TLV BT3N User manual

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 July 2013

Manufacturer

Kakogawa, Japan

is approved by LRQA LTD. to ISO 9001/14001

Bypass Blowdown Steam Trap

BT3N / MBT3N / PBT3N

Copyright © 2013 by TLV CO., LTD.

All rights reserved

1

Contents

Introduction ........................................................................ 1

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

4

5

6

8

11

15

16

19

24

27

Safety Considerations ........................................................ 2

Checking the Piping ...........................................................

Operation ...........................................................................

Specifications .....................................................................

Configuration......................................................................

Installation and Operation ................................................

Manual Operation.............................................................

Maintenance.....................................................................

Disassembly / Reassembly ..............................................

Troubleshooting ...............................................................

Product Warranty .............................................................

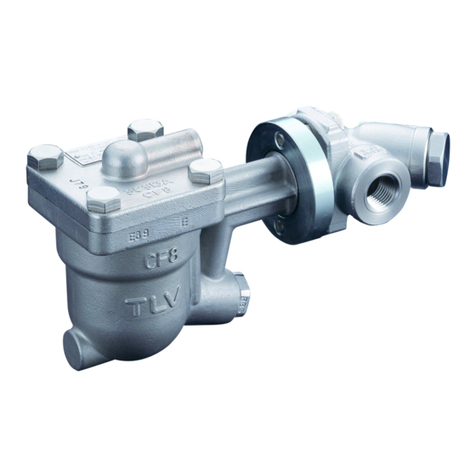

Introduction

Thank you for purchasing the Bypass Blowdown Steam Trap.

This product has been thoroughly inspected before being shipped from the factory.

When the product is delivered, before doing anything else, check the specifications

and external appearance to make sure nothing is out of the ordinary. Also be sure to

read this manual carefully before use and follow the instructions to be sure of using

the trap properly.

The Bypass Blowdown Steam Trap features a combination of: the most reliable

of steam traps, the free float; a compact ball valve, with superior long-lasting sealing

properties; and an actuator unit (electric, pneumatic).

The following models are contained in this manual:

BT3N: Steam trap with an integrated compact bypass blowdown ball valve with a

manual operation handle

MBT3N: Steam trap with an integrated compact bypass blowdown ball valve with an

electric actuator

PBT3N: Steam trap with an integrated compact bypass blowdown ball valve with a

pneumatic actuator

If detailed instructions for special order specifications or options not contained in this

manual are required, please contact for full details.

This instruction manual is intended for use with the model(s) listed on the front cover.

It is necessary not only for installation but for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for future

reference.

2

Safety Considerations

•Read this section carefully before use and be sure to follow the instructions.

•Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

•The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

•The three types of cautionary items above are very important for safety: be sure to

observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage occurring

as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGE

R

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING Indicates that there is a potential threat of death or serious injury

CAUTION Indicates that there is a possibility of injury or equipment / product

damage

WARNING

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

DO NOT use this product in excess of the maximum operating

pressure differential.

Such use could make discharge impossible (blocked).

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the discharge

of fluids.

CAUTION

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Safety cautions continued on next page

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

3

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes

to the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

Do not stand on or apply body weight to the handle.

The handle may break, resulting in injury or other accidents.

Make sure the power supply is OFF before carrying out work

on the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger that

equipment may malfunction or electric shock may occur, leading to

injury or other accidents.

Make sure that wiring work requiring a special license is

carried out only by qualified personnel.

If carried out by unqualified personnel, overheating or short circuits

leading to injury, fires, damage or other accidents may occur.

CAUTION

When using this product, NEVER stand close to, or leave

tools anywhere near moving parts such as the shaft.

Contact with moving parts or objects becoming caught in moving

parts could lead to injury, damage or other accidents.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

4

Checking the Piping

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Check to make sure that the pipes to be connected to the trap have been installed

properly.

1. Is the pipe diameter suitable?

2. Has sufficient space been secured for maintenance? (Refer to step 3. in the

“Installation” section.)

3. Are the inlet and outlet connections on the same horizontal plane?

4. Have maintenance valves been installed at the inlet and outlet? If the outlet is

subject to back pressure, has a check valve (TLV-CK) been installed?

5. Is the inlet pipe as short as possible, with as few bends as possible, and installed

so the liquid will flow naturally down into the trap?

