Acromag PMC408 Series User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

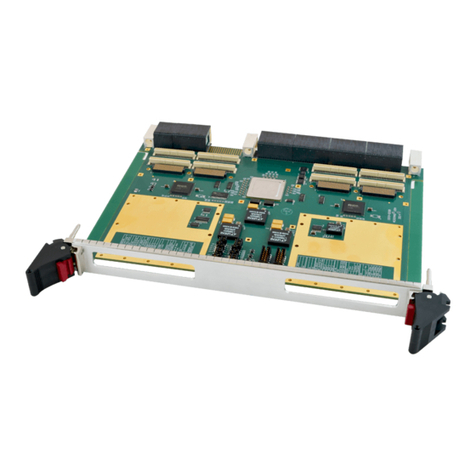

Series PMC408 PCI Mezzanine Card

32-Channel Digital I/O Module

USER’S MANUAL

ACROMAG INCORPORATED

30765 South Wixom Road

P.O. BOX 437

Wixom, MI 48393-7037 U.S.A.

Tel: (248) 624-1541

Fax: (248) 624-9234

Copyright 2000, Acromag, Inc., Printed in the USA.

Data and specifications are subject to change without notice.

8500-672-B03E011

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 2 -

The information contained in this manual is subject to change

without notice. Acromag, Inc. makes no warranty of any kind with

regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose.

Further, Acromag, Inc. assumes no responsibility for any errors that

mayappear in this manual and makes no commitment to update, or

keep current, the information contained in this manual. No part of

this manual may be copied or reproduced in any form, without the

prior written consent of Acromag, Inc.

Table of Contents Page

1.0 GENERAL INFORMATION............................................... 2

KEY PMC408 FEATURES................................................ 2

PCI MEZZANINE CARD INTERFACE FEATURES......... 3

SIGNAL INTERFACE PRODUCTS.................................. 3

PMC MODULE ActiveX CONTROL SOFTWARE............ 3

PMC MODULE VxWORKS SOFTWARE……….............. 3

2.0 PREPARATION FOR USE................................................ 3

UNPACKING AND INSPECTION..................................... 3

CARD CAGE CONSIDERATIONS................................... 4

BOARD CONFIGURATION.............................................. 4

CONNECTORS................................................................. 4

Front Panel Field I/O Connector P1............................... 4

I/O Noise and Grounding Considerations....................... 4

Output Off-State Loading Considerations...................... 4

PCI Local Bus Connector ........................………........... 4

3.0 PROGRAMMING INFORMATION.................................... 5

PCI CONFIGURATION ADDRESS SPACE……...……... 5

CONFIGURATION REGISTERS……………...………….. 6

MEMORY MAP….............................................................. 6

Interrupt Register………................................................ 6

IP Digital Input Registers A & B..................................... 6

IP Digital Output Registers A & B.................................. 7

Interrupt Enable Register............................................... 7

Interrupt Type Configuration Register............................ 7

Interrupt Polarity Register............................................... 7

Interrupt Status Register................................................ 8

PMC408 PROGRAMMING CONSIDERATIONS............. 8

Programming Interrupts................................................ 8

4.0 THEORY OF OPERATION............................................... 9

INPUT/OUTPUT................................................................ 9

PCI INTERFACE LOGIC…............................................. 9

PMC MODULE SOFTWARE............................................ 10

5.0 SERVICE AND REPAIR.................................................... 10

SERVICE AND REPAIR ASSISTANCE........................... 10

PRELIMINARY SERVICE PROCEDURE......................... 10

6.0 SPECIFICATIONS............................................................. 10

PHYSICAL……………………............................................ 10

ENVIRONMENTAL…………………………………………. 10

DIGITAL INPUTS.............................................................. 11

DIGITAL OUTPUTS.......................................................... 11

OUTPUT MOSFETS......................................................... 11

PCI LOCAL BUS INTERFACE…………........................... 11

APPENDIX......................................................................... 12

CABLE, SCSI-2 to Flat Ribbon (Shielded):

MODEL 5028-187………...................................................

