aci AFP Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 7.0

I0000584

GENERAL INFORMATION

The AFP allows an analog (voltage or current)

signal to control a oating point actuator. It

converts an analog signal into two relay contact

outputs (one increase/one decrease). The isolated

oating point output can be controlled by any one

of nine analog input signal ranges (using an oset

jumper). Upon power-up, the decrease relay will

drive 100% of the chosen timing range to ensure

that the output is at its minimum position. On a

loss of power, the output relays will be open and

no signal will be generated. The actuator will

remain at the last commanded position unless it

has "spring return". The AFP output rate of change

(sixteen ranges, in eight versions) is DIP switch

selectable.

MOUNTING INFORMATION

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop”may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not ex board. Use no tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect

or disconnect wiring with power applied.

• When using a shielded cable, ground the

shield only at the controller end. Grounding

both ends can cause a ground loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when powering

the unit with 24 VAC. Failure to wire the

devices with the correct polarity when sharing

transformers may result in damage to any

device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with

devices that have coils such as relays,

solenoids, or other inductors, each coil must

have an MOV, DC/AC Transorb, Transient

Voltage Suppressor (ACI Part: 142583), or

diode placed across the coil or inductor. The

cathode, or banded side of the DC Transorb or

diode, connects to the positive side of the

power supply. Without these snubbers, coils

produce very large voltage spikes when

de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and

National Electric Codes.

