Component Testing Procedures

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires it.

July 2012 16500038

©2012 ACP, Inc.

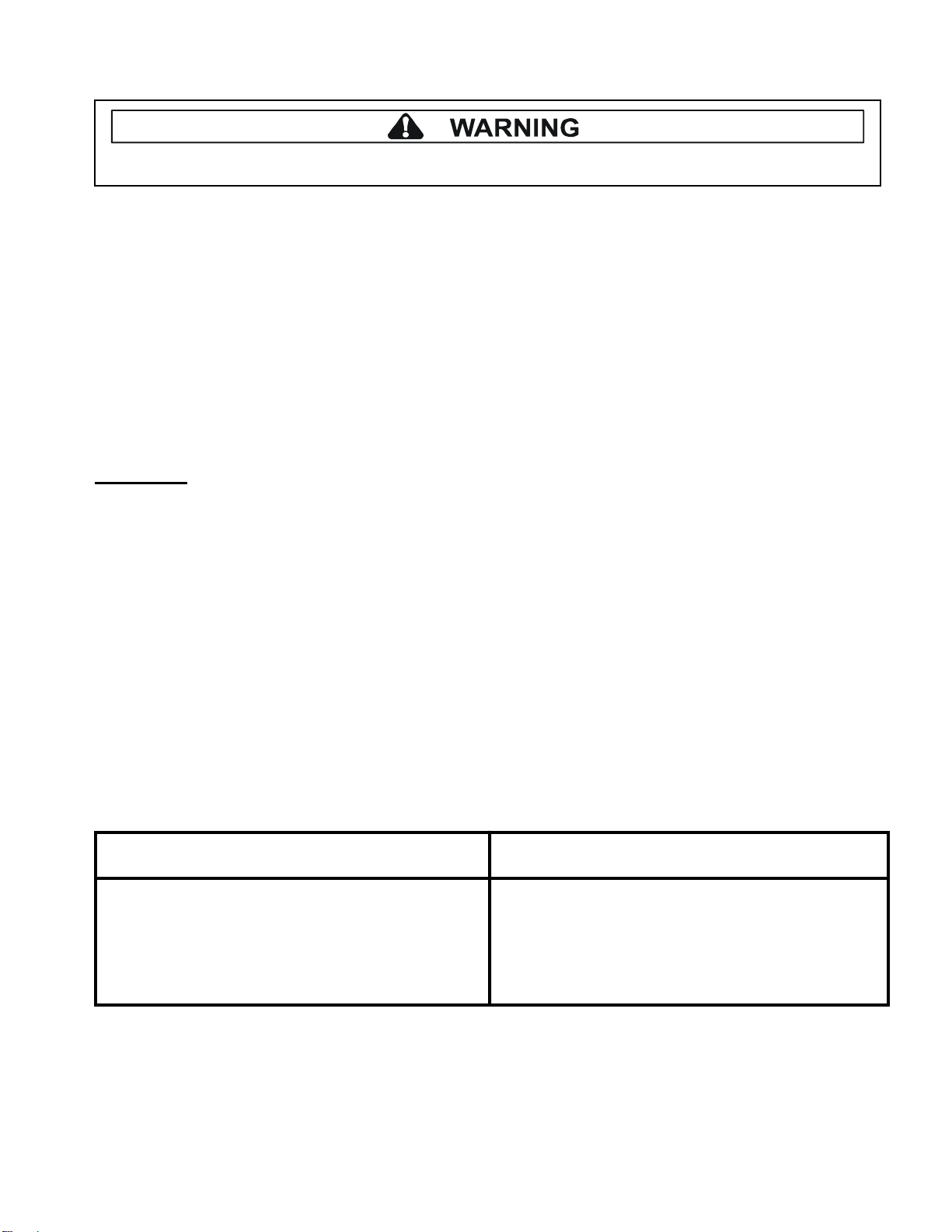

All Amana and Menumaster microwave oven power outputs are rated using the IEC705 standards. Using the IEC705

test method requires precision measurements and equipment that is not practical to be performed in the field. Using

the test shown below will indicate if the oven performance is satisfactory.

Test equipment required:

1000 ml test container and thermometer.

Digital watch / watch with a second hand for use on ovens with electromechanical timers.

Important Notes:

Low line voltage will cause low temperature rise / power output.

Ovens must be on a dedicated circuit, properly grounded, and polarized. Other equipment on the same

circuit may cause a low temperature rise / power output.

This test and results are not a true IEC705 test procedure and are only intended to provide servicers with an

easy means of determining if the microwave oven cooking output is correct.

Procedure

1. Fill the test container to the 1000 ml line with cool tap water.

NOTE: Water temperature should be approximately 60° F / 16° C.

2. Using the thermometer, stir water for five to ten seconds; measure, and record the temperature (T1).

3. Place test container of water in the center of oven cavity and close door.

4. Heat the water for a 33-second full power cycle.

NOTE: Use a digital watch or a watch with a second hand for ovens with electromechanical timers.

5. At end of the cycle, remove test container. Using the thermometer, stir water for five to ten seconds and record

temperature (T2).

6. Subtract the starting water temperature (T1), from the ending water temperature (T2) to obtain the temperature

rise (∆T).

7. If the temperature rise (∆T) meets or exceeds the minimum, the test is complete. If the temperature rise (∆T)

fails to meet the minimum temperature rise, test the line voltage to verify it is correct. Then repeat steps 1 - 6

making sure to change the water. If the temperature rise (∆T) fails to meet the minimum temperature rise again

the oven will require service.

Minimum Temperature Rise at Thirty -Three (33) Seconds Run Time

∆T Cooking ∆T Cooking ∆T Cooking ∆T Cooking

(°F) Power Output (°F) Power Output (°C) Power Output (°C) Power Output

10..................1000 20 .................2000 5 ...............1000 11 ............2000

11..................1100 21 .................2100 5.5.............1100 11.5.........2100

12..................1200 22 .................2200 6.5.............1200 12............2200

14..................1400 24 .................2400 7.5.............1400 13............2400

17..................1700 25 .................2500 9.5.............1700 13.5.........2500

18..................1800 27 .................2700 10..............1800 15............2700

19..................1900 30 .................3000 10.5...........1900 16.5.........3000