12

TERMINATION PANEL: MODEL 5025-552..................... 12

DRAWINGS Page

4501-859 PMC MECHANICAL ASSEMBLY..............…... 13

4501-866 PMC408 BLOCK DIAGRAM............................ 14

4501-867 PMC408 EXAMPLE OUTPUT

CONNECTIONS………………………………...

15

4501-868 PMC408 EXAMPLE INPUT

CONNECTIONS………………………………..

16

4501-758 CABLE, SCSI-2 to Flat Ribbon (Shielded)

5028-187…..………………..............................

17

4501-464 TERMINATION PANEL 5025-552................... 18

IMPORTANT SAFETY CONSIDERATIONS

It is very important for the user to consider the possible adverse

effects of power, wiring, component, sensor, or software failures in

designing any type of control or monitoring system. This is

especially important where economic property loss or human life is

involved. It is important that the user employ satisfactory overall

system design. It is agreed between the Buyer and Acromag, that

this is the Buyer's responsibility.

1.0 GENERAL INFORMATION

The PCI Mezzanine Card (PMC) Series PMC408 is a 32-

channel combination digital input/output board. This model supports

both 0 to 60V DC inputs, and 60VDC low-side switch outputs, in any

combination up to 32 channels. As a combination input/output

module, input channels on this model can be used for “loopback”

monitoring of the output channel states. Up to 8 input channels can

be programmed to generate Change-Of-State (COS), Low, or High

level transition interrupts. The PMC408 utilizes state of the art

Surface-Mounted Technology (SMT) to achieve its high channel

density and is an ideal choice for a wide range of industrial control

and monitor applications that require high-density, high-reliability,

and high-performance at a low cost.

The PMC408 module is available in standard and extended

temperature ranges as follows;

MODEL OPERATING TEMPERATURE RANGE

PMC408 0 to +70°C

PMC408E -40 to +85°C

KEY PMC408 FEATURES

•

High Channel Count - Interfaces with up to 32 input/output

points. Input and output channels may be intermixed in any

combination. The input circuitry of a single channel can also

be used to monitor the output state of the same channel to

efficientlyimplement “loopback” output control.

•

TTL-Compatible Input Threshold - Input threshold is at TTL

levels and includes hysteresis.

•

Input Hysteresis - Buffered inputs include hysteresis for

increased noise immunity.

•

Programmable Change-of-State/Level Interrupts -

Interrupts are software programmable for any bit Change-Of-

State or level on up to 8 channels.

•

Loopback Output Control & Fault Diagnostics - Input and

output circuitry is connected in tandem to each I/O channel,

making it directly compatible for “loopback monitoring” of the

output channel states. This feature can also be used to

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 3 -

implement self-test or fault diagnosis, since inherent loopback

can be used to detect open output switches or shorts.

•

High Voltage Inputs & Outputs - Inputs and outputs are

rated to 60VDC. I/O channels are non-isolated and share a

common connection.

•

High Impedance Inputs - High impedance inputs minimize

loading of the input source and input current.

•No Configuration Jumpers or Switches - All configuration is

performed through software commands with no internal

jumpers to configure or switches to set.

•

Power Up & System Reset is Failsafe - For safety, the

outputs are always OFF upon power-up and cleared after a

system reset. Unlike some competitive units, output gate

pulldowns are included to ensure that the outputs do not turn

on momentarily when output load power is applied with no

power to the IP module.

•

True Logic - Outputs operate using True-Logic

(1=ON/SWITCH CLOSED, 0=OFF/SWITCH OPEN).

•

Low R

dsON

(0.2ΩMaximum)- Low output drain-to-source ON

resistance ensures TTL logic-low compatibility at high currents

and reduces power dissipation.

•

High Output Current - individual output channels may sink up

to 1A DC continuous (up to 10A total, all channels combined),

or 312mA DC (with all 32 channels ON). No deration of

maximum output current is required at elevated ambient

temperatures.

