ABB Automation Inc.

Instrumentation Division

125 E. County Line Road

Warminster, PA 18974 USA

Tel: +1 215-674-6000

Fax: +1 215-674-7183 ABB Automation

Customer Support

ABB Instrumentation provides a comprehensive after sales service via a

Worldwide Service Organization. Contact one of the following offices for details on

your nearest Service and Repair Centre.

United Kingdom

ABB Kent-Taylor Limited

Tel: +44 (0)1480 475321

Fax: +44 (0)1480 470787

United States of America

ABB Instrumentation Inc.

Tel: +1 716 2926050

Fax: +1 716 2736207

Client Warranty

Prior to installation, the equipment referred to in this manual must be stored

in a clean, dry environment, in accordance with the Company's published

specification. Periodic checks must be made on the equipment's condition.

In the event of a failure under warranty, the following documentation must be

provided as substantiation:

1. A listing evidencing process operation and alarm logs at time of failure.

2. Copies of operating and maintenance records relating to the alleged faulty

unit.

Use of Instructions

Although Warning hazards are related to personal injury, and Caution hazards

are associated with equipment or property damage, it must be understood that

operation of damaged equipment could, under certain operational conditions,

result in degraded process system performance leading to personal injury or

death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient

operation of our equipment. Use of this manual for any other purpose is

specifically prohibited and its contents are not to be reproduced in full or part

without prior approval of Technical Communications Department, ABB Kent-Taylor.

Health and Safety

To ensure that our products are safe and without risk to health, the following

points must be noted:

1. The relevant sections of these instructions must be read carefully before

proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out

by suitably trained personnel and in accordance with the information

given.

4. Normal safety precautions must be taken to avoid the possibility of an

accident occurring when operating in conditions of high pressure and/or

temperature.

5. Chemicals must be stored away from heat, protected from temperature

extremes and powders kept dry. Normal safe handling procedures must be

used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual

or any relevant hazard data sheets (where applicable) may be obtained from

the Company address on the back cover, together with servicing and spares.

Series 2000 Pressure Transducer

The Company's policy is one of continuous product

improvement and the right is reserved to modify the

information contained herein without notice.

© ABB 1997 Printed in UK (6.97)

ABB Instrumentation Ltd.

St. Neots,

Cambs.

England, PE19 8EU

Tel: (01480) 475321

Fax: (01480) 217948

IM/2000 Issue 1

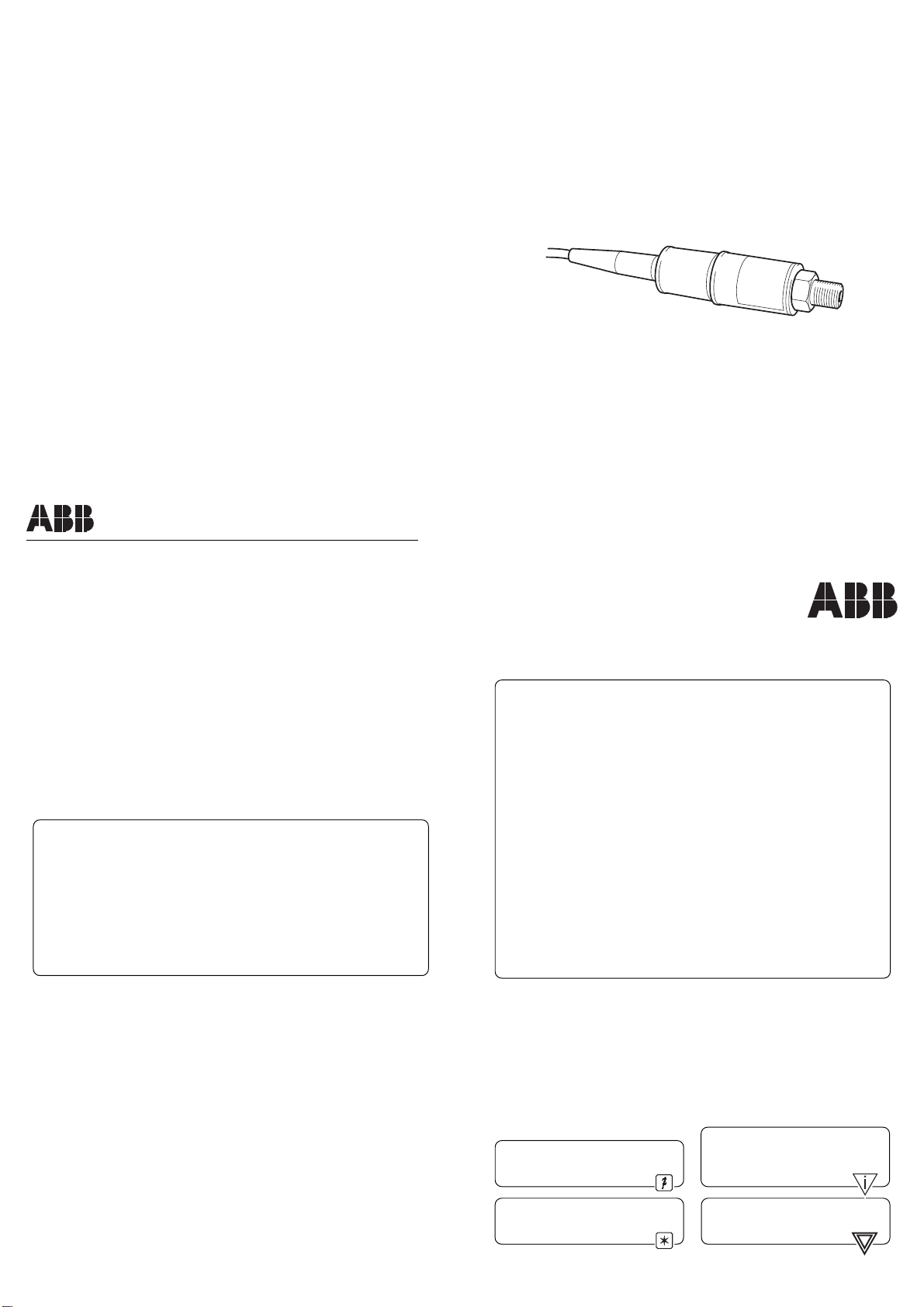

Warning.

An instruction that draws attention

to the risk of injury or death.

Caution.

An instruction that draws attention

to the risk of damage to the product,

process or surroundings.

Note.

Clarification of an instruction or

additional information.

Information.

Further reference for more detailed

information or technical details.

User Guide