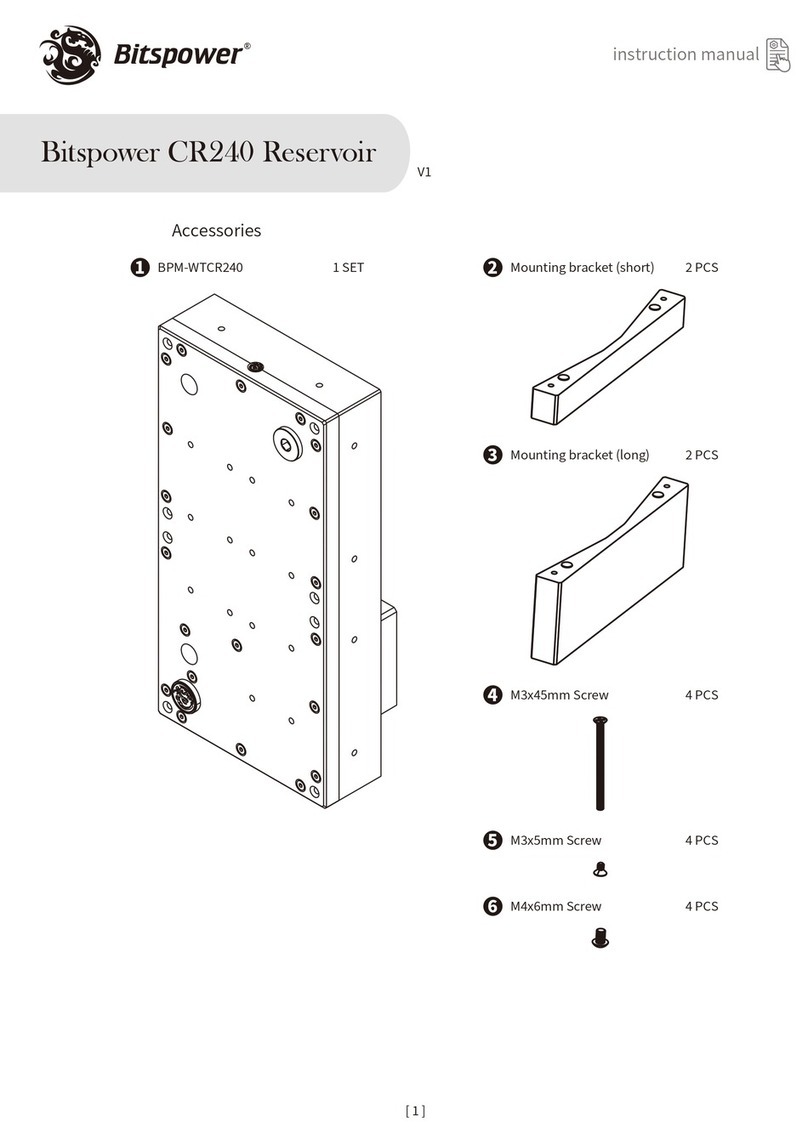

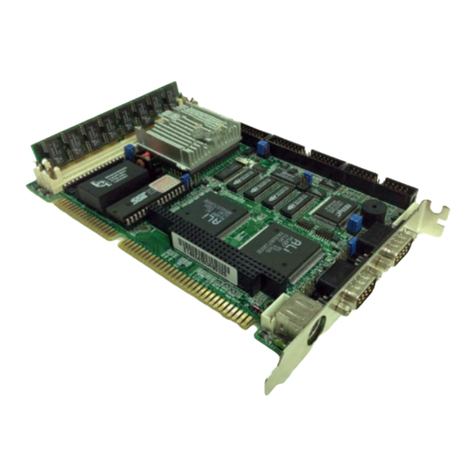

FIGURE 1: DIMENSIONS

INTERFACE SERIES

Installation & Operation Instructions

AFP

Phone: 1-888-967-5224

Website: workaci.com

3.25”

(82.55mm)

4.00” (101.60mm)

3.25”

(82.55mm)

3.88”(98.55mm)

0.70”

(17.78mm)