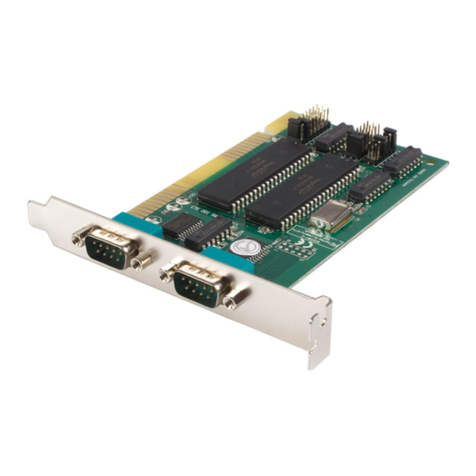

PCI MEZZANINE CARD INTERFACE FEATURES

•

High density - Single-width PMC Target module.

•

Field Connections – All digital inputs/outputs (channels 0 –

31) and common connections are made through a single 50-pin

SCSI-2 front panel I/O connector.

•

16-bit I/O - Channel register Read/Write is performed through

through 32-bit, 16-bit or 8-bit data transfer cycles in the PCI

memory space.

•

Compatibility – IEEE P1386.1 compliant PMC module which

complies to PCI Local Bus Specification Revision 2.2.

Provides one multifunction interrupt. 5V signaling compliant

and 3.3V signaling tolerant.

SIGNAL INTERFACE PRODUCTS

(See Appendix for more information on compatible products)

This PMC Module will mate directly to any standard PMC

carrier/CPU board that supports one single width PMC mezzanine

module. Once connected, the module is accessed via a 50 pin front

panel connector.

The cables and termination panels, described in the following

paragraphs, are also available. For optimum performance with the

PMC408 digital I/O module, use of the shortest possible length of

shielded I/O cable is recommended.

Cables:

Model 5025-187 (SCSI-2 to Flat Ribbon Cable, Shielded): A

round 50 conductor shielded cable with a male SCSI-2

connector at one end and a flat female ribbon connector at the

other end. The cable is used for connecting the PMC408

moduleto Model 5025-552 termination panels.

Termination Panel:

Model 5025-552: DIN-rail mountable panel provides 50 screw

terminals for universal field I/O termination. Connects to

Acromag PMC408, via SCSI-2 to Flat Ribbon Cable, Shielded

(Model 5028-187).

PMC MODULE ActiveX CONTROL SOFTWARE

Acromag provides a software product (sold separately)

consisting of PMC module ActiveX (Object Linking and Embedding)

controls for Windows 98, 95®, ME, 2000 and Windows NT®

compatible application programs (Model PMCSW- ATX, MSDOS

format). This software provides individual controls that allow

Acromag PMC modules to be easily integrated into Windows®

application programs, such as Visual C++™, Visual Basic®,

Microsoft®Office®97 applications and others. The ActiveX

controls provide a high-level interface to PMC modules, eliminating

the need to perform low-level reads/writes of registers, and the

writing of interrupt handlers—all the complicated details of

programming are handled by the ActiveX controls. These functions

consist of an ActiveX control for each Acromag PMC module.

PMC MODULE VxWORKS SOFTWARE

Acromag provides a software product (sold separately)

consisting of PMC module VxWorks®libraries. This software

(Model PMCSW-API-VXW, MSDOS format) is composed of

VxWorks®(real time operating system) libraries for all Acromag

PMC modules. The software is implemented as a library of “C”

functions which link with existing user code to make possible simple

control of all Acromag PMC modules.

2.0 PREPARATION FOR USE

UNPACKING AND INSPECTION

Upon receipt of this product, inspect the shipping carton for

evidence of mishandling during transit. If the shipping carton is

badly damaged or water stained, request that the carrier's agent be

present when the carton is opened. If the carrier's agent is absent

when the carton is opened and the contents of the carton are

damaged, keep the carton and packing material for the agent's

inspection.

