Higen FDA5000 Series User manual

OPERATION MANUAL

AC Servo Drive

FDA5000 Series

Ver 3.3 (Soft. Ver. 6.02 ~)

FDA5000 Series

ServoDriveUser Manual

< CAUTION >

1. Check Motor ID certainly. ( P1-01 )

2. Check Drive Amp-Type certainly. ( P1-10 )

Model 5001 5002 5004 5005 5010 5012 5015 5020 5030 5045 5075

Amp Type 0 1 2 5 6 7 11 12 13 14 15

3. Check Encoder Pulse certainly. ( P1-12 )

Example)

Encoder Type

4. Operate servo system after autotuning is off. ( P2-24 )

5. Avoid impacting to the Motor in connecting. Especially, avoid

impacting to the Encoder in connecting coupling to the Motor shaft or

operating.

6. Recommended specifications in Encoder wiring.

Check Encoder Type and use authorized shield cable.

Encoder Type Reference Page

Incremental Encoder 3-17

Absolute Encoder 3-20

7. Treatment of the servo motor attached holding brake .

: The brake built in the servo motor is a normal closed type brake.

Which is used only to hold and can not be used for braking. Use the

holding brake only to hold a stopped servo motor.

Symbol Pulse Type

A 2000

B 2500

C 3000

D 5000

E 6000

F 2048

Incremental

15 wires

G 2048 Absolute 11/13bit

FMALN09-AA00

Table of Contents

1. Checking and Handling --------------------------------------------- 1-1

1-1 Handling(Connection of main circuit and motor) --------------------- 1-1

1-2 Caution during Use ---------------------------------------------------------- 1-2

1-3 Installation --------------------------------------------------------------------- 1-3

1-4 Order Specifications --------------------------------------------------------- 1-7

1-5 Functions that facilitate starting ------------------------------------------- 1-10

2. Ratings and Specifications ---------------------------------------- 2-1

2-1 Ratings and Specifications for AC Servo driver

FDA-5000 series ------------------------------------------------------------- 2-1

2-2 AC Servo Motor Ratings and Specifications -------------------------- 2-2

3. Wiring and Signals --------------------------------------------------- 3-1

3-1 Representative wiring ------------------------------------------------------ 3-1

3-2 Internal Configuration ------------------------------------------------------ 3-2

3-3 Main Circuit Terminal Board Wiring ------------------------------------- 3-3

3-4 CN1 Wiring and Signal ----------------------------------------------------- 3-9

3-5 Description of CN2 Wiring and Signals -------------------------------- 3-17

4. Digital Loader Operation ------------------------------------------- 4-1

4-1 Displays after power is connected -------------------------------------- 4-3

4-2 Sub-menu Group ------------------------------------------------------------ 4-5

4-3 Operation Monitoring Menu ----------------------------------------------- 4-5

4-4 Changing Parameters ------------------------------------------------------ 4-8

4-5 Test Mode (Test Mode:P6--) ---------------------------------------------- 4-9

5. Mount Loader Operation ------------------------------------------- 5-1

5-1 Initial screen after power is connected --------------------------------- 5-3

5-2 Sub-menu Group ------------------------------------------------------------- 5-4

5-3 Operation Monitoring Menu ------------------------------------------------ 5-5

5-4 Changing Parameters ------------------------------------------------------- 5-9

5-5 Test Mode (P6--) -------------------------------------------------------------- 5-10

6. Parameter Setting ---------------------------------------------------- 6-1

6-1 Parameter Summary -------------------------------------------------------- 6-2

Table of Contents

6-2 Description of servo status (Status Window: ST--) ------------------ 6-6

6-3 Motor and System Parameters (Motor Parameters: P1--) --------- 6-10

6-4 Common Parameters Related to Control (Control Mode: P2--) -- 6-13

6-5 Speed control parameters (Speed Mode: P3--) ---------------------- 6-21

6-6 Position control parameters (Position Mode: P4--) ------------------ 6-24

6-7 Torque control parameters (Torque Mode: P5--) --------------------- 6-27

6-8 Test Mode parameters (Test Mode: P6--) ------------------------------ 6-28

6-9 Alarm status display (Alarm Status: ALS--) ---------------------------- 6-30

7. How to Use Speed Servo ------------------------------------------ 7-1

7-1 Power Supply Wiring ------------------------------------------------------- 7-1

7-2 CN1 Wiring -------------------------------------------------------------------- 7-1

7-3 CN2 Wiring -------------------------------------------------------------------- 7-3

7-4 Setting Parameters Related to Motor and Servo -------------------- 7-4

7-5 Limiting Output Torque ----------------------------------------------------- 7-6

7-6 Inputting Speed Command ------------------------------------------------ 7-7

7-7 Setting Motor Deceleration/Acceleration Characteristics ---------- 7-10

7-8 Using Monitor ----------------------------------------------------------------- 7-11

