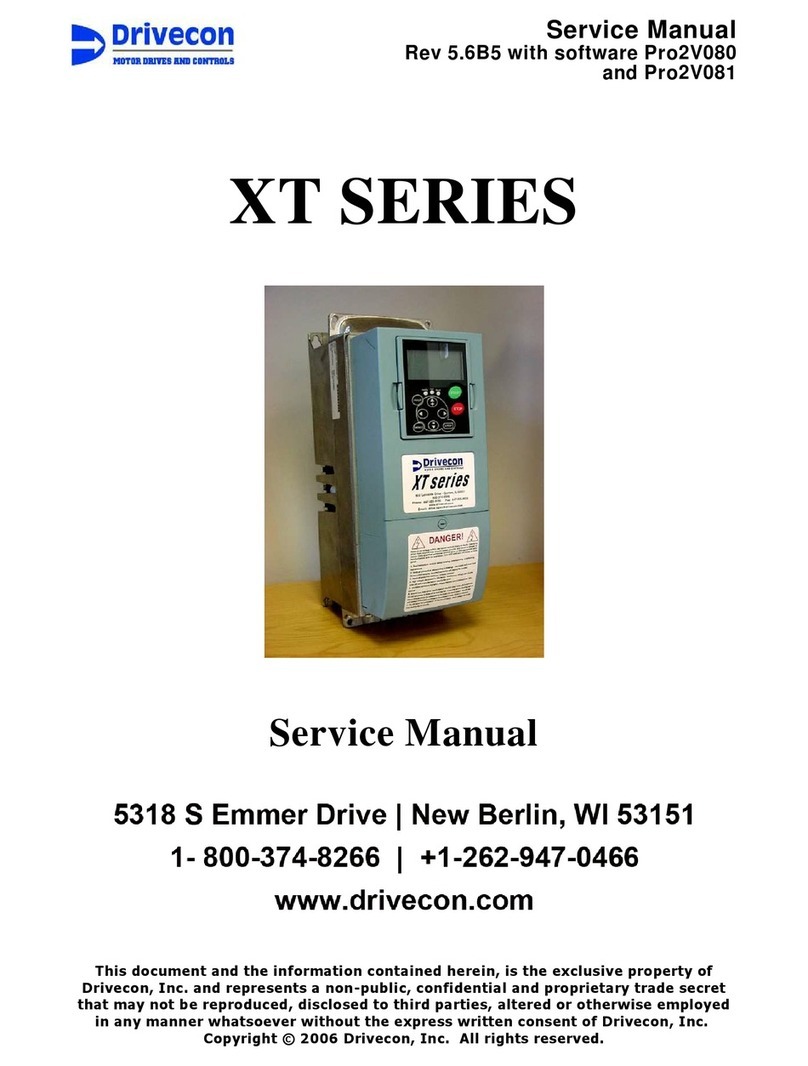

1. Press the PROG/RUN key. This will cause the PASSWORD prompt

to appear (unless the password protection has been disabled), as

shown below:

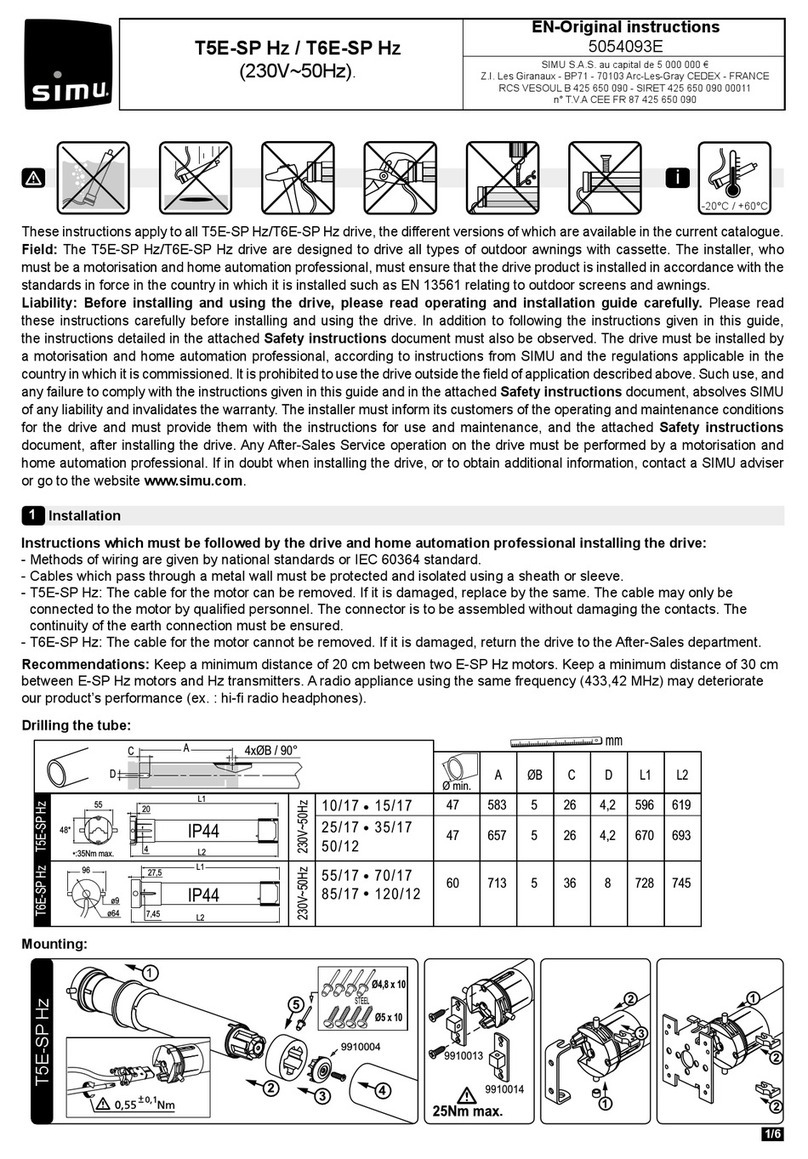

THE MC1000 KEYPAD

PROGRAMMING THE MC1000 DRIVE

2. Use the Vand Wkeys to scroll to the correct password value

(the factory default password is 0019) and press ENTER. The

PROGRAM mode will be entered at the start of the parameter

menu. A cursor will highlight the parameter name.

3. Use the Vand Wkeys to scroll to the desired parameter and

press ENTER. The cursor will shift from the parameter name

to the parameter value, as the example below illustrates:

4. Use the Vand Wkeys to scroll to the desired parameter value,

and press ENTER to store the new value.

5. Press PROG/RUN to exit the PROGRAM mode.

PASSWORD 0000

CURSOR

ACCEL 30.0 SEC

CURSOR

ENTER

STOP > 20.00 HZ

START

STOP

ENTER FWD

REV

AUTO

MAN

PROG

RUN

MC1000 KEYPAD FUNCTIONS

Press the START key to start the drive. The START

key is only active in LOCAL mode.

Press the STOP key to stop the drive.

NOTE: The STOP key is active in both LOCAL and

REMOTE mode.

The STOP key is also used to reset faults. If the fault

condition has passed, pressing the STOP key will clear

the fault and return the drive to a STOP condition.

UP and DOWN ARROWS - Used to change the speed

setpoint in MANUAL mode, scroll through the

parameter menu, and change parameter values.

Toggles between FORWARD and REVERSE rotation.

NOTE: Parameter 27 - ROTATION must be set to FWD

& REV, and the drive must be in LOCAL mode for this

key to be active.

Toggles between AUTOMATIC (terminal strip) and

MANUAL (keypad) speed control.

NOTE: Parameter 28 - AUTO/MAN must be set to

BOTH for this key to be active.

Used to enter and exit the PROGRAM mode to set the

parameters.

Used for: toggling the display between SPEED, LOAD,

and MOTOR VOLTAGE; confirming new parameter

values; confirming AUTO and MANUAL speed control

selections; confirming LOCAL and REMOTE start/stop

mode selections.

Press and hold the ENTER key to activate the

AUXILIARY MODE, which consists of two displays

that cycle in one second intervals. One indicates

LOCAL/REMOTE mode,AUTO/MANUALmode, and

the speed reference source, and the other is an elapsed

time meter that indicates total run time.