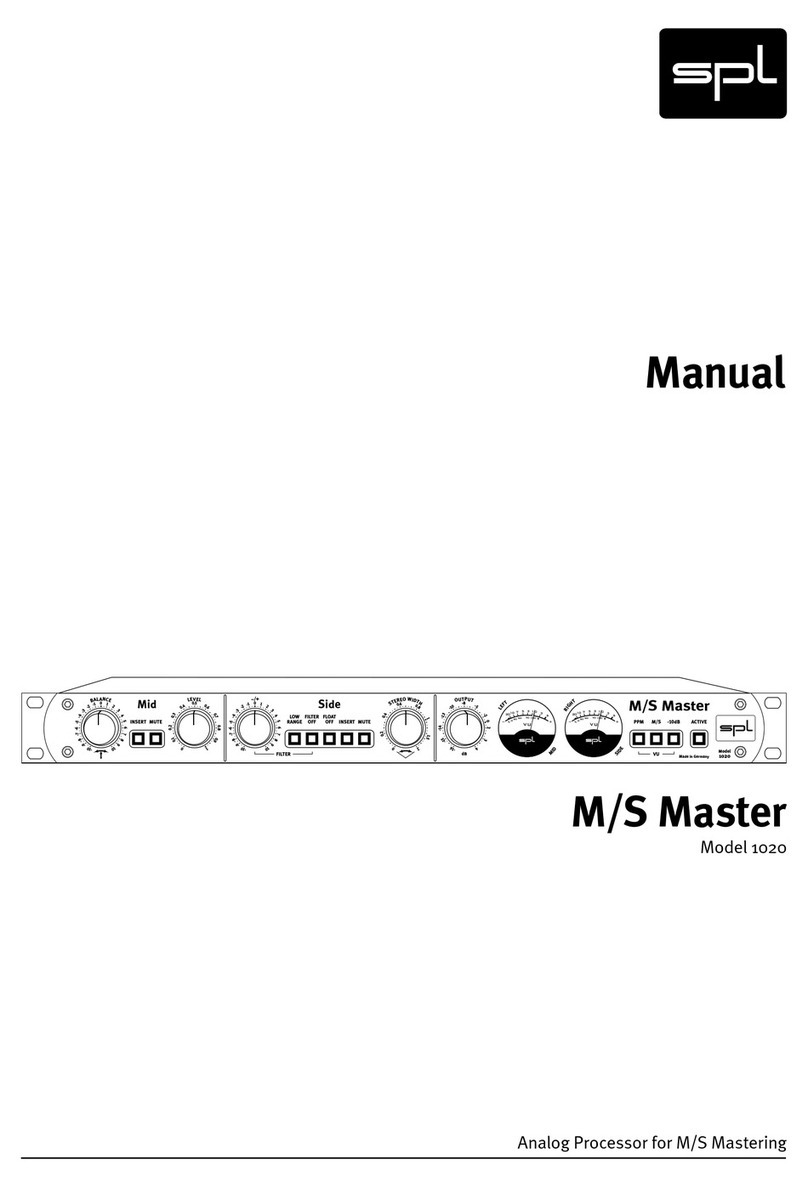

FIGURE 2: WIRING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 7.0

I0000584

(-)

(+)

4 - 20mA

Loop Powered

Signal

(+) 24 Volt Accessory (Option)

(+) Analog Input

(-) Analog, Power and Accessory Common

(+) Power - 24 VDC/VAC @ 50/60Hz

Relay Common

N.O. (Counter-clockwise or DOWN)

N.O. (Clockwise or UP)

