8

4 Installation

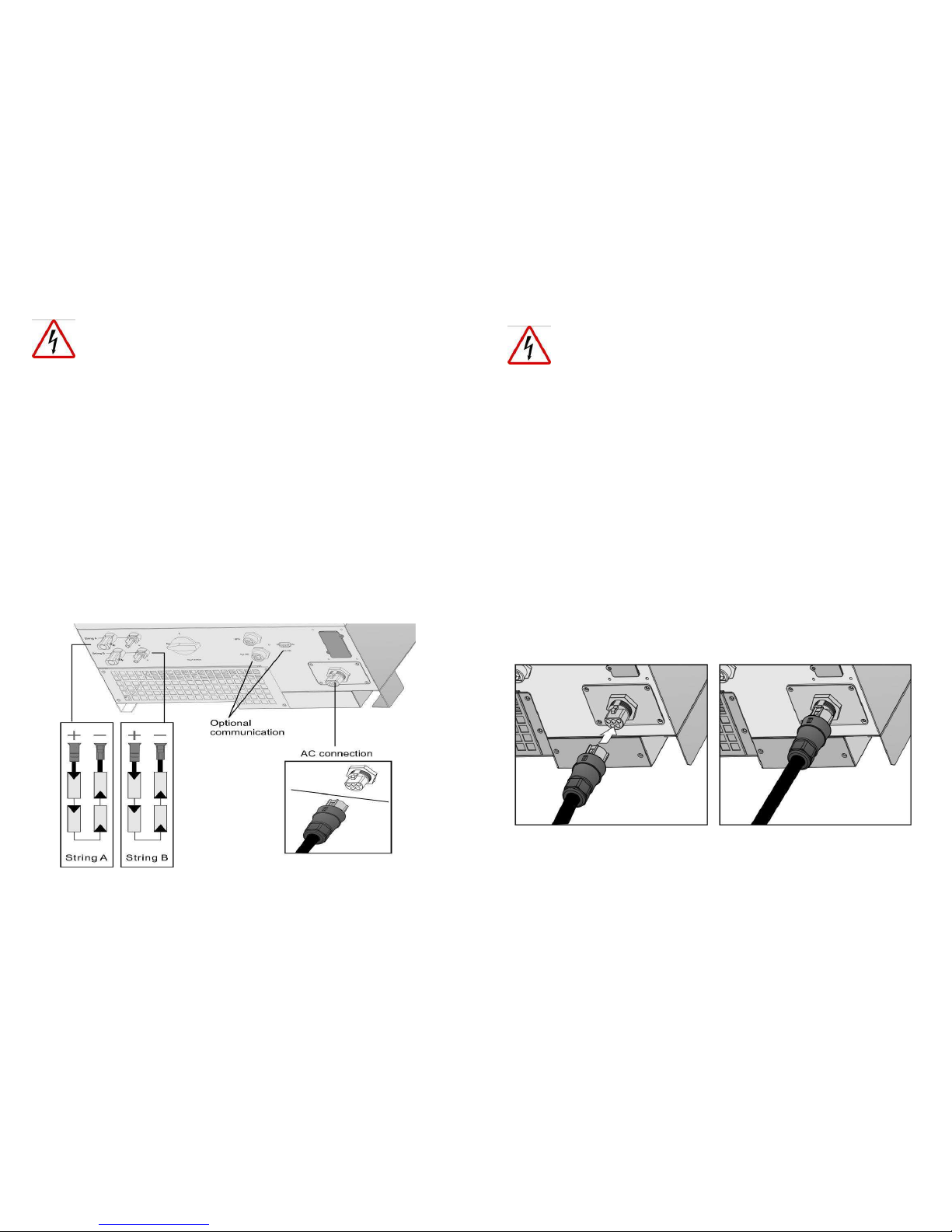

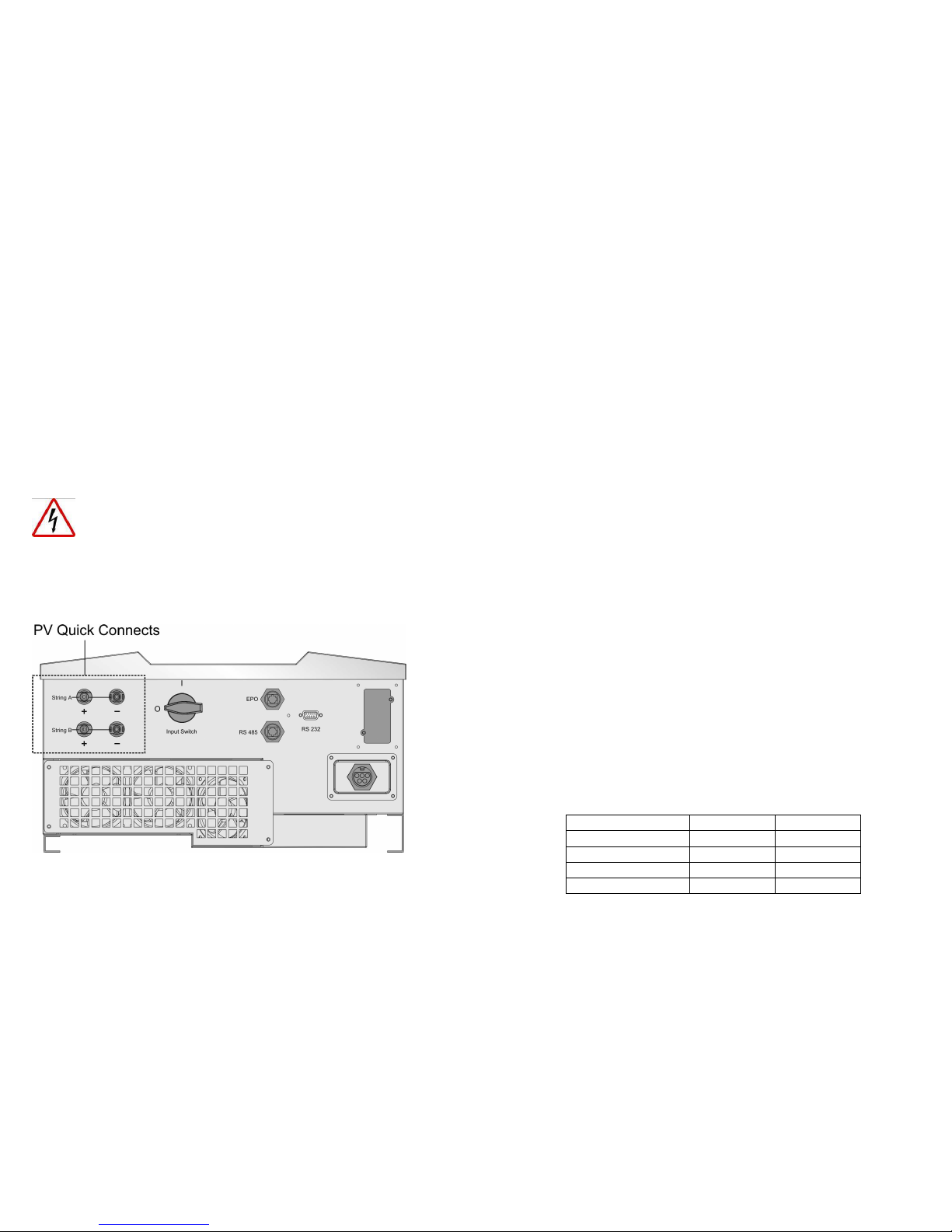

Warning: Be sure to read the safety instructions on pages 3 and 4 before

installing the PV inverter.

