ABB SACE Emax 2 E1.2 manual

—

INSTRUCTION HANDBOOK

1SDH002303A1001 - ECN000285442

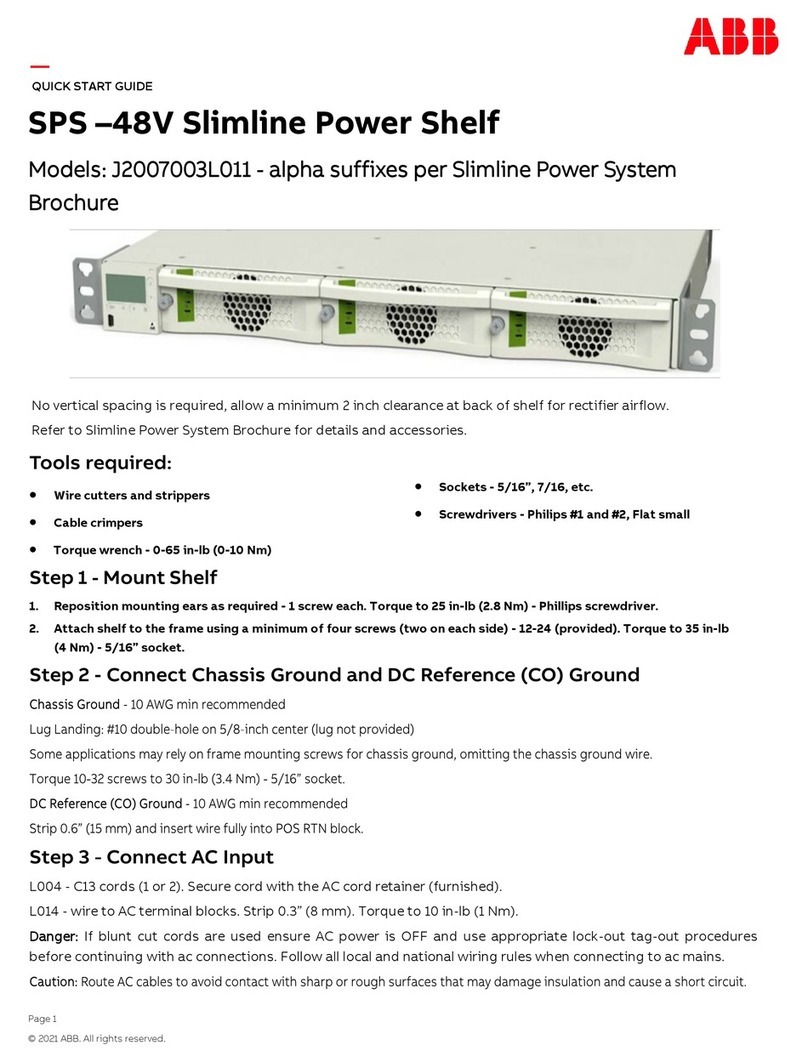

EMAX 2 E1.2

Disassembly instructions

3

Disassembly instruction emaX 2 e1.2

1. SCOPE

Scope of this document is to illustrate the step-by-step disassembly process of ABB SACE Emax 2 E1.2

air case circuit breaker equipped with an electronic trip unit (type Ekip TOUCH LSIG).

Document is focused on Emax 2 E1.2 3p IEC version, anyway it allows to cover other versions of Emax 2

E1.2 circuit breaker equipped with a electronic trip unit with just few slight differences to be taken into

account.

Gloves Glasses Safety shoes Protective clothes

4. TOOLS

Disassembly operations require the use of tools (e.g. screwdriver, torx key, pliers, …); tools to be used

are specified inside each phase of the disassembly process (see Chapter 6).

3. PERSONAL PROTECTIVE EQUIMENT (PPE)

When performing disassembly, following safety Personal Protective Equipment (PPE) must be worn:

2. SAFETY NOTES

Before proceeding with any disassembly operation, it’s mandatory to put the circuit breaker in open

position and make sure that the springs of the operating mechanism are discharged.

Disassembly operations of circuit breakers must be performed by qualified and skilled personnel in

the electrical field (IEV 195-04-01: person with relevant education and experience to enable him or her

to perceive risks and to avoid hazards which electricity can create) and having a detailed knowledge of

circuit breakers.