To Floating

Point Actuator

Optional Wiring Setup

4 - 20mA Loop Powered Signal

Controlling a Floating Point Actuator

CCW

CW

COM

Floating

Point

Actuator

24 VAC

or 24VDC

Power

Supply

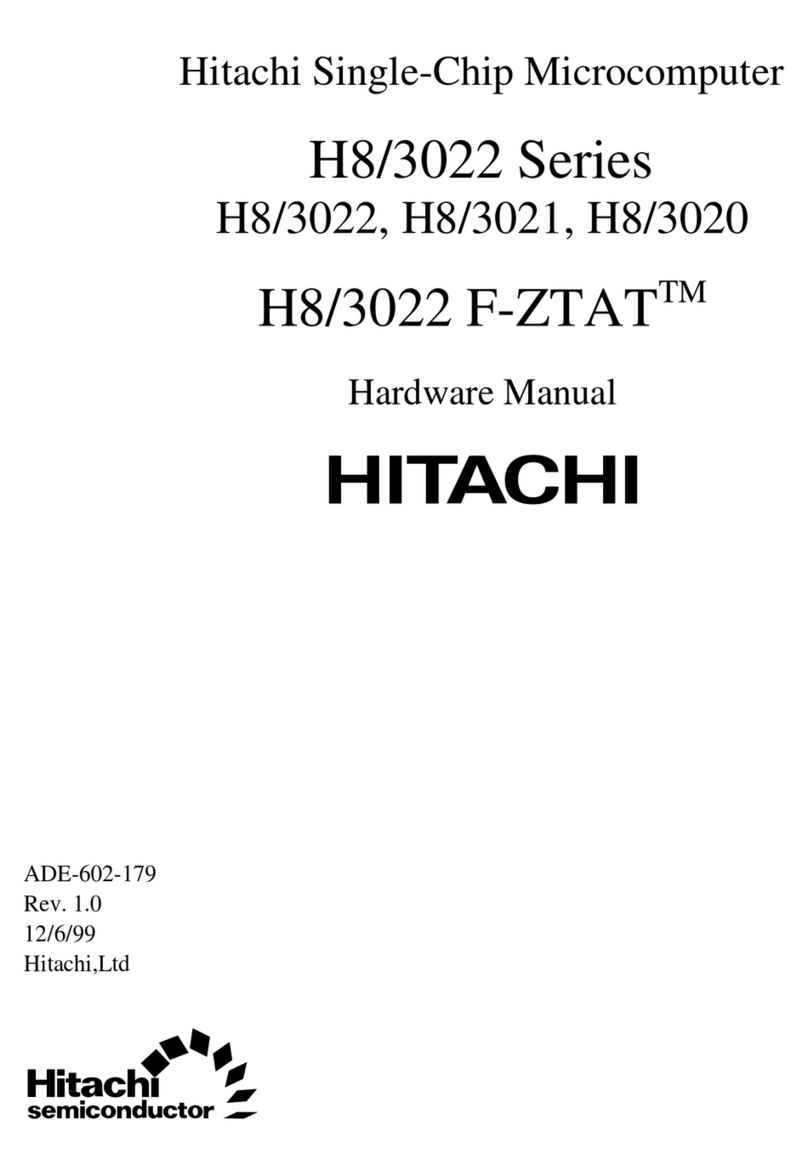

FIGURE 3: JUMPER SETTINGS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 7.0

I0000584

SETUP

Analog input signal ranges are jumper selectable by using Jumper

J3, see Figure 3. The output of the AFP has two relays. One relay

controls UP (increase), the other DOWN (decrease) depending, of

course, on the actuator conguration. The rate of change these

outputs make on the actuator are determined by DIP switch SW1

setting. Refer to“Rate of Change” Chart and set switches according-

ly. Jumper J6 is to be in the CD mode at all times. Due to minor

dierences in the AFP timing range and product timing range, an

error may develop between the commanded position and actual

position of the actuator. There are two ways to calibrate the unit.

Version #1 - Program AFP_0101.hex

30, 60, or 90 seconds

Switch (SW1) 1 2 34

30 sec. - - Off On

60 sec. - - Off Off

90 sec. - - On Off

Version #2 - Program AFP_0201.hex

120, 150 or 180 seconds

Switch (SW1) 1 2 34

120 sec. - - Off On

150 sec. - - Off Off

180 sec. - - On Off

Drives actuator 200% of range if power is reapplied

Version #3 - Program AFP_0301.hex

14, 16.5 or 19 seconds

Switch (SW1) 1 2 34

14 sec. - - Off On

16.5 sec. - - Off Off

19 sec. - - On Off

Version #4 - Program AFP_0401.hex

30, 60, or 90 seconds

Switch (SW1) 1 2 34

30 sec. - - Off On

60 sec. - - Off Off

90 sec. - - On Off

Relay stays on at Min. & Max. voltage

Version #5 - Program AFP_0501.hex

90, 135, or 180 seconds

Switch (SW1) 1 2 34

90 sec. - - Off On

135 sec. - - Off Off

180 sec. - - On Off

Relay stays on with 5% of Max. or Min. input

voltage. No overshoot on Max. or Min. input voltage

Version #6 - Program AFP_0601.hex

18, 75, or 360 seconds

Switch (SW1) 1 2 34

18 sec. - - Off On

75 sec. - - Off Off

360 sec. - - On Off

Version #7 - Program AFP_0701.hex

30, 60, or 90 seconds

Switch (SW1) 1 2 34

30 sec. - - Off On

60 sec. - - Off Off

90 sec. - - On Off

Drives actuator 105% up if power is reapplied

Version #8- Program AFP_0801.hex

46, 240, or 600 seconds

Switch (SW1) 1 2 34

46 sec. - - Off On

240 sec. - - Off Off

600 sec. - - On Off

Input Signal Type

Moving jumper to ON adds offset

to the input or 1-5, 2-10, 3-15 or

4-20mA based on what range is

selected. OFF provides input

as selected on J3 above.

Jumper must remain

on CD setting

Manual Relay Control-Digital Outputs

Off Auto Manual

FIRST METHOD

Remove power (via control relay or switch). When power is removed

and reapplied the AFP will drive or stroke the actuator down 105%

of selected timing range (200% on Version 2, 105% up on Version 7).

Whenever the input on AFP Version 2 is within 2-5% of extreme up

or down, the relay will activate for an additional time that is 100% of

selected timing range. After the AFP has driven down (or up), it will

return to the position commanded by the analog level of the input.

