- 2 - LR3.9-7.8 User Manual

Catalogue

Safety Information............................................................................................................................................... - 3 -

1.Product Introduction......................................................................................................................................- 5 -

1.1Product Main Features........................................................................................................................- 5 -

1.2Product Specifications.........................................................................................................................- 6 -

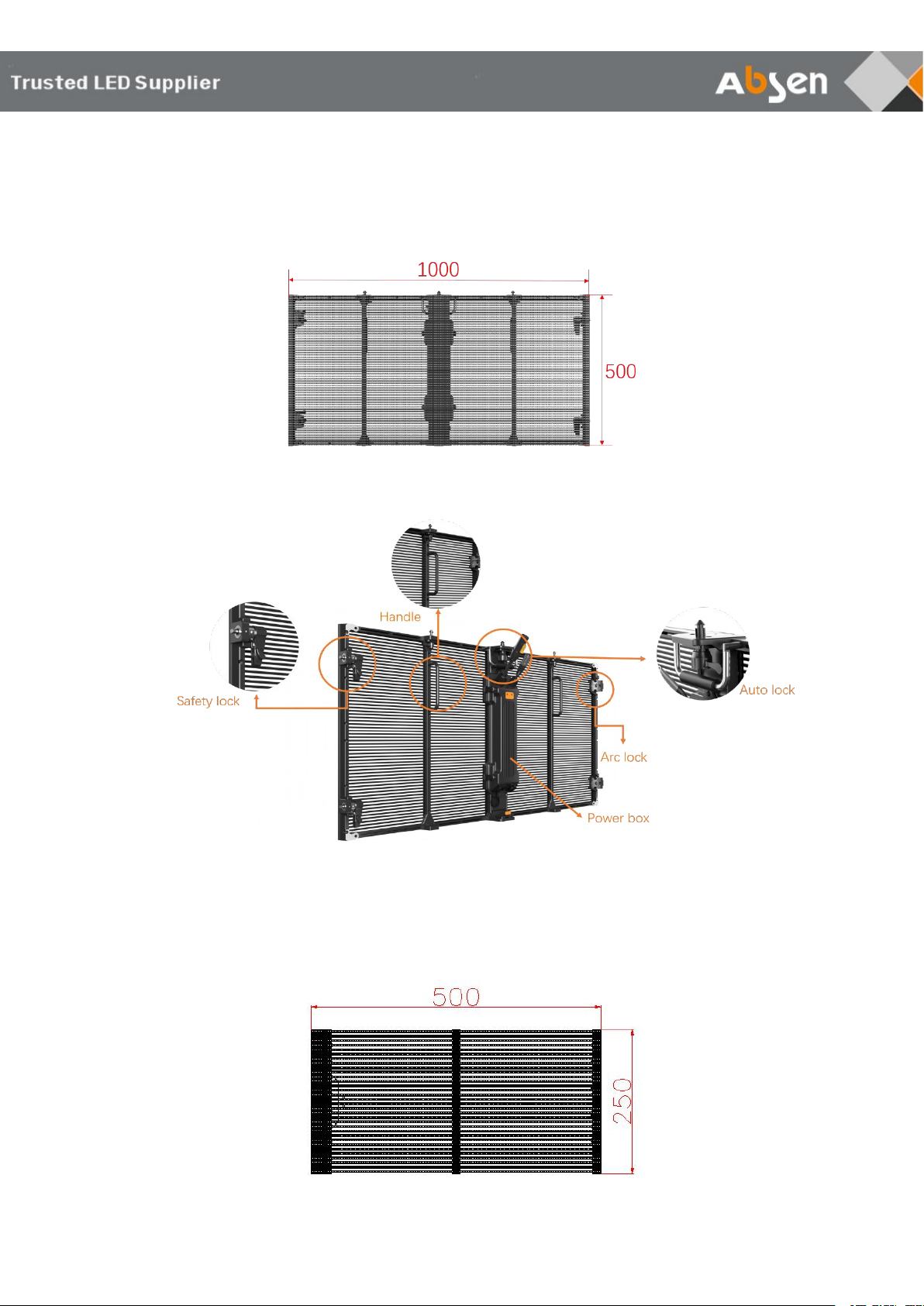

1.3Cabinet.................................................................................................................................................. - 7 -

1.3.1 Cabinet dimension figure.......................................................................................................- 7 -

1.3.2 Cabinet structure description................................................................................................ - 7 -

1.4Module................................................................................................................................................... - 7 -

1.4.1 Module dimension figure....................................................................................................... - 7 -

1.4.2 Features of Module................................................................................................................ - 8 -

