6

Operation

indicators

SPCF 1D15

TRIP

RESET

STEP

0024C

PROGRAM

IRF

f

U

f

<

>

<

>

d

f

d

t

SGR

SGB

SGF

[ ]

n

f

U

/

<

Hz

n

U

[ ]

f

Hz

∆

[ ]

r

t

s

>

[ ]

d

f

d

t

/ /

Hz s

[ ]

1

f

Hz

[ ]

4

f

Hz

[ ]

3

f

Hz

[ ]

2

f

Hz

[ ]

1

t

s

,1

t

,

[ ]

2

t

s

,2

t

,

[ ]

3

t

s

,3

t

,

[ ]

4

t

s

,4

t

,

U

RS 452 001 - Ser.No.

SPAF 140 C

aux

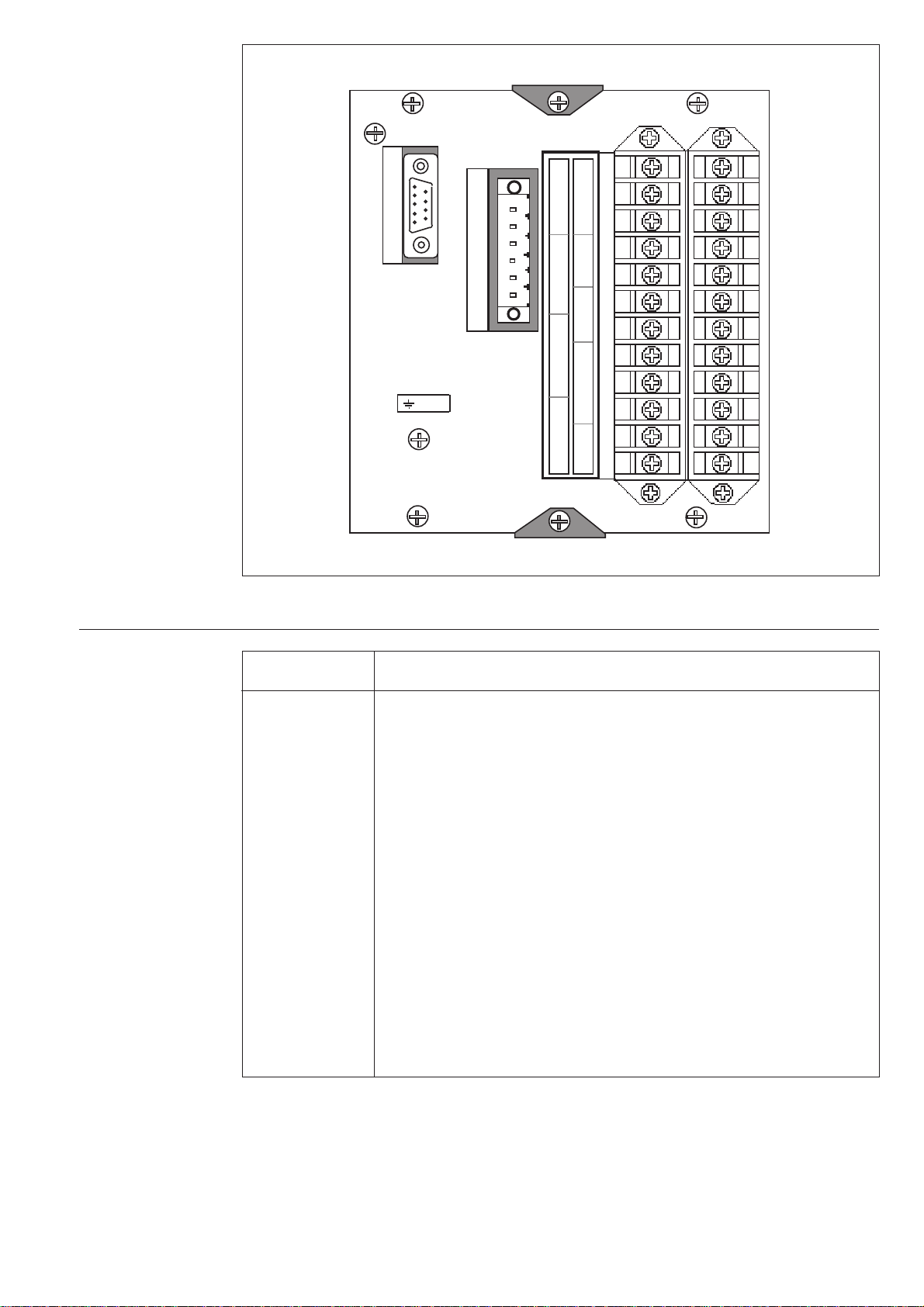

REGISTERS OPER.IND.