The analog input can remain connected during a power reset. If the

accumulated error is greater than 5% and the analog signal at 100%,

this process may need to be repeated. Allow a 5 second or greater

delay before power is applied.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 7.0

I0000584

SECOND METHOD

The other way to calibrate the actuator is to drive the output to 0% and 100% of selected input range.

Depending the direction and amount of developed error, it may be necessary to repeat this process. This

calibration process should be done at a time when the large changes in the actuator position will not cause

problems with the environment it is controlling. When power is applied to terminals +24V and (-), the

“POWER” LED will light. When the AFP is not powered on terminals +24v and (-), both relays are open.

Tranzorbs are incorporated in the output circuit of the AFP.

TROUBLESHOOTING & TESTING

1.) Make sure the input and oset jumper and output timing switches 3 and 4.

2.) Apply 24 VAC/VDC to the 24 (+) and (-) terminals, conrm the power LED is on and measure

voltage to conrm proper voltage. A DC voltage can be measured from the Vout (+) terminal to the

24 (-) terminal. This voltage will vary depending on the supply voltage supplied. Voltage ranges will

be from 21 to 25 VDC. Please note supply and Vout voltages if unit is not functioning properly.

Contact technical support at ACI.

3.) Y2 will drive the actuator down 105% of selected range (200% on Version 2, 105% up on Ver 7) if

power is removed and reapplied. This is to assure the device being controlled is at 0% when

command voltage is applied. Output will return to commanded position after this calibration

process.

TESTING THE OUTPUT

Note: Output is contact closure only.

Placing J4 or J5 in the H position will close the corresponding contacts or the output. Never place both at

the same time. Conrm the resistance operation of meter and connect meter only to the corresponding

output terminal. “G” terminal is common for both. Resistance can be measured now. A “dead” or “near

dead” short should be measured when the output has been placed in the “H” position. Conrm the

appropriate LED it lit. Contact tech support if the output is not functioning.

TEST PROCEDURE (Version 1, 2, 3, 5, 6, 7 & 8)

Set the input jumpers to the required input signal settings. Set all the output switches to OFF. Place jumper

J6 CD/CE in the center position or remove (do not discard or lose jumper). With power and input only

connected, ramp input signal from 0 to 100% or in steps of 20%. Y2 will turn on from 25 – 49% of set range.

Y1 will turn on and Y2 will turn o from 50 – 73% of set range. Both relays will be on at 74% or greater. This

test conrms the unit is functional and operating correctly. Reset timing switches to desired range and J6

to the CD position. Reconnect input and output connections and retry application. Contact tech support

if application problems still exist.

TEST PROCEDURE (Version 4 ONLY)

Set the input jumpers to the required input signal settings. Set all the output switches to OFF. Place jumper

J6 CD/CE in the center position or remove (do not discard or lose jumper). With power and input only

connected, ramp input signal from 0 to 100% or in steps of 20%. Both relays will be on at 0-25%.Y1 will turn

on from 25 – 49% of set range. Y2 will turn on and Y1 will turn o from 50 – 73% of set range. Both relays

will be o at 74% or greater. This test conrms the unit is functional and operating correctly. Reset timing

switches to desired range and J6 to the CD position. Reconnect input and output connections and retry

application. Contact tech support if application problems still exist.

INPUT SIGNAL JUMPERS

Refer to the input signal range and oset jumper settings shown in the diagram on page 1.

Voltage Input

Connect the “+” or positive wire to the “UP/A+” terminal. Connect the common to the “24V-“ terminal.

Apply a voltage from control source. Measure the voltage at the input terminals. If the commanded

voltage is not present, remove the“+”or positive wire and measure from + wire to the“24V-“ terminal. If no

voltage is measured, check wiring from controller. If voltage disappears or is reduced when connected to

the AFP. Conrm input jumper is set to voltage mode and remove input wires. Remove power from unit

and measure the resistance from “Vout+” to “24V-“ terminals. Resistance in the voltage modes will be

around 10K Ohms and greater. If input is shorted contact tech support at ACI. If not shorted remove the

controller input common and connect power only to AFP. NOTE: Place meter in voltage mode and

measure VAC and VDC from analog input common wire to power supply common. If any voltage is

measured in DC or AC, a ground loop most likely exists. Use a separate 24V transformer for the AFP and let

common oat.