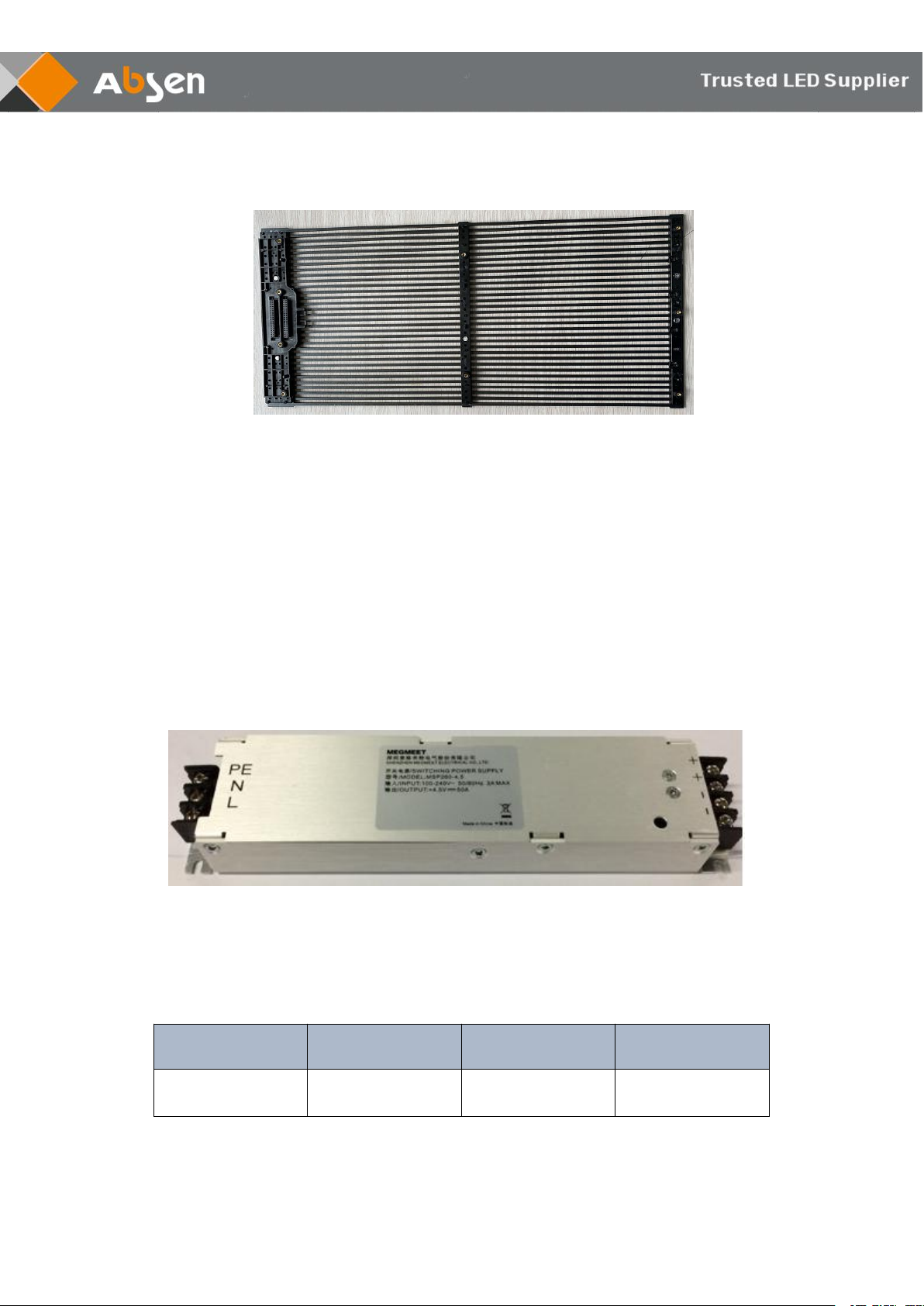

1.5Power Supply........................................................................................................................................- 8 -

1.5.1 Power Output characteristics............................................................................................... - 8 -

1.5.2 Power Input characteristics.................................................................................................. - 9 -

1.6Receive Card........................................................................................................................................ - 9 -

2.Product Installation..................................................................................................................................... - 10 -

2.1 Preparation Before Installation........................................................................................................- 10 -