6. Has the piping work been done with the proper methods, shown in the figures

below?

Requirement Correct Incorrect

Install catchpot with the

proper diameter.

Diameter is too small.

Make sure the flow of

condensate is not obstructed.

Diameter is too small and inlet

protrudes into pipe interior.

To prevent rust and scale

from flowing into the trap, the

inlet pipe should be

connected 25 - 50 mm above

the base of the T-pipe.

Rust and scale flow into the

trap with the condensate.

When installing on the blind

end, make sure the flow of

condensate is not obstructed.

Condensate collects in the

pipe.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

5

Operation

1. At start-up, the bypass blowdown valve can be

opened to allow a large quantity of condensate

to be rapidly discharged, minimizing the time

required for the unit to warm up. The bimetal

holds the float away from the orifice so that

initial air in the trap chamber is also

discharged.

Bypass Valve:

Opened

2. After the blowdown operation ends, the

bimetal strip retracts and the valve closes, the

float automatically adjusts the valve opening in

response to the fluctuation in load, and the

condensate is continuously discharged –no

condensate will accumulate ahead of the

steam trap.

Bypass Valve:

Closed

3. When the amount of condensate flowing into

the chamber decreases, the float gradually

closes the orifice. Steam leakage is prevented

through the use of a 3-point seating design

and the water sealing of the valve. Normally

the bimetal remains retracted and has no

effect on the operation of the float, but if air

should accumulate in the trap and the

temperature drops, it extends, forcing the float

up and the air is automatically vented.

Air, Condensate

Steam

Condensate

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

6

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

DO NOT use this product in excess of the maximum operating pressure

differential; such use could make discharge impossible (blocked).

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Steam Trap Body

Refer to the product nameplate for detailed specifications.

Model

Maximum Allowable

Temperature* (TMA)

Maximum Allowable

Pressure*

Nominal Diameter

Maximum Operating

Temperature

Maximum Differential

Pressure

Valve No.**

Serial Number

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

MBT3N: Motor Unit

Motor Type Reversible motor (condenser run type single-phase induction motor)

Power Consumption 52 VA (100 - 110 V), 62 VA (200 – 220 V)

Control System ON-OFF (fully open/fully closed)

Overload Protection Built-in thermal protector 120±5 °C

Direction of Rotation 90° reciprocating

Open/Close Time

(90° rotation)

3.5 seconds/50 Hz

3.0 seconds/60 Hz

Water Resistance Rainproof

Manual Override Possible when the power is OFF

Ambient Temp. Range

and Operation Cycles

(within 1 cm of the trap

cover)

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

Open Closed

AB

Operation Cycle*

A: Closed-to-open

B: Open-to-closed

1000

500

200

100

50

20

15

020 40 60 70 80

1.0 MPaG Steam

0.5 MPaG Steam

Operation Cycles (sec.)

Ambient Temp. (°C)

*“Operation cycle” is the interval

between the motor stop at the end

of one open or close operation

and the motor start at the

beginning of the next.

Example: When the ambient temperature is 40 °C, and the medium in use

is steam at 0.5 MPaG, allow for a cycle operation interval of at

least 36 seconds. When the cycle operation interval is less than

36 seconds, a thermal protector will prevent the motor unit from

operating until it cools down sufficiently.

(1 MPa = 10.197 kg/cm2)

7

PBT3N: Actuator Unit

Actuator Type Vane rotary actuator

Air Supply Pressure 0.3 - 1.0 MPaG

Air Supply Port Size Rc(PT)1/8

Control System ON-OFF (fully open/fully closed) reciprocating

Open/Close Time

(90° rotation) 0.09 - 0.8 seconds

Actuator Capacity 42 cm3

Ambient Temp. Range 60 °C or lower

Water Resistance Rainproof

Manual Override Possible in absence of motive pressure

Air Consumption

(Graph represents

consumption for one

reciprocating cycle)

1.5

1.0

0.5

00.4 0.6 0.8 1.0

(kg/cm

2

G)

Air Supply Pressure (MPaG)

46810

Air Consumption (N litre)

(1 MPa = 10.197 kg/cm2)

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

8

Configuration

BT3N

Part No. 29 (bushing)

attached only for

sizes 15 & 20 mm

Enlarged view of the

valve section

Enlarged view of the

orifice area

NOTE: Removing the handle or locknut causes degradation of the gland section seal. Do not

remove the handle or locknut except when performing a disassembly inspection.