1

2

3

4

5

6

Stage 1 Start

Stage 1 Trip

0476A

80...265V ~

–

18...80V –

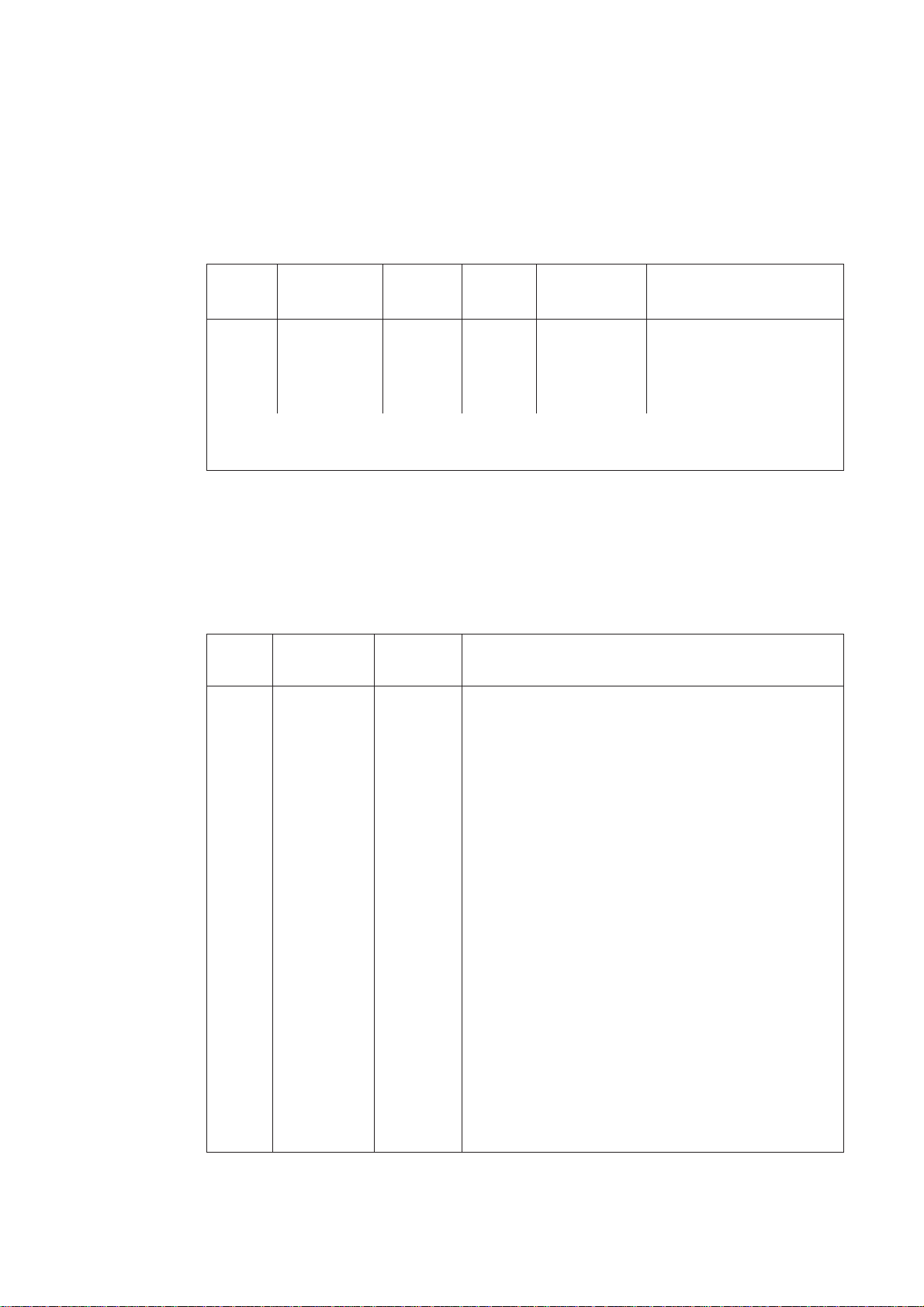

Stage no.

Start ctr

U

n

U

/

f[Hz] [Hz/s]

Stage 2 Trip

Stage 3 Start

Stage 3 Trip

Stage 2 Start

SPCF 1D15

2

5

1

2

3

4

5

6

Stage 4 Start

Stage 4 Trip

Rec. Due

Rec. Over

A

7

8

9

max

min

f

max

min

df/dt

df/dt

n

U

=100V/110V/115V/120V

0000 0

modules and on the system panel of the fre-

quency relay.

Start indications can be programmed to re-

main lit, even though the stage resets. In gen-

eral, the numbers indicating start are auto-

matically reset, whereas trip codes have to be

manually reset by pressing the RESET push-

button. The TRIP indicator at the bottom

part of the front panel can be set to indicate

tripping of any stage. The BS_ signals can be

configured to automatically reset the trip

indicators. A non-reset operation indicator

does not affect the operation of the relay

module.

3. A measured or set value presented on the dis-

play is identified by yellow LEDs on the front

panel.

4. A permanent fault detected by the self-

supervision system is indicated by the IRF

indicator of the concerned relay module

and a fault code on the display of the relay

module. The fault code should be recorded

to facilitate maintenance and repair.

The operation indicators are described in more

detail in the descriptions of the relay modules.

