4

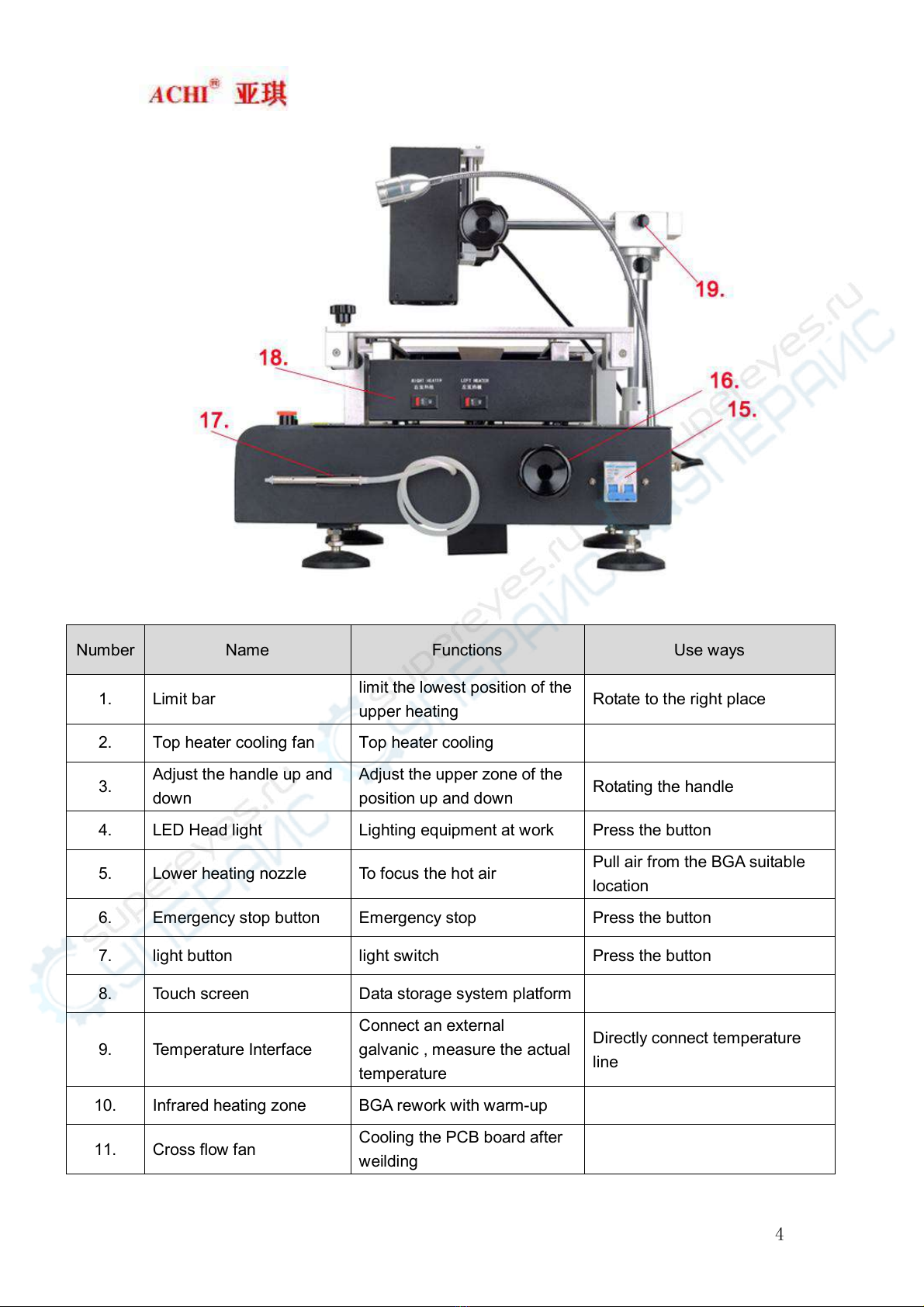

Number

Name Functions Use ways

1. Limit bar limit the lowest position of the

upper heating Rotate to the right place

2. Top heater cooling fan Top heater cooling

3. Adjust the handle up and

down

Adjust the upper zone of the

position up and down Rotating the handle

4. LED Head light Lighting equipment at work Press the button

5. Lower heating nozzle To focus the hot air Pull air from the BGA suitable

location

6. Emergency stop button Emergency stop Press the button

7. light button light switch Press the button

8. Touch screen Data storage system platform

9. Temperature Interface

Connect an external

galvanic , measure the actual

temperature

Directly connect temperature

line

10. Infrared heating zone BGA rework with warm-up

11. Cross flow fan Cooling the PCB board after

weilding