 40° C, with a humidity level not

higher than 50% at 40° C or 90% at 20° C.

• The oor, as well as having an adequate load capacity for the machine weight, must be stable and levelled in order to

guarantee a correct support.

X

Y

7

A44-P

2.5 SURROUNDING CONDITIONS

The machine does not need special surrounding condions. It has to be installed inside an industrial building, lit, aired

and with a compact and at oor. The permied temperatures go from 5° to 40° C, with a humidity level not higher

than 50% at 40° C or 90% at 20° C.

2.6 LIGHTING

Premises lighng must be conformed to the norms in force in that Country where the machine is installed and has to

guarantee a clear visibility and can not create dangerous light reecons.

2.6 NOISE EMISSIONS

In standard working condions the Machine noise power level is:

• Acoustic Continuous Equivalent weighed pression A <70dB

• Acousc Istantaneous weighed pression <130dB

In case of any machine modicaon, the above menoned levels could be changed

2.7 TECHNICAL DATA

We have listed below the Machine’s data and technical characteriscs to which you can make reference for any eventual

contact with your distributor for Technical Assistance.

TABLE 2. 7 A Tecnical data

Frames thickness (min-max) 5-80mm / 1/4” - 3 5/32”

Frames width (min-max) 6-120mm/ 1/4” - 4” 23/32”

Wedges magazine capacity n. 230

Wedges size 7, 10, 15 mm.

Wedges size on request 3, 5, 12 mm.

Pneumatic feed BAR 3-6 / PSI 40-80

Air consumption 4,0 Nl at 6 BAR - 0.14 cf3 at 73 PS

Weight approx. 90 kg / 198 lbs

Height of working bench 960 mm / 38”

Overall dimensions 600x520x1220mm - 24" x 20" x 48"

2.8 EQUIPMENT SUPPLIED

2.8.1 Standard accessories 2.8.2 Optional accessories

• N.1 wedge claw-head mm. 7 • Metal support extensions

• N.1 wedge claw-head mm.10 • Wedges claw-heads size 3-5-12 mm

• N.1 wedge claw-head mm.15 • Horizontal clamping w/wider leaf (see Pict. 1)

• N.1 L shaped pressure pad

• N.1 Allen Wrench 5 mm. claw-head replacement

• N.1 Brass rod magnet to remove Wedges

8

A44-P

3. SAFETY

3.1 GENERAL WARNINGS

• The manufacturer, during the design and manufacturing stages, has paid special aenon to the aspects that might

jeopardize the safety and health of the personnel that operates the machinery. As well as the compliance with current

regulaon on the maer, the manufacturer has adopted all the “rules of good crasmanship”. The purpose of this

informaon is to make the user aware to pay special aenon in order to foresee any risk. There is no substute for

carefulness. Safety also lies in the hands of all operators that work on the machinery.

• Carefully read the instrucons of the manual supplied with the machinery and the ones directly ed on the machinery,

especially the ones concerning safety. A lile me dedicated to the study of this manual will prevent unpleasant accidents.

• Pay aenon to the meaning of the symbols of the plates ed on the machinery; their shape and colour are important

for safety purposes. Keep them readable and comply with their informaon.

• Do not tamper with, do not dodge, eliminate or bypass the safety devices installed on the machinery. The non compliance

with this requirement may cause serious risks for personnel’s safety and health.

• The personnel that carries out any type of operaon during the enre useful life of the machinery must have specic

technical competence, special skills and experience acquired and acknowledged in the specic sector. The lack of these

requisites may jeopardize the safety and health of personnel.

• During operaon only use the personal protecon clothes and/or devices listed in the instrucons supplied by the

manufacturer and the ones provided for by current regulaons on safety at work.

• During the normal use or for any intervenon, keep the surrounding area in adequate condion, especially the one

accessing the controls, in order to avoid jeopardizing the safety and health of personnel.

• The operator, as well as being adequately informed on the use of machinery, must possess skills and competence adequate

to the type of working acvity to perform.

