202

F16ADA Series Instructions

© 02-09

INSTALLATION AND PRECAUTIONS

Install or remove gauge using wrench on hex fitting only. Do not turn using housing or any

other part of the gauge. Use fittings appropriate for the pressure range of the gauge. Do

not apply vacuum to gauges not designed for vacuum operation. Due to the hardness of

316 stainless steel, it is recommended that a thread sealant be used to ensure leak-free

operation. NEVER insert objects into the gauge port or blow out with compressed air.

Permanent damage not covered by warranty will result to the sensor.

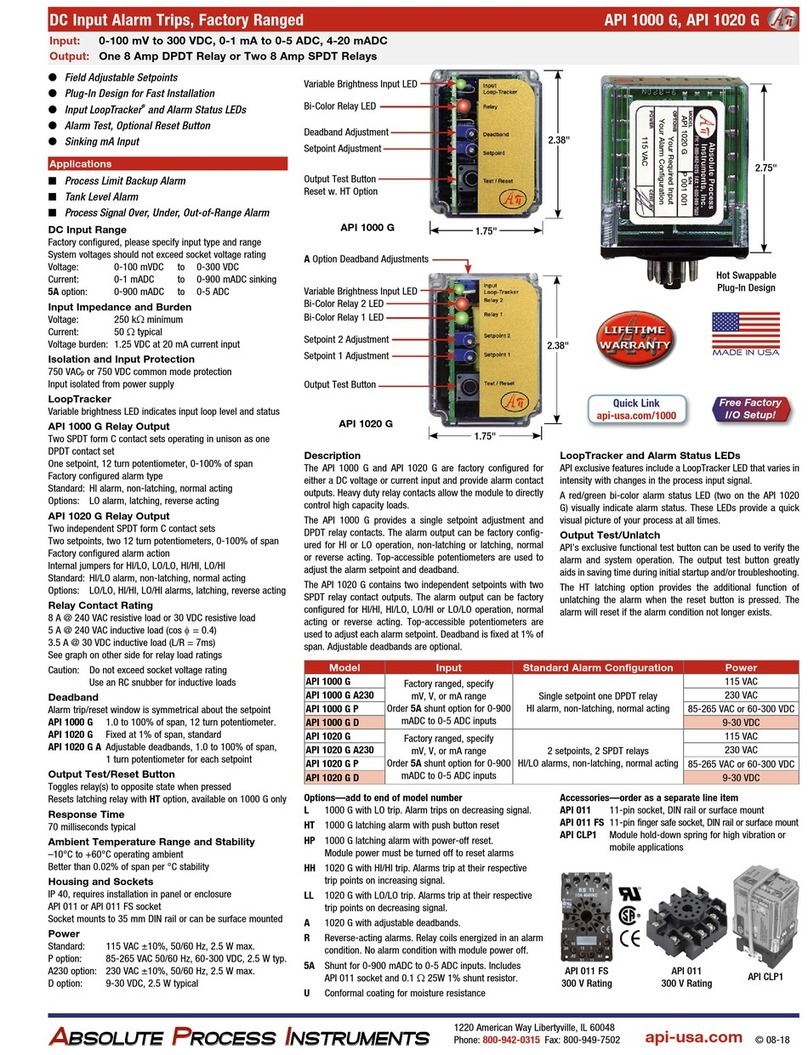

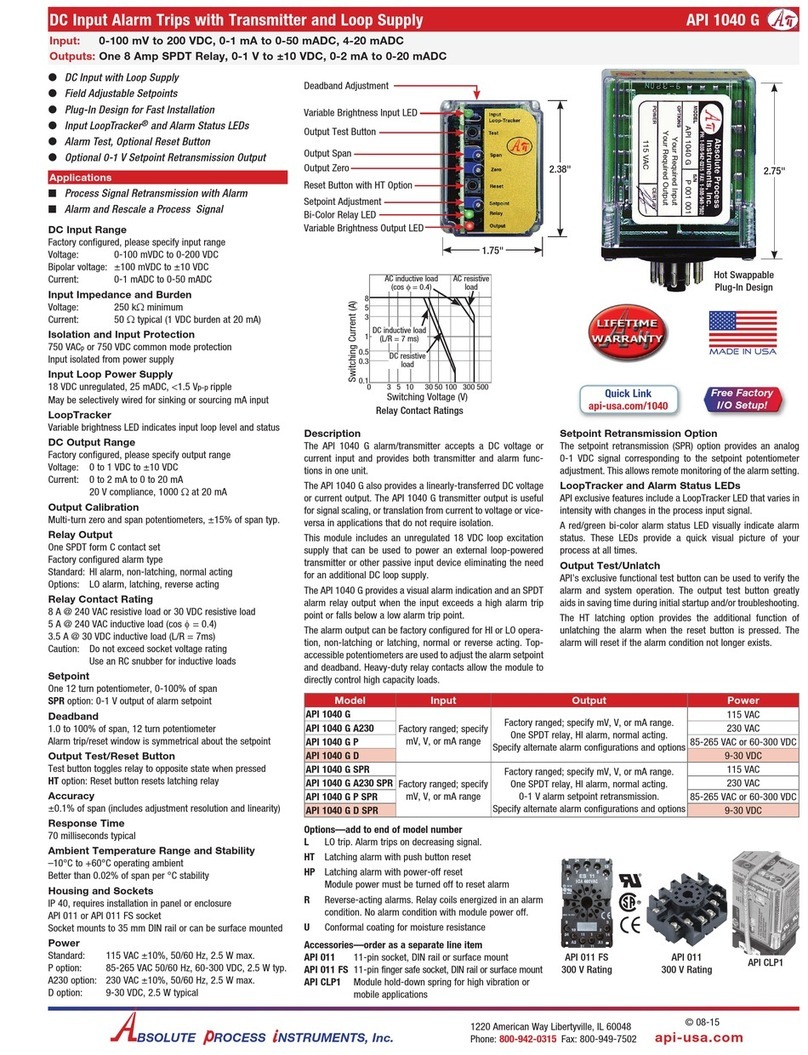

POWER CONNECTIONS

NEVER connect the gauge power wires directly to 115 VAC or permanent damage not cov-

ered by warranty will result! The F16ADA sereis can be powered by an AC source of 8 to

24 VAC 50/60 Hz or DC source: 9 to 32 VDC

Connect power to the smaller two-conductor cable with one RED and one BLACK lead. The

gauge will operate on either AC or DC power, so there is no need to observe polarity.

Operation with less than 8 VAC RMS if AC, or 9 VDC may cause erratic or erroneous read-

ings or alarm operation.

The gauge is powered on whenever a supply voltage is applied. During power-up, the dis-

play briefly indicates the rated full-scale pressure with “FS” indicated on the lower display.

This is followed by a test of all display segments. The gauge then proceeds to the normal

operating mode. The gauge may be left on at all times or as required. Alarm setpoints, the

calibration passcode, and calibration information are stored in non-volatile memory.

ALARM OUTPUT WIRING

The 6-conductor cable is for the 2 SPDT relay contacts.

Contact 1 Normally Closed (NC) BLACK

Contact 1 Common (C) RED

Contact 1 Normally Open (NO) WHITE

Contact 2 Normally Closed (NC) GREEN

Contact 2 Common (C) BROWN

Contact 2 Normally Open (NO) BLUE

Contact Rating and Protection - The contacts of the

alarm relays are rated at 1A/24VDC or 0.5A/115VAC. Using mechanical relay contacts

above their rating, or with large inductive loads, will shorten their useful life. In circuits other

than low-level switching or pilot duty, the user should consider whether external contact

protection such as snubber networks or arc suppression networks are required to protect

the contacts. No internal fusing is included in the alarm contact circuits. The alarm outputs

should be externally fused by the user in applications where good design practice dictates.

NORMAL OPERATION

In normal operation the display indicates the applied pressure with engineering units dis-

played on the character segments. A green LED indicates a normal or no-alarm condition.

If any alarm condition is present, the relevant LCD alarm icon will be shown on the display

and the corresponding bi-color LED will be red and blink at a slow rate until the alarm is

acknowledged or the alarm condition clears. Press and release the TEST button to

acknowledge an alarm condition.

The alarm trip point values are displayed by pressing the SEL (select) button. Press once

to show Trip 1 and press again to show Trip 2. Pressing the SEL button again returns

the gauge to the normal display.

If a particular setpoint is configured as a HI alarm, the gauge will provide a RED alarm indi-

cation when the system pressure exceeds the setpoint. If a particular setpoint is configured

as a LO alarm, the gauge will provide a RED alarm indication when the system pressure

falls below the setpoint. Alarm configurations are set at the factory and may be ordered as

HI/LO, HI/HI, or LO/LO configurations.

USING THE TEST FUNCTION

For system setup, testing, and troubleshooting, the test function can be used to toggle the

state of the alarm relays. This allows them to be switched to their opposite state on demand

without the need to vary the system pressure to test devices connected to the alarms.

While in the normal operating mode, press and hold the TEST button and press the SEL

button. Release both buttons when the display indicates – – – – .

While in the Test Alarms mode the display will indicate the applied pressure with engineer-

ing units blinking at a slow rate.

To invert the alarm states, press the TEST button. As long as the TEST button is held

pressed, the alarm indicators and the alarm relays will be opposite to what they would nor-

mally be for the applied pressure displayed.

When the TEST button is released, the alarm indicators will return to their normal operat-

ing state corresponding to the applied pressure being displayed. To exit the Test Alarms

mode and return to normal operation, press and release the SEL button.

ALARM TYPES: NORMAL VS. REVERSE ACTION

With Normal configuration (alarm options 1N, 2N, or 3N), the alarm output relays will be

CLOSED (relay energized) for a non-alarm condition and OPEN (relay not energized) for

an alarm condition. This produces an alarm condition if the gauge loses power.

Therefore, with the Normal configuration, in a green or non-alarm condition the relay will be

energized so that continuity can be expected between the common and normally open

leads. In a red or alarm condition, the relay will be open (not energized), so that continuity

can be expected between the common and normally closed leads.

If no alarm condition is required when the gauge power is off specify Reverse action (alarm

options 1R, 2R, or 3R). In this case, the relay will be open (not energized) in the non-alarm

condition and closed for the alarm condition. In this case, continuity can be expected from

common to normally closed in the green (non-alarm) condition and from common to nor-

mally open in the red (alarm) condition.

DEADBAND

The alarm circuit setpoints have built-in deadbands, also known as hysteresis, of 1% of

span as standard. This is a fixed value set at the factory. This means, for example, the

deadband is approximately 1 psi in a 0 to 100 psi gauge.

This deadband serves to eliminate output oscillation or “chatter” in the process due to minor

fluctuations in pressure. If, for example, the system pressure in a 0-100 psi system is 40.0

psi, and Setpoint 1 is set to 50.0 psi (HI alarm), the alarm indication will trip if the pressure

exceeds 50.0 psi. After the HI alarm has tripped, pressing the SP1 button will show that the

alarm indication will “release” at 1 psi lower (approximately 49 psi).

ALARM SETPOINT ADJUSTMENTS

Setpoint is defined as the value of applied pressure that will result in a change of state only

from a normal to an alarm condition. Trip Point is defined as the value of applied pressure

that will result in a change of state of alarm condition, and includes the effect of deadband

when returning from an alarm to a normal condition.

1. Make sure the gauge is in the normal operating mode. To adjust setpoint 1 press the

SEL (select) button once to show TRIP1 on the lower display.

2. While pressing and holding the TEST button, press the SEL button. Release both but-

tons when the display indicates – – – – .

3. The display will indicate trip point 1 with TRIP1 blinking on the lower display.

4. To adjust the setpoint 1 value, press and hold the TEST button. The display will indi-

cate setpoint 1 with SP1 on the character segments.

5. Use the ▲and ▼buttons to adjust the setpoint to the desired value. The setpoint value

is stored when the TEST button is released. The LEDs will turn off and the gauge will

not respond to changes in applied pressure while the TEST button is held pressed. The

alarm relays and LCD indicators will maintain their prior states until the TEST button is

released.

6. To exit the setpoint adjust mode and return to normal operation, press and release the

SEL button.

7. Setpoint 2 is adjusted in the same manner. Press the SEL button twice to show TRIP2

on the lower display and follow the same procedure as setpoint 1.

CALIBRATION

The gauge is calibrated at the factory using equipment traceable to NIST. There is no need

to calibrate the gauge before putting it in service.

A user-settable passcode is required to access the gauge calibration functions. Passcode

information and gauge calibration instructions can be downloaded from www.cecomp.com

or requested by calling us at 800-942-0315. Gauges may be also returned to Cecomp for

factory certified or NIST traceable calibration.

DIMENSIONS

1/4" NPT

Cecomp Electronics / Made in USA

2.88"

3.38"

0.75" 0.75"

1.65"

Turn at

hex

fitting only

Two 3 ft long,

22 AWG cables, 2-

conductor power,

6 conductor alarm

SEL TEST ▼

▲

XXXXX

8

8

8

8

82

ALARM 1 ALARM 2

BSOLUTE ROCESS NSTRUMENTS, Inc.

1220 American Way Libertyville, IL 60048

Phone: 800-942-0315 Fax: 800-949-7502

For latest product information or to contact

your local representative visit api-usa.com

Cecomp maintains a constant effort to upgrade and improve its products. Specifications

are subject to change without notice. Consult factory for your specific requirements.

Pressure

1/4" NPT

3.0"

3.5"

0.75"

2.0"

F16ADAN

XXXXX

8

8

8

8

82

Two 3 ft long,

22 AWG cables, 2-

conductor power,

6 conductor alarm

0.75"

Turn at

hex fitting

only!

Cecomp Electronics / Made in USA

SEL TEST ▼

▲

F16ADA

NC 1

C1

NO 1

NC 2

C2

NO 2

NC 1

C1

NO 1

NC 2

C2

NO 2