CONTENTS

PRODUCT

ACS5000W gen. 2

DOCUMENT KIND

User manual

DOCUMENT ID.

3BHS799208 E01

REV.

J

LANG.

en

PAGE

5/186

5.4.5. Installation material.............................................................................................................67

5.4.6. Tools ........................................................................................................................................67

5.5. Preparing the installation site...................................................................................................... 68

5.6. Aligning transport units ................................................................................................................ 69

5.7. Joining transport units ................................................................................................................... 71

5.8. Applying silicone...............................................................................................................................72

5.9. Installing roof joints.........................................................................................................................72

5.10. Installing roof-mounted cooling units........................................................................................73

5.10.1. Lifting a cooling unit with a crane ...................................................................................73

5.10.2. Installing IP42 roof-mounted cooling units...................................................................74

5.10.3. Installing IP54 roof-mounted cooling units...................................................................76

5.11. Installing roof attachments on marine drives...........................................................................78

5.12. Joining water pipes.........................................................................................................................80

5.12.1. Removing a pipe joint ........................................................................................................ 80

5.13. Joining busbars ................................................................................................................................81

5.13.1. AC busbars............................................................................................................................ 82

5.13.2. PE ground busbar ............................................................................................................... 82

5.13.3. DC busbars ........................................................................................................................... 83

5.14. Connecting the heating cable ...................................................................................................... 83

5.15. Connecting raw water pipes......................................................................................................... 84

5.16. Fixing the drive to the floor .......................................................................................................... 84

6. Electrical installation ...........................................................................................................85

6.1. Safety.................................................................................................................................................. 85

6.2. Overview ............................................................................................................................................ 85

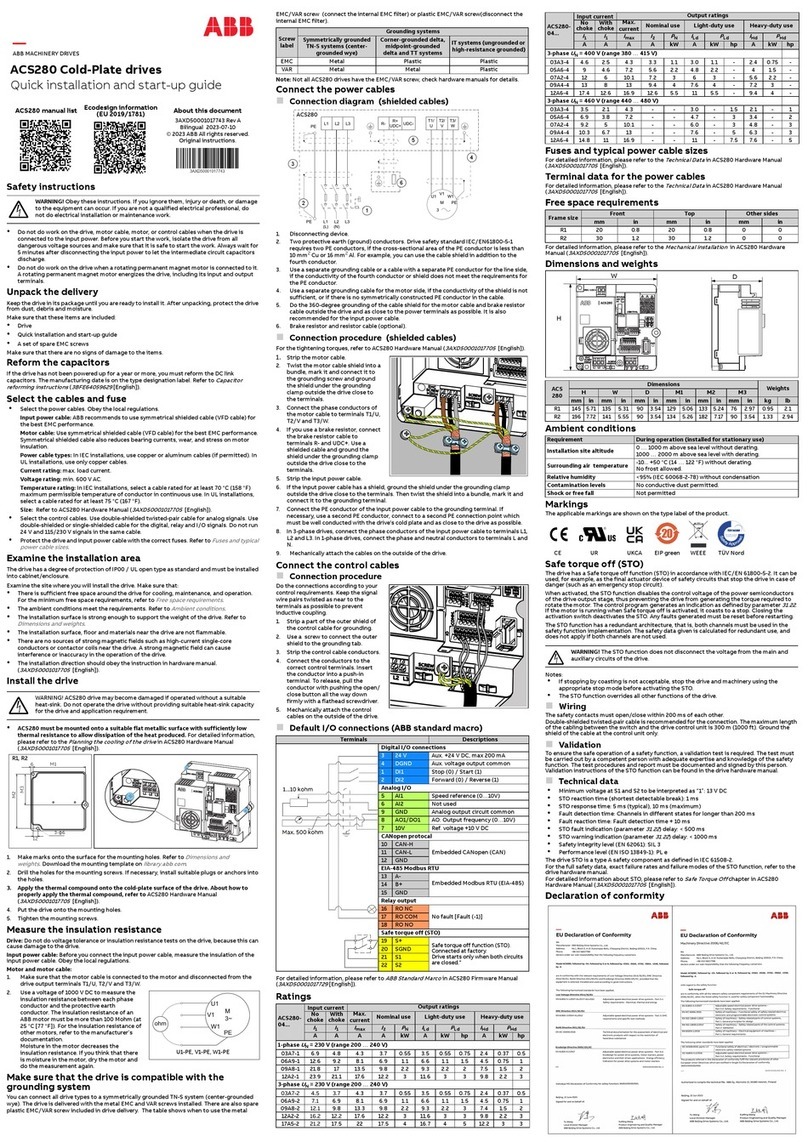

6.3. Cable requirements ........................................................................................................................ 85

6.3.1. Power cables......................................................................................................................... 85

6.3.2. Auxiliary and control cables.............................................................................................. 85

6.4. Grounding ......................................................................................................................................... 86

6.4.1. Grounding the transformer and an 18-pulse drive..................................................... 86

6.4.2. Grounding the transformer and a 36-pulse drive........................................................87

6.4.3. Grounding the drive and the motor (multi-point bonding)..................................... 88

6.4.4. Grounding the drive and the motor (single-point bonding).................................... 89

6.4.5. Ground cable connection.................................................................................................. 90

6.4.6. EXU cabinet ground connections ....................................................................................91

6.5. Internal wiring ...................................................................................................................................91

6.5.1. Optical fibers........................................................................................................................ 94

6.5.1.1. Optical fibers for internal arc protection.......................................................... 94

6.6. Cable entries..................................................................................................................................... 95

6.6.1. Cable entry with sealing modules, type 1...................................................................... 95

6.6.2. Cable entry with sealing modules, type 2 ......................................................................97

6.6.3. Cable entry with cable glands...........................................................................................97

6.6.4. Cable entry with EMC plates ............................................................................................ 98

6.7. Power cables, ground cables, equipotential bonding conductor....................................... 99

6.7.1. Preparing the cable entry and the cables ..................................................................... 99

6.7.1.1. Determining the cable length .............................................................................. 99

6.7.1.2. Preparing cables for cable entries with cable glands.................................... 99

6.7.1.3. Preparing cables for cable entries with sealing modules ........................... 101

6.7.2. Connecting the cables ......................................................................................................102

6.7.2.1. Checking the cable insulation.............................................................................102

6.7.2.2. Connecting the cables ..........................................................................................102

6.7.2.3. Bolted connections................................................................................................105