7-9 De-resonance Frequency Operation ------------------------------------ 7-13

7-10 Other Set Values ----------------------------------------------------------- 7-13

8. How To Use Position Servo ---------------------------------------- 8-1

8-1 Power Suuply Wiring ------------------------------------------------------- 8-1

8-2 CN1 Wiring -------------------------------------------------------------------- 8-1

8-3 CN2 Wiring -------------------------------------------------------------------- 8-3

8-4 Setting Parameters Related to Motor and Servo -------------------- 8-4

8-5 Limiting Output Torque ----------------------------------------------------- 8-6

8-6 Inputting Position Commands -------------------------------------------- 8-7

8-7 Using Monitor ----------------------------------------------------------------- 8-9

8-8 De-resonance Frequency Operation ------------------------------------ 8-9

9. How To Use Torque Servo ------------------------------------------- 9-1

9-1 Power Supply Wiring ------------------------------------------------------- 9-1

9-2 CN1 Wiring -------------------------------------------------------------------- 9-1

9-3 CN2 Wiring -------------------------------------------------------------------- 9-3

9-4 Setting Parameters Related to Motor and Servo -------------------- 9-4

Table of Contents

9-5 Speed Limiting --------------------------------------------------------------- 9-4

9-6 Inputting Torque Command ----------------------------------------------- 9-5

9-7 Using Monitor ----------------------------------------------------------------- 9-6

9-8 Other Set Values ----------------------------------------------------------- 9-6

10. How to Use Speed/Position Servo ------------------------------ 10-1

10-1 Power Supply Wiring ------------------------------------------------------- 10-1

10-2 CN1 Wiring -------------------------------------------------------------------- 10-1

10-3 CN2 Wiring -------------------------------------------------------------------- 10-3

10-4 How To Use Speed/Position Servo -------------------------------------- 10-4

11. How to Use Speed/Torque Servo -------------------------------- 11-1

11-1 Power Supply Wiring ------------------------------------------------------- 11-1

11-2 CN1 Wiring -------------------------------------------------------------------- 11-1

11-3 CN2 Wiring -------------------------------------------------------------------- 11-3

11-4 How To Use Speed/Torque Servo --------------------------------------- 11-4

12. How to Use Position/Torque Servo ----------------------------- 12-1

12-1 Power Supply Wiring ------------------------------------------------------- 12-1

12-2 CN1 Wiring -------------------------------------------------------------------- 12-1

12-3 CN2 Wiring -------------------------------------------------------------------- 12-4

12-4 How To Use Position/Torque Servo ------------------------------------- 12-4

13. Examples of Operation Flow and PLC Wiring -------------- 13-1

13-1 Generating Speed Command (speed control) ------------------------- 13-1

13-2 Generating Speed Command (position control) ----------------------- 13-1

13-3 Generating Speed Command (position/speed control) -------------- 13-2

13-4 Generating Speed Command (torque control) ------------------------- 13-2

13-5 Example of positioning Unit K7F-POSP connection between FDA-5000,

the AC servo driver of HIGEN and PLC MASTER-K ----------- 13-3

13-6 Example of positioning Unit MD71 connection between FDA-5000,

the AC servo driver of HIGEN and PLC GOLDSEC-M ------------ 13-4

13-7 Example of positioning Unit G3F-POAA connection between FDA-5000,

the AC servo driver of HIGEN and PLC GLOPAPLC -------------- 13-5

13-8 Example of positioning Unit G4F-POPA connection between FDA-5000,

the AC servo driver of HIGEN and PLC GLOFAPLC -------------- 13-6

Table of Contents

13-9 Example of positioning Unit G3F-POPA connection between FDA-5000,

the AC servo driver of HIGEN, and PLC GLOFAPLC -------------- 13-7

14. Maintenance and Inspection -------------------------------------- 14-1

14-1 Caution ------------------------------------------------------------------------- 14-1

14-2 Inspection Items ------------------------------------------------------------- 14-1

14-3 Replacing Parts -------------------------------------------------------------- 14-2

14-4 Maintenance ------------------------------------------------------------------ 14-3

15. Troubleshooting ------------------------------------------------------ 15-1

15-1 Servo Motor ------------------------------------------------------------------- 15-1

15-2 Servo Driver ------------------------------------------------------------------- 15-2

16. External View ---------------------------------------------------------- 16-1

16-1 External Dimensions of AC Servo Driver ------------------------------ 16-1

16-2 External Dimensions of AC Servo Motor ------------------------------ 16-2

17. Specifications of Options ------------------------------------------ 17-1

17-1 AC servo motor cable specifications ----------------------------------- 17-1

17-2 AC servo driver -------------------------------------------------------------- 17-3