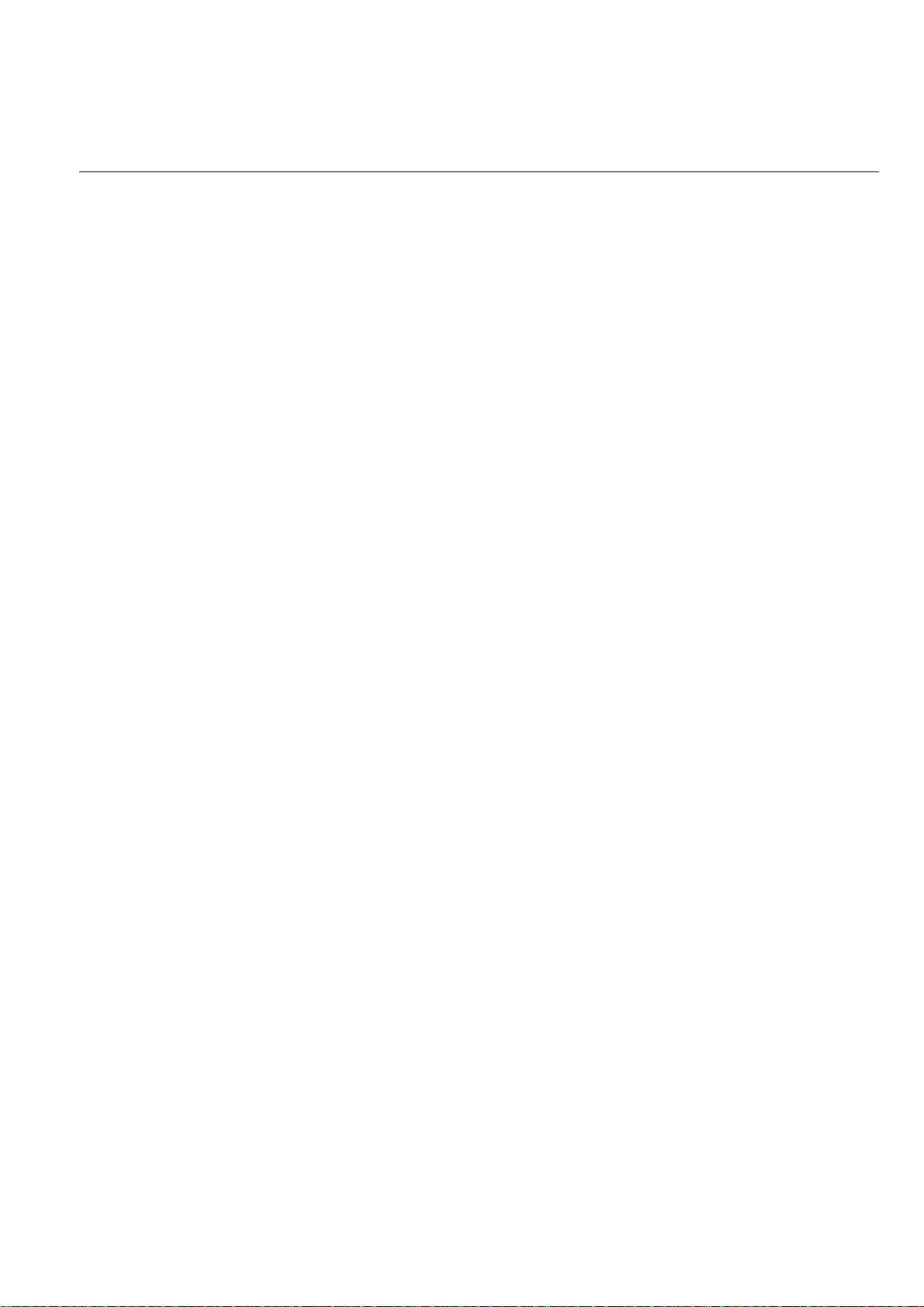

Fig. 3. Front panel of frequency relay SPAF 140 C

1. The green LED indicator Uaux on the sys-

tem panel is lit when the power supply is

operating.

