1. Motor pin definition

2. Precautions for motor installation

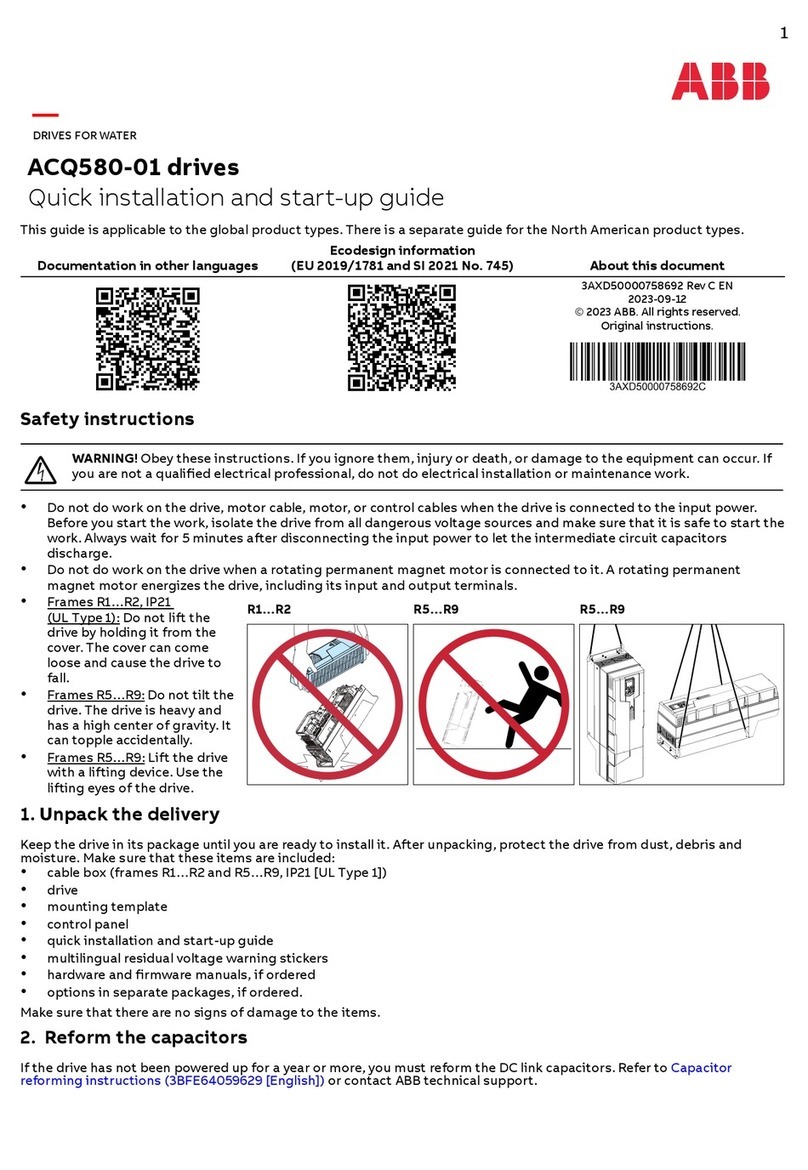

2.1 Cautions for opening the package

2.2 Safety notes on carrying and installation

2.3 Safety notes on wiring

2.4 Safety notes on operation

3. DSM Motor Series

Flange 40,50W,without brake

Flange 60,400W,with brake

Flange 60,400W,without brake

Flange 80,750W,without brake

Flange 130,1kW,with brake

Flange 130,1kW,without brake

Flange 130,1.5kW,without brake

ABB Drives manuals About this manual

3AXD50000942756

Rev A ZH&EN 2022-08-20

©2022 ABB All Rights Reserved

Power connection without brake (40/60/80 mm)

AMP - 4P

Power connection without brake (130 mm)

20 - 18P

Power connection with brake (40/60/80 mm)

AMP - 6P

Power connection with brake (130 mm)

20 - 18P

sensAR Encoder - Single-turn (40/60/80 mm)

AMP - 9P

sensAR Encoder - Single-turn (130 mm)

20 - 29P

sensAR Encoder - Muliti-turn (40/60/80 mm)

AMP - 9P

sensAR Encoder - Muliti-turn (130 mm)

