Page 2

© 2023 ABB. All rights reserved. CC1600SC55_QSG Rev 4.0

Important Safety Instructions ........................................................................................................................3

Precautions ........................................................................................................................................................4

Introduction .......................................................................................................................................................5

Installation..........................................................................................................................................................5

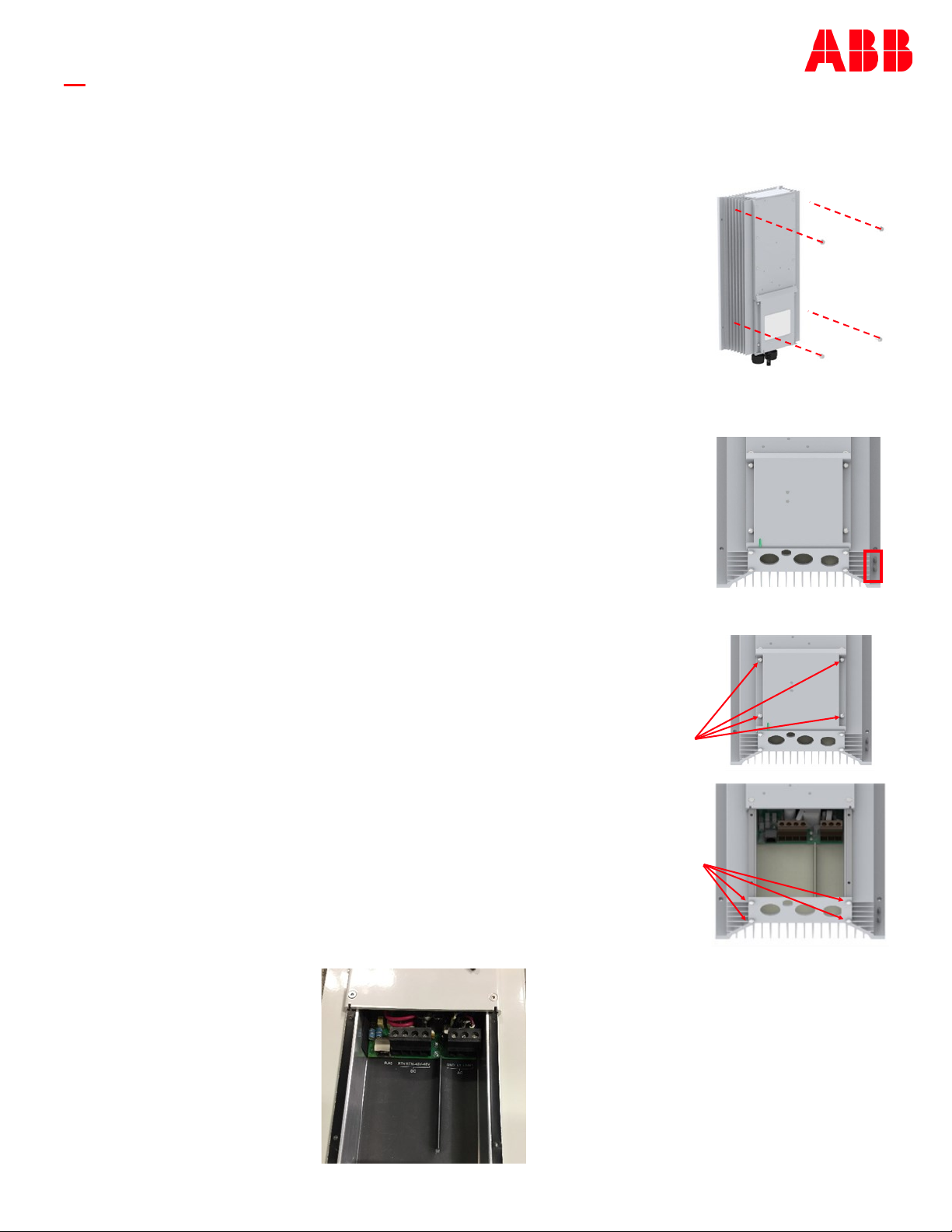

1. Prepare a Location and mounting option for the Small Cell -48V Power Source

w/ Shield Base Option. 1...................................................................................................................5

2. Mount the Solar Shield Base w/ Solar Shield Base Option 1 ......................................................5

3. Prepare a Location & mounting for the Small Cell -48V Power Source

w/ Five (5”) Elevation Option. 2.......................................................................................................7

4. Mount the Base Rectifier .................................................................................................................8

5. Ground the Rectifier ..........................................................................................................................8

6. Open the Field Wiring Compartment .............................................................................................8

7. Wire the DC Output with Panel Option #1 .....................................................................................9