2. Measured values, settings and start and trip

data are indicated on the display. Starting and

tripping are indicated by a red operation code

to the left of the display. The operation codes

are explained in the descriptions of the relay

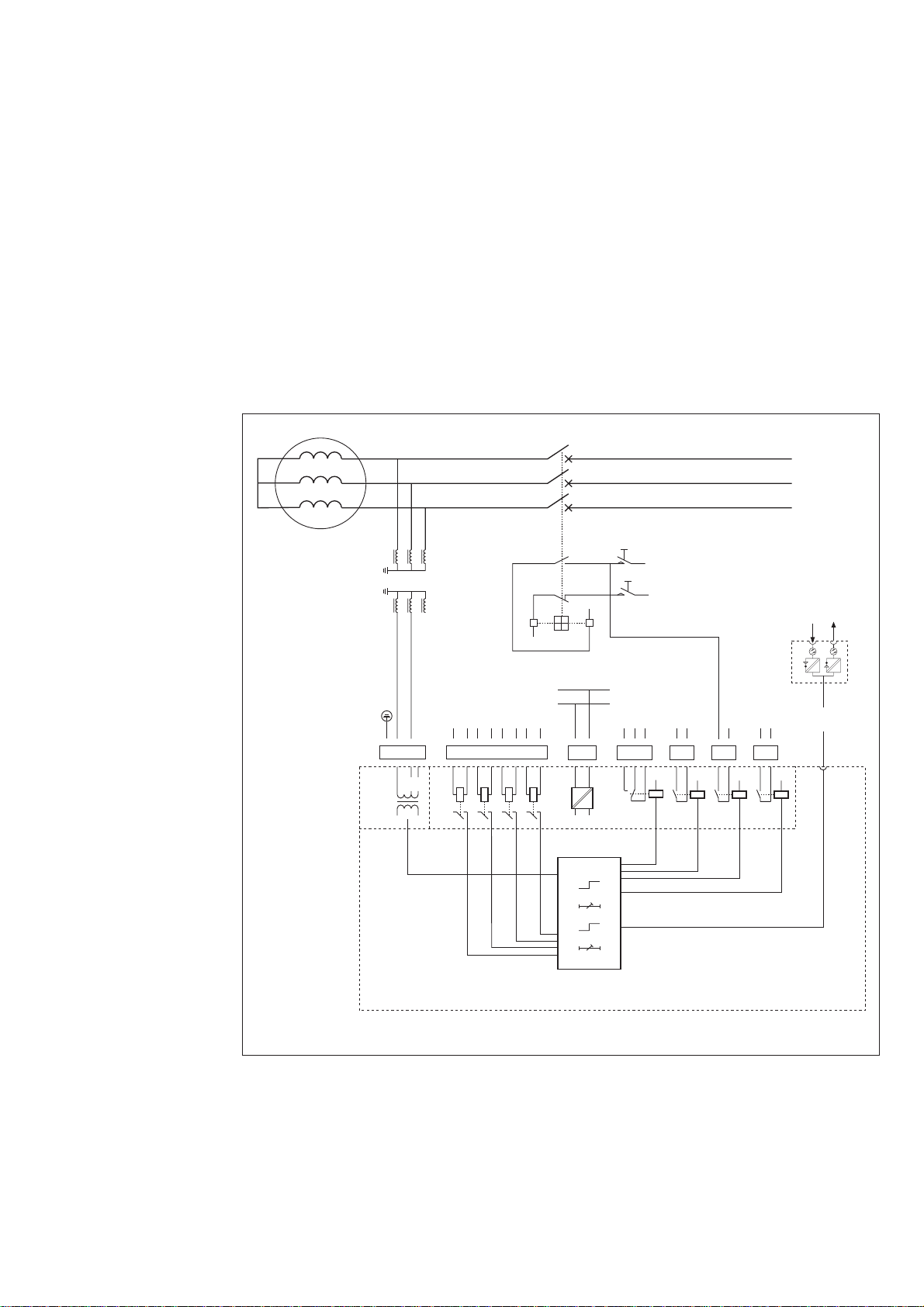

Combined power

supply and I/O

module

The power supply and I/O module of the fre-

quency relay SPAF 140 C is located behind the

system panel of the relay. The module can be

withdrawn after removal of the system panel.

The power supply and I/O module includes the

power supply unit, the output relays with con-

trol circuits and the electronic circuits of the

external control inputs.

The power supply module is a transformer-con-

nected, i.e. galvanically isolated primary and

secondary circuits, flyback type DC converter.

The primary side is protected with a fuse, F1,

situated on the PC board of the module. The

fuse size is 1 A (slow).

The green LED indicator Uaux on the front

panel is lit when the power supply unit is in

operation. The supervision of the voltages sup-

plying the electronic circuits is integrated into

the relay module. A self-supervision alarm is

received once a secondary voltage deviates from

its rated value by more than 25%. An alarm sig-

nal is also received, if the power supply module

is removed or the auxiliary voltage supply to the

relay is interrupted.

The power supply and I/O module is available

in two versions with the following input voltages:

- SPTU 240 R4 Uaux = 80...265 V ac/dc

- SPTU 48 R4 Uaux = 18...80 V dc

The voltage range of the power supply module

of the relay is marked on the system panel of

the relay.

The output signals SS1 and TS1...TS2 of the

mother PC board control an output relay with

the same designation. The operation of a stage

is not fixed to a specific output relay, but can be

configured for the desired relay. However, it

should be noted that the output relays TS1 and

TS2 can be used for circuit breaker control. The

configuration of the switchgroups is described

in the module-specific manuals.

The switchgroups of the relay modules are used

for configuring the external control inputs,

which can be used for blocking one or several

protection stages, resetting operation indicators

or selecting second settings, etc.