20 - 29P

—

ABB SERVO PRODUCTS

DSM Servo Motor

Quick installation guide

Pin Motor side

lead wire color Description Motor - Drive

wire color

1 Red U Red

2 White V White

3 Black W Black

4 Yellow/Green PE Yellow/Green

Pin Motor side

lead wire color Description Motor - Drive

wire color

F Red U Red

I White V White

B Black W Black

E Yellow/Green PE Yellow/Green

Pin Motor side

lead wire color Description Motor - Drive

wire color

1 Red U Red

2 White V White

3Yellow BK Blue

4 Black W Black

5 Yellow/Green PE Yellow/Green

6Yellow BK Brown

Pin Motor side

lead wire color Description Motor - Drive

wire color

FRed U Red

I White V White

BBlack W Black

E Yellow/Green PE Yellow/Green

CYellow BK Blue

DYellow BK Brown

Pin Motor side

lead wire color Description Motor - Drive

wire color

1GreenDATA+ Blue

2 Yellow DATA- Blue/Black

6Brown VCC Red

7White GND Black

8 Shield Shield Shield

Pin Motor side

lead wire color Description Motor - Drive

wire color

EGreenDATA+ Blue

F Yellow DATA- Blue/Black

GWhite GND Black

HBrown VCC Red

J Shield Shield Shield

Pin Motor side

lead wire color Description Motor - Drive

wire color

1Green DATA+ Blue

2 Yellow DATA- Blue/Black

4 Black VBAT Green+battery Red

6Brown VCC Red

7 White GND Black+battery Black

8 Shield Shield Shield

Pin Motor side

lead wire color Description Motor - Drive

wire color

EGreen DATA+ Blue

F Yellow DATA- Blue/Black

G White GND Black+battery Black

HBrown VCC Red

T Black VBAT Green+battery Red

J Shield Shield Shield

Read these safety precautions thoroughly before using the

motor !

After opening the package, confirm

that the correct product has been

shipped and there are no signs of

damage.

1. Do not carry the motor by the leads or the shaft. Careless

handling may cause damage to the motor or personal injury.

2. Do not hit the motor or jar the shaft. Shock can damage the disk

inside the encoder.

3. The motor is not waterproof or oil-proof. Do not expose the

motor to water, oil, or oil baths.

4. Never use the motor in the presence of harmful gas or liquid, or in

an environment containing excessive moisture or water vapor.

5. To protect the delicate encoder inside the motor, take all

necessary precautions against electrical noise, vibration, shocks

and abnormal temperatures.

1. Contact ABB if motor current exceeds more than 3 times the

rated current, which can cause demagnetization of the motor

magnets.

2. Check the phase sequence of the motor, the cables and the brake

voltage. Also carefully check the power and signal wires to the

encoder. Incorrect wiring can cause irregular running of the

motor which leads to damage or burnout of the motor.

3. Take particular care to avoid incorrect wiring or operation of the

encoder, otherwise the electronics could be damaged.

4. Wire the power line of the motor and the power/signal wires of

the encoder as far away from each other as practical to prevent

noises problems. Never wire them in the same duct.

5. Always connect the earth terminals to ground.

6. Never subject the encoder terminals to a withstand-voltage test

or a megger-test. Such tests can damage the terminal.

7. Disconnect the controller when performing the withstand-

voltage test or megger-test on the motor, brake or resolver. Do

not perform the tests unnecessarily, which can cause

deterioration of the product.

1. This AC servomotor is designed to be controlled by a dedicated

drive. Never connect it directly to a commercial power source

(115/230 VAC 50/60 Hz etc.). Read the instruction manual

carefully to properly use the motor.

2. Make sure to use the motor within the specified conditions. Note

that the specified motor temperature assumes that a radiator

plate is attached to the motor.

3. The built-in brake is used to hold the stationary motor. Never use

it for braking. Also note that the holding brake is not a stopping

device to assure the safety of the machine. A safety stopping

mechanism should be provided on the machine side.

4. If any abnormal smell, noise, smoke, heating or vibration is

detected, stop the motor immediately and turn off the power.

5. Do not drop or splash water or oil into the product.

6. When installing the servo motor, the axis of the servo motor and

the axis of the load machine should be aligned. If the coaxiality is

not enough, vibration will occur, and sometimes the bearing and

encoder may be damaged.

7. It is recommended to use hexagon socket screws with 8.8

strength class or higher to fix the motor.

8. In the environment with grinding fluid, oil mist, iron powder,

cutting, etc., choose the motor type with oil seal.

9. When making vertical installations with the shaft extending

upwards, make sure that no liquid can seep into the upper

bearing.

10. In applications with liquid, please install the motor with the

wiring port facing downward (as shown in the figure below) to

prevent the liquid from dripping down the cables to the motor.

11. Try to increase the bending radius of the cable to reduce the

bending stress. It is recommended that the bending radius of the

motor power cable and signal cable are greater than 10 times the

outer diameter of the cable.

12. If the motor shaft is with a flat key, remove it before rotation,

otherwise there is a risk of the key being thrown away from the

rotation.

13. Do not use the motor in an enclosed environment, the enclosed

environment will lead to high temperature of the motor and

shorten its lifetime.

14.Motor surfaces can reach temperatures above 100 °C and

contact with these hot surfaces can cause burns.