Current Input

Conrm the input jumper is in the 20mA mode. Measured input resistance is around 250 Ohms. Connect

“+” or positive wire to “UP/A+”and input “-“ or common to“24V-“. Apply mA signal. Place meter in voltage

and measure voltage across“UP/A+” and “24V-“. 4mA is equal to 1 volt and 20mA is equal to 5 volts. Use

Ohms Law to nd voltage from current. Current x 250 Ohms = Volts.

Example: 12mA (or 0.012) x 250 Ohms = 3 Volts. If no voltage is present, check wiring for open. Current

cannot exist without voltage present unless the input is dead shorted. If problem still persist see the“Note”

in voltage section.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 7.0

I0000584

SECOND METHOD

The other way to calibrate the actuator is to drive the output to 0% and 100% of selected input range.

Depending the direction and amount of developed error, it may be necessary to repeat this process. This

calibration process should be done at a time when the large changes in the actuator position will not cause

problems with the environment it is controlling. When power is applied to terminals +24V and (-), the

“POWER” LED will light. When the AFP is not powered on terminals +24v and (-), both relays are open.

Tranzorbs are incorporated in the output circuit of the AFP.

TROUBLESHOOTING & TESTING

1.) Make sure the input and oset jumper and output timing switches 3 and 4.

2.) Apply 24 VAC/VDC to the 24 (+) and (-) terminals, conrm the power LED is on and measure

voltage to conrm proper voltage. A DC voltage can be measured from the Vout (+) terminal to the

24 (-) terminal. This voltage will vary depending on the supply voltage supplied. Voltage ranges will

be from 21 to 25 VDC. Please note supply and Vout voltages if unit is not functioning properly.

Contact technical support at ACI.

3.) Y2 will drive the actuator down 105% of selected range (200% on Version 2, 105% up on Ver 7) if

power is removed and reapplied. This is to assure the device being controlled is at 0% when

command voltage is applied. Output will return to commanded position after this calibration

process.

TESTING THE OUTPUT

Note: Output is contact closure only.

Placing J4 or J5 in the H position will close the corresponding contacts or the output. Never place both at

the same time. Conrm the resistance operation of meter and connect meter only to the corresponding

output terminal. “G” terminal is common for both. Resistance can be measured now. A “dead” or “near

dead” short should be measured when the output has been placed in the “H” position. Conrm the

appropriate LED it lit. Contact tech support if the output is not functioning.

TEST PROCEDURE (Version 1, 2, 3, 5, 6, 7 & 8)

Set the input jumpers to the required input signal settings. Set all the output switches to OFF. Place jumper

J6 CD/CE in the center position or remove (do not discard or lose jumper). With power and input only

connected, ramp input signal from 0 to 100% or in steps of 20%. Y2 will turn on from 25 – 49% of set range.

Y1 will turn on and Y2 will turn o from 50 – 73% of set range. Both relays will be on at 74% or greater. This

test conrms the unit is functional and operating correctly. Reset timing switches to desired range and J6

to the CD position. Reconnect input and output connections and retry application. Contact tech support

if application problems still exist.

TEST PROCEDURE (Version 4 ONLY)

Set the input jumpers to the required input signal settings. Set all the output switches to OFF. Place jumper

J6 CD/CE in the center position or remove (do not discard or lose jumper). With power and input only

connected, ramp input signal from 0 to 100% or in steps of 20%. Both relays will be on at 0-25%.Y1 will turn

on from 25 – 49% of set range. Y2 will turn on and Y1 will turn o from 50 – 73% of set range. Both relays

will be o at 74% or greater. This test conrms the unit is functional and operating correctly. Reset timing

switches to desired range and J6 to the CD position. Reconnect input and output connections and retry

application. Contact tech support if application problems still exist.