• The machine must only be used for the applicaons intended by the manufacturer. Only use the machinery for the

purposes intended by the manufacturer. The employment of the machinery for improper uses may cause risks to the

safety and the health of personnel and economic loss.

• Provide appropriate containers to stock the pieces you will be working with.

• Keep your foot o of the pedal and disconnect the main air supply while performing any machine maintenance .

3.2 SCHEDULED USE

The Machine is designed and built to execute juncons of frames.

The machine is projected for manual use only (under operator control).

3.3 INADVISABLE USE

The machine can not to be used:

• For uses dierent from those listed in 3.2 paragraph • Outside in all weather severity

• In an explosive or aggressive atmosphere where there is a high

density of dust or oily substances suspended in the air

• For molding to be assembled not suitable with the

machine’s characteriscs.

• In a ammable atmosphere

3.4 DANGEROUS AREAS

The area of frames assembly is dened as the “working

area”

The dangerous areas of machine, include the movable

parts and surrounding zones.

Figure 3.4.A - Working area and dangerous zones

Dangerous Area

9

A44-P

3.5 PROTECTION DEVICES

The machine is equipped with protecon shield for persons exposed to the risks due to the transmission of mobile elements

taking part in working (driver blade, horizontal clamp, vercal clamp).

3.6 STOP MODE

Uncontrolled stop It is obtained by disconnecng the quick connect ng from the main air supply.

Controlled stop It is obtained by liing the foot from the pneumac pedal not allowing the horizontal clamping

3.7 SAFE WORKING PROCEDURES

The machine is projected and realized to eliminate any risk connected with its use.

The user is requested to achieve an adequate training to be instructed by their distributor.

The other risks related with using the machine are:

• Finger crushing in the frontal and vercal clamp working area

It is necessary to carefully follow the following instrucons:

1. Keep the ngers away from frontal and vercal clamp working areas

2. Disconnect the air pressure and during any maintenance intervenons

3. Keep the foot away from the pedal during machine maintenance

3.8 DESCRIPTION OF SAFETY SIGNS

Some of these signals are applied on the machine. Their meaning is specied on their side.

Make sure that the plates are perfectly readable, otherwise replace them with new ones to be ed correctly in place

Adhesive sign concerning the finger danger zone

4. HANDLING AND INSTALLATION

4.1 HANDLING

The personnel in charge of loading, unloading and moving the machinery

must possess the skills and experience acquired and acknowledged in the

specic sector, and must thoroughly know the liing means to be employed.

The machine has to be shipped in a safe way to avoid any damage to its parts

• All the protecons and guard devices must be properly closed and

locked.

• The machine has to be shipped like it is posioned for installaon.

• Before the shipment it is necessary to lubricate the parts which are

not painted.

• According to the type of shipment, it is necessary to protect the

machine from any jarring impact or stress

Machine total weight: about 90 Kilos / 198 lbs

Lifting must be done by using a specific device.

10

A44-P

4.2 WAREHOUSING AND STORAGE PROCEDURES

• In order to avoid that the components cause dangers or are damaged, the storage area must be covered (preferably a

closed area) and accessible only for authorised personnel.

• Avoid corrosive materials that could touch the machine

• Lubricate the parts which are not painted or chromed.

4.3 UNPACKING

According to the installaon requirements, the personnel authorised by the manufacturer will unpack the components in the

most suitable way and will check their integrity. Keep all packages (carton box, pallets, etc.) for future use and dispose of the

protecon materials (nylon, polystyrene, etc.) according to the laws in force.

4.4 PRELIMINARY ARRANGEMENTS

In order to install the machine it is necessary to prepare a working area (a table) adequate to the machines dimensions and

the length of moulding you will be working with. To fulll the characteriscs of precision and steadiness, the bench frame

assembling machines must be posioned on a solid and leveled plane able to sustain the weight of the machine. The bench

must be studied and prepared by the customer and/or qualied sta.

4.5 PNEUMATIC CONNECTION

The machine is controlled by a foot pedal that allows the acvaon of frontal clamp and by a joysck that controls the vercal

clamping snd wedge inseron.

