8GRIDSHIELD®3P/3SP RECLOSER

—

2 Introduction

2.1 General instructions

Please carefully read these instructions before

proceeding with installation, and refer to them

as a guide throughout the installation and initial

operation process. It is essential to keep these

instructions filed together with other instruction

books, drawings and descriptive data for the

recloser. This manual should always be easily

accessible for future reference during the

equipment’s installation, operation and maintenance.

By following these instructions, you will ensure the

proper maintenance of the equipment and extend

its useful life.

2.2 Scope of instructions

The provided instructions are of a general nature

and cover the requirements for installation, setup,

operation and maintenance of all ratings of the ABB

GridShield®3P/3SP medium voltage three-phase

vacuum recloser. However, please note that these

instructions do not cover all possible variations

and combinations of equipment and installations.

For specific information regarding installations,

please refer to the following resources:

• Bills of materials: These lists include electrical

devices and equipment.

• Single line drawings: These diagrams illustrate

power connections.

• Elementary and schematic diagrams: These

diagrams provide detailed visual representations.

• Connection diagrams: These diagrams show how

different components are connected.

It’s important to understand that these

instructions do not aim to address every possible

question that may arise during the application,

operation and maintenance of the product.

Additionally, as improvements are made to parts

and assemblies, the appearance of some parts

may differ from the illustrations. However, their

functionality will remain equivalent.

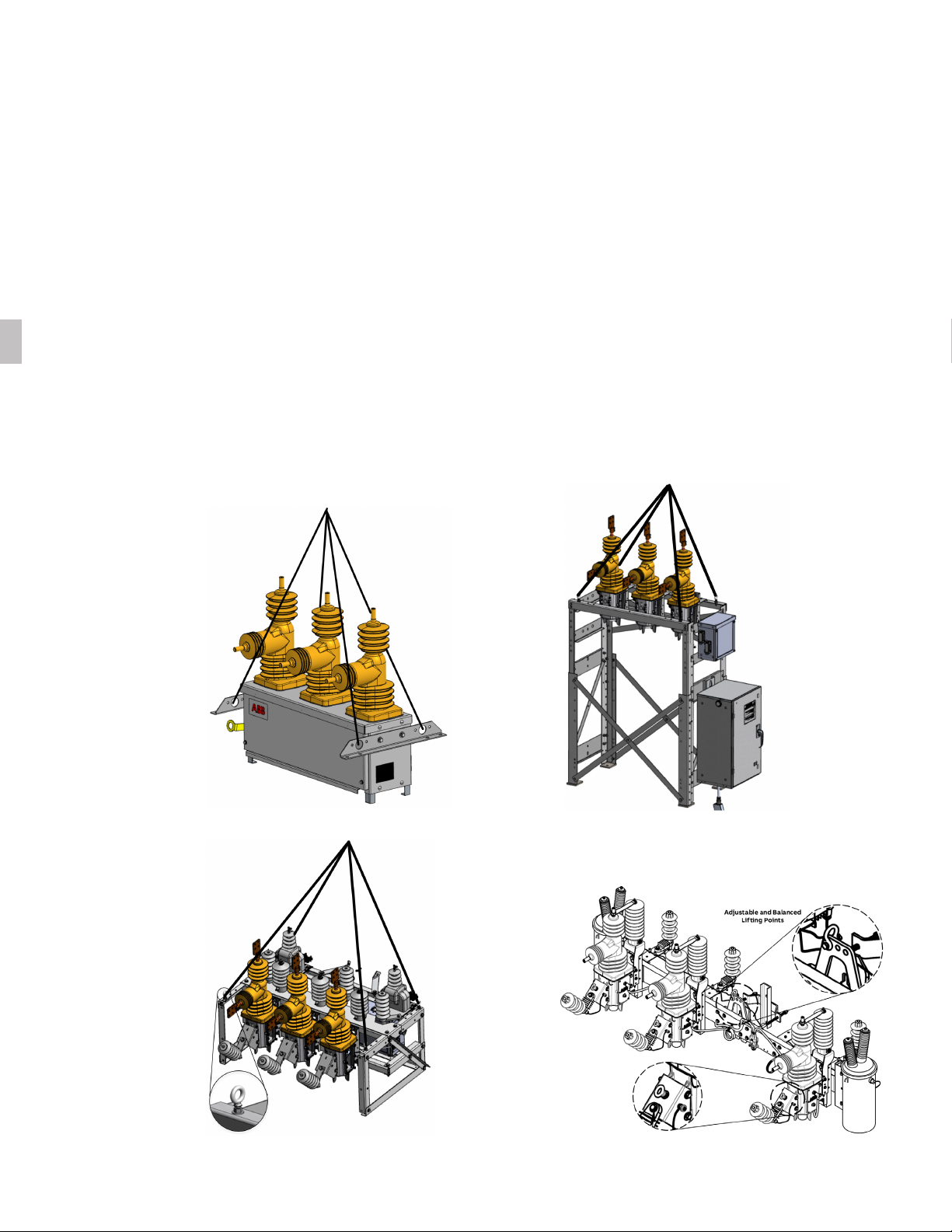

2.3 GridShield 3P/3SP recloser introduction

The GridShield vacuum recloser is an advanced

device that operates in three phases. It consists

of three vacuum interrupters, each driven by a

separate magnetic actuator. These components,

along with the voltage and current sensors, are

embedded in a pole cast from a special material

called hydrophobic cycloaliphatic epoxy (HCEP)

polymer. The current-sensing current transformer

(CT) is located in the H2 (horizontal or Y-side)

position. In a standard SVS (single voltage sensing)

unit, the voltage sensor is placed in the H2 bushing.

In a DVS (dual voltage sensing) unit, the voltage

sensors are positioned in both the H1 (vertical or

Z-side) and H2 (horizontal or Y-side) bushings

(see figure 11).

The recloser is equipped with specialized control

functions. It can detect an overload and

automatically open. After a pre-set time delay,

it will close again. If the overload persists, the

recloser will trip and reclose once more. With

the standard GridShield controls (RER620 and

RER615), the recloser can perform up to five

reclosing operations before it locks open.

Alternatively, using the optional Beckwith M-7679

or SEL-651R controls, the recloser allows up to four

reclosing operations before it goes into lockout

mode. To restore normal service, the fault causing

the condition must be eliminated.

To help ensure satisfactory performance of

the recloser, correct installation, adequate

maintenance and proper servicing of the product

are crucial. By carefully studying and following

these instructions, users can maximize the

benefits they obtain from this device.

02