8. Wire the DC Output with Panel Option #2.....................................................................................10

9. Wire the Alarms ..................................................................................................................................11

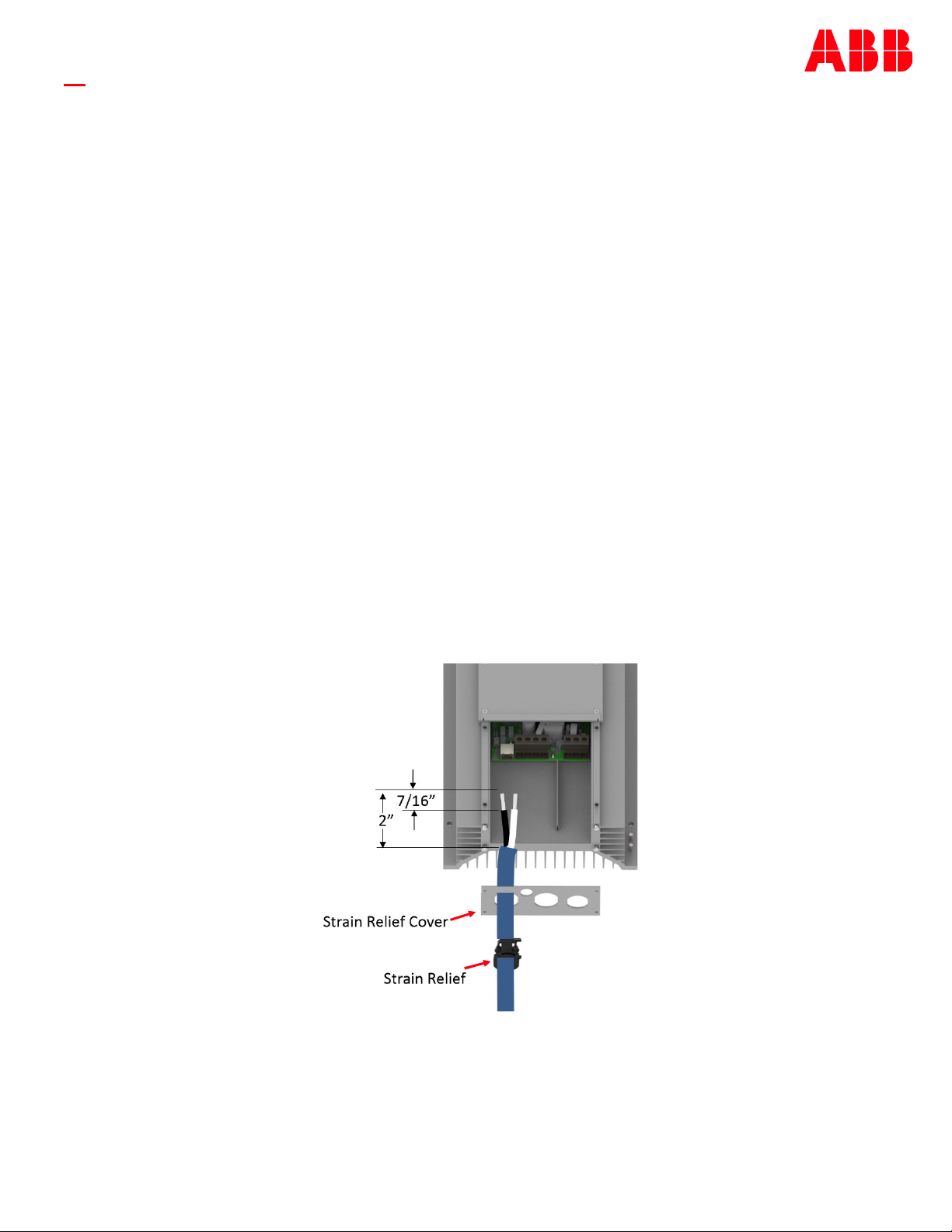

10. Wire the AC Input ...............................................................................................................................11

11. Close the Field Wiring Compartment.............................................................................................12

12. Apply AC Power and Confirm -48V Power Delivery ......................................................................13

13. Attach the Solar Shield Cover for Solar Option 1..........................................................................13

14. Attach the Solar Shield Cover for Solar Option 2..........................................................................14

Information:

Electrical Connections................................................................................................................................14

LED States ....................................................................................................................................................14

Pole Mount Bracket Detail for Option 1...................................................................................................16

Pole Mount Bracket Detail for Option 2...................................................................................................17

Parts List.............................................................................................................................................................18

Specifications & Application ...........................................................................................................................18

Reference Documents ......................................................................................................................................18

Contents