Screw the supplied manometer in the air lter lubricator placed on the oor stand right side (see pict. 4.6.1.1).

Picture 4.6.1.1

Use the supplied fast clutch ng to connect the air compressed system. You could use also another ng suitable with

your pneumac system (see pict. 4.6.1.2 and 4.6.1.3).

Picture 4.6.1.2 Picture 4.6.1.3

Once connected the machine with the pneumac system, check the funconing of the 2 posions foot pedal and that of the

Wedges ring lever (2 posions control lever).

The proper funconing of the foot pedal is the following:

• when the foot pedal is PRESSED HALF WAY it acvates the horizontal clamp

A

B

11

A44-P

The manual control lever with 2 posions buon acvates the following

commands:

• Pressing the foot pedal it acvates the locking of the horizontal clamp;

• Pressing pushbuon half-way down, it acvates the vercal clamp

and the posion brake;

• The Pushbuon pressed full down acvates the wedge driving.

Check that pressure value showed on the pressure dial (B) of the lubricator/reducer filter is between

6 and 8 Bar (see picture 5)

DO NOT adjust by using the A regulator of lubricator/reducer filter (see 4.6.1.1)

4.6 PRELIMINARY CONTROLS

Before setting up the machine, execute checks to prevent mistakes or accidents during setup.

• Verify that machine has not been damaged.

• Verify the pipes integrity

4.7 MACHINE ARRANGEMENT

4.7.1 Wedges magazine loading

To load the wedge magazine proceed as follows:

• Move the claw pusher backwards by ipping the special

lever located on the right side of the machine working

bench. This will give you access to the nail magazine (see

pict. 4.7.1.1).

Picture 4.7.1.1

• Insert one or more nail strips into the magazine. Make sure that the sharpened edge of the nails (glue side) faces up and

that they are loaded with the V of the nails pointing in the direction indicated in the figures 4.7.1.2 and 4.7.1.3. Check to

see if the nail size is suitable with the type of claw head mounted.

Picture 4.7.1.2 Picture 4.7.1.3

• Move the claw pusher forward by flipping the control lever (see pict. 4.7.1.1)

12

A44-P

4.7.2 Nail guide head replacement to change Wedges size

The nail guide head must be changed each me you use nails of dierent sizes. Proceed as follows to replace it:

• Loosen the locking screw of the nail guide head using the proper

5 mm Allen wrench (the screw is on the opposite side from the

nails magazine(See pic. 4.7.2.1)

• Take out the nail guide head

Picture 4.7.2.1

• Move the clawpusher backwards (as per par. 4.7.1).

• Remove all the nails that are sll in the magazine (using the proper

brass magnet, if necessary). See pic. 4.7.2.2.

Picture 4.7.2.2

• Insert the new nail strip (of desired height) into the magazine

• Close the magazine (as per par. 4.7.1).

• Insert the new size nail guide head to match the nails you will be

using (see pic. 4.7.2.3).

• Tighten the locking screw of the nail guide head (see pic. 4.7.2.1).

Picture 4.7.2.3

13

A44-P

4.8 ADJUSTMENTS

The machine has been completely tested and checked in Alfa Automaon plants before its shipment. All the operator

has to do is perform the following adjustments:

4.8.1 SengstopsforWedgesposioning

The working stroke of the driver blade is adjusted by 2 stop

handles posioned on a measurement gauge (see g. 4.8.1).

The stop located inside the hand lever (operator side), refers

to the Wedges rear posion; the located in front of a.m. lever

refers to the Wedges external posion.

The carriage with the driver blade is posioned by shiing the

handle from the eternal posion to the rear one.

Picture 4.8.1

4.8.2 Vercalclampadjustment

The vercal clamp posion can be adjusted by the side-handle. Proceed as follows to posion properly the vercal clamp:

• Loosen the side clamp (see picture 4.8.2.1) by using the

handle and adjust the pressure pad height over the frame

(it is advisable to adjust an height between 5 and 8 mm

to avoid any accidental ngers crushing).