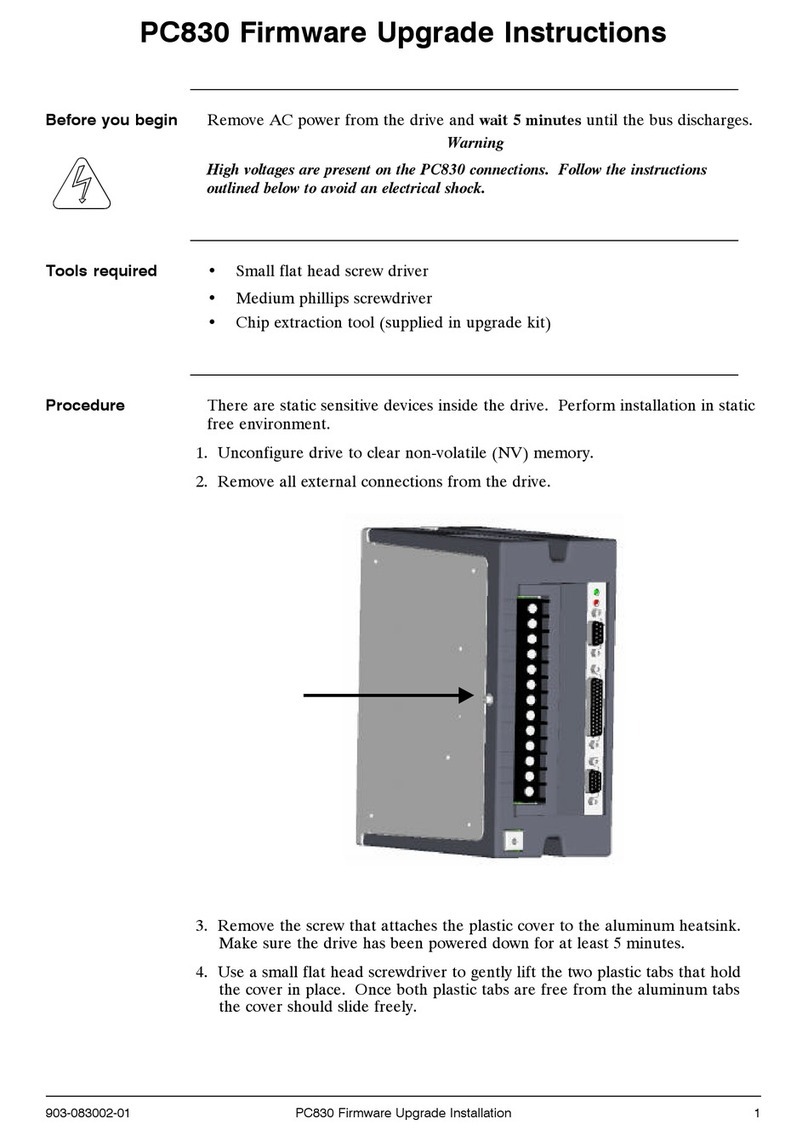

Chapter 1. Checking and Handling

1-1

1. Checking and Handling

1.1 Handling (Connection of main circuit and motor)

Thank you for purchasing HIGEN AC Servo Driver. Incorrect handling of the driver may lead to

unsatisfactory operation or, in some cases, to the rapid reduction of its life, or damage to the servo.

Handle and operate the driver according to the instructions given in this manual.

distance. (Caution) Use hi

g

her than class-3 earth

* Power Supply : Use power supply within specification

(3-phase AC200~230V)

(Caution!) If the power voltage is AC 440V,use a

transformer to change AC 440V to AC 220V

* Install magnetic contactors

Do not use magnetic contactor to start or stop the servo

as it may reduce its life.

* No Fuse Circuit Breaker or Auto Breaker : Large level

of current flows when power is applied to the servo

For selection of breakers, refer to Table 3.1, chapter3.3

* Installation place : The operating life of the servo is

affected by ambient temperature.

Maintain ambient temperature at a level below 50℃

* Wiring : Improper wiring may damage to the servo. The control

signal line must be sufficiently away from the main

circuit wiring so that the line is not affected by

noises.

* Connection with output terminals : Do not connector condensers

,radios or noise filters during operation as it may

cause damage to the equipment.

* Grounding : To prevent electric shock and effectively control

noise,ground the motor and driver at the shortest

* Motor system : Do not strike the motor shaft and detecter with

a hammer.

(Caution) Impact may cause damage th the encoder inside the motor

* Noise Filter : Use noise filters to eliminate external

noise that comes with the commercial power supply

For selection of noise filters, refer to Table3.1, Chapter3.3

HIGEN

GND

Chapter 1. Checking and Handling

1-2

1.2 Caution during Use

Improper handling of the driver may lead to unexpected accident or damage. The following are

important points in operating the driver.

1.2.1 Handling

yAvoid impact to the encoder, the motor detector.

Striking the shaft with a hammer may cause the motor to drop leading to unexpected damage.

yDo not connect commercial power supply (AC 220V) directly to the motor.

Direct connection induces flow of overcurrent leading to the deterioration of the magnetic effect.

Always use specified servo driver.

