5

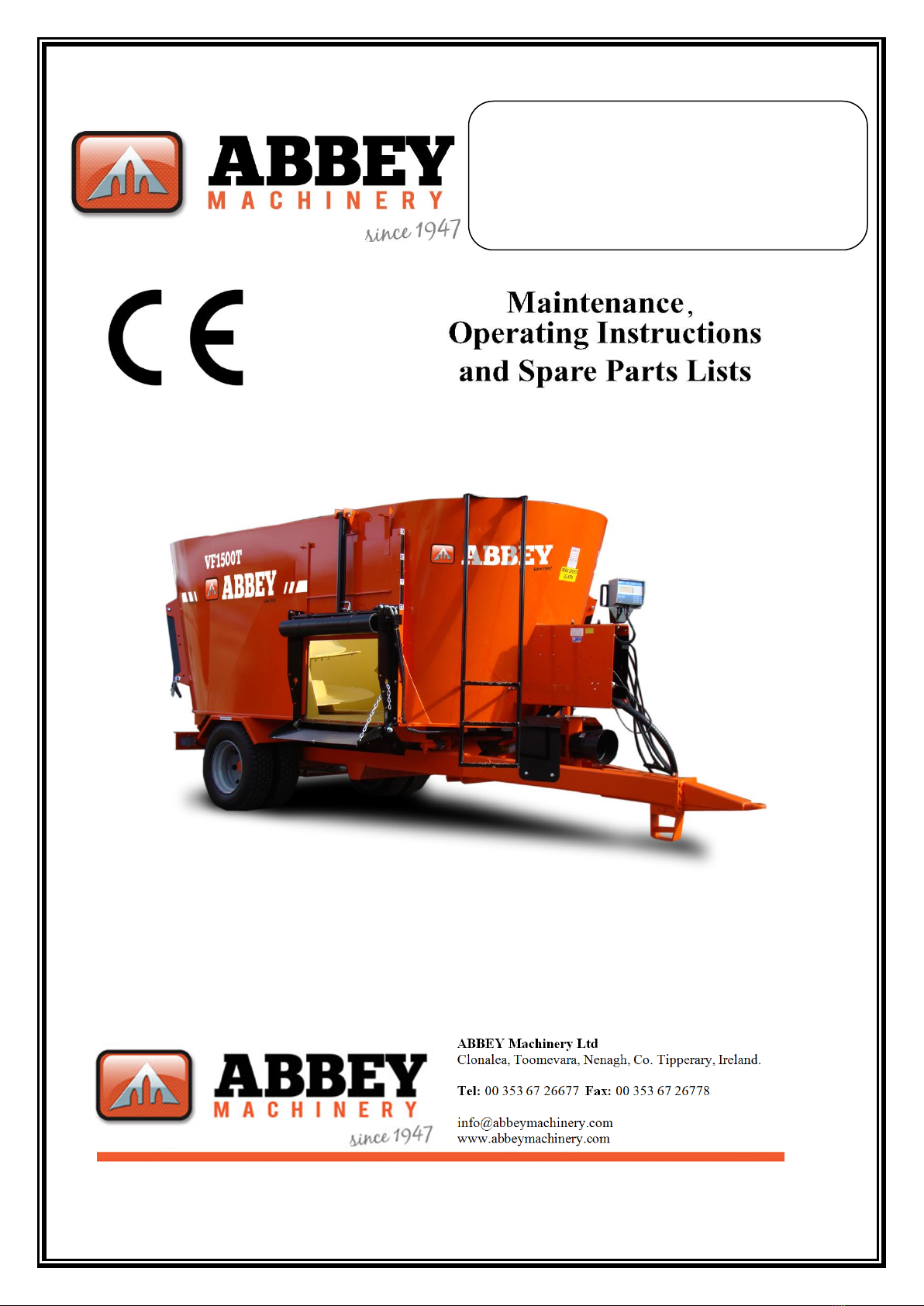

The Range of Abbey Diet Feeders includes

100 CD, 145 GD

The Range of Abbey Vertical Augur Tub Feeders includes

VF Single 750, 800, 1000, 1050, 1250, 1450,

VF Twin 1500, 1650, 1850. 2050. 2250, 2450, 2650, 2850

6.0 THE FUNCTION OF THE TUB FEEDER

The Abbey Tub Feeder is a trailed machine which is capable of independently mixing, transporting and feeding

set weights of ingredients to make a complete diet for cattle. It could be also used as a processing unit to

produce rations for other animals (i.e. pigs, sheep, or poultry). The Tub Feeder has been solely designed for

agricultural use, but may in certain circumstances be used to produce mixed rations for other purposes (it

must be noted that the standard Abbey Tub Feeder (unladen) has not been designed to travel at speeds over

25km/h).

The principle of the standard Abbey Tub Feeder is to be loaded with set weights of ingredients which are

mixed as they are loaded into the machine. The Abbey Tub Feeder uses a central vertical auger to chop and

mix the material with the door of the machine closed, and to feed out the material with the door of the

machine open. The ingredients are weighed by the feeder weighing system as they are loaded and unloaded. A

range of functions on the digital scales allows a number of formulae for each ration to be stored.