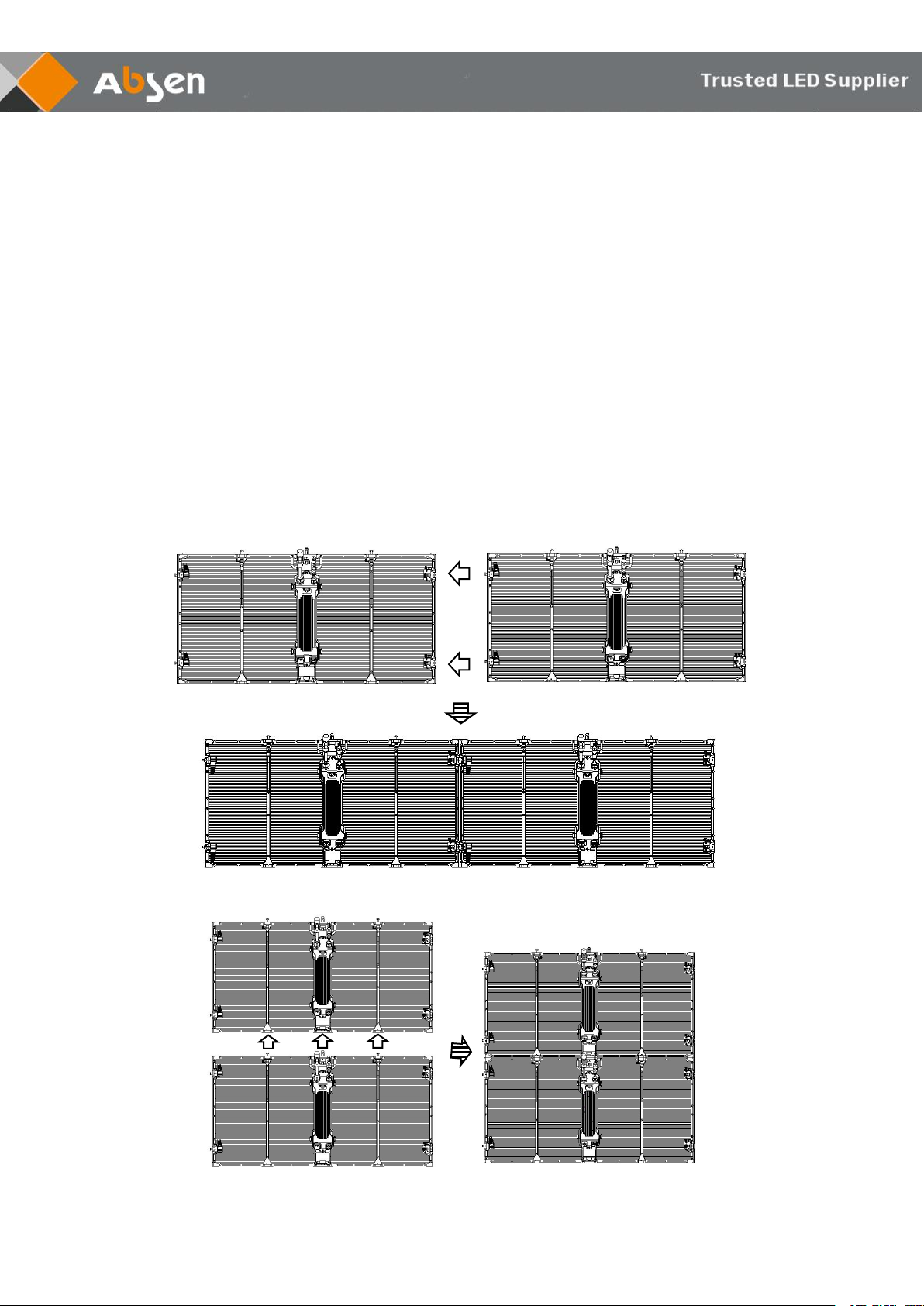

2.2 Cabinets Splicing...............................................................................................................................- 10 -

2.2.1 Splicing horizontally............................................................................................................. - 10 -

2.2.2 Splicing vertically.................................................................................................................. - 10 -

2.2.4 90-degree Splicing............................................................................................................... - 11 -

2.2 Hanging Installation.......................................................................................................................... - 12 -

2.2.1 Preparation for hanging installation................................................................................... - 12 -

2.2.2 Hanging installation steps................................................................................................... - 12 -

2.3 Fixed Installation............................................................................................................................... - 15 -

2.3.1 Preparation for fixed installation.........................................................................................- 15 -

2.3.2 Fixed installation steps........................................................................................................ - 15 -

3.Product Cabling...........................................................................................................................................- 17 -

3.1 Attention of Cabling...........................................................................................................................- 17 -

3.2 Wring Diagram...................................................................................................................................- 18 -

4.Maintenance................................................................................................................................................ - 18 -

4.1 Preparation of Maintenance Tools..................................................................................................- 18 -

4.2 Module Maintenance........................................................................................................................ - 19 -

4.2.1 Module maintenance steps................................................................................................. - 19 -

4.3 Power Supply Maintenance.............................................................................................................- 20 -

4.3.1 Power supply maintenance steps...................................................................................... - 20 -

4.4 Receive Card Maintenance............................................................................................................. - 21 -

4.4.1 Receive card maintenance steps.......................................................................................- 21 -

4.5 Hub Maintenance.............................................................................................................................. - 22 -

5. Flight Case.....................................................................................................................................................- 22 -

6. Common Faults and troubleshooting.........................................................................................................- 23 -