No. Name No. Name No. Name

1 Body 11 Nameplate 21 Disc Spring

2 Cover 12 Screen 22 Gland Packing

3 Float 13 Ball 23 Washer

4 Orifice 14 Outlet Valve Seat 24 Thrust Washer

5 Orifice Gasket 15 Inlet Valve Seat 25 Washer

6 Air Vent Strip (Bimetal) 16 Spindle

7 Screw & Spring Washer 17 Gland

26 O-ring (Inlet/Outlet

Valve Seat)

8 Cover Gasket 18 Gland Gasket 27 Valve Holder

9 Cover Bolt 19 Handle 28 Locknut

10 Orifice Plug 20 Disc Spring 29 Bushing*

* Included only with 15 and 20 mm sizes.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

9

MBT3N

Enlarged view of the

valve section

Enlarged view of the

orifice area

No. Name No. Name No. Name

1 Body 13 Ball 25 Seal

2 Cover 14 Outlet Valve Seat 26 Washer

3 Float 15 Inlet Valve Seat

4 Orifice 16 Spindle

27

O-ring (Inlet/Outlet

Valve Seat )

5 Orifice Gasket 17 Gland Holder 28 Valve Holder

6 Air Vent Strip (Bimetal) 18 Gland Holder Gasket

7 Screw & Spring Washer 19 Gland Seat

29 Holder Screw

(Gland Holder)

8 Cover Gasket 20 Disc Spring 30 Bushing*

9 Cover Bolt 21 Disc Spring 31 Motor Unit

10 Orifice Plug 22 Gland Packing 32 Shaft Coupling

11 Nameplate 23 Washer

12 Screen 24 Guide Bushing

* Included only with 15 and 20 mm sizes.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

10

PBT3N

Enlarged view of the

valve section

Enlarged view of the

orifice area

No. Name No. Name No. Name

1 Body 13 Ball 25 Seal

2 Cover 14 Outlet Valve Seat 26 Washer

3 Float 15 Inlet Valve Seat

4 Orifice 16 Spindle

27 O-ring (Inlet/Outlet

Valve Seat)

5 Orifice Gasket 17 Gland Holder 28 Valve Holder

6 Air Vent Strip (Bimetal) 18 Gland Holder Gasket

7 Screw & Spring Washer 19 Gland Seat

29 Holder Screw

(Gland Holder)

8 Cover Gasket 20 Disc Spring 30 Bushing*

9 Cover Bolt 21 Disc Spring 31 Actuator Unit

10 Orifice Plug 22 Gland Packing 32 Shaft Coupling

11 Nameplate 23 Washer

12 Screen 24 Guide Bushing

* Included only with 15 and 20 mm sizes.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

11

Installation and Operation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specifica tion ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from comin

g

into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the dischar

g

e of fluids.

CAUTION

Do not use excessive force when connectin

g

threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Do not stand on or apply body weight to the handle. The handle may

break, resulting in injury or other accidents.

CAUTION

Make sure the power supply switch is OFF before carrying out work on

the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger that

equipment may malfunction or electric shock may occur, leading to

injury or other accidents.

CAUTION

Make sure that wirin

g

work requirin

g

a special license is carried out by

qualified personnel.

If carried out by unqualified personnel, overheating or short circuits

lead in

g

to in

j

ur

y

, fires, dama

g

e or other accidents ma

y

occur.

CAUTION

Wh en u s in

g

this product, NEVER stand close to, or leave tools anywhere

near moving parts, such as the shaft.

Contact with moving parts or objects becoming caught in moving parts

cou ld le a d to i n

j

ur

y

, dama

g

e or other accidents.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Before installation, be sure to remove all protective seals.

2. Before installing the trap, open the inlet valve and thoroughly blow out the piping

to remove any piping scraps, dirt and oil. Blowdown is possible after the product

has been installed, however it is recommended that you remove all dirt, oil, etc.

from the inlet piping before installation. Close the inlet valve after blowdown.