1.2.2 Wiring

yConnect the driver and the motor earth terminals in the direction of the driver, and ground the

terminals at the shortest distance in one operation. To prevent electric shock and improper

operation, use class-3 earth (Less than 100 Ω).

yAlways match the U, V ,W and FG terminals of the motor with those of the driver. You cannot

change the direction of rotation by changing 2 wires as in the case of widely used common

motors.

yConnecting commercial power supply to the U, V, W and FG terminals of the driver may cause

damage.

(Apply 200V power supply to R, S and T terminals)

Use a transformer in case power supply is other than 200V.

yConnect standard regenerated resistance to the P and B terminals of the driver.

Chapter 1. Checking and Handling

1-3

1.2.3 Operation

yUse the magnetic brake of the motor only for emergency and maintenance (preservation).

The brake is designed for maintenance (preservation) during power outage. If used to reduce

speed, the brake wears out fast.

yInstall brakes and magnetic contactors on power supply terminals R, S and T.

In case an error occurs or abnormal current flows, shut off the circuit to prevent secondary fire.

1.2.4 Maintenance and inspection

y"High voltage" still remains inside the driver for a while even after power supply is shut off.

(Danger!)

To prevent electric-shock, carry out wiring work or inspection at least l0 minutes after the power

is cut off and the charge lamp is turned off.

yThe regenerated resistance and the servo motor remain hot for a while after power is turned off.

Touching them may cause burns.

yConducting megger test on the driver may cause damage to the driver. Do not perform megger

test.

yThe motor detector is not detachable. Never remove the cover.

1.3 Installation

1.3.1 Installation of servo driver

yOperating environment

Ambient temperature 0-50℃(There should be no freezing) Note)

Ambient humidity 90% RH or lower (There should be no steam)

Note) Inside panel temperature specifications: To ensure maximum operating life and reliability

of the driver, maintain the average panel temperature at 40℃or lower.

If the driver is installed in a place within arm’s reach, install the fan to maintain the

temperature of driver at 70℃or lower.

Chapter 1. Checking and Handling

1-4

yInstallation direction and intervals

- Install the servo driver in such a way that FDA-5000 can be seen from the front.

- If the drivers are installed in a closed panel, maintain an interval of more than 10 mm

between drivers and more than 40 mm between top and bottom. If multiple number of panels

are installed in parallel, about 100 mm space is required on the upper side. Avoid heat by

installing fans.

- Install heat sources, such as regenerated resistance, away from the driver.

yPrevention of ingress of foreign matter

- Exercise caution when drilling control panels to prevent chips produced by drilling from

getting into the driver.

- Take appropriate measures to prevent oils, water and metal powder from getting into the

driver from openings in the control panels and the fan installed on the ceiling.

- If the driver is used in a place with large amount of toxic gases and dust, protect the driver

with an air purge.

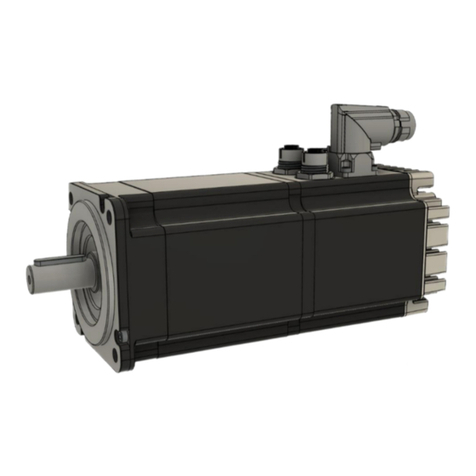

1.3.2 Servo motor installation

yOperating environment

Ambient temperature 0-40℃(There should be no freezing)

Ambient humidity 80% RH or lower (There should be no steam)

External vibration X, Y = 19.6 m/s2 (2G)

yCaution when assembling load system (Prevent impact on shaft)

It is important to accurately match the motor shaft with the shaft center of the connecting

machine. Unmatched shaft center causes vibration, and may cause damage to the bearing. Use

a rubber hammer to install couplings to prevent excessive force from being applied to the shaft

and bearing.

Check 4 places in turn. The difference between maximum and minimum should be 0.03 or lower.

Load tolerance on shaft

- Use flexible couplings, and maintain the shaft center deviations within the specified tolerance.

- Use pulleys and sprockets that can accomodate the allowable load.

Chapter 1. Checking and Handling

1-5

MOTOR MODEL RADIAL LOAD AXIAL LOAD

Series Type N Kgf N kgf REFERENCE DIAGRAM

CN01~CN05 196 20 68 7

CN06~CN08 245 25 98 10

CN09~CN15 490 50 196 20

CN20~CN30 686 70 343 35

CN

CN30A~CN50A 1470 150 490 50

KN03~KN07 245 25 98 10

KF08~KN11 490 50 196 20

KF15~KN22 686 70 343 35

KN

KN22A~KN55 1470 150 490 50

TN05~TN09 490 50 196 20

TN13~TN17 686 70 343 35

TN

TN20~TN75 1470 150 490 50

LN03~LN06 490 50 196 20

LN09~LN12 686 70 343 35

LN

LN12A~LN40 1470 150 490 50

KF08~KF10 490 50 196 20

KF15 686 70 343 35

KF

KF22~KF50 1470 150 490 50

TF05~TF09 490 50 196 20

TF13 686 70 343 35

TF

TF20~TF44 1470 150 490 50

LF03~LF06 490 50 196 20

LF09 686 70 343 35

LF

LF12~LF30 1470 150 490 50

Radial

Load

A

xial

Load

yAccuracy of attachments

The accuracies of the output shaft and attachments of the AC servo motor are shown on the

following table.