For repairs to a product damaged

in shipment, refer to the Acromag

Service Policy to obtain return

instructions. It is suggested that

salvageable shipping cartons and

packing material be saved for future

use in the event the product must be

shipped.

This board is physicallyprotected with

packing material and electrically

protected with an anti static bag during

shipment. However, it is recommended

that the board be visually inspected for

evidence of mishandling prior to

applying power.

The board utilizes static sensitive components and should onlybe

handled at a static-safe workstation.

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 4 -

CARD CAGE CONSIDERATIONS

Refer to the specifications for loading and power requirements.

Be sure that the system power supplies are able to accommodate

the power requirements of the carrier board, plus the installed IP

modules, within the voltage tolerances specified.

IMPORTANT: Adequate air circulation must be provided to prevent

a temperature rise above the maximum operating temperature.

The dense packing of the PMC modules to the carrier/CPU

board restricts air flow within the card cage and is cause for

concern. Adequate air circulation must be provided to prevent a

temperature rise above the maximum operating temperature and to

prolong the life of the electronics. If the installation is in an industrial

environment and the board is exposed to environmental air, careful

consideration should be given to air-filtering.

BOARD CONFIGURATION

Power should be removed from the board when installing PMC

modules, cables, termination panels, and field wiring. Refer to

Mechanical Assembly Drawing 4501-859 and your PMC module

documentation for configuration and assembly instructions. Model

PMC408 I/O Boards have no jumpers or switches to configure--

interrupts are configured through software command.

CONNECTORS

Front Panel Field I/O Connector P1

The front panel connector P1 provides the field I/O interface

connections. The front panel connector is a SCSI-2 50-pin female

connector (AMP 787082-5 or equivalent) employing latch blocks and

30 micron gold in the mating area (per MIL-G-45204, Type II, Grade

C). Connects to Acromag termination panel 5025-552 from the front

panel via round shielded cable (Model 5028-187).

Front panel connector P1 pin assignments are shown in Table

2.1.

Table 2.1: PMC408 Field I/O Pin Connections P1

Pin Description Number Pin Description Number

OD00 1 OD25 32

OD01 2 OD26 33

OD02 3 OD27 34

OD03 4 OD28 36

OD04 6 OD29 37

OD05 7 OD30 38

OD06 8 OD31 39

OD07 9 Not Used 41

OD08 11 Not Used 42

OD09 12 Not Used 43

OD10 13 Not Used 44

OD11 14 Not Used 46

OD12 16 Not Used 47

OD13 17 Not Used 48

OD14 18 Not Used 49

OD15 19 COMMON 5

OD16 21 COMMON 10

OD17 22 COMMON 15

OD18 23 COMMON 20

OD19 24 COMMON 25

OD20 26 COMMON 30

OD21 27 COMMON 35

OD22 28 COMMON 40

OD23 29 COMMON 45

OD24 31 COMMON 50

I/O Noise and Grounding Considerations

The output channels of this model are the open drains of

mosfets with a common source connection. The PMC408 is non-

isolated between the logic and field I/O grounds since output

common is electrically connected to the PMC module ground.

Consequently, the field I/O connections are not isolated from the

carrier/CPU board and backplane. A copper ground plane foil has

been employed in the design of this model to help minimize the

effects of ground bounce, impedance drops, and switching

transients. However, care should be taken in designing installations

without isolation to avoid noise pickup and ground loops caused by

multiple ground connections.

This device is capable of switching many channels at high

currents. Additionally, the nature of the PMC interface is inherently

inductive. The outputs of this model are protected to voltages up to

60V. As such, when switching inductive loads, it is important that

careful consideration be given to the use of snubber devices to

shunt the reverse emf that develops when the current through an

inductor is interrupted. Filtering and bypassing at the load may also

be necessary. Additionally, proper grounding with thick conductors

is essential. Interface cabling and ground wiring should be kept as

short as possible. For outputs, the use of an interposing relay may

also be desireable for isolating the load, raising the drive capability,

or providing additional system protection. Please refer to Drawing

Drawing 4501-867 & 4501-868 for examples of these connections

and proper output and grounding connections.