3. Confirm that sufficient maintenance space has been provided around the product.

100 mm

150 mm

25 mm 25 mm

100 mm

MBT3N

Motor Unit

PBT3N

Actuator Unit

4. Where the product is installed in a location that may be affected by radiant heat

from nearby heat-generation, install a device to block the radiant heat, such as a

protective plate.

5. 15 mm and 20 mm sizes come with an additional bushing (refer to the

“Configuration” section). Be sure to screw the bushing or 25mm diameter piping to

the body only up to a point where at least 15 mm remain protruding from the

connecting screw. Over-tightening may cause breakage.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

12

6. Install the product so that the arrow on the product is pointing in the direction of

condensate flow.

7. The product should be inclined no more than 5° horizontally and front-to-back.

8. Install the condensate outlet valve and the outlet piping.

Tolerance Angle for Installation - 5°

Make sure the trap is installed with the raised lettering on the body horizontal.

BT3N: Operation

1. Turn the handle to a position perpendicular to the piping.

(The integrated ball valve will close, causing the product to function as a trap.)

Open the inlet and outlet valves slowly and check to make sure that the product

functions properly as a steam trap.

If there is a problem, determine the cause by using the “Troubleshooting” section in

this manual.

2. To use the bypass function, turn the handle to a position parallel to the piping.

(The integrated ball valve will open.)

3. Return the handle to a position perpendicular to the piping to stop using the bypass

function.

(The integrated ball valve will close, causing the product to function as a trap.)

4. The integrated ball valve should be closed when the product is used as a trap.

NOTE: Operate the bypass valve (ball valve) in only the fully open or fully closed

positions. Operation in an intermediate position will damage the valve seat

and may lead to leaking of the valve.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

13

MBT3N: Wiring/Operation

1. Connect the ON/OFF control switch as follows:

When the control switch is ON, the valve will open; when it is OFF, the valve will

close.

2. If connected to the yellow wire, a pilot lamp will light when the valve is open; if to

the brown, a pilot lamp will light when the valve is closed.

3. When checking the operation of the motor unit before installation, keep fingers well

clear of the bypass blowdown valve section.

Y yellow

BR brown

Rred

BK black

Wwhite

Ggreen

Y

BR

R

BK

W

G

Power AC

Electrical Ground

Control Switch

ON-open / OFF-closed

Lights when closed

Lights when open

PL

PL

4. Carry out an operational check of the motor under no-load conditions (no pressure)

before actual operation to ensure that the wiring is done properly.

You can check whether the valve is opened or closed by checking the orientation of

the flat surfaces on the shaft coupling at the base of the motor unit.(See p.15)

When the flat surfaces of the shaft coupling are lined up with the piping, the valve is

open; when they are perpendicular, the valve is closed.

5. Make sure the control switch is OFF at start-up.

(The integrated ball valve is closed, causing the product to function as a trap.)

Open the inlet and outlet valves slowly and check to make sure that the product

functions properly as a steam trap.

If there is a problem, determine the cause by using the “Troubleshooting” section of

this manual.

6. Turn the control switch ON to use the bypass function.

(The integrated ball valve will be open.)

7. Turn the control switch OFF to stop using the bypass function.

(The integrated ball valve will be closed.)

8. The integrated ball valve should be closed when the product is used as a trap.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

14

PBT3N: Air Supply Piping/Operation

1. Use only clean air, which has been run through an air trap, filter, oiler, etc.

2. Make sure there is no foreign matter, particularly dirt or sealing tape, in the

pneumatic actuator.

3. The table below shows the relationship between the air supply and valve

opening/closing.

Port: A Port: B Valve

Supply Exhaust Open

Exhaust Supply Closed

4. When checking operation of the pneumatic actuator before installation, keep

fingers well clear of the bypass blowdown valve section.

Air Supply to Port A (air-to-open)

Air supply pressure: 0.3 – 1.0 MPaG

Air Supply to Port B (air-to-close)

Air supply pressure: 0.3 – 1.0 MPaG

Open/Closed Indicator

5. Carry out an operational check of the actuator under no-load conditions (no

pressure) before actual operation to ensure that the air is supplied properly.

The “Open/Closed” Indicator located in the lower part of the actuator indicates

whether the valve is opened/closed.

6. Make sure that the integrated ball valve is closed at start-up, causing the product to

function as a trap.