Item Accuracy

(T.I.R.) Reference Diagram

Perpendicularity of flange attachment plane and

output shaft (A) 0.04mm

Eccentricity of flange fitting outer diameter (B) 0.04mm

Vibration of output shaft end (C) 0.02mm

(Note) T.I.R : Total Indicator Reading

Chapter 1. Checking and Handling

1-6

yImpact resistance

The driver withstands an acceleration of 10G and two times of

impacts when up-and-down impacts are applied after setting the

motor shaft horizontally.

However, a precision detector is attached to the end of the shaft on

the opposite side of the load. Take caution not to apply impact

directly to

this end.

yVibration resistance

The driver withstands a vibration acceleration of 2.0G when

vibration is applied in up and down, left and right, and front

and back directions after setting the motor shaft horizontally.

yVibration grade

The vibration grade of the AC servo motor is V15 at the rated rpm.

yDirection of installation

- Motor can be installed horizontally or at the top

or bottom of the shaft.

- Keep the motor cable downward.

- If the motor is installed vertically, install a cable trap so that oils or water do not flow into the

motor.

yCable disconnection

- Take caution not to cause stress or damage to the cables.

- If the motor is used as a mobile motor, use movable cables.

Chapter 1. Checking and Handling

1-7

1.4 Order Specifications

Prior to installing the product, check the ratings plate to see if the related specifications match with

those of the order.

1.4.1 Servo motor model marking

1.4.2 Servo driver model marking

♦Rated Power (Watt)

Symbol Rated Output (W) Symbol Rated Output (W)

01 100 15 1500

02 200 16 1600

03 300 20 2000

04 400 22 2200

05 450/500 30 3000

06 550/600 35 3500

07 650 40 4000

08 750/800 44 4400

09 850/900 50 5000

10 1000 55 5500

12 1200 75 7500

13 1300

♦AC Servo Motor

♦Series

Symbol Use

CN,CK High-speed, Low torque type

KF,KN Medium-speed, Standard type

TF,TN Medium-speed, High torque type

LF,LN Low-speed, High torque type

♦Encoder Type

Symbol Pulse Type

A 2000

B 2500

C 3000

D 5000

E 6000

F 2048

G 2048 Absolute 11/13 bit

Incremental 15 line

FMA

♦Shaft Type

Symbol Item

A Straight & No Key

B Straight & Key

C Tapper & Key

♦Break Installed

Symbol Item

0 None

1 Oil seal attached

2 130 Flange ( Brake for 24V )

♦Seal Type

Symbol Item

0 None

1 Oil seal attached

♦AC Servo Drive

♦Rated Power (Watt)

Symbol Power (W) Symbol Power (W) Symbol Power (W)

01 100 10 1000 30 3000

02 200 12 1200 45 4500

04 400 15 1500 75 7500

05 500 20 2000

50

FDA

♦FDA5000 Series

♦Encoder Type

Symbol Encoder Type

None Incremental

A Absolute

♦Type

Symbol Encoder Type

None Standard type

M Standard type + M/Loader

C Position decision type

Chapter 1. Checking and Handling

1-8

1.4.3 AC Servo application table

Drive

Motor Flange Model FDA-

5001 FDA-

5002 FDA-

5004 FDA-

5005 FDA-

5010 FDA-

5012 FDA-

5015 FDA-

5020 FDA-

5030 FDA-

5045 FDA-

5075

CKZ5 ◎

40 CK01 ◎

CK02 ◎

CK

Series

3000

/5000

(r/min) 60 CK04

◎

CN01 ◎

CN02 ◎

CN03 ◎

CN04 ◎

60

CN05 ◎

C

N04

A

◎

CN06

◎

CN08

◎

80

CN10

◎

CN09

◎

CN15 ◎

CN22

◎

130

CN30

◎

C

N30

A

◎

C

N50

A

◎

CN

Series

3000

/5000

(r/min)

180 CN70 ◎

KN03 ◎

KN05 ◎

KN06

◎

80

KN07

◎

KN06

A

◎

KN11

◎

KN16 ◎

130

KN22

◎

KN22

A

◎

KN35

◎◎

KN55

KN

Series

2000

/3000

(r/min)