Disassembly activites must be performed in an ergonomic workspace able to ensure protection of per-

sons demanded to perform disassembly activities.

Applicable national legislation and international standards in force at the time of disassembly of circuit

breakers must be taken into account in addition to prescriptions illustrated in this document.

ABB declines any responsibility for injury to people or damage to property resulting from a failure to

comply with the instructions set out in this document and with any applicable safety standard.

4

INSTRUCTION HANDBOOK

If disassembled parts require a separate treatment a specific indication is provided inside each phase

with reason why for the separate treatment (see Chapter 6).

Description Position inside circuit breaker Quantity

Lever In the T.U. reset group

Lever support In the T.U. reset group

Right side wall Mounted on the sliding contacts block

Flat cables assemblies Mounted on the sliding contacts block

Connector cables assembly Mounted on the sliding contacts block

Sliding contacts base Mounted on the sliding contacts block

Slide Mounted on the right shoulder

Support Mounted on the upper part of the circuit breaker

Cables protection Mounted on the back part of the trip unit

Rating plug case Mounted on the front of the trip unit

Rating plug printed circuit board In the rating plug case

Ekip measuring blind printed circuit board On the trip unit

Battery cover On the trip unit

Battery On the trip unit

Display printed circuit board On the trip unit

Display On the trip unit

Backplane Mounted on the back part of the trip unit

Trip unit case On the trip unit

Trip unit back cover On the trip unit

Trip unit printed circuit board In the trip unit

Measuring module connector On the trip unit

Protections Mounted on the back part of the circuit breaker

Motor PCS support Mounted on the left part of the circuit breaker

Microswitch support Mounted on the left part of the circuit breaker

Mounted on the left part of the circuit breaker

Trip coil In the trip coil group

Trip coil group Mounted on the left part of the circuit breaker

Connector On the MID

Auxiliary contacts On the MID

Microswitch I/O On the MID

Microswitch I/O support On the MID

MID Mounted on the right part of the circuit breaker

Wires cover Mounted on the left part of the circuit breaker

Wiring Mounted on the left part of the circuit breaker

Open lever On the right side of the circuit breaker

RTC lever Mounted on the right side of the operating mechanism

Conduit Behind the trip unit

Operating mechanism Mounted on the center of the circuit breaker

Unlocking shaft appendices Mounted on the pin of the operating mechanism

Springs charging lever Mounted on the left side of the operating mechanism

Protections Mounted on the upper case assembly

Plastic parts Mounted on the fixed contacts

Covers Below the sensors

Sensors In the bottom part of the circuit breaker

Insulation protections On the moving contacts assembly

5. SEPARATE TREATMENT

Table below lists parts requiring a separate treatment adding information about part location inside

circuit breakers and related quantity.

5

Disassembly instruction emaX 2 e1.2

6. DISASSEMBLY PROCESS

Circuit breakers disassembly process is constituted by a sequence of operations to be performed on

products after their dismounting from original installation. For each phase following information is

provided:

applicable)

6

INSTRUCTION HANDBOOK

Tools

Flat screwdriver

6.1 PHASE 1 – CIRCUIT BREAKER FRONT COVER, COVERS AND OPERA-

TING MECHANISM COVER

1

Manually push the trip unit transparent

protection as indicated by the arrow and

remove it.

3

Manually complete the removal of the cover.

5

By means of the cross screwdriver unscrew the

2 screws located in the upper part of the circuit

breaker fixing the circuit breaker front cover to

the circuit breaker main structure.

2

By means of the cross screwdriver unscrew the

3 screws fixing the cover.

4

Lift the spring charging lever and by means

of the cross screwdriver unscrew the screw

located below the springs charging lever fixing

the circuit breaker cover to the circuit breaker

main structure.

6

By means of the cross screwdriver unscrew

the 2 screws fixing the withdrawable terminals

cover.

Actions to be performed

Cross screwdriver

Torx key

No. 8

7

Disassembly instruction emaX 2 e1.2

7

Manually complete the removal of the

withdrawable terminals cover.

11

Manually lift the T.U. reset group and complete the

removal.

12

By means of the flat screwdriver unhook the reset

lever from the reset support of the T.U. reset group.

