Precautions

WARNING! All wiring must be performed by a qualified electrician

or instrumentation engineer. See diagram for terminal designa-

tions and wiring examples. Consult factory for assistance.

WARNING! Avoid shock hazards! Turn signal input, output, and

power off before connecting or disconnecting wiring, or remov-

ing or installing module.

Précautions

ATTENTION! Tout le câblage doit être effectué par un élec-

tricien ou ingénieur en instrumentation qualifié. Voir le dia-

gramme pour désignations des bornes et des exemples de

câblage. Consulter l’usine pour assistance.

ATTENTION! Éviter les risques de choc! Fermez le signal

d’entrée, le signal de sortie et l’alimentation électrique avant

de connecter ou de déconnecter le câblage, ou de retirer ou

d’installer le module.

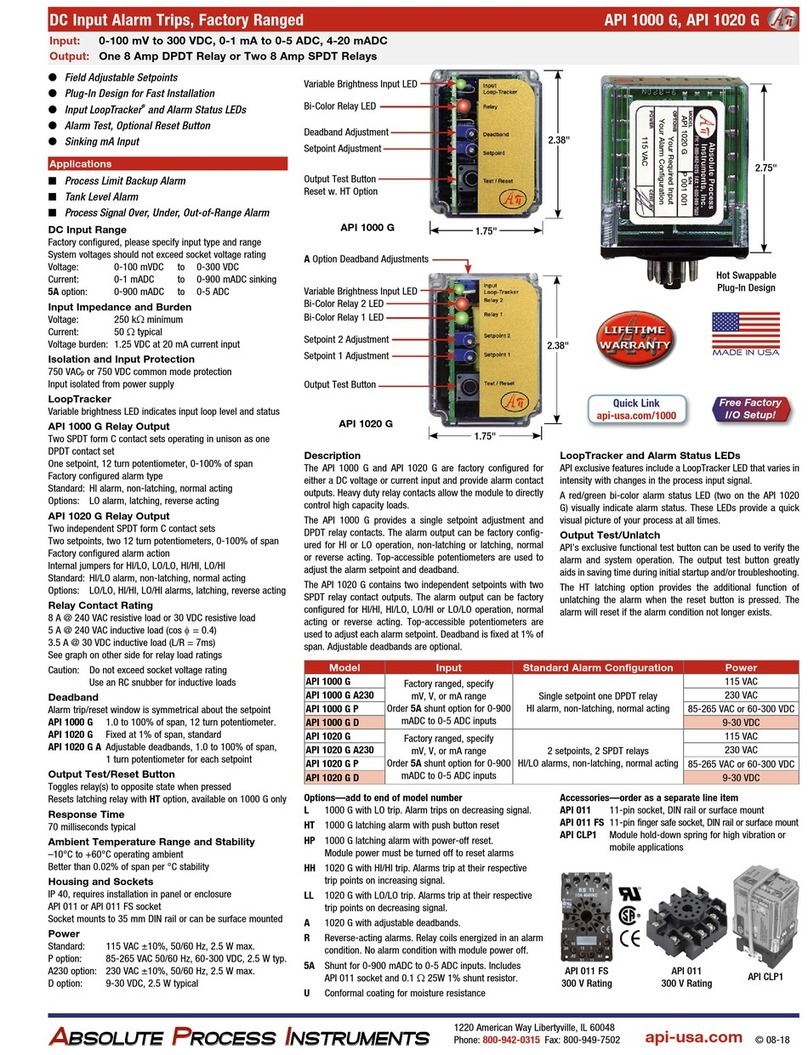

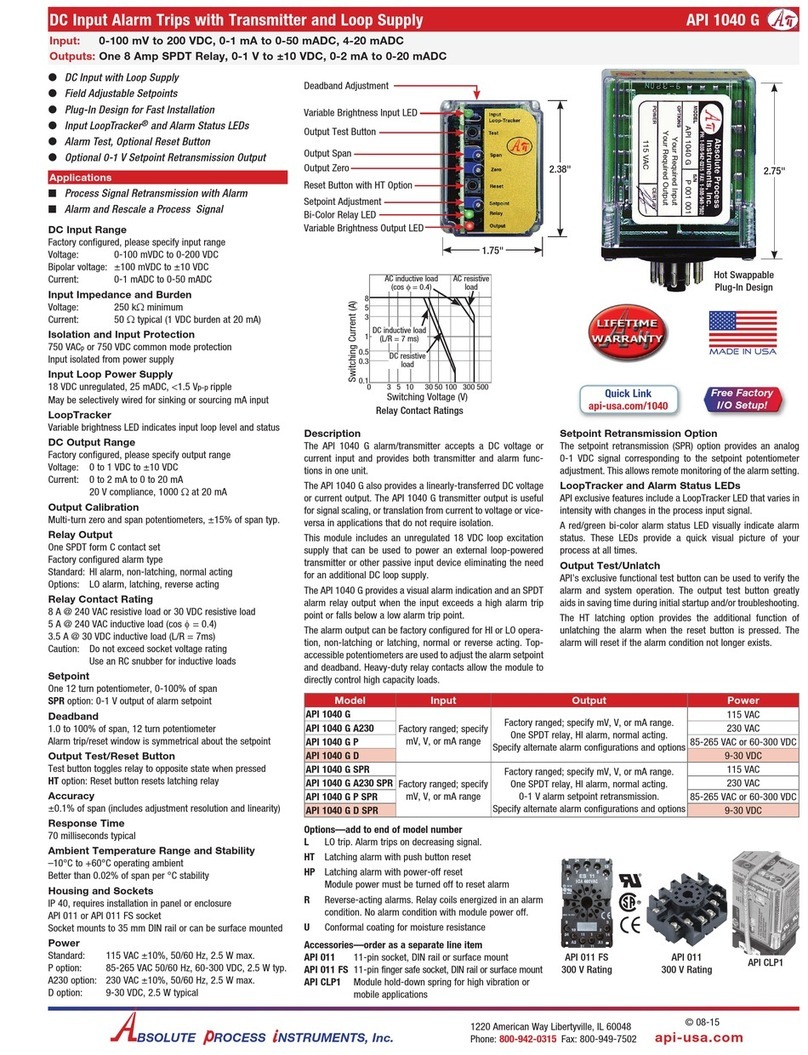

Range Selection

It is generally easier to select ranges before installation. See

the model/serial number label for module information, options,

or if a custom range was specified.

Set input selector switch A to "I" for a current input or to "V"

for a voltage input.

Switch settings B and C determine the input range.

Switch D determines the alarm configuration.

Socket and Mounting

Install module in a protective panel or enclosure. Use API 011

or finger-safe API 011 FS socket. See specifications for maxi-

mum allowable socket voltages. The socket clips to a standard

35 mm DIN rail or can be attached to a flat surface using the

two mounting holes.

Signal Input Terminals

See wiring diagrams below. Polarity must be observed for input

wiring connections. If the input does not function, check switch

settings and wiring polarity.

The milliamp input can be used with either sinking or sourcing

mA transmitters. Determine if your transmitter provides power

to the current loop or if it must be powered by the API module.

Only one device must provide power to the current loop. Use

a multi-meter to check for voltage at the transmitter's output

terminals. Typical voltage may be in the range of 9 to 24 VDC.

In this case, wire the device to terminals 4 and 5.

Relay Output Terminals

See wiring diagrams below. API modules do not provide power

to the relay contacts. Inductive loads (motors, solenoids, con-

tactors, etc.) will greatly shorten relay contact life unless an

appropriate RC snubber is installed.

Module Power Terminals

Check model/serial number label for module operating voltage

to make sure it matches available power.

When using DC power, polarity must be observed. Wire (+) to

terminal 1 and negative (–) to terminal 3.

Setpoint

This multi-turn potentiometer (one for each setpoint on the API

1090 G) allows the operator to adjust the level at which the

alarm is activated. This control is adjustable from 0 to 100%

of the input range.

Deadband

The deadband potentiometer (one for each setpoint on the API

1090 G) allows the alarm trip/reset window to be adjusted

symmetrically about the setpoint from 1 to 100% of the span.

Deadband allows the operator to fine tune the point at which

the alarm trips and resets. The deadband is typically used to

prevent chattering of the relays or false trips when the process

signal is unstable or changes rapidly.

Adjustments

To calibrate the alarm section, set the deadband control to

the minimum (counterclockwise). The deadband will be 1% of

input span in this case.

Set the signal source to a reference that represents the desired

trip point.

Adjust the setpoint control to the point at which the relay

changes state from a non-alarm to an alarm condition.

If a larger amount of deadband is desired turn the deadband

potentiometer clockwise. The deadband is symmetrical about

the setpoint; both transition points will change as deadband

is increased.

Alternately set the setpoint and deadband until the desired trip/

reset points are set.

The adjustment procedure needs to be repeated any time

switch settings are changed.

Output Test / Latching Function

When the test button is depressed it will drive the relays to

their opposite state. This can be used as a diagnostic aid during

initial start-up or troubleshooting. When released, the relays

will return to their prior states.

When the latching mode is selected, it will be necessary to

push the output test button or remove power from the module

to reset the alarm. The alarm will only reset if the alarm condi-

tion no longer exists.

Operation

The green LoopTracker®input LED provides a visual indication

that a signal is being sensed by the input circuitry of the mod-

ule. It also indicates the input signal strength by changing in

intensity as the process changes from minimum to maximum.

If the LED fails to illuminate, or fails to change in intensity as

the process changes, check the module power or signal input

wiring. Note that it may be difficult to see the LEDs under bright

lighting conditions.

The bi-color alarm LED provides a visual indication of the alarm

status. In all configurations, a green LED indicates a non-alarm

condition and a red LED indicates an alarm condition.

High Alarm

The alarm relay changes state when the input exceeds the

deadband trip point. The relay resets when the input drops

below the deadband reset point unless latching is enabled. For

a high alarm, the trip point is above the reset point.

Low Alarm

The alarm relay changes state when the input goes below the

deadband trip point. The relay resets when the input exceeds

the deadband reset point unless latching is enabled. For a low

alarm, the trip point is below the reset point.

Latching

In this mode the alarm latches when an alarm occurs. The Test

button or powering the module off can be used to reset the

alarm provided the alarm condition no longer exists.

Normal Acting Alarms

Normal acting alarms energize the relay coils in a non-alarm

condition and de-energize them in an alarm condition. This will

create an alarm condition if the module loses power.

Reverse Acting Alarms

Reverse-acting alarms energize the relay coils in an alarm con-

dition and de-energize them in a non-alarm condition. There is

no alarm condition with module power off.

Installation and Setup API 1080 G, API 1090 G

4

C

0

8

E

2

A

6

3

F

B

7

5

9

D

1

I V

Input

Select

4

C

0

8

E

2

A

6

3

F

B

7

5

9

D

1

Input

Attenu-

ation

Input

Offset

Alarm

Config.

1. Set input selector switch to either (V)

Voltage or (I) Current as required.

2. From input table, set switches B and C

for specific input range.

3. From alarm configuration table set switch D

for specific alarm action required.

A B C D

1080G

0

5

1

6

4

2

9

7

3

8

4

C

0

8

E

2

A

6

3

F

B

7

5

9

D

1

4

C

0

8

2

A

6

3

F

B

7

5

9

D

1

I V

Input

Select

4

C

0

8

E

2

A

3

F

B

7

5

9

D

1

Input

Attenu-

ation

Input

Offset

Alarm

Config.

1. Set input selector switch to either (V)

Voltage or (I) Current as required.

2. From input table, set switches B and C

for specific input range.

3. From alarm configuration table set switch D

for specific alarm action required.

A B C D

1090G

6

E

API 1080 G Alarm States with Normal Action HI Alarm

Relay 1

8NC

7Common

6NO

Relay 2

11 NC

10 Common

9NO

GREEN

No Alarm RED

HI Alarm

Relay 1

8NC

7Common

6NO

Relay 2

11 NC

10 Common

9NO

API 1090 G Alarm States with Normal Action HI/LO Alarms

No Alarm

GREEN Relay 1

8NC

7Com.

6NO

Relay 2

11 NC

10 Com.

9NO

GREEN GREEN

Relay 1

8NC

7Com.

6NO

Relay 2

11 NC

10 Com.

9NO

RED

HI Alarm LO Alarm

GREEN Relay 1

8NC

7Com.

6NO

Relay 2

11 NC

10 Com.

9NO

RED

32111109

87654

(–) (+)

AC or

DC–

AC or

DC+

Contact Set 1

NC C NO

Module power

Socket

top view

Key down

when panel

mounting

See

api-usa.com/accessories

for socket information

and dimensions

Passive

mA

SignalRi

Terminals 2 and 4 provide

18 V loop power for a

passive mA input

Input

(+)

18 VDC

NO = Normally Open

C = Common

NC = Normally Closed

(–) (+)

5 4

Input

Voltage

or Sourcing

mA Signal

Use terminals 4 and 5 for

a voltage input or mA input

from a sourcing transmitter

NO C NC

Contact Set 2

API maintains a constant effort to upgrade and improve its products.

Specifications are subject to change without notice. See api-usa.com for

latest product information. Consult factory for your specific requirements.

WARNING: This product can expose you to chemicals includ-

ing lead and nickel, which are known to the State of California

to cause cancer or birth defects or other reproductive harm.

For more information go to www.P65Warnings.ca.gov

Input

Range

Switch API 1080 G Alarm Settings

A B C SP1 Latch Action D

0-50 mV V81 HI No Normal 2

0-100 mV V91 HI No Reverse 6

0-200 mV VA1 HI Yes Normal 0

0-250 mV VC1 HI Yes Reverse 4

0-400 mV VB1 LO No Normal 3

0-500 mV V01 LO No Reverse 7

±50 mV* VA4 LO Yes Normal 1

±100 mV* VB4 LO Yes Reverse 5

0-1 V V11

0-2 V V21 API 1090 G Alarm Settings

0-2.5 V V41 SP1 SP2 Latch Action D

0-4 V V31 HI LO No Normal 6

1-5 V V5F HI LO No Reverse E

0-5 V V51 HI LO Yes Normal 2

0-10 V V61 HI LO Yes Reverse A

±5 V V64 HI HI No Normal 4

±10 V V74 HI HI No Reverse C

0-1 mA IC1 HI HI Yes Normal 0

0-2 mA I01 HI HI Yes Reverse 8

0-4 mA I11 LO LO No Normal 7

0-8 mA I21 LO LO No Reverse F

2-10 mA I2F LO LO Yes Normal 3

0-10 mA I41 LO LO Yes Reverse B

0-16 mA I31 LO HI No Normal 5

0-20 mA I51 LO HI No Reverse D

4-20 mA I5F LO HI Yes Normal 1

* AP1090 G only LO HI Yes Reverse 9