180

KN70

TN05

◎

TN09

◎

TN13 ◎

130

TN17

◎

TN20

◎

TN30

◎◎

TN44

TN55

TN

Series

1500

/3000

(r/min) 180

TN75 ◎

Chapter 1. Checking and Handling

1-9

Drive

Motor Flange Model FDA-

5001 FDA-

5002 FDA-

5004 FDA-

5005 FDA-

5010 FDA-

5012 FDA-

5015 FDA-

5020 FDA-

5030 FDA-

5045 FDA-

5075

LN03 ◎

LN06 ◎

LN09 ◎

130

LN12 ◎

L

N12

A

◎

LN20

◎

LN30

◎◎

LN

Series

1000

/2000

(r/min) 180

LN40

◎

KF08 ◎

KF10 ◎

130 KF15 ◎

KF22

◎

KF35

◎

KF

Series

2000

/3000

(r/min) 180 KF50

◎

TF05 ◎

TF09 ◎

130 TF13 ◎

TF20

◎

TF30

◎

TF

Series

1500

/3000

(r/min) 180 TF44

◎

LF03 ◎

LF06 ◎

130 LF09 ◎

LF12 ◎

LF20

◎

LF

Series

1000

/2000

(r/min) 180 LF30

◎

Chapter 1. Checking and Handling

1-10

1.5 Functions that facilitate starting

The following are the functions that help diagnosing and starting of the control panel and the

machine.

Major function Description

Autotuning

This function automatically calculates the load's inertia moment by

detecting the current and speed at the time of starting. Adjusting of

the machine, which so far has been carried out based on experience

and senses (six senses and intuition), can easily be performed.

[Refer to Control Mode, P2-23, 24]

Test operation

carried out without

external instructions

(Jog operation)

Motor can be run with only the servo driver loader without positioning

system or separate operation panel. Motor speed can also be

selected freely, and machine operation can be tested easily.

[Refer to Test Mode, P6]

Motorless operation

(Simulation

operation)

This test mode operation function can operate the servo amplifier

without the motor. The control panel can independently check

functions or sequences.

[Refer to Test Mode, P6]

Abundant status

display functions

With abundant status displays, such as command speed, rpm, load

ratio, pulse error and I/O status, the digital servo enables simplified

diagnosis of operations.

[Refer to Status Window, St--]

Chapter 2. Ratings and Specifications

2-1

2. Ratings and Specifications

2.1 Ratings and specifications for AC servo driver FDA-5000 series

Model

Item FDA-

5001 FDA-

5002 FDA-

5004 FDA-

5005 FDA-

5010 FDA-

5012 FDA-

5015 FDA-

5020 FDA-

5030 FDA-

5045 FDA-

5075

Power supply voltage

*(Note 1) 3 phase AC200~230V +10/-15%, 50/60Hz

Input power

supply Power capacity [kVA] 0.5 0.8 1.3 1.5 2.1 2.5 3.1 4.1 6.0 8.0 12.0

Voltage type 3-phase sine wave drive AC servo motor

Continuous output

current [A] 1.25 2.1 3.2 4.2 6.9 9.8 11 16 21 32 50

Applicable

motor Maximum output

current [A] 3.8 6.3 9.6 12.6 19.2 29 33 48 63 96 132

Detector model Standard: Incremental 2000 [p/rev] 15-wire type

Output signal type Differential line driver output

Detector accuracy 1000-10000 [p/rev] (Not to exceed 400 [kp/sec])

Detector

Detector power supply Not to exceed DC 5 [V], 0.3 [A]

Drive system 3-phase voltage type PWM drive (IPM used)

Speed control range 1:5000

Frequency response

characteristics 250 Hz

Speed command input DC -10 ∼+10 [V], maximum speed (can be adjusted on loader)

Internal digital command (operation can be set in 7 steps)

Speed fluctuation rate Not exceeding ±0.01% (Rated load: 0-100%)

Not exceeding ±0.01% (Rated power supply: ±10% )

Not exceeding ±0.1% (Temperature fluctuation : 25 ±25℃)

Speed control

specifications

Acceleration/deceleration

time Can be accelerated/decelerated in straight line or in "S" shape (0-100 [sec] in unit

of 0.01 sec)

Position input frequency 300 [kpps]

Position input type Direction + pulse, forward run pulse + reverse run pulse

2-phase pulse (A phase + B phase)

Position

control

specifications

Position input type Open collector, line driver system

Torque command input DC -10 ∼+10 [V], Maximum command (can be adjusted on loader)

Torque linearity Not exceeding 4 [%]

Torque control

specifications Limit speed command DC -10 ∼+10 [V], Maximum speed (can be adjusted on loader)

Protective functions Overcurrent, regenerated overvoltage, overload, motor miswiring, drive overheat,

encoder error, voltage shortage, overspeed and excessive error.