Output Off-State Loading Considerations

With respect to output control, the 100KΩinput buffer current-

limiting resistors in combination with +4.7V voltage clamps will tend

to increase the off-state drain current with increased drain voltage

(up to 0.5mA at 60V). This is due to the fact that the input buffer

circuitry and output mosfet drain circuitry are connected in tandem to

the same I/O pin. If this presents a problem for your application,

then you should consider separating the inputs and outputs by using

multiple PMC408 modules.

PCI Local Bus Connector

The PMC408 module provides a 32-bit PCI interface to the

carrier/CPU via two 64 pin connectors. These connectors are 64-

pin female receptacle header (AMP 120527-1 or equivalent) which

mates to the male connector of the carrier/CPU board (AMP

120521-1 or equivalent). This provides excellent connection integrity

and utilizes gold-plating in the mating area. Threaded metric screws

and spacers are supplied with the PMC module to provide additional

stability for harsh environments (see Drawing 4501-859 for

assembly details). The pin assignments of the PCI local bus

connector are standard for all PMC modules according to the PCI

Mezzanine Card Specification (see Tables 2.2 and 2.3).

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 5 -

Table 2.2: PMC Connector Pin Assignments for J1 (32-bit PCI)

Signal Name Pin # Signal Name Pin #

TCK 1 -12V 2

GND 3 INTA# 4

INTB# 5 INTC# 6

BUSMODE1# 7 +5V 8

INTD# 9 PCI-RSVD* 10

GND 11 PCI-RSVD* 12

CLK 13 GND 14

GND 15 GNT# 16

REQ# 17 +5V 18

V(I/O) 19 AD[31] 20

AD[28] 21 AD[27] 22

AD[25] 23 GND 24

GND 25 C/BE[3]# 26

AD[22] 27 AD[21] 28

AD[19] 29 +5V 30

V(I/O) 31 AD[17] 32

FRAME# 33 GND 34

GND 35 IRDY# 36

DEVSEL# 37 +5V 38

GND 39 LOCK# 40

SDONE# 41 SBO# 42

PAR 43 GND 44

V(I/O) 45 AD[15] 46

AD[12] 47 AD[11] 48

AD[09] 49 +5V 50

GND 51 C/BE[0]# 52

AD[06] 53 AD[05] 54

AD[04] 55 GND 56

V(I/O) 57 AD[03] 58

AD[02] 59 AD[01] 60

AD[00] 61 +5V 62

GND 63 REQ64# 64

# Indicates that the signal is active low.

BOLD ITALIC Signals are NOT USED by this PMC Model.

Table 2.3: PMC Connector Pin Assignments for J2 (32-bit PCI)

Signal Name Pin # Signal Name Pin #

+12V 1 TRST# 2

TMS 3 TDO 4

TDI 5 GND 6

GND 7 PCI-RSVD* 8

PCI-RSVD* 9 PCI-RSVD* 10

BUSMODE2# 11 +3.3V 12

RST# 13 BUSMODE3# 14

+3.3V 15 BUSMODE4# 16

PCI-RSVD* 17 GND 18

AD[30] 19 AD[29] 20

GND 21 AD[26] 22

AD[24] 23 +3.3V 24

IDSEL 25 AD[23] 26

+3.3V 27 AD[20] 28

AD[18] 29 +GND 30

AD[16] 31 C/BE[2]# 32

GND 33 PCI-RSVD 34

TRDY# 35 +3.3V 36

GND 37 STOP# 38

Signal Name Pin # Signal Name Pin #

PERR# 39 GND 40

+3.3V 41 SERR# 42

C/BE[1]# 43 GND 44

AD[14] 45 AD[13] 46

GND 47 AD[10] 48

AD[08] 49 +3.3V 50

AD[07] 51 PCI-RSVD 52

+3.3V 53 PCI-RSVD 54

PCI-RSVD 55 GND 56

PCI-RSVD 57 PCI-RSVD 58

GND 59 PCI-RSVD 60

ACK64# 61 +3.3V 62

GND 63 PCI-RSVD 64

# Indicates that the signal is active low.

BOLD ITALIC Signals are NOT USED by this PMC Model.