• Tighten the handle once reached the proper posion

• Acvate the vercal clamp by pressing half way the foot

pedal and then the control buon or pressing full down

the full pedal.

• Check that the mouldings to be assembled are properly

clamped.

Picture 4.8.2.1

4.8.3 Horizontalclampadjustment

The Frontal Clamp (horizontal clamp) has a series of holes in the flat bar (see Pict. 4.8.3.1) that lock into a peg in the

front channel. Lift the bar to take it out of its initial position and make it move forward and backward.

To lock the bar it is sufficient to insert it into the proper peg located at the centre of the guide channel.

Proceed as follows to position the Horizontal Clamp correctly:

• Remove the bar from the peg (lifting it by about 10-15

mm) and move it forward up to reach the mouldings to

be assembled;

• Lower the bar to allow the insertion of tracking screw

and the locking in the next position.

Picture 4.8.3.1

14

A44-P

In case of continued use without needing to remove the frontal clamp from its position, it is possible to

fix it into the peg using the proper screw.

When shipping the machine it is advisable to lock down the frontal clamp by using the supplied knob.

4.8.4 Fencesadjustment

Machines are equipped with a fence composed by two separate parts.

Each part of the fence (right and le) is equipped with a knob that allows the lng of supports.

The use of this fence is suggested for working frames with irregularies or lile cambers on the external side.

If once the frontal clamping is inserted, the combining of the mitres is not perfect, the lng fence can compensate such a fault.

For 90°(4 sided frames), 120°(6 sided frames) or 135° (8 sided frames) juncons, seng properly the two fence supports

(see g. 18-19-20).

To modify the posion of the two fence supports, proceed as follows:

• Remove the external screw by using the 5 mm Allen

wrench

• Release the internal screw and shi the fence up to reach

the holes located on the working bench

The exact posion of fence supports can be obtained with the

help of a special fence.

Make sure that the 120° or 135° angle formed by the two

supports is exactly centered on the internal vertex of Wedges

claw head.

Picture 4.8.4.1

4.8.5 Protecveshieldadjustment

The machine is equipped with a protecve shield (see pict. 4.8.5.1) made of transparent plasc material, to avoid the operator

accidental ngers crushing.

Proceed as follows to adjust the protecon shield:

• posion the mouldings to be assembled on the working

bench

• loosen the screw shaped handle xing the protecon

and li or lower it at an height of about 6-8 mm from

mouldings to be assembled;

• ghten the screw shaped handle to lock the protecon

shield.

Picture 4.8.5.1

The protection shield opening, effected by its overturning, causes the control pedal deactivation.

Even if the protective shield is properly adjusted, it is necessary following instructions listed below:

• Keep the ngers away from the frontal and vercal clamp working area.

• Disconnect the pressure supply during any maintenance intervenon.

• Keep your foot off of the pedal while adjusting the machine.

4.8.6 Workingpressureadjustment

The working pressure must be adjusted to the hardness of the mouldings to be assembled.

15

A44-P

The pressure regulaon allows you to change the clamping pressure

of mouldings to be assembled.

Too high of a working pressure can cause a poor juncon and

(especially on small-size frames) the moulding could be crushed.

Too low of a working pressure can cause an incomplete inseron

of the nail into the frame.

The working pressure is adjusted by means of the regulator on the

panel (see g. 19).

Proceed as follows to adjust the working pressure:

1. Pull up the regulator cap by about 3÷4 mm. This will unlock it.

2. Turn it clockwise to increase the pressure and counter-clockwise

to decrease it.

3. Push the regulator cap back down to lock it into position

Picture 4.8.6.1

DO NOT ADJUST the pressure if the machine is not connected to the air supply.

The suggested pressures are:

Soft woods (samba,........) 1.5 - 2.0 Bar

Medium (ramin,........) 2.0 - 3.0 Bar

Very hard woods (oak, MDF) 3.0 - 5.0 Bar

The above listed values apply to 7 and 10 mm high Wedges.