Regenerated resistance Standard separately attached type

Load inertia(GD²) See motor specifications table

Monitor output Speed, torque (-4 ∼+4 [V])

Dynamic brake built in

Built-in

functions

Additional functions Testing function (jog and motorless operation), alarm history, forward and backward

run, encoder signal frequency division output

Power cable, encoder cable, CN1 connector, CN2 connector

Option Loader: Mount Loader Digital Loader D/Loader

Operating ambient

temperature 0-50 [℃]

Ambient humidity Not to exceed 90 [%] (Should be free of dewing)

Storage temperature -20 ~ +80 [℃]

Environmental

specifications

Insulating resistance To be greater than DC 500 [V] 10 [MΩ]

Structure Book Type

(Note 1) The model name of the servo driver which uses absolute value encoder is FDA-5000A.

(Note 2) Single-phase AC 220V can also be used. However, as output may become lower

than the rated value, increase the servo driver capacity by 1 step if possible.

Chapter 2. Ratings and Specifications

2-2

2.2 AC Servo Motor Ratings and Specifications

Motor CN01 CN02 CN03 CN04 CN05 CN04A CN06 CN08 CN10

Model

Spec. Driver 5001 5002 5004 5005 5010

Flange size ( □) 60 80

Rated output ( W ) 100 200 300 400 500 400 600 800 1000

( N·m ) 0.32 0.64 0.96 1.27 1.59 1.27 1.91 2.54 3.18

Rated torque ( kgf·cm ) 3.25 6.5 9.75 13.0 16.2 13.0 19.5 26.0 32.5

( N·m ) 0.96 1.92 2.88 3.81 4.77 3.81 5.3 6.85 9.53

Maximum

instantaneous

torque ( kgf·cm ) 9.75 19.5 29.3 39.0 48.7 39.0 54.5 70.2 97.5

Rated rpm ( r/min ) 3000

Maximum rpm ( r/min ) 5000

( gf·cm·s2) 0.061 0.095 0.126 0.160 0.204 1.1 1.5 1.77 2.11

Rotor

inertia

( = GD2/4 ) (kg·m2ⅹ10-4) 0.06 0.093 0.129 0.163 0.208 1.08 1.47 1.74 2.07

Allowable load inertia

Ratio(Versus rotor) Not exceeding 30 times Not exceeding 20 times

Rated power rate ( kW/s ) 17.0 43.6 73.9 103.5 126.1 15.0 24.8 37.4 49.0

Standard Incremental 2000

Detector type Option Absolute 11/13bit 2048P/rev

Weight (kg) 0.85 1.14 1.43 1.73 2.03 2.1 2.55 3.1 3.7

■Speed and Torque Characteristics

A : Continuous duty zone & B : Intermittent duty zone

1000 2000 3000 4000 5000

Speed (r/min )

0.2

Torque(N

·

m )

1.0

0.8

0.6

0.4

CN01

1000 2000 3000 4000 5000

Speed (r/min )

0.4

Torque(N

·

m )

2.0

1.6

1.2

0.8

CN02

1000 2000 3000 4000 5000

Speed (r/min )

0.6

Torque(N

·

m )

3.0

2.4

1.8

1.2

CN03

1000 2000 3000 4000 5000

Speed (r/min )

0.8

Torque(N

·

m )

4.0

3.2

2.4

1.6

CN04

1000 2000 3000 4000 5000

Speed (r/min )

1.0

Torque(N

·

m )

5.0

4.0

3.0

2.0

CN05

1000 2000 3000 4000 5000

Speed (r/min )

0.8

Torque(N

·

m )

4.0

3.2

2.4

1.6

CN04A

1000 2000 3000 4000 5000

Speed (r/min )

1.1

Torque(N

·

m )

5.5

4.4

3.3

2.2

CN06

1000 2000 3000 4000 5000

Speed (r/min )

2

Torque(N

·

m )

10

8

6

4

CN10CN08

1000 2000 3000 4000 5000

Speed (r/min )

7.0

1.4

Torque(N

·

m )