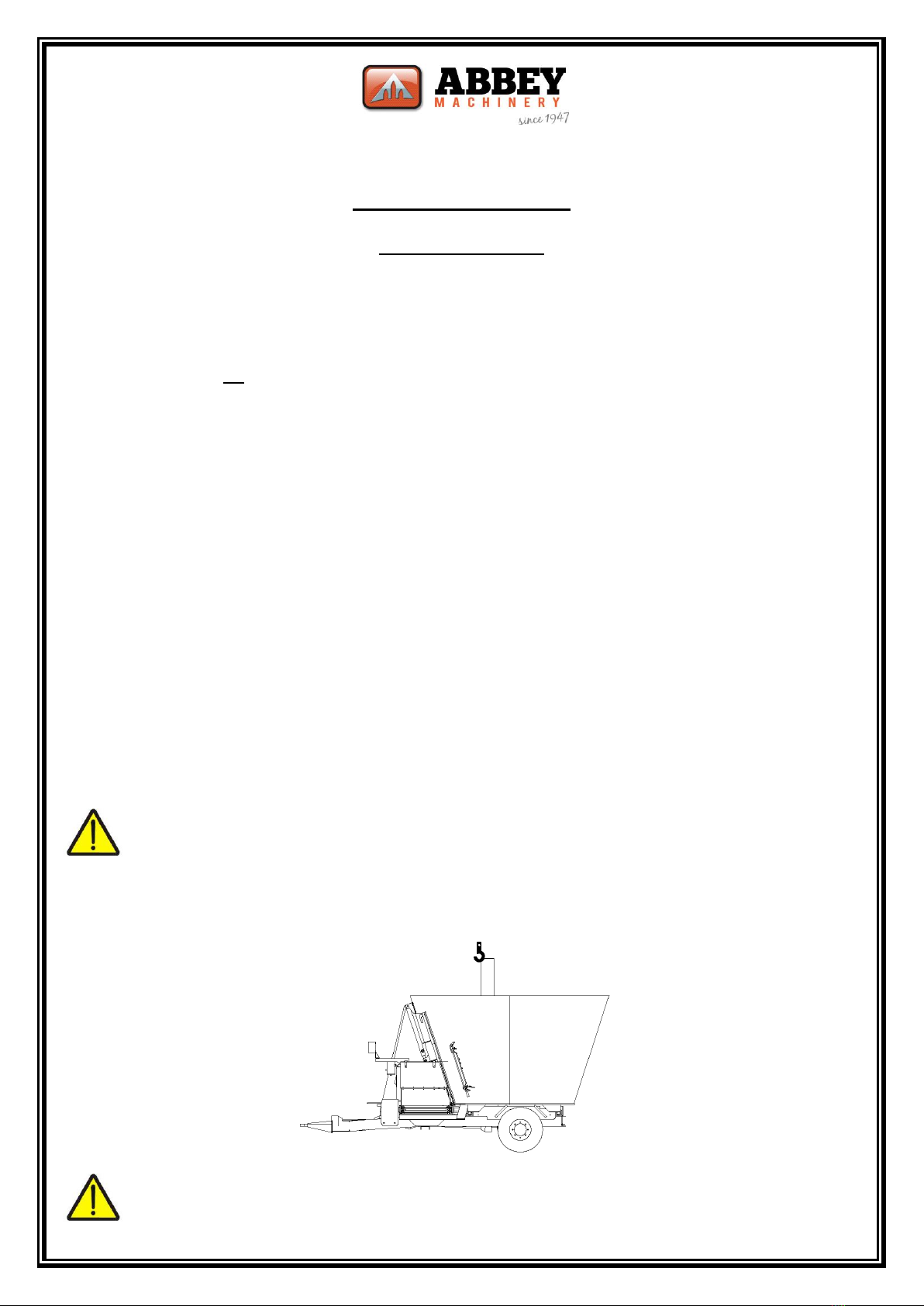

The feeder can be fitted with one of three systems for feeding out the ration. The standard system is a

conveyor used to transfer the ration to the feed passage. The second optional system is an elevator, and is

used to feed the material into walled troughs or over barriers. The elevator’s height can also be controlled

from the tractor cab and can be set to suit the operator’s needs. The third optional system allows the machine

to be used in blind passages by feeding out through two rear doors. The Abbey Tub Feeder was solely built for

this function and should be operated within the limit of the instruction manual. The above descriptions of the

functions of each Tub Feeder, are provided to show how each Tub Feeder can be used. Further detail on the

Tub Feeder and their variations can be found on the relevant leaflets.

* IMPORTANT *

READ INSTRUCTIONS CAREFULLY BEFORE

OPERATING THIS MACHINE

* The entire manual must be read and understood before operating

this machine, If there is confusion about the safe operation

of any part of the machine, contact your dealer

before operating it.