Increase the pressure by 10 % for 15 mm high Wedges.

When stacking 2 or more Wedges, increase the working pressure by 10/15 %.

In order to allow an easy use of the machine lted back ,the A44-P is

equipped with a ballast cylinder with a regulator (Pict. 4.8.6.3) and a surge

tank (located on the oor stand) that provide an air cushion to balance

the weight of internal components when the machine is lted.

To obtain an oponal regular balancing, set the pressure at:

• 0 BAR, when the machine is flat

• 1,0÷1,2 BAR, when the machine’s tilted

Picture 4.8.6.3

DO NOT ADJUST other pressure regulator not described in this manual: keep them as set at the mfactory

to avoid machine malfunctions.

16

A44-P

4.9 ITEMS TO BE PERFORMED BEFORE OPERATING THE MACHINE

Once the machine has been properly installed (as previously described), check that:

• The magazine is loaded with the type of Wedges suitable with the mouldings to be assembled

• The adjustment of the vercal and horizontal clamps are correct (chapter 4.8.2 and 4.8.3)

• The protecve shield is properly posioned (see chapter 4.8.5)

• The working pressure is adequate to the wood hardness (see chapter 4.8.4)

• The mouldings to be assembled are properly posioned on the work bench

• Pressing down the pedal to acvate the frontal clamps so to hold the frame properly

• Move the posion handle to the inserng posion and press half-down the pushbuon to acvate the brake and the

vercla clamp

Press the pushbutton all the way down to insert the wedge

If you want to insert 2 or more wedges one upon the other in the same position, you must release the

pushbutton until halfway and then press it full down again to insert the second wedge

5. OPERATING MODES

5.1 OPERATORS

The machine has been designed to be used by only one operator.

The operator, as well as being adequately informed on the use of machinery, must possess skills and competence adequate

to the type of work to be performed.

Even aer being adequately informed, during the rst use, if necessary, simulate some operang maneuvers to idenfy the

controls, especially the ones for starng and stopping the machinery and their main funcons.

How to operate in case of emergency , where to nd the individual protecon means and how to use them properly.

5.2 DESCRIPTION OF FUNCTIONS

The machine has only one possible operating mode:

• manual mechanic functioning by using the pneumatic foot pedal and the manual joystick.

Press the foot pedal down: the horizontal clamp is acvated.

The handle/joysck allows the shi of posioning of Wedges ring group. According to the use of the foot pedal, the joysck

allows several operaons:

If the foot pedal is pressed down:

• pressing the buon half way, the vercal clamp and the brake are acvated

• pressing the buon full down, the Wedge is red.

To make a junction, the operator must proceed as follows:

1. position the mouldings to be assembled on the machine

working bench

2. set the insertion limits by mean of the stops along the

joystick stroke

3. adjust the horizontal clamp position

4. adjust the vertical clamp height

5. press down the foot pedal to activate the frontal clamp

6. shift the joystick on the 1st inserting point

7. press the button half way to activate the vertical clamp

8. press the button full down to insert the Wedge

Take care: if you want to stack 2 or more Wedges in the same position, you must release the button up

to half way and then press again it full down to insert the 2nd Wedge and so on.

9. completely release the button to rearm the driver blade

and release the brake on position

10. shift the joystick in the next inserting point

11. repeat the steps 6, 7, 8, 9 and 10.

17

A44-P

When working with big sized frames, on the machine can be mounted

a working bench extension (metal or wooden), and it can work in

tilted position.

Usually, when the machine is tilted back, the operator working position

is opposite to the normal one.

To tilt back the machine, operate as follows:

• loosen the handle located on floor stand right side (pict. 5.2.1-A)

• tilt the machine up to reach the desired angle (pict. 5.2.1-B)

• tighten the handle to lock the machine in position.

Picture 5.2.2

A44-P in lted posion with metal extension arms

Picture 5.2.1

5.3 TIPS FOR QUALITY JUNCTIONS

a) Wedge types

In order to allow the machine to make excellent quality joints using different materials, it has been necessary to manufacture

different Wedges types for different uses (see attachment D).