9

Manually lift the circuit breaker front cover to

complete the removal.

8

By means of the cross screwdriver unscrew the

2 screws located in the lower part of the circuit

breaker fixing the circuit breaker front cover to

the circuit breaker main structure.

10

By means of the cross screwdriver unscrew the

screw fixing the T.U. reset group to the circuit

breaker front cover.

8

INSTRUCTION HANDBOOK

13

Manually separate the lever support and the lever.

17

By means of the tork key remove the 2 screws

fixing the front cap to the circuit breaker front

cover and after manually remove the front cap.

18

By means of the cross screwdriver unscrew the 2

screws located in the lower part of the operating

mechanism cover fixing the operating mechanism

cover to the circuit breaker main structure.

15

Manually remove the reset spring from the lever

support.

14

Manually remove the spring from the lever.

16

By means of the tork key remove the screw

fixing the operation counter cap to the circuit

breaker front cover and after manually remove the

operation counter cap.

9

Disassembly instruction emaX 2 e1.2

19

By means of the cross screwdriver unscrew the screw

located on the right of the operating mechanism

cover fixing the operating mechanism cover to the

circuit breaker main structure and manually complete

the removal of the operating mechanism cover.

Disassembled parts

(Thermoplastics containing brominated flame

retardants)

(Thermoplastics containing brominated flame

retardants)

10

INSTRUCTION HANDBOOK

Tools

Flat screwdriver

Cutter

Pliers

6.2 PHASE 2 – SLIDING CONTACTS BLOCK

20

Manually push the sliding contacts block as

indicated by the arrow.

22

Using one hand manually slightly push as

indicated by the arrow the right shoulder

and using the other hand unhook the sliding

contacts block from main circuit breaker

structure.

24

By means of the flat screwdriver unhook the

3 flat cables assemblies and the connector

cables assembly.

21

By means of the pliers unhook the 2 springs

mounted at the extreme sides of the sliding

contacts block, keeping them mounted on the

sliding contacts block.

23

After completion of previous operation, sliding

contacts block must be put as indicated in

picture here below.

25

Manually complete the removal of the sliding

contacts block from the circuit breaker main

structure.

Actions to be performed

11

Disassembly instruction emaX 2 e1.2

26

By means of the flat screwdriver unhook the right

side wall from the sliding contacts block main

assembly.

30

Inser 2 flat screwdrivers at the sides of each block,

slightly push them as indicated by the arrow

and complete the removal of the 3 flat cables

assemblies and of the connector cables assembly

manually pulling them.

31

By means of the flat screwdriver push as indicated

by the arrow the 2 bars mounted inside the sliding

contacts block.

28

By means of the cutter start removing the sliding

contacts label located on the right side wall and

manually complete the operation.

27

Manually complete the removal of the right side

wall.

29

By means of the pliers remove the 2 springs from

the sliding contacts block.

12

INSTRUCTION HANDBOOK

32

Manually complete the removal of the 2 bars.

33

By means of the pliers remove the 4 pins and the

related nuts mounted at both sides of the sliding

contact base.

Disassembled parts

(Thermoplastics containing brominated flame

retardants)

containing brominated flame retardants)

containing brominated flame retardants)

brominated flame retardants)

13

Disassembly instruction emaX 2 e1.2

Tools

Cutter

Pliers

6.3 PHASE 3 – SHOULDERS

34

By means of the cross screwdriver unscrew the

2 screws fixing the cover to the circuit breaker

main structure.

36

By means of the cross screwdriver unscrew

the 2 screws fixing the withdrawable terminals

cover to the circuit breaker main structure.

38

By means of the cross screwdriver unscrew the

2 screws fixing the left shoulder to the circuit

breaker main structure.

35

Manually complete the removal of the cover.

37

Manually complete the removal of the

withdrawable terminals cover.

39

By means of the cross screwdriver unscrew the

2 screws fixing the left shoulder to the circuit

breaker main structure and collect the 2 nuts

mounted behind the 2 screws

Actions to be performed

Cross screwdriver

14

INSTRUCTION HANDBOOK

40

Manually remove the left shoulder.

44

By means of the cross screwdriver unscrew the

2 screws fixing the right shoulder to the circuit

breaker main structure and collect the 2 nuts

mounted behind the 2 screws.

45

Manually remove the right shoulder.

42

By means of the cutter start removing the 3

labels located on the left shoulder and manually

complete the operation.

41

By means of the pliers remove the 2 springs

mounted on the left side support.

43

By means of the cross screwdriver unscrew the

2 screws fixing the right shoulder to the circuit

breaker main structure.

15

Disassembly instruction emaX 2 e1.2

46

Manually remove the slide mounted on the right

shoulder.

47

By means of the pliers remove the spring

mounted on the right shoulder.

Disassembled parts

(Thermoplastics containing brominated flame

retardants)

16

INSTRUCTION HANDBOOK

Tools

Flat screwdriver

Scissors

Cutter

Torx key

6.4 PHASE 4 – TRIP UNIT

48

By means of the cross screwdriver unscrew the

2 screws located in the upper part of the circuit

breaker fixing the trip unt to the circuit breaker

main structure.

50

By means of the flat screwdriver unhook the

white connector from the trip unit.

52

By means of the flat screwdriver unhook the

cable protection from the trip unit and after

manually complete the removal.

49

By means of the cross screwdriver unscrew

the 2 screws located on the front of the circuit

breaker fixing the trip unt to the circuit breaker

main structure.

51

Manually complete the removal of the white

connector.

53

By means of the flat screw driver unhook the

white connector from the trip unit.

Actions to be performed

No. 8

Cross screwdriver

Pliers

17

Disassembly instruction emaX 2 e1.2

54

By means of the flat screw driver unhook the

white connector from the trip unit.

59

By means of the cutter start removing the label

mounted over the plug removed at step before and

manually complete the removal operation.

58

Manually remove the plug mounted on the left part of

the trip unit.

56

By means of the scissors cut the cabling

completing the removal of the trip unit from the

circuit breaker main structure.

55

Manually unhook the last cabling connecting the

trip unit to the circuit breaker main structure.

57

By means of the torx key unscrew the 4 screws

fixing the 2 plugs to the trip unit.

18

INSTRUCTION HANDBOOK

60

By means of the flat screwdriver remove the

rating plug from the trip unit.

65

Manually complete the removal of the Ekip measuring

blind plug.

64

By means of the flat screwdriver unhook the Ekip

measuring blind plug from the trip unit.

62

By means of the cutter start removing the label

located on the front of the rating plug case and by

means of the pliers complete the operation.

61

Manually push the rating plug case appendix as

indicated by the arrow and by means of the pliers

remove the rating plug printed circuit board.

63

By means of the cutter start removing the rating

plug data matrix label located on the rating plug

case and by means of the pliers complete the

operation.

19

Disassembly instruction emaX 2 e1.2

66

By means of the cutter start removing the label

located on the Ekip measuring blind plug and by

means of the pliers complete the operation.

71

By means of the torx key unscrew the screw fixing the

display to the trip unit main structure.

70

Manually remove the printed circuit board from the

Ekip measuring blind cover.

68

By means of the torx key unscrew the 2 screws

fixing the Ekip measuring blind case to the Ekip

measuring blind cover.

67

By means of the cutter start removing the data

matrix label located in the back part of the Ekip

measuring blind plug and by means of the pliers

complete the operation.

69

Manually remove the Ekip measuring blind case.

20

INSTRUCTION HANDBOOK

72

By means of the flat screwdriver unhook the

display from the trip unit main structure.

77

By means of the flat screwdriver unhook the HMI box

from the display.

76

Manually remove the battery.

74

By means of the cutter start removing the

trip unit front label and by means of the pliers

complete the operation.

73

Manually complete the removal of the display.

75

By means of the flat screwdriver remove the

battery cover on the right side of the display.

Other manuals for SACE Emax 2 E1.2

1

Table of contents

Other ABB Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Grunbeck

Grunbeck GENO-OSMO-AVRO 125 RU Operation manual

Siemens

Siemens Sivacon S8 operating instructions

STI

STI EZ-Path 33 Series Installation sheet

Dorner

Dorner 3200 Series Installation, maintenance & parts manual

Siemens

Siemens SIMATIC NET S7-CPs Configuring and Installing

SCHUNK

SCHUNK SRU 20 Assembly and operating manual