REJ 523 Technical Reference Manual ABB Substation Automation

Products and Systems

MRS750940-MUM

2

Contents

1 Introduction.................................................................................................4

1.1 About this manual..............................................................................4

1.2 The use of the relay...........................................................................4

1.3 Features.............................................................................................4

1.4 Guarantee..........................................................................................5

2 Safety information.......................................................................................6

3 Instructions .................................................................................................7

3.1 Application.........................................................................................7

3.2 Requirements ....................................................................................7

3.3 Configuration .....................................................................................8

4 Technical description ..................................................................................9

4.1 Functional description........................................................................9

4.1.1 Product functions......................................................................9

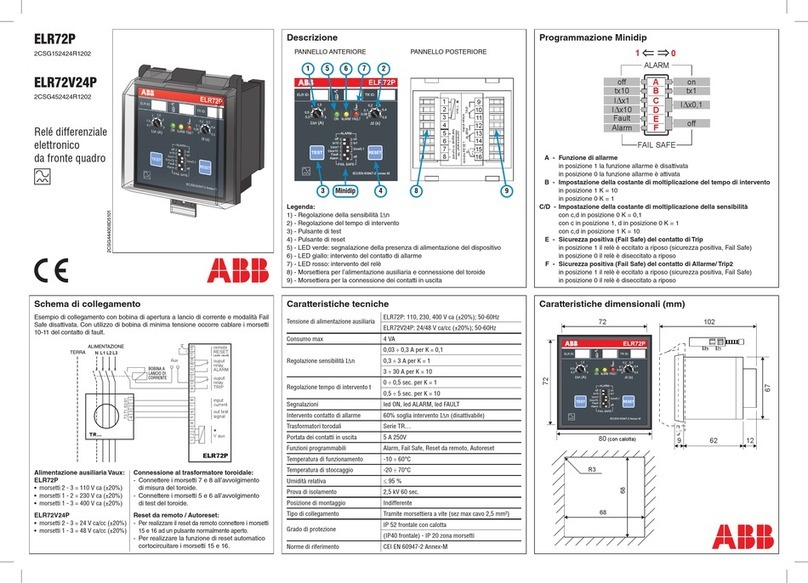

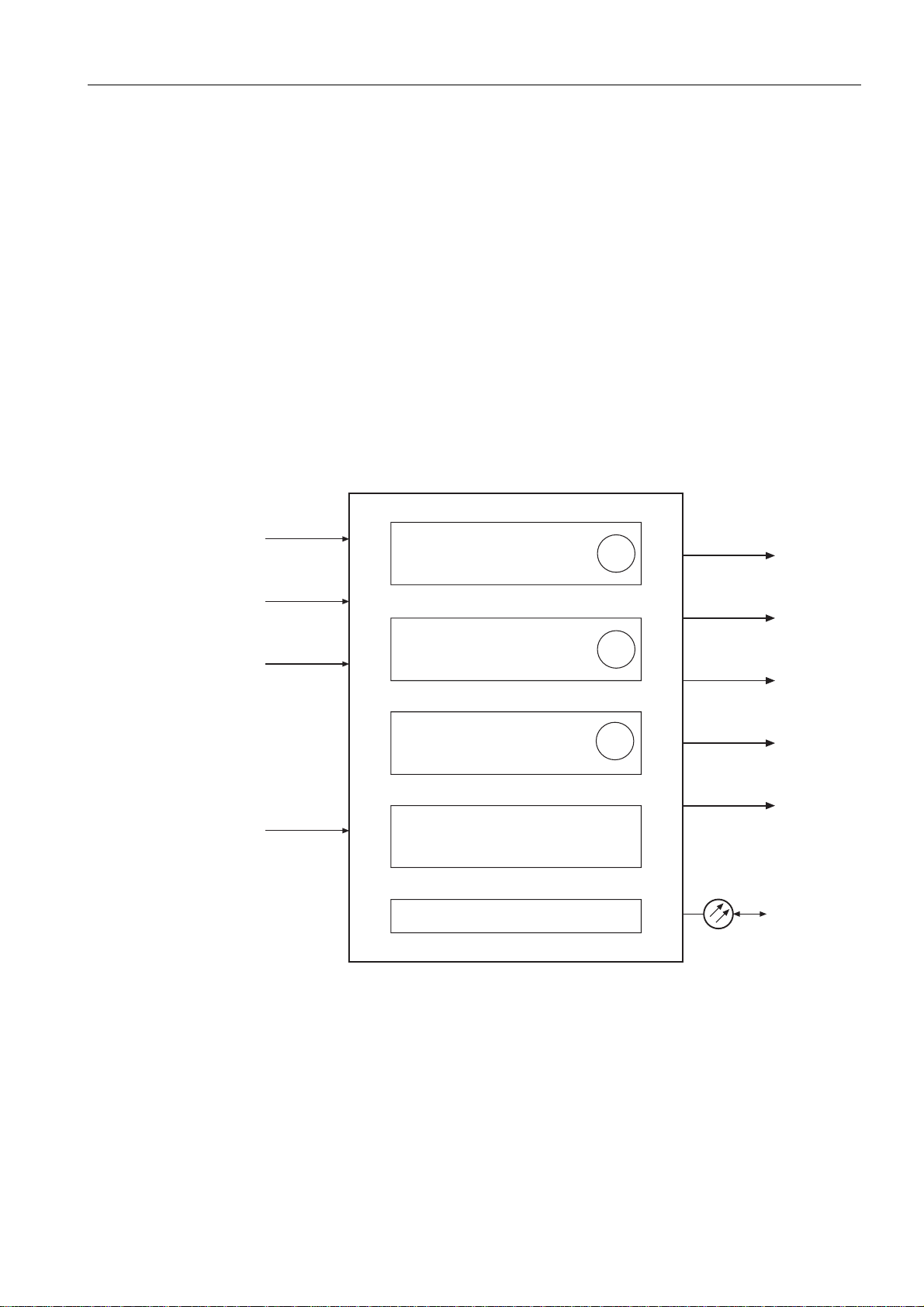

4.1.1.1 Schema of product functions ...........................................9

4.1.1.2 Overcurrent....................................................................10

4.1.1.3 Inputs.............................................................................10

4.1.1.4 Outputs..........................................................................10

4.1.1.5 Circuit-breaker failure protection....................................10

4.1.1.6 Disturbance recorder .....................................................10

4.1.1.7 MMI module...................................................................11

4.1.1.8 Self-supervision.............................................................11