Wedges can be classified in three different groups:

Material Suggested code Color Ref.

soft materials (wood, soft plastic) SW Green

for medium materials (wood, ...) MW Gray

for hard materials (wood, MDF, HDF) HW Red

b) Assembling positions

It is advisable to operate as follows in order to achieve the best results in terms of junction quality:

• Never drive Wedges near the external vertex. The minimum recommended

distance from the external vertex is at least 10 mm.

• When you want to make the junction using only one Wedge, the most suitable

position is in the middle of the moulding (see fig. 21)

• In case you want to insert 2 or more Wedges into each junction, we recommend

you to insert the most external one 1/3 from the external vertex and the most

internal one 1/4 from the internal vertex (not less than 5mm).

picture 5.3.1

5.4 MACHINE STOP

To stop it, lift your foot from the pedal.

It is possible also to disconnect the quick connect fitting from the air supply.

In case on long inactivity periods it is necessary to disconnect the quick connect fitting from pneumatic system.

6. MAINTENANCE

6.1 RECOMMENDATIONS FOR MAINTENANCE

Carry out maintenance or repair operations with the machine isolated from air supply, as indicated by the Manufacturer.

18

A44-P

Before performing any cleaning intervention, the operator must disconnect the air supply

During the maintenance or repair operaons is suggested to proceed as follows:

• Before starng any operaon place a sign “machine under maintenance” in a well visible posion.

• Do not use solvents or ammable materials

• Do not step on the machine parts, because they have not been projected to sustain the weight of persons.

• Put on a pair of safety glasses.

• Once all the operaons are nished replace any protecons and shields you removed or opened.

6.2 CLEANING THE MACHINE

The machine is of simple construcon and the mechanical parts do not require any special maintenance.

Keep the machine in maximum eciency condions and perform all the scheduled maintenance operaons provided by the

manufacturer. Good maintenance will result in beer performance, a longer operang life and keep the safety requirements

unchanged over me.

Follow the rules listed below:

• Regularly remove glue or other residues from the wedges claw-head and from the upper part of the driver blade;

• Always keep the wedge magazine clean and without residues.

• Remove any residues from the wedges guide “L” shaped support.

• Do not use water to clean the machine, otherwise metallic parts may rust.

6.3 ROUTINE MAINTENANCE OPERATION

Frequency Ispecon Acon

Every 1.000.000 wedges shot wedges driver blade Replace

Every 300 working hours Movable parts lubricaon Lubricate

Every 5.000.000 wedges shot Wedges claw-heads Replace

Every 5.000.000 wedges shot “L” shaped supports (wedges guide) Replace

20 million of wedges shot Valves and Reducers Check and in case, replace

Every 6.000.000 wedges shot Frontal and vercal clamping gaskets Replacement in case of leak of air

6.4 RECOMMENDED OIL

Use CASTROL MAGNA GC 32 or equivalent oil

Unsuitable lubricants may cause valve seal problems (seals may become too large) and consequent Valve

jamming.

7. DIAGNOSTIC

7.1 SAFETY WARNINGS

The intervenons must be executed by personnel properly trained for this specic machine and they must take all precauons

in order to avoid accidental starts.

During the tests, it is suggested to remove the vercal clamp assembly or posion it to its full upwards posion.

19

A44-P

TABLE 7. 2 - A

TROUBLE POSSIBLE CAUSE REMEDY

Pressing the foot pedal the Wedges

ejection is irregular

Insufficient working pressure • Check that the minimum value indicated from

main regulator is higher than 3 Bar

Wedges wrongly positioned into the

magazine

• Check that the Wedges sharpened side (glue

side) faces up

• Check that Wedges V vertex is pointing toward

machine’s external side

Guide channels damaged or jammed • Check that the guide channels are not dirty

or jammed

Claw pusher has insufficient thrust

• Check that the pressure of the regulator feeding

the claw pusher cylinder is at least 2 Bar. If

necessary, increase it by 10%.