The state of the integrated ball valve can be confirmed using the “open/closed”

indicator. Open the inlet and outlet valves slowly and check to make sure that the

product functions properly. If there is a problem, determine the cause by using the

“Troubleshooting” section in this manual.

7. To use the bypass function, supply air through port A and exhaust the air in the

actuator through port B. The integrated ball valve will open.

8. To stop using the bypass function, supply air through port B and exhaust the air in

the actuator through port A. Integrated ball valve will close.

9. The integrated ball valve should be closed when the product is used as a trap.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

15

Manual Operation

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

MBT3N

1. Perform manual operation only after making sure that the power is OFF. Manual

operation cannot be performed when the power is ON. For safety, make sure the

power is OFF even during a power outage.

2. Grasp the flat surfaces of the shaft coupling at the base of the motor unit with a

wrench, and turn in the direction of the arrows. When the flat surfaces of the shaft

coupling are lined up with the piping, the valve is open; when they are

perpendicular, the valve is closed (distance across flats: 19 mm).

PBT3N

1. Perform manual operation only after shutting off the air supply first and making

sure there is no pressure remaining inside the actuator unit. Manual operation can

not be performed if there is pressure remaining inside the actuator unit.

2. Grasp the manual operation key on the top of the actuator unit with a wrench, and

turn in the direction of the arrows (distance across flats: 10 mm).

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

16

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the dischar

g

e of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the prod uct in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

When using this product, NEVER stand close to, or leave tools anywhere

near moving parts, such as the shaft.

Contact with moving parts or objects becoming caught in moving parts

cou ld le a d to i n

j

ur

y

, dama

g

e or other accidents.

CAUTION

BT3N/MBT3N/PBT3N: Operational Check of the Steam Trap

The following inspections should be carried out only after making sure that the bypass

valve is closed: A visual inspection of the following items should be done on a daily

basis to determine whether the trap is operating properly or has failed. Periodically (at

least biannually) the operation should also be checked by using diagnostic equipment,

such as a stethoscope or thermometer. (Inspection, installation, maintenance, repairs,

disassembly, adjustment and valve opening/closing should be carried out only by

trained maintenance personnel.)

To determine whether the bypass valve is closed, make sure that the flat surfaces of

the spindle (BT3N) or the shaft coupling (MBT3N and PBT3N) are perpendicular to

the piping.

If the valve is not fully closed when the flat surfaces are in this position, there is a

problem. Refer to the “Troubleshooting” section to determine the cause, then correct

the problem.

If the trap or bypass blowdown valve should fail, it may cause damage to piping and

equipment, resulting in faulty or low quality products or losses due to steam leakage.

Normal : Condensate, together with flash steam, is discharged

continuously, accompanied by the powerful rushing sound of

flow. When the amount of condensate being discharged is very

slight, the sound of flow is almost inaudible.

Blocked

(Discharge

Impossible)

: No condensate is discharged. The trap is quiet and makes no

noise, and the surface temperature of the trap is low.

Blowing : Live steam continuously flows from the outlet and there is a

continuous piercing metallic sound.

Steam Leakage : Live steam is discharged through the outlet together with the

condensate and there is a high-pitched hissing sound.

(When conducting a visual inspection, flash steam is sometimes mistaken for steam

leakage. For this reason, the use of a steam trap diagnostic instrument - such as

TLV TrapMan - in conjunction with the visual inspection is highly recommended.)

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

17

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

MBT3N: Operational Check of the Motor Unit and Bypass Valve Section

1. An operational check shall be performed at least once every 6 months.

2. Turn the motor unit power ON and check the operation of the motor unit (angle of

rotation, time required to open/close the valve, sound).

3. After turning the motor unit power OFF, manually operate the valve, check for

foreign matter in the valve and confirm torques.

Refer to the following table for tightening torques. A torque of more than 2 times

the shown torque is considered abnormal, and an inspection should be performed.

Tightening Torque N·m

No load 0.5 MPaG load 1.0 MPaG load

0.4 0.5 0.6

(1 N·m ≈10 kg·cm) (1 MPa = 10.197 kg/cm2)

PBT3N: Operational Check of the Actuator Unit and Bypass Valve Section

1. An operational check shall be performed at least once every 6 months.

2. Making sure there is air supplied to the actuator, check the operation (angle of

rotation, time required to open/close the valve, sound).

