Gunite®Automatic Slack Adjusters

1. Manually uncage the spring brakes.

2. Build-up vehicle air pressure. If the axle in question has

parking brakes, be sure they’re released. Using template,

recheck for proper clevis setting. If incorrect, readjust per

instructions under installation procedures.

3. Fully apply the brakes and allow the air chamber to travel

its maximum stroke. Clearance must exist between the slack

and all adjacent chassis components such as axle housing,

suspension brackets, etc. Release the brakes.

4. After completing this procedure, follow the instructions for

the proper brake adjustment after installation on page 4.

Installation Check

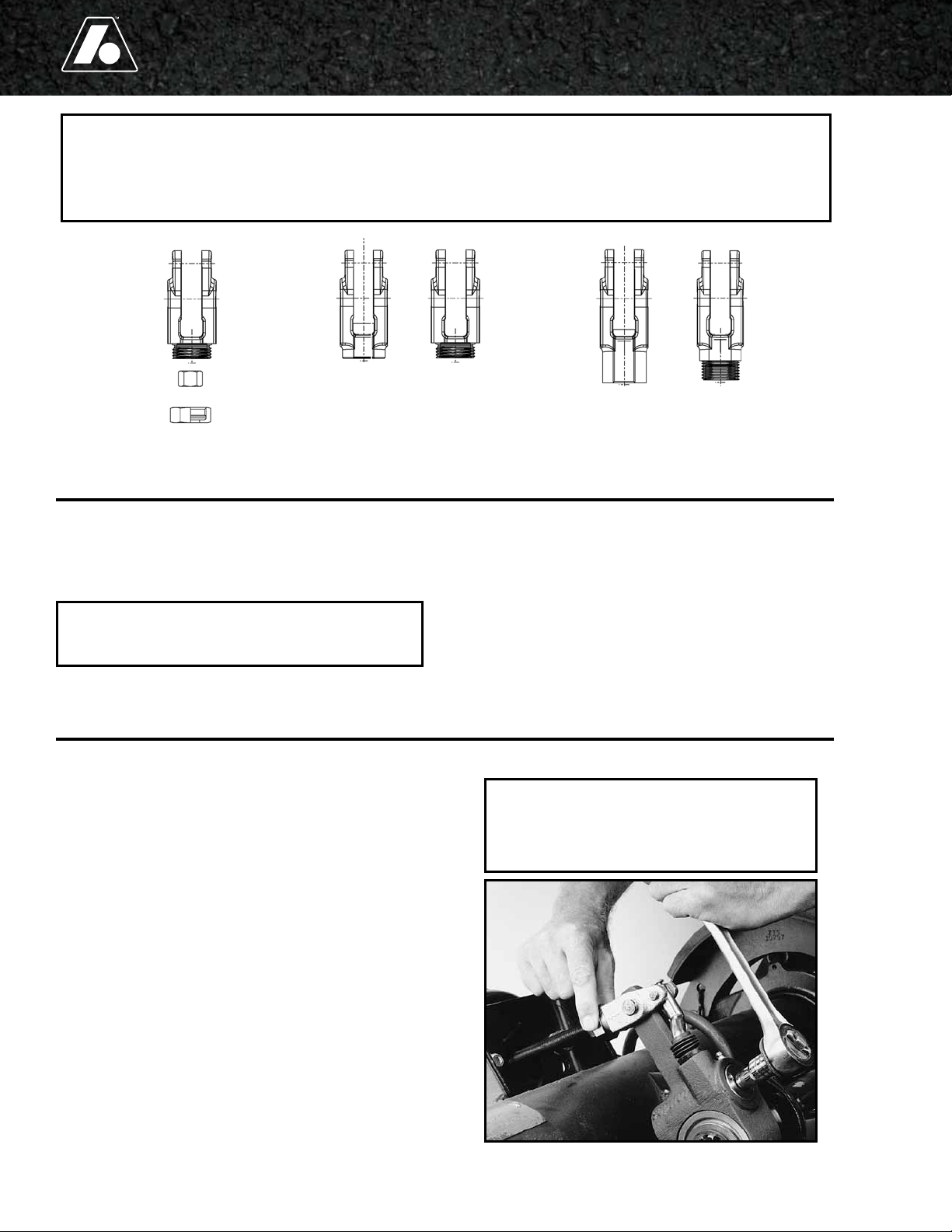

5. Thread the 1-1/4" collar nut

onto the clevis and install

the template over the large

and small pins as shown in

Figure 3.

6. Align the slack by

adjusting the 3/4" hex

nut on the push rod until

the proper centering hole

aligns with the center hole

on the camshaft.

7. Once the slack is properly aligned, tighten the 1-1/4" collar nut

to the clevis using 40 to 50 ft. lbs. of torque.

8. After tightening the 1-1/4" collar lock nut, tighten the 15/16"

jam nut against the collar lock nut using 40 to 50 ft. lbs.

torque.

9. Next follow the instructions in the installation check section

below.

NOTE:

Failure to tighten the jam nut will allow the air chamber

push rod to rotate in the clevis and change the installed

position of the slack, preventing proper automatic adjuster

function.

1. Apply anti-seize compound to the air chamber push rod.

Install the new clevis on the air chamber push rod in the

same location as the clevis which was removed. Do not

tighten the jam nut at this

time.

2. Insert the clevis pins into

the threaded clevis. Install

the template over the

small and large pins as

shown in Figure 4. Align

the slack by adjusting

the clevis in or out on the

push rod until the hole at

the bottom of the template

aligns with the center hole

on the camshaft.

3. If the push rod threads

protrude through the clevis opening more than 1/16",

remove the clevis and cut the push rod to length. The push

rod must not be more than 1/8" short of being flush with

the clevis opening. Follow instruction in the service manual

for cutting a push rod to length.

4. If the push rod fails to come within 1/8" of full engagement

with the clevis opening, install a long push rod and cut to

length. On trailer applications, an extended clevis can be used

instead of replacing the push rod. However, you must have at

least 1/2" of thread engagement inside the clevis. If you have

less than 1/2" thread engagement, a new push rod must be

installed.

5. Tighten the jam nut against the clevis housing using 40 to 50

ft. lbs. of torque. Failure to tighten the jam nut now will allow

the clevis to rotate freely and change the position of the clevis

resulting in improper installation.

6. Apply anti-seize to the camshaft and install the slack using

original mounting hardware. Using a wrench or socket,

rotate the hex extension until the holes in the slack housing

align properly with the holes in the clevis. Hold the link (rod

with small 1/4” hole) down while rotating the hex extension

clockwise. Failure to do so can cause the link to disengage

from the drive.

7. Once properly aligned, insert both the large and small clevis

pins and insert the cotter pins.

8. Next follow the instructions in the installation check section

below.

NOTE:

On axles equipped with spring brake chambers, be sure the

chambers are fully caged before cutting the push rod. If the

spring brakes are not fully caged, the push rod can be cut too

short.

NOTE:

Failure to tighten the jam nut will allow the air chamber

push rod to rotate in the clevis and change the installed

position of the slack, preventing proper automatic adjuster

function.

Installation of the Gunite Threaded Clevis and Extended Threaded Clevis

Figure 3 -

Gage Location

Figure 4 - Gage Location