5.6

4.2

2.8

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

B

A

Chapter 2. Ratings and Specifications

2-3

Motor CN09 CN15 CN22 CN30 CN30A CN50A KN03 KN05 KN06 KN07

Model

Spec. Driver 5010 5015 5020 5030 5030 5045 5004 5004 5005 5010

Flange size ( □) 130 180 80

Rated output

( W ) 900 1500 2200 3000 3000 5000 300 450 550 650

( N·m ) 2.86 4.77 7.0 9.54 9.54 15.9 1.43 2.15 2.57 3.04

Rated

torque ( kgf·cm ) 29.2 48.7 71.4 97.4 97.4 162.3 14.6 21.9 26.2 31

( N·m ) 8.6 14.3 21 28.6 23.9 39.8 4.29 6.45 7.42 9.12

Maximum

instantaneo

us torque ( kgf·cm ) 87.6 146 214 292 243.5 405.8 43.8 65.7 72.7 93

Rated rpm ( r/min ) 3000 2000

Maximum rpm ( r/min ) 5000 4500 3000

( gf·cm·s2) 4.12 7.63 11.12 14.63 26.1 43.8 1.1 1.5 1.77 2.11

Rotor

inertia

( = GD2/4 ) (kg·m2ⅹ10-4)4.04 7.48 10.9 14.34 25.6 42.9 1.08 1.47 1.74 2.07

Allowable load inertia

Ratio(Versus rotor) Not exceeding 10 times Not exceeding 20 times

Rated power rate

( kW/s ) 20.4 30.6 45.1 63.9 35.7 58.9 18.9 31.3 38.0 44.6

Standard Incremental 2000

Detector

type Option Absolute 11/13bit 2048P/rev

Weight

( kg ) 5.5 7.0 8.5 10.0 12.9 18.2 2.1 2.55 3.1 3.7

■Speed and Torque Characteristics

A : Continuous duty zone & B : Intermittent duty zone

1000 2000 3000 4000 5000

Speed (r/min )

2

Torque(N

·

m )

10

8

6

4

CN09

A

B

1000 2000 3000 4000 5000

Speed (r/min )

3

Torque(N

·

m )

15

12

9

6

CN15

A

B

1000 2000 3000 4000 5000

Speed (r/min )

6

Torque(N

·

m )

30

24

18

12

CN30

A

B

1000 2000 3000 4000 5000

Speed (r/min )

5

Torque(N

·

m )

25

20

15

10

CN22

A

B

1000 2000 3000

Speed (r/min )

1

Torque(N

·

m )

5

4

3

2

KN03

A

B

1000 2000 3000

Speed (r/min )

1.3

Torque(N

·

m )

6.5

5.2

3.9

2.6

KN05

A

B

1000 2000 3000

Speed (r/min )

1.5

Torque(N

·

m )

7.5

6.0

4.5

3.0

KN06

A

B

1000 2000 3000 4000 5000

Speed (r/min )

2

Torque(N

·

m )

10

8

6

4

CN50A

A

B

Torque(N

·

m )

2

10

8

6

4

1000 2000 3000 4000 5000

Speed (r/min )

CN30A

A

B

1000 2000 3000

Speed (r/min )

2

Torque(N

·

m )

10

8

6

4

KN07

A

B

Chapter 2. Ratings and Specifications

2-4

Motor KN06A KN11 KN16 KN22 KN22A KN35 KN55

Model

Spec. Driver 5005 5010 5015 5020 5020 5030 5045

Flange size ( □) 130 180

Rated output ( W ) 600 1100 1600 2200 2200 3500 5500

( N·m ) 2.86 5.25 7.64 10.5 10.49 16.67 26.18

Rated torque ( kgf·cm ) 29.2 53.6 77.9 107 107 170 267

( N·m ) 8.6 14.2 22.5 28.6 26.2 41.7 65.4

Maximum

instantaneous

torque ( kgf·cm ) 87.6 145 230 292 267.5 425.0 667.5

Rated rpm ( r/min ) 2000

Maximum rpm ( r/min ) 3000

( gf·cm·s2) 4.12 7.63 11.12 14.63 26.1 43.8 67.8

Rotor

inertia

( = GD2/4 ) (kg·m2ⅹ10-4) 4.04 7.48 10.9 14.34 25.6 42.9 66.4

Allowable load inertia

Ratio(Versus rotor) Not exceeding 10 times

Rated power rate ( kW/s ) 20.4 30.6 53.5 76.7 43.0 64.7 103.0

Standard Incremental 2000

Detector type Option Absolute 11/13bit 2048P/rev

Weight ( kg ) 5.5 7.0 8.5 10.0 12.9 18.2 26.8

■Speed and Torque Characteristics

A : Continuous duty zone & B : Intermittent duty zone

1000 2000 3000

Speed (r/min )

3

Torque(N

·

m )

15

12

9

6

KN11

A

B

1000 2000 3000

Speed (r/min )

5

Torque(N

·

m )

25

20

15

10

KN16

A

B

1000 2000 3000

Speed (r/min )

6

Torque(N

·

m )

30

24

18

12

KN22

A

B

1000 2000 3000

Speed (r/min )

Torque(N

·

m )

KN35

10

50

40

30

20

1000 2000 3000

Speed (r/min )

Torque(N

·

m )

KN55

15

75

60

45

30

1000 2000 3000

Speed (r/min )

Torque(N

·

m )

KN22A

A

B

6

30

24

18

12

A

B

A

B

1000 2000 3000

Speed (r/min )

2

Torque(N

·

m )

10

8

6

4

KN06A

A

B

Table of contents

Other Higen Servo Drive manuals

Popular Servo Drive manuals by other brands

Parker

Parker P Series user guide

Panasonic

Panasonic MINAS A6B Series Reference Specifications

Omron

Omron OMNUC U Series user manual

ABB

ABB 8 Series Use and installation manual

Rockwell Automation

Rockwell Automation Allen-Bradley Ultra3000 Migration guide

YET

YET XtraDrive XD Series Short form installation guide