4.1

4.14.1

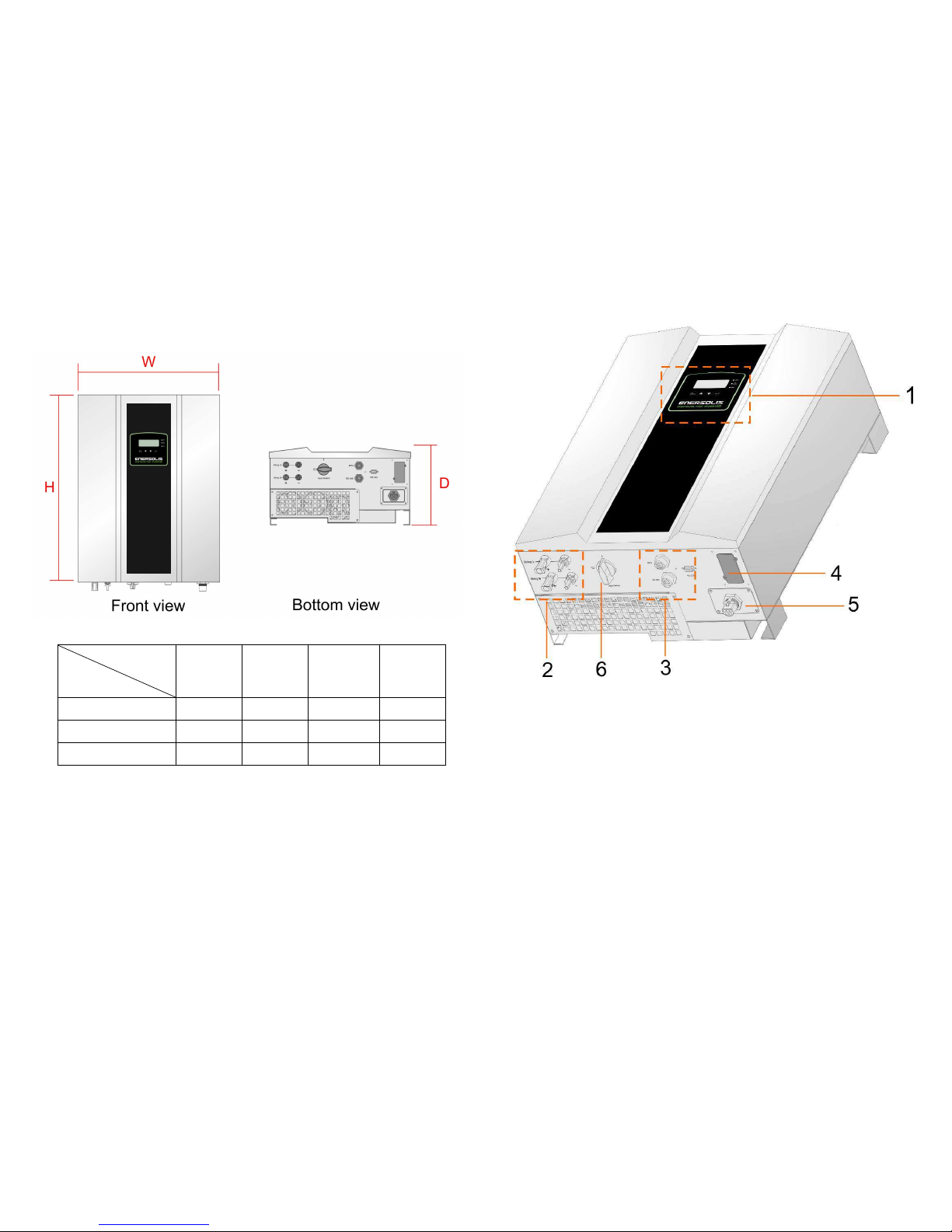

4.1 Unpacking

Inspect the PV inverter upon receipt. The packaging is robust, but accidents and

damage may still occur during shipment. Notify the forwarder and dealer if there is

damage.

The packaging is recyclable and reusable.