Claw head not suitable with Wedges

size

• Check that the number engraved on the wedge

claw head match the Wedges size

Faulty Wedges • Replace the Wedges

Insufficient working pressure • Check that the air pressure coming out from

the compressor is at least 3 Bars.

Opened Wedges magazine • Close the magazine by means of the special

lever

Faulty valves • Replace the foot pedal valve

• Replace the control valves

Pressing the foot pedal for several times

the machine’s working that was correct

at the beginning becomes irregular later

Jammed valves because of surplus

of oil or condensation

• Remove the surplus of oil and condensation

from the valves by disconnecting the air lines

one by one . This will force out the oil/water.

Pressing the foot pedal the working

pressure indicated on the regulator

deeply decreases

Faulty pressure regulator • Replace the regulator

Air supply line too long or of

inadequate diameter

• Replace the air line with a new one of bigger

diameter

Pressing the foot pedal the machine

works properly, but once the pedal is

released you can note a certain delay

in the re-positioning of the driver blade

and/or vertical clamp cylinders

Faulty or jammed valves

• Remove the surplus of oil and/or condensation

• Replace the foot pedal valve

• Replace the faulty control valves

Wishing to insert several Wedges one

upon the other in the same point, they

do not stack properly or tilt during their

insertion

Unsuitable Wedges • Replace the Wedges with suitable ones

Poor frames clamping (the frame

moves during the Wedge insertion)

• Check and reposition the vertical and frontal

clamps

• Increase the pressure by using the regulator

• Replace the pressure pad with the proper one

Wore and torn driver blade • Replace the driver blade

Jammed driver blade • Clean the driver blade’s upper part by removing

any material jamming the upper profile

7.3 TECHNICAL SERVICE REQUEST PROCEDURES

For any requirement, please contact the Manufacturer’s Customer Service.

For any request for technical service, list the data on the idencaon plate, the approximate number of hours the machinery

has been used and the type of malfuncon.

E_Mail: [email protected]

FAX: +39-0543-480770

Via Selva, 23/25 - 47122 Forlì - Italy

In the USA please contact:

E_Mail: [email protected]

FAX: 248-851-8777

31874 Northwestern Highway

Farmington Hills, MI 48334

20

A44-P

8. SPARE PARTS

8.1 SPARE PARTS LIST

Even though the machine has been submitted to several tests and functional checks, we listed below the components that

we suggest you to have a minimum and sufficient set of. This will help guarantee the shortest possible downtime.

TABLE 8.1 - A

COMPONENT

• WEDGES DRIVER BLADE

• WEDGES CLAW-HEADS

• “L” SHAPED SUPPORT (WEDGES GUIDE)

• VALVES-REDUCERS-REGULATORS

• VERTICAL AND HORIZONTAL CLAMPING

• GASKETS

8.2 SPARE PARTS ORDERING

We remind you that only a qualied technician can repair the machine.

Therefore we suggest the intervenon of your local distributor or A-Plus Automaon Center of Technical Assistance, which

has access to qualied sta, proper equipment and tools, and who uses original spare parts.

To order the above spare parts, send the following data by fax, e-mail or leer:

• Model of the Machine

• Code of drawing scheme

• Reference number of spare part or group indicated on the mechanical drawing

• Code number of single or group spare part

9. MACHINE DEMOLITION

9.1 MACHINE DEMOLITION

When scrapping the machine, group components by chemical composion and dispose of separately in accordance with

applicable legislaon. Do not dispose of non-biodegradable materials, lubricant oils and non-ferrous arcles (rubber, PVC,

plascs etc.) in the environment.

10. ATTACHMENTS

10.1 DECLARATIONS

You can nd here aached the following declaraons

• Declaraon of conformity to the Norm 89/392/CEE

10.2 SCHEMATICS

You can nd here aached the following schemes:

• (A) Mechanical Schemac

• (B) Pneumac Schemac

• (C) Plate locaons

• (D) Sharpening Table

Table of contents

Other A-PLUS AUTOMATION Industrial Equipment manuals