4.1.2 Configuration ..........................................................................12

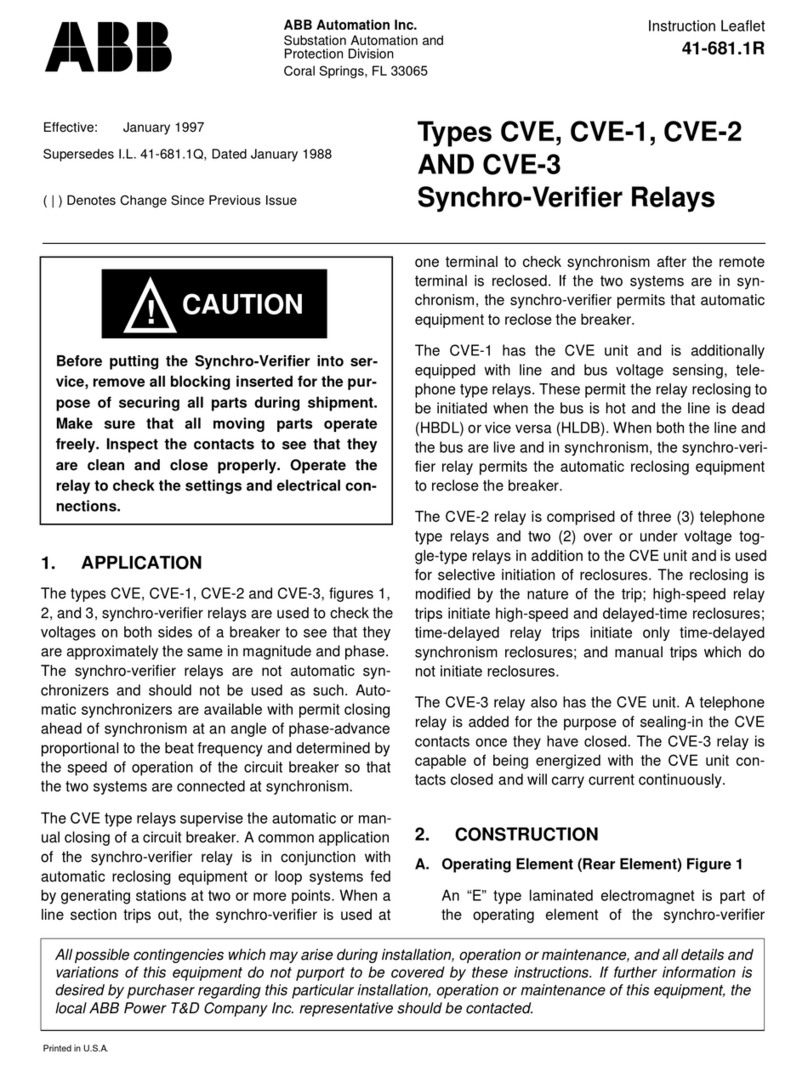

4.1.3 Protection ...............................................................................13

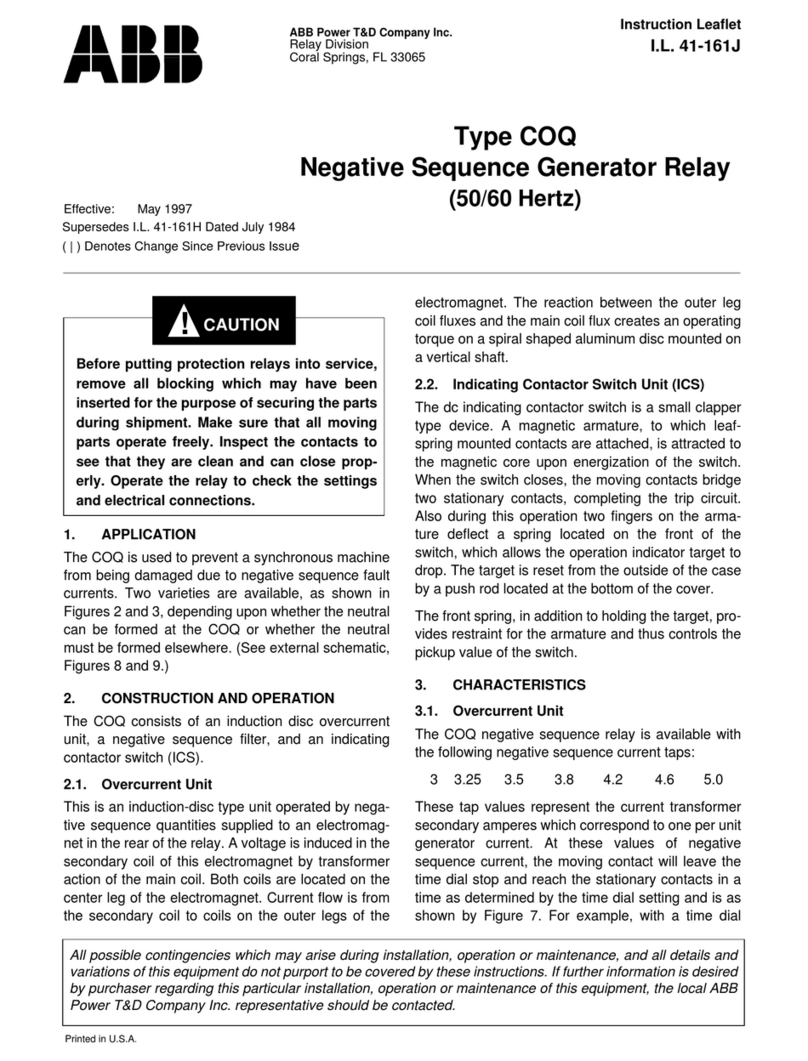

4.1.3.1 Overcurrent unit.............................................................13

4.1.3.2 Time/current characteristics...........................................14

4.1.3.3 Settings..........................................................................23

4.1.3.4 Technical data of protection functions............................30

4.1.4 Monitoring...............................................................................31

4.1.5 Self-supervision (IRF).............................................................31

4.1.6 I/O test....................................................................................32

4.1.7 Disturbance recorder ..............................................................32

4.1.7.1 Function.........................................................................32