After removing the inverter from the carton check for the following standard

package contents, in addition to the inverter itself.

accessories set (cover, PV connector)

CD-ROM

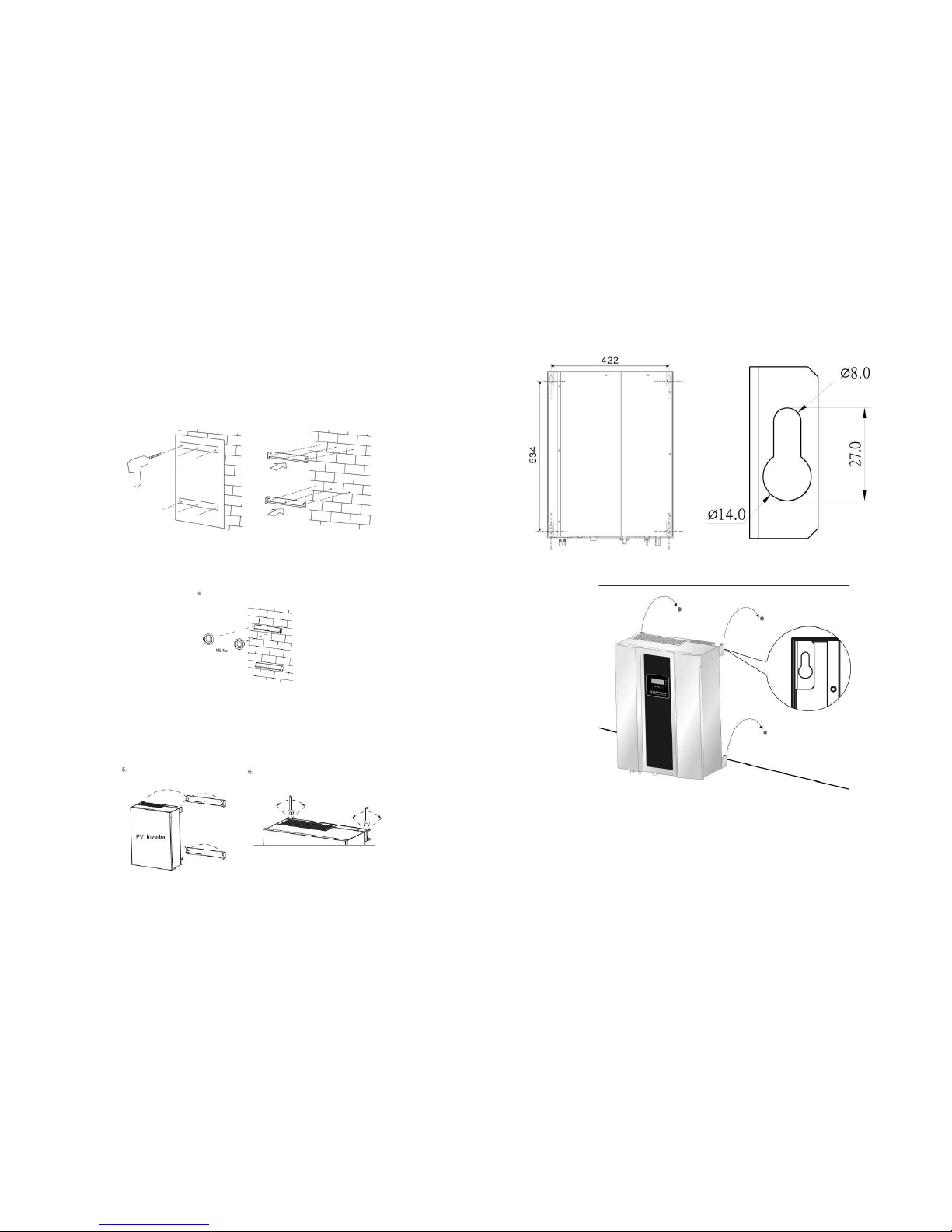

A wall mount kit set (backrest and backplane positioning paper)