3. After shutting off the air supply, manually operate the valve, check for foreign

matter in the valve and confirm torques.

Refer to the following table for tightening torques. A torque of more than 2 times

the shown torque is considered abnormal, and an inspection should be performed.

Tightening Torque N·m

No load 0.5 MPaG load 1.0 MPaG load

0.4 0.5 0.6

(1 N·m ≈10 kg·cm) (1 MPa = 10.197 kg/cm2)

BT3N: Additional Tightening of the Valve Unit Gland Section

It is possible to further tighten the gland section in the BT3N valve unit.

Holding the handle tightly, by hand, so that it cannot rotate, use a wrench to tighten

the locknut at the top of the handle (distance across flats: 10 mm).

Cautions when applying additional tightening:

•Do not tighten the locknut completely the first time. Do not tighten it any more than

is necessary to stop leakage.

•If leakage continues even after applying additional tightening to the locknut, replace

parts (part No. 16, spindle; part No. 18, gland gasket; part No. 22, gland packing;

part No. 28, locknut).

18

MBT3N/PBT3N: Additional Tightening of the Valve Unit Gland Section

It is possible to further tighten the gland section in the MBT3N/PBT3N valve units.

1. Detach the actuator unit (refer to the “Disassembly/Reassembly” section for

details).

2. Follow the steps given below to apply additional tightening

1) Loosen the holder screw. 2) Tighten the gland holder further in with

a socket wrench.

Holder Screw Gland Holder

Hex Key

Diameter: 2 mm

Socket Wrench:

diameter 17 mm

3) Retighten the holder screw.

Cautions when applying additional tightening:

•Do not tighten the gland holder completely the first time. Do not tighten it any more

than necessary to stop leakage.

•If leakage continues even after applying additional tightening to the gland holder,

replace parts.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

19

Disassembly / Reassembly

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the prod uct in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Make sure the power supply is OFF before carrying out work on the wiring

or inspections involving disassembly.

If such work is carried out with the power on, there is a danger that

equipment may malfunction or electric shock may occur, leading to

injury or other accidents.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble.

(Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.)

BT3N/MBT3N/PBT3N: Disassembly/Reassembly of the Steam Trap

Part During Disassembly During Reassembly During Inspection

Orifice

Plug

Remove with a wrench:

dist. across flats - 17 mm

Wrap 3-3.5 turns of sealing

tape around threads and

tighten to the proper torque:

torque - 70 N·m

dist. across flats - 17 mm

—

Cover Bolt Remove with a wrench:

dist. across flats - 13 mm

Coat threads with anti-seize

and tighten to the proper

torque: torque - 40 N·m

dist. across flats - 13 mm

—

Cover Remove the cover Replace the cover —

Cover

Gasket

Remove the cover gasket Replace with a newcover

gasket only if misshapen or

damaged

—

Float Remove the float Reinsert the float gently Check for deformation

or scratches

Screw &

Spring

Washer

Remove the screw & the

spring washer

Coat threads with anti-seize

and tighten to the proper

torque: torque - 1.5 N·m

—

Air Vent

Strip

Remove the air vent strip Be careful not to deform the

strip

Check the tip for

splitting, corrosion, etc.

Orifice Remove with a socket

wrench:

dist. across flats - 17 mm

Coat threads with anti-seize

and tighten to the proper

torque: torque - 40 N·m

dist. across flats - 17 mm

Check the sealing

surfaces for scratches,

wear, etc.

Orifice

Gasket

Remove the orifice gasket Replace with a new orifice

gasket only if misshapen or

damaged

—

Refer to the sketch shown on the next page.

172-65162M-03 (BT3N/MBT3N/PBT3N) 5 Jul 2013

This manual suits for next models

2

Table of contents

Other TLV Industrial Equipment manuals

TLV

TLV SS1VG-M User manual

TLV

TLV V1 Series User manual

TLV

TLV PowerDyne HR-A Series User manual

TLV

TLV PowerTrap GT5C User manual

TLV

TLV JH5SL-P User manual

TLV

TLV QuickTrap FJ32-X User manual

TLV

TLV PowerDyne QuickTrap P46UC-Y User manual

TLV

TLV QuickTrap FP32 User manual

TLV

TLV JH7.5R-P User manual

TLV

TLV DC3-L User manual