v

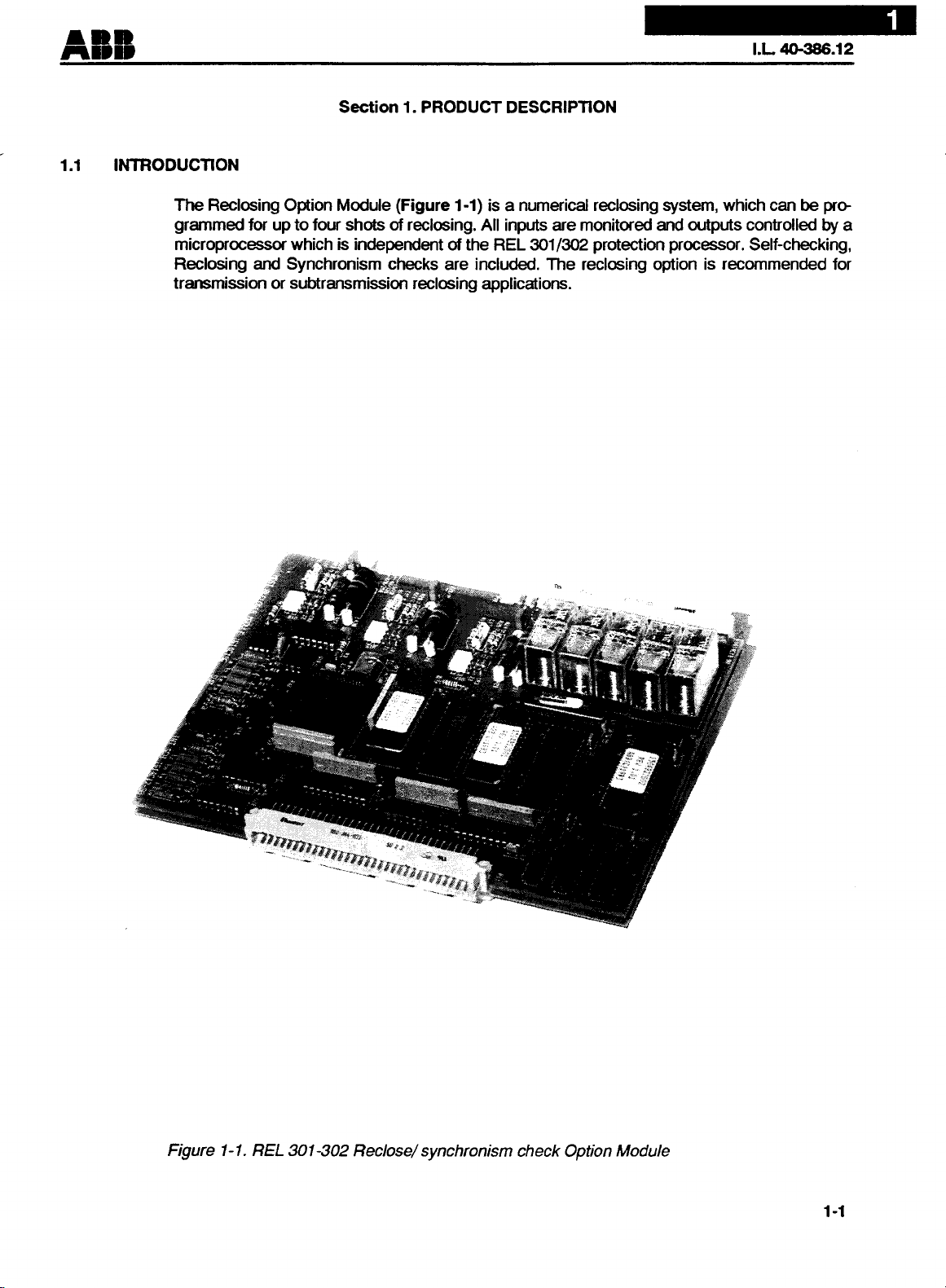

I.L. 40-386.12

REL301/302 RECLOSING SOFTWARE VERSION 1.20

FEATURES ADDED AND IMPROVEMENTS MADE

TO RECLOSING SOFTWARE VERSION 1.10

1. Improved the application flexibility by Adding a setting of “Sync Volt” with a selection of “Line/Bus” to cor-

rectlyindicatetheconnectionofsynchronisminputvoltageonlineorbusside.Previouslythe‘bus’reference

was fixed as the protection source and ‘line’ reference was fixed as the synchronism source. This improve-

ment causes LED indication, metering and targeting of ‘line’ and ‘bus’ to accurately reflect the connection

(e.g. HLDB, HBDL).

2. Additional functionality was added to the 52a input. To accommodate both existing logic and the new man-

ual close logic, the setting for the input 52a was changed from “52a?” to “52a/Mancls”. “52a/Mancls” has the

following setting options:

a) “Yes, 52a” for the 52b NOT 52a (pole disagreement) logic application. Previously, the setting for this logic

was “52a? = Yes”.

b) “Man Close” configures 52a input for use with manual close logic.

c) “No, Disabled” 52a input is not used by the reclosing logic functions.

3. Added a manual close function with the following settings. Manual close allows the operation of the REL

301/302 close contacts by energizing the 52a input. Manual close is available with the basic reclosing func-

tion and is enhanced when used with the optional voltage/synchronism check logic. The voltage/synchro-

nism check settings will be displayed only when the manual close function is enabled (“Man Close” = “Yes”)

and the optional voltage/synchronism check logic is present:

a) “Man Close” = “Yes/No” - Enable/disable manual close function

b) “Man HLDB” = “Yes/No” - Manual close with Hot Line Dead Bus voltage check.

b) “Man HBDL” = “Yes/No” - Manual close with Hot Bus Dead Line voltage check.

c) “Man SYNC”= “Yes/No” - Manual close with synchronism check.

d) “Max Wait” = “0-990 sec” or “No Time Limit”. Maximum time allowed to wait for voltage check and/or

sync check before reclosing logic goes to lockout state. If No Time Limit is chosen then

logic waits indefinitely for voltage or sync check.

4. Corrected metering and targeting error for 120 volt synchronism input voltage option. Previously, when us-

ing the 120 volt version of the reclosing logic, the voltage would be displayed as 70 volts instead of the cor-

rect value of 120 volts. In Version 1.20, of the firmware, the correct voltage value is displayed and targeted.

As stated in paragraph 1 above, this also allows the user to set the synchronism voltage reference for either

line side or bus side, maintain the reference (protection) voltage at 70 Vrms and display the correct voltage

level from the 120 volt synchronism voltage input.

5. Corrected the setting range of “Live” voltage from 30-70 Vrms to 50-120 Vrms and the “Dead” voltage from

0-30 Vrms to 0-50 Vrms for the 120 volt synchronism check option. Previously the voltage ranges were dis-

played as the 70 volt ranges even when the 120 volt synchronism check option had been supplied.