3.0 PROGRAMMING INFORMATION

This Section provides the specific information necessary to

program and operate the PMC408 module.

This Acromag PMC408 is a PCI Local Bus Specification version

2.2 compliant PCI bus target only PMC module. The carrier/CPU

connects a PCI host bus to the PMC module.

The PCI bus is defined to address three distinct address

spaces: I/O, memory, and configuration space. The PMC module

can be accessed via the PCI bus memory space and configuration

spaces, only.

The PCI card’s configuration registers are initialized by system

software at power-up to configure the card. The PMC408 module is

a Plug-and-PlayPCI card. As a Plug-and-Play card the board’s

base address and system interrupt request line are not selected via

jumpers but are assigned by system software upon power-up via the

configuration registers. A PCI bus configuration access is used to

access a PCI card’s configuration registers.

PCI Configuration Address Space

When the computer is first powered-up, the computer’s system

configuration software scans the PCI bus to determine what PCI

devices are present. The software also determines the configuration

requirements of the PCI card.

The system software accesses the configuration registers to

determine how many blocks of memory space the carrier requires. It

then programs the PMC module’s configuration registers with the

unique memory address range assigned.

The configuration registers are also used to indicate that the

PMC module requires an interrupt request line. The system

software then programs the configuration registers with the interrupt

request line assigned to the PMC module.

Since this PMC module is relocatable and not fixed in address

space, this module’s device driver provided by Acromag uses the

mapping information stored in the module’s Configuration Space

registers to determine where the module is mapped in memory

space and which interrupt line will be used.

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 6 -

Configuration Registers

The PCI specification requires software driven initialization and

configuration via the Configuration Address space. This PMC

moduleprovides 256 bytes of configuration registers for this

purpose. The PMC408 contains the configuration registers, shown

in Table 3.1, to facilitate Plug-and-Play compatibility.

The Configuration Registers are accessed via the Configuration

Address and Data Ports. The most important Configuration

Registers are the Base Address Registers and the Interrupt Line

Register which must be read to determine the base address

assigned to the PMC408 and the interrupt request line that goes

activeon a PMC408 interrupt request.

Table 3.1 Configuration Registers

Reg.

Num. D31 D24 D23 D16 D15 D8 D7 D0

0 Device ID=464D Vendor ID= 16D5

1 Status Command

2 Class Code=118000 Rev ID=00

3 BIST Header Latency Cache

4 32-bit Memory Base Address for PMC408

4K-Byte Block

5 : 10 Not Used

11 Subsystem ID=0000 Subsystem Vendor

ID=0000

12 Not Used

13,14 Reserved

15 Max_Lat Min_Gnt Inter. Pin Inter. Line

MEMORY MAP

This board is allocated a4K byte block of memory that is

addressable in the PCI bus memory space to control the ON/OFF

states of individual low-side switches and/or the acquisition of digital

inputs from the field.

The memory space address map for the PMC408 is shown in

Table 3.2. Note that the base address for the PMC408 in memory

space must be added to the addresses shown to properlyaccess

the PMC408 registers. Register accesses as 32, 16, and 8-bit data

in memory space are permitted. All the registers of the PMC408 are

accessed via data lines D0 to D15. The most significant word of a

32-bit access is not used by the PMC408. A 32-bit read will return

logic “0” for the most significant word

Table 3.2: PMC408 I/O Space Address Memory Map

Hex

Base

Addr.+

MSB

D15 D08 LSB

D07 D00 Hex

Base

Addr.+

001 INTERRUPT REGISTER 000

201

READ- Digital Input

Channel Register A

CH15 ↔CH08

READ- Digital Input

Channel Register