EN - 2

ABICOOLER 1300

EN Translation of the original operating instructions

1 Identification.................................................................................................................................EN-3

1.1 Marking .............................................................................................................................................EN-3

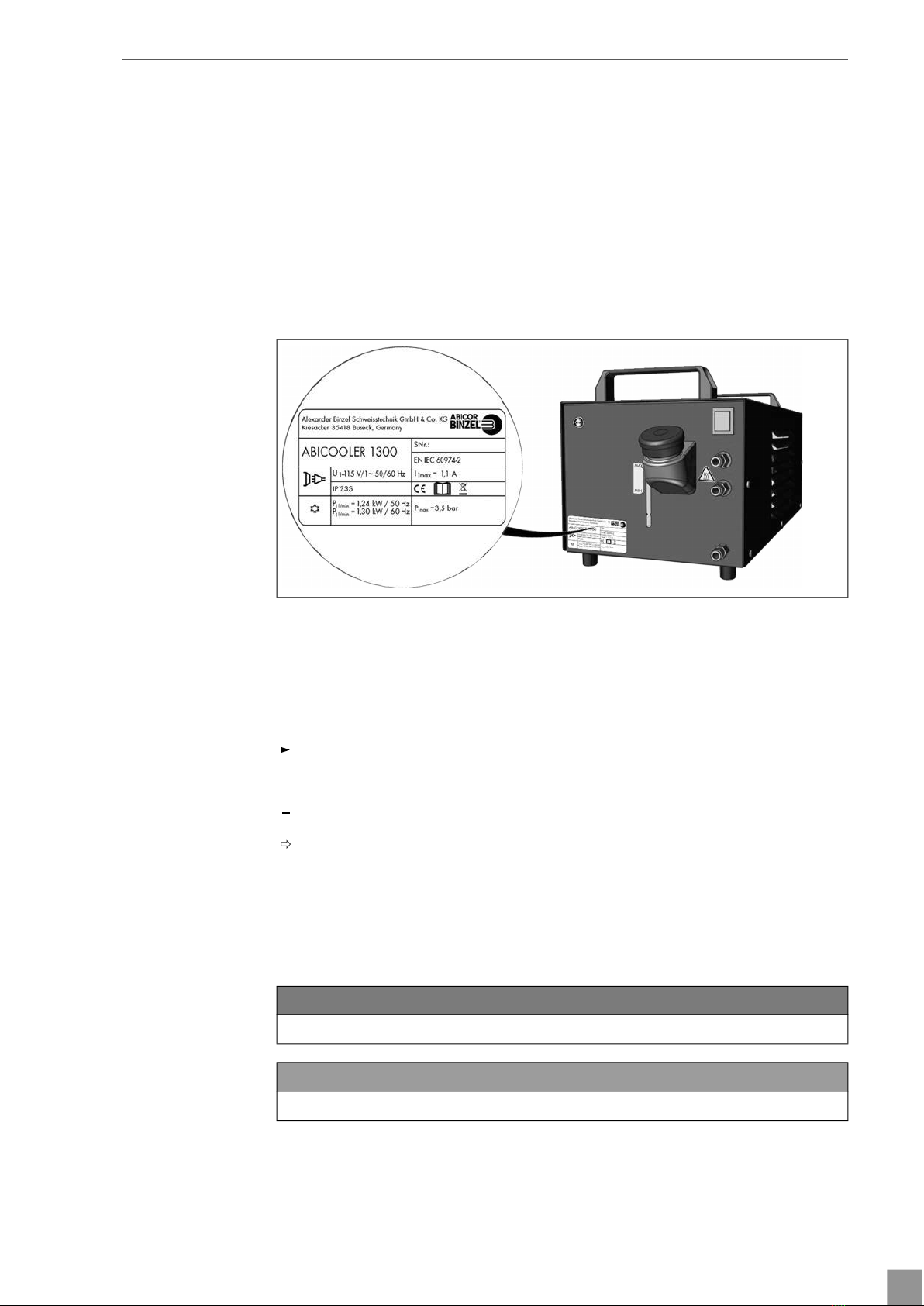

1.2 Nameplate.........................................................................................................................................EN-3

1.3 Signs and symbols used ...................................................................................................................EN-3

1.4 Classification of the warnings ..........................................................................................................EN-3

2 Safety ..............................................................................................................................................EN-4

2.1 Designated use..................................................................................................................................EN-4

2.2 Obligations of the operator .............................................................................................................EN-4

2.3 Warning and notice signs ................................................................................................................EN-4

2.4 Basic safety instructions ....................................................................................................................EN-5

2.5 Safety instructions for the power supply .........................................................................................EN-6

2.6 Personal protective equipment (PPE)...............................................................................................EN-6

2.7 Emergency information.....................................................................................................................EN-6

3 Scope of delivery........................................................................................................................EN-6

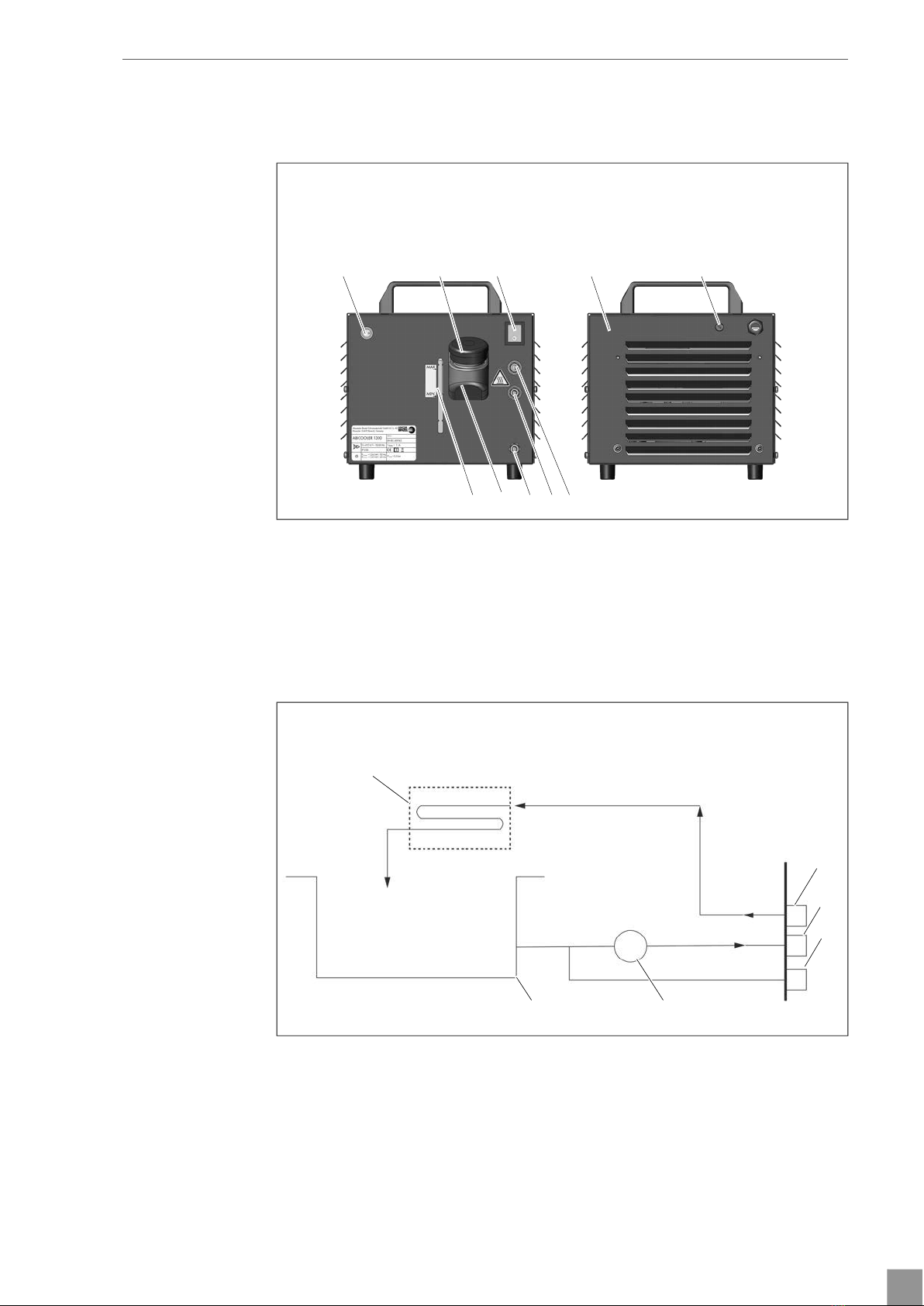

4 Product description ....................................................................................................................EN-7

4.1 Assembly and use .............................................................................................................................EN-7

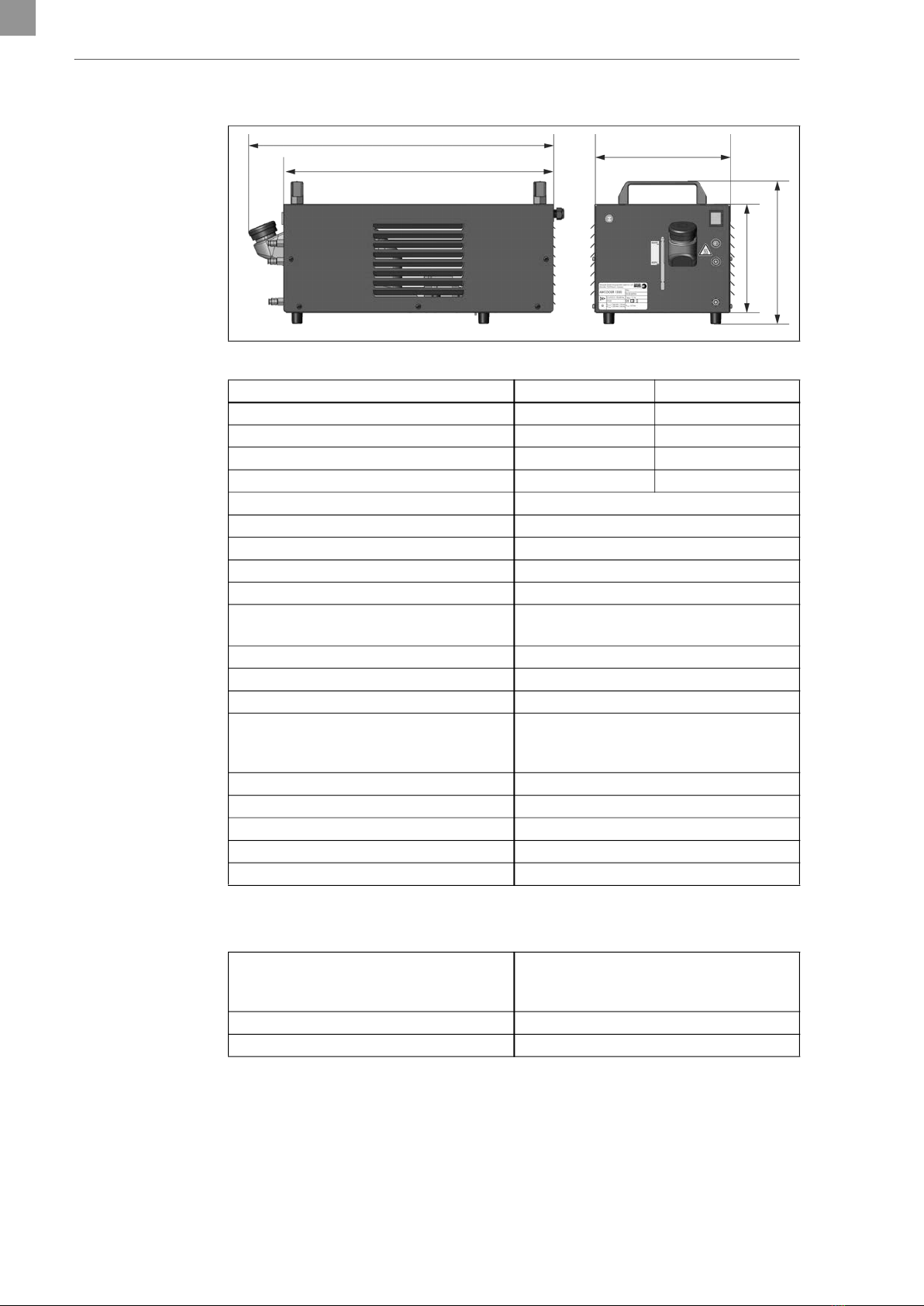

4.2 Technical data...................................................................................................................................EN-8

5 Transport and installation.......................................................................................................EN-9

6 Commissioning.......................................................................................................................... EN-10

6.1 Fuse protection for the device....................................................................................................... EN-10

6.2 Initial commissioning.......................................................................................................................EN-11

6.2.1 Bleed the device..............................................................................................................................EN-11

6.2.2 Bleeding the cable assembly ........................................................................................................ EN-13

6.2.3 Commissioning the flow control.................................................................................................... EN-13

7 Operation.................................................................................................................................... EN-14

7.1 Prior to initial commissioning and after a longer standstill......................................................... EN-14

8 Decommissioning..................................................................................................................... EN-14

9 Maintenance and cleaning .................................................................................................. EN-15

9.1 Maintenance and cleaning intervals............................................................................................ EN-15

9.2 Change the coolant ....................................................................................................................... EN-16

9.3 Replacing the fuse.......................................................................................................................... EN-16

9.4 Replacing the handles ................................................................................................................... EN-17

10 Troubleshooting ....................................................................................................................... EN-18

11 Disassembly ............................................................................................................................... EN-19

12 Disposal ....................................................................................................................................... EN-19

12.1 Disposing of materials ................................................................................................................... EN-19

12.2 Disposing of consumables.............................................................................................................EN-20

12.3 Packaging ....................................................................................................................................... EN-20

13 Appendix ....................................................................................................................................EN-20

13.1 Connecting diagram for flow control ........................................................................................... EN-20

13.2 ABICOOLER 1300 circuit diagram for 115 V............................................................................. EN-21

13.3 ABICOOLER 1300 circuit diagram for 230 V............................................................................ EN-22

13.4 Spare parts ..................................................................................................................................... EN-23

14 Warranty..................................................................................................................................... EN-23