9

4.2

4.24.2

4.2 Installation requirements

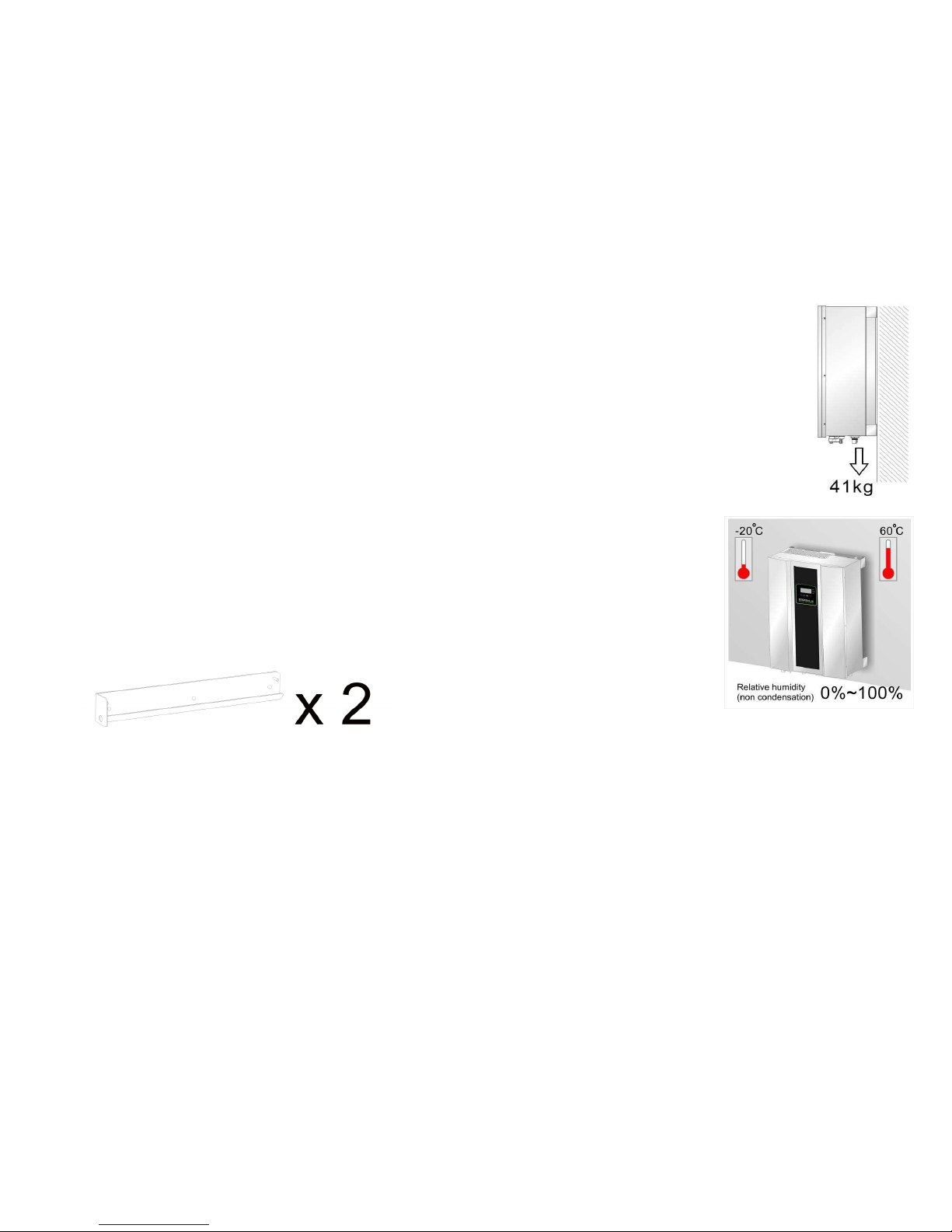

The PV inverter is heavy. Take this weight into account

when choosing the installation site and method of

installation.

To ensure proper operation and long operating life,

position the inverter according to the following

requirements:

(1)

ES 6000(ES 8000/ES 10000/ES

12000) are designed to comply with

Index of Protection class 65, which

allows units to be installed in outdoor

and wet environment . The PV

inverter is designed for outdoor

installation. It should be installed in a

place here it is not exposed to direct

sunlight. The yield of the PV system

may be reduced at increased

ambient temperatures or when installed in poorly ventilated and warm indoor

locations. We recommend an ambient temperature range of -20°C to +60 °C