INPUT SIGNAL JUMPERS

Refer to the input signal range and oset jumper settings shown in the diagram on page 1.

Voltage Input

Connect the “+” or positive wire to the “UP/A+” terminal. Connect the common to the “24V-“ terminal.

Apply a voltage from control source. Measure the voltage at the input terminals. If the commanded

voltage is not present, remove the“+”or positive wire and measure from + wire to the“24V-“ terminal. If no

voltage is measured, check wiring from controller. If voltage disappears or is reduced when connected to

the AFP. Conrm input jumper is set to voltage mode and remove input wires. Remove power from unit

and measure the resistance from “Vout+” to “24V-“ terminals. Resistance in the voltage modes will be

around 10K Ohms and greater. If input is shorted contact tech support at ACI. If not shorted remove the

controller input common and connect power only to AFP. NOTE: Place meter in voltage mode and

measure VAC and VDC from analog input common wire to power supply common. If any voltage is

measured in DC or AC, a ground loop most likely exists. Use a separate 24V transformer for the AFP and let

common oat.

Current Input

Conrm the input jumper is in the 20mA mode. Measured input resistance is around 250 Ohms. Connect

“+” or positive wire to “UP/A+”and input “-“ or common to“24V-“. Apply mA signal. Place meter in voltage

and measure voltage across“UP/A+” and “24V-“. 4mA is equal to 1 volt and 20mA is equal to 5 volts. Use

Ohms Law to nd voltage from current. Current x 250 Ohms = Volts.

Example: 12mA (or 0.012) x 250 Ohms = 3 Volts. If no voltage is present, check wiring for open. Current

cannot exist without voltage present unless the input is dead shorted. If problem still persist see the“Note”

in voltage section.

WARRANTY

The ACI AFP Series is covered by ACI’s Two (2)Year Limited Warranty, which is located in the front of ACI’S SENSORS

& TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

PRODUCT SPECIFICATIONS

24 VAC or 24 VDC, (+/- 10%), 50/60 Hz

105 mA maximum without 24 VDC auxiliary output

190 mA maximum with 24 VDC auxiliary output

0-5 VDC, 0-10 VDC, 0-15 VDC

0-20 mA

1-5 VDC, 2-10 VDC, 3-15 VDC

4-20 mA

Voltage @ 10,000 Nominal / Current @ 250 nominal

Two relay contact outputs (Increase / Decrease)

Dry Contact, Form C, 2A maximum @ 24 VDC

100,000 operations minimum

1,000,000 operation

90° Pluggable Screw Terminal Blocks

16 (1.31 mm) to 26 AWG (0.129 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

35 to 120°F (1.7 to 48.9°C)

10 to 95% non-condensing

-20 to 150°F (-28.9 to 65.5°C)

Polyvinyl Chloride (PVC)

SENSOR NON-SPECIFIC INFORMATION

Supply Voltage:

Supply Current:

Input Voltage Signal Range:

Input Current Signal Range:

Analog Voltage Signal Input Range with Oset

Jumper:

Analog Current Signal Input Range with Oset

Jumper:

Input Impedances (Nominal):

Output (Floating Point):

Relay Contact Rating:

Relay Electrical Life:

Relay Mechanical Life:

Connections:

Wire Size:

Terminal Block Torque Rating:

Operating Temperature Range:

Operating Humidity Range:

Storage Temperature:

Snaptrack Material:

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 6

Version: 7.0

I0000584

NOTES

Page 7

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 7.0

I0000584

Page 8

Automation Components, Inc.

2305 Pleasant View Road

Middleton, WI 53562

Phone: 1-888-967-5224

Website: workaci.com

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 7.0

I0000584

Table of contents