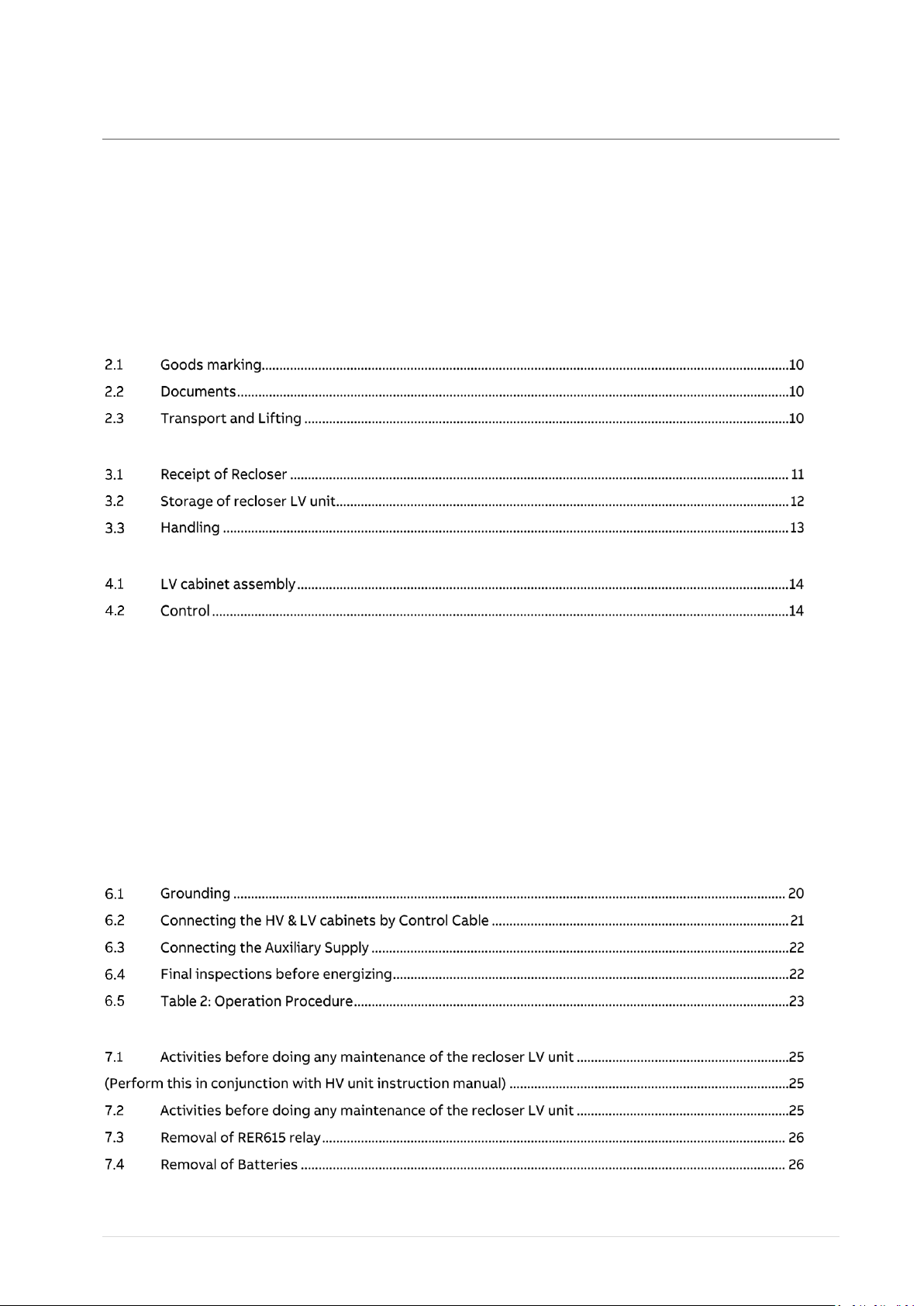

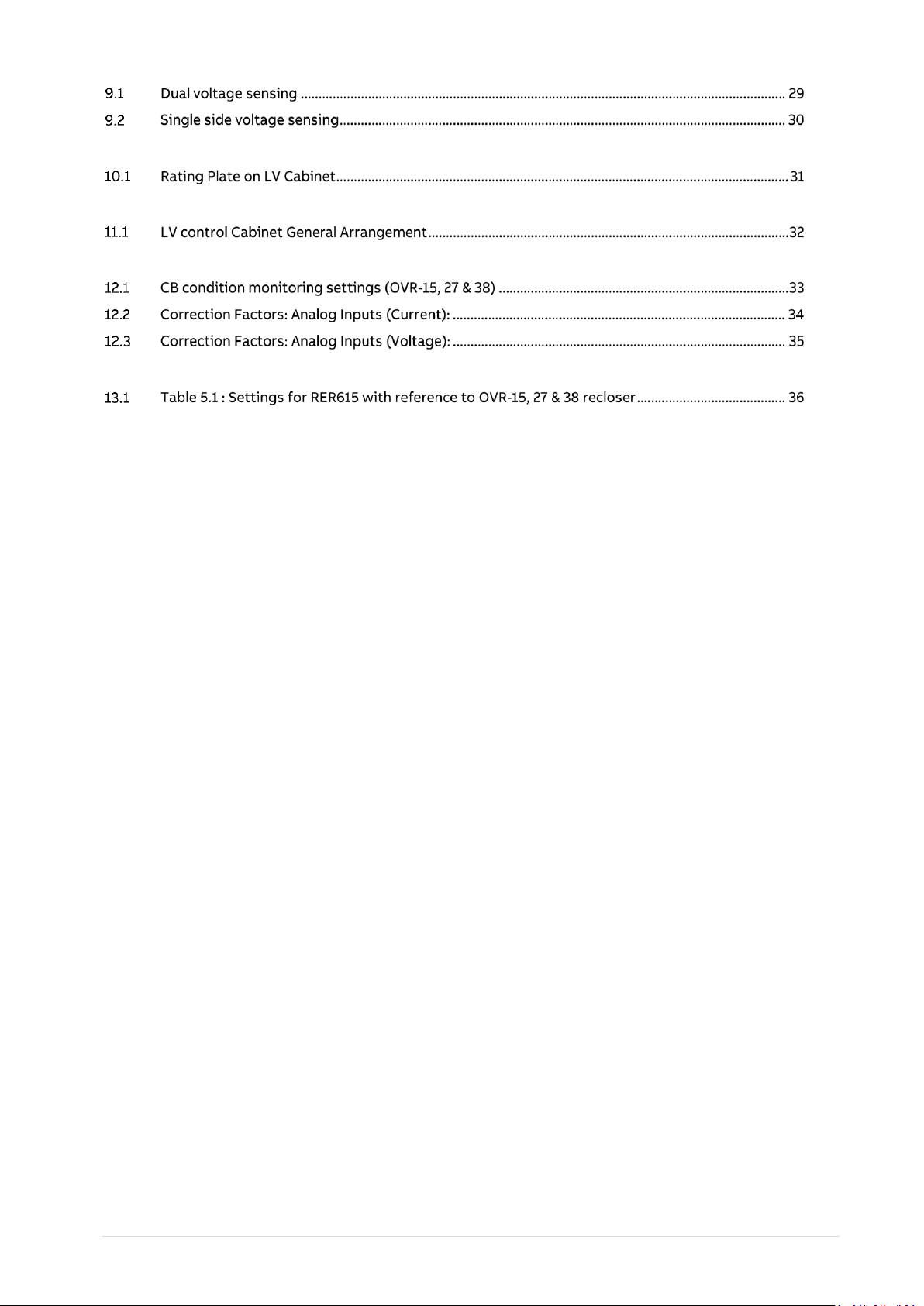

6 | P a g e

OVR-15, 27 & 38 LV cabinet Instruction Manual

A. INTRODUCTION

This manual contains the information needed to install Low voltage (LV) cabinet of medium voltage

OVR-15, 27 & 38 vacuum recloser and put them into service.

For correct use of the product, please read this manual carefully along with instruction, operation, and

maintenance manual for high voltage unit.

OVR-15, 27 & 38 reclosers are designed for different installation configurations. However, the mounting

structure for this apparatus allows further technical-construction modifications (at the customer’s

request) to adapt to special installation requirements. Consequently, the information given below may

sometimes not contain instructions concerning special configurations.

Apart from this manual, it is therefore always necessary to consult the latest technical documentation

(electric circuit and wiring diagrams, assembly and installation drawings, any protection coordination

studies, etc.), especially regarding any variants requested in relation to the standardized configurations.

Only use original spare parts for maintenance operations. For further information, please refer

recommended spare part list mentioned in this manual.

All the installation, putting into service, running and maintenance operations must be carried out by

skilled personnel with in-depth knowledge of the apparatus.

B. ENVIRONMENTAL PROTECTION PROGRAM

OVR-15, 27 & 38 reclosers LV cabinet recloser is manufactured in accordance with the ISO 14001

Standards (Guidelines for environmental management).

The production processes are carried out in compliance with the Standards for environmental protection

in terms of reduction in energy consumption as well as in raw materials and production of waste

materials. All this is thanks to the medium voltage apparatus manufacturing facility environmental

management system.

C. END OF LIFE RECYCLE/DISPOSAL

ABB is committed for complying with relevant legal and other statutory requirements for environment

protection according to the ISO 14001 standard. The duty of the end user is to facilitate end of life

recycling & disposal according to the applicable regulations.

During disposal of product, it is necessary to act in according with local legal requirements in force.

Disposal can either be carried out thermally in an incineration plant or by storing on a waste site.

Following are the methods of recycle/disposal: