Intellectual Property & Copyright Notice

©2010 by ABB Inc., Totalflow Products (“Owner”), Bartlesville,

Oklahoma 74006, U.S.A. All rights reserved.

Any and all derivatives of, including translations thereof, shall remain

the sole property of the Owner, regardless of any circumstances.

The original US English version of this manual shall be deemed the

only valid version. Translated versions, in any other language, shall

be maintained as accurately as possible. Should any discrepancies

exist, the US English version will be considered final. ABB is not

liable for any errors and omissions in the translated materials.

Notice: This publication is for information only. The contents are

subject to change without notice and should not be construed as a

commitment, representation, warranty, or guarantee of any method,

product, or device by Owner.

Inquiries regarding this manual should be addressed to ABB Inc.,

Totalflow Products, Technical Communications, 7051 Industrial

Blvd., Bartlesville, Oklahoma 74006, U.S.A.

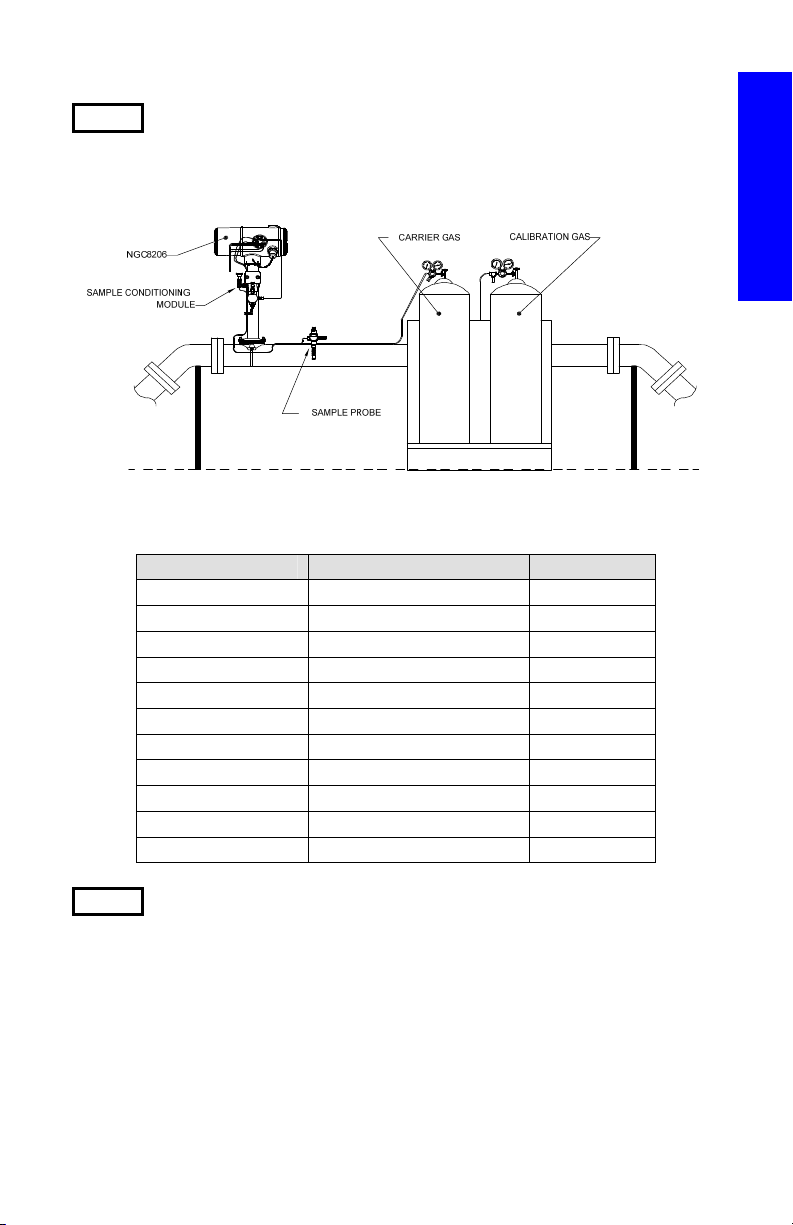

Introduction

This is a quick start guide designed for typical installations only. It is

recommended that inexperienced technicians consult the Totalflow

NGC8206 User’s Manual for more detailed information while performing

the installation and start-up. Scan through the guide to see what

information is available before beginning the installation. If there are

questions that are not answered in this guide or other documentation, the

user should call their local Totalflow representative, or call the number

listed on the back of this guide. Although there are alternate methods of

installation, it is recommended that technicians perform these

procedures in the presented order.

Unpack and inspect the NGC8206 and optional equipment, if purchased.

Inspect all parts and pieces for damage and missing or incorrect

components.

Before Beginning

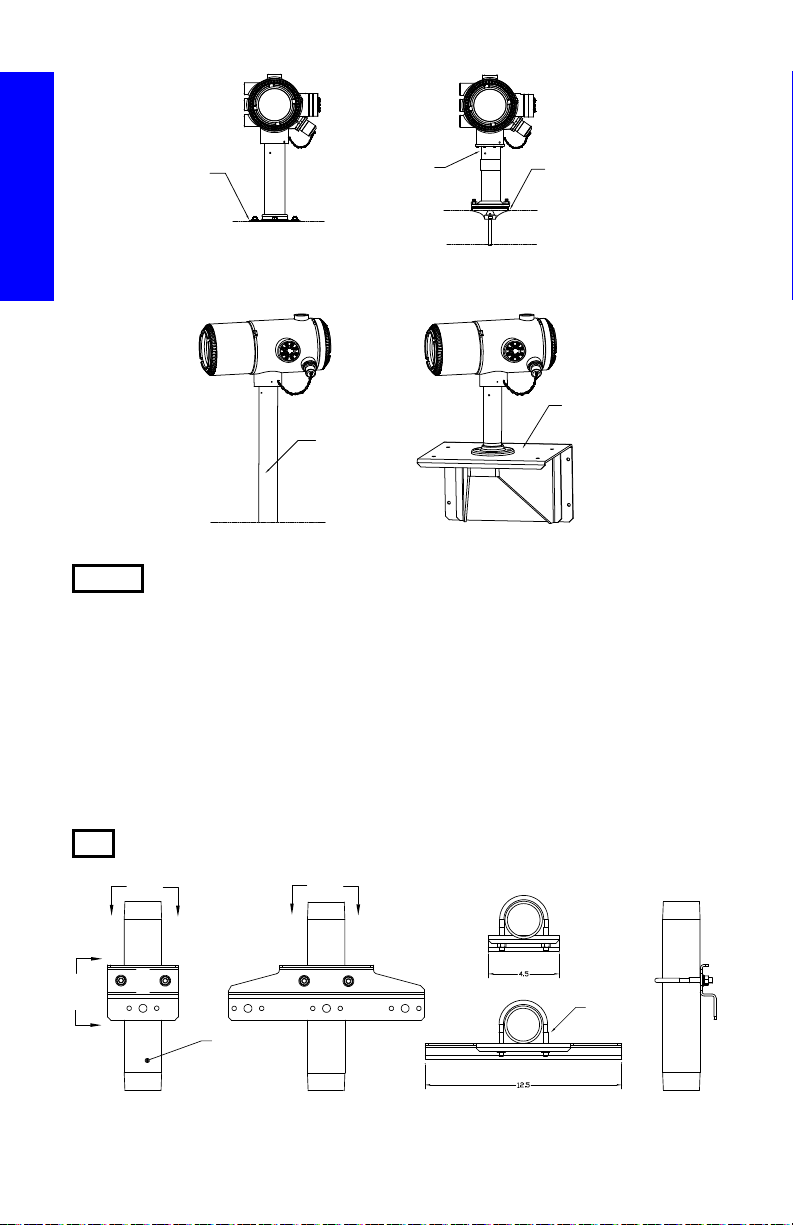

The NGC may be configured with a multitude of optional equipment.

Please see the NGC8206 User’s Manual for optional equipment

installation instructions.

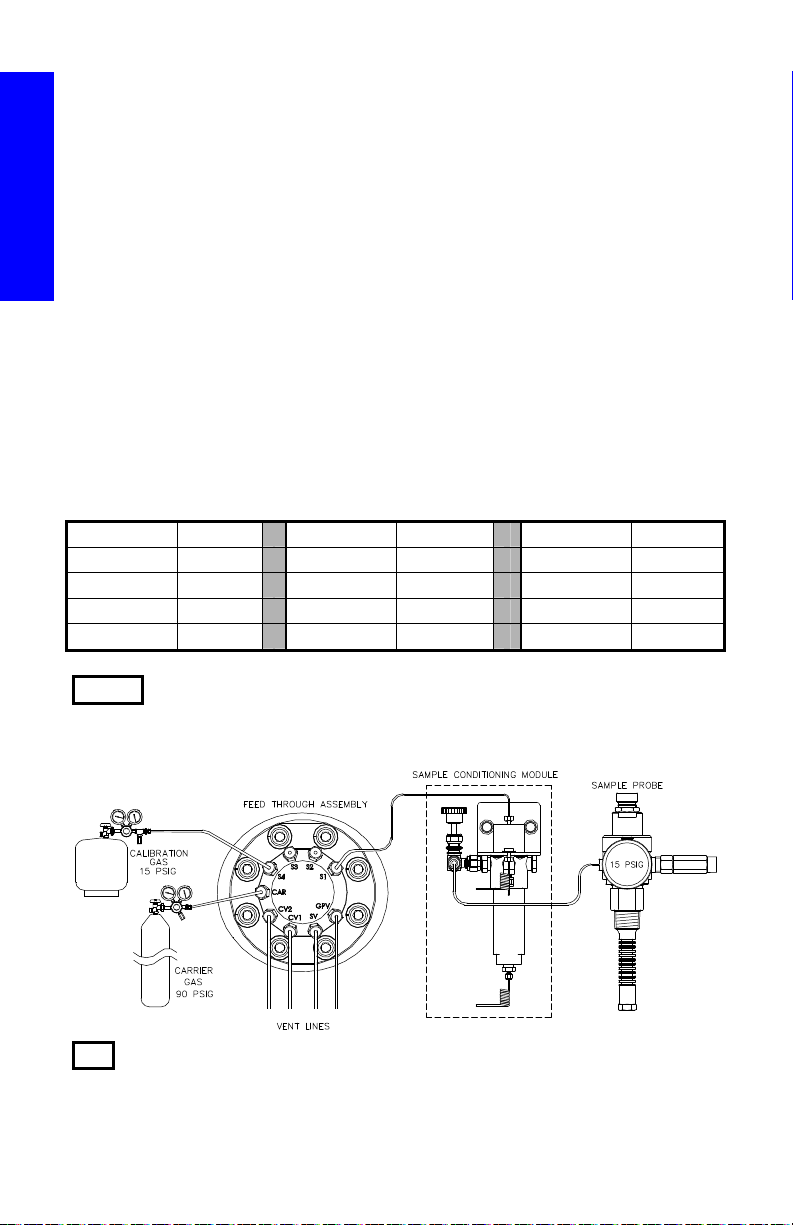

If the Optional Equipment Unit (OEU) was purchased to house the power

supply, battery and/or communications, this should be installed in a

Division 2 or general purpose area prior to the NGC installation. Specific

instructions may also be found in the NGC8206 User’s Manual.

Communication wiring information is presented in this guide.