START

STOP

ENTER

PROG

RUN

AUTO

MAN

FWD

REV

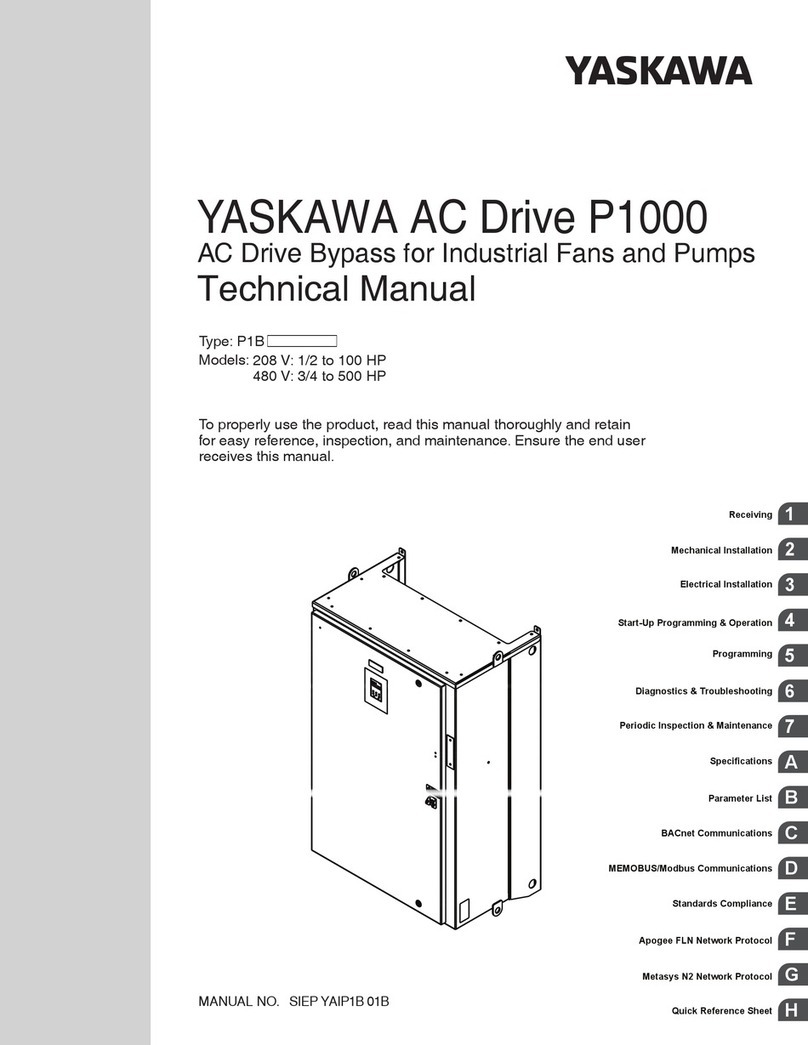

MC1000 DISPLAYS

Shown below are examples of MC1000 displays. To scroll through the

SPEED, LOAD, and MOTOR VOLTAGE displays, press and release

the ENTER key.

Press and hold the ENTER key to activate the AUXILIARY MODE

display, which indicates the control source (LOCAL, REMOTE, or

SERIAL), AUTO or MANUAL mode, and the speed reference source.

An example is shown below (IDC = 4-20 mA signal):

LOCAL -- AUTO -- IDC

CONTROL

SOURCE

AUTO/MAN

MODE

SPEED

REFERENCE

SOURCE

AUXILIARY MODE

DISPLAY

PRESS

& HOLD

ENTER

SPEED DISPLAY

LOAD DISPLAY

MOTOR VOLTAGE

DISPLAY

○○○○

ENTER

ENTER

RUN > 85% LOAD

DRIVE

STATUS

PERCENT

LOAD

RUN > 460 VAC

DRIVE

STATUS

MOTOR

VOLTAGE

RUN > 60.00 HZ

DRIVE

STATUS

SPEED

SETPOINT

SPEED

UNITS

○○○○ ○○○○ ○○○○

ROTATION DIRECTION

(“>” = Forward, “<” = Reverse)