8

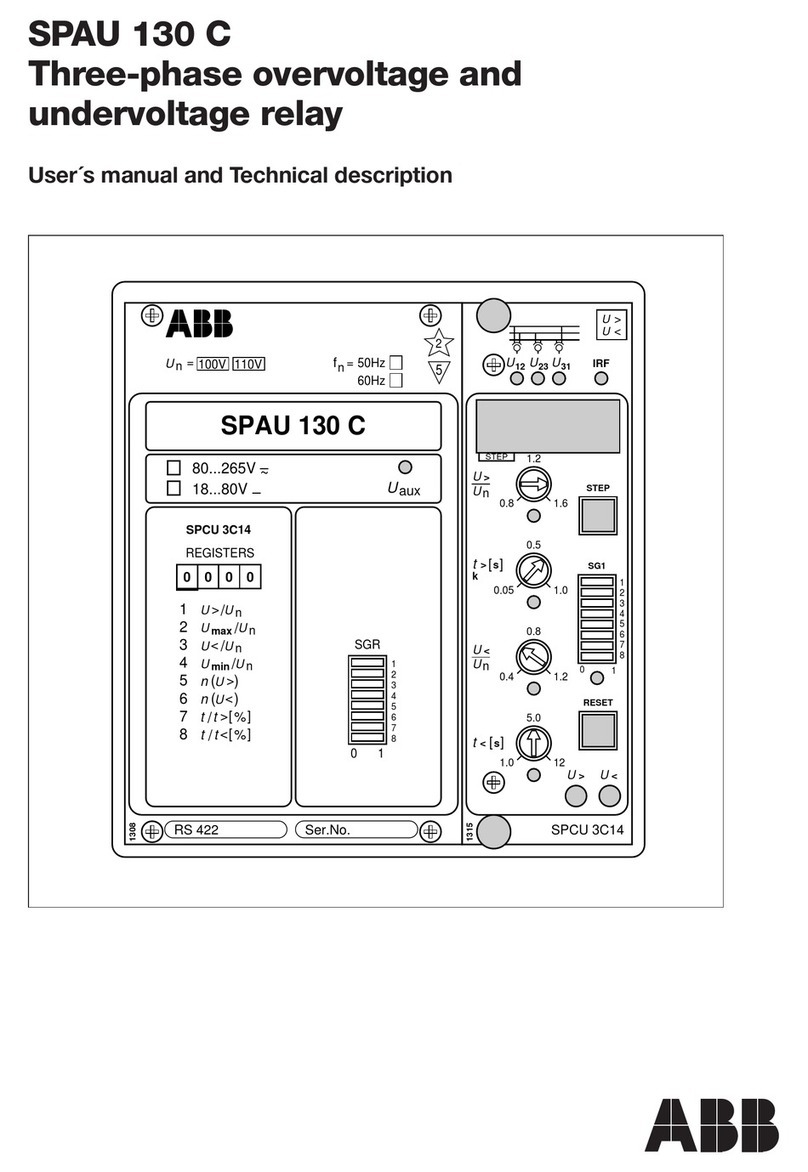

Connections Terminal Function

13-14 Measured voltage U1, rated voltage 100 V

13-15 Measured voltage U1, rated voltage 110 V

16-17 Measured voltage U2, rated voltage 100 V

16-18 Measured voltage U2, rated voltage 110 V

19-20 Measured voltage U3, rated voltage 100 V

19-21 Measured voltage U3, rated voltage 110 V

The relay is able to measure either phase-to-phase voltages or phase-to-neutral

voltages, but phase-to-phase voltages are preferred.

10-11 Stage 1 of the synchro-check relay can be blocked by applying an external auxiliary

voltage level blocking signal BS to terminals 10-11. The blocking function is se-

lected with switch 1 of switchgroup SGB in the main menu of the relay. The

blocking function is not activated in the default setting of the relay.

22-23 Stage 2 of the synchro-check relay can be blocked by applying an external auxiliary

voltage level blocking signal BS to terminals 22-23. The blocking function is se-

lected with switch 2 of switchgroup SGB in the main menu of the relay. The

blocking function is not activated in the default setting of the relay.

45-46 When command mode operation has been selected for stage 1, the stage is acti-

vated for CB closing by an auxiliary voltage level control signal CS13, applied to

the terminals 45-46. If continuous mode operation has been selected no control

signal need be applied to the relay. Switch 3 of switchgroup SGB is used for select-

ing the desired mode of operation. Default setting of stage 1: continuous mode

operation.

47-48 When command mode operation has been selected for stage 2, the stage is acti-

vated for CB closing by an auxiliary voltage level control signal CS23, applied to

the terminals 47-48. If continuous mode operation has been selected no control

signal need be applied to the relay. Switch 4 of switchgroup SGB is used for select-

ing the desired mode of operation. Default setting of stage 2: continuous mode

operation.

68-69 At command mode operation the alarm signal for failed circuit breaker closing

(NC13 and NC23) and for CB close request signals that have remained activated

(CSF13 and CSF23) is received via output relay A at command mode operation.

The switches 1, 3, 5 and 7 of switchgroup SGR are used for the configuration of

the alarm signals. No alarm signals are received at continuous mode operation.

87-88 Output relay B provides the permission signal for CB closing via stage 2 of the

synchro-check relay module.

85-86 Output relay C provides the permission signal for CB closing via stage 1 of the

synchro-check relay module.

70-71-72 Output relay D, terminals 70-71-72, operates as the output relay of the self-super-

vision system of the synchro-check relay. Normally, the relay operates on the closed-

circuit principle and the contact gap 70-72 is closed. If the self-supervision system

detects a permanent fault or the voltage supply to the relay fails, the output relay D

provides an alarm signal by closing the normally open contact gap 71-72.

61-62 The auxiliary supply voltage of the synchro-check relay is connected to terminals

61-62. At DC supply voltage the positive lead is connected to terminal 61. The

permitted voltage range of the power supply and output relay module fitted in the

relay module is indicated on the front panel of the relay. Further technical details

about the auxiliary voltage supply system is given in the section "Power supply and

output relay module".

The synchro-check relay is connected to the data

communication bus and, further, to a control

data communicator, e.g. SACO 148D4, via the

9-pole, D-type subminiature connector located

on the rear of the relay and a bus connection

module type SPA-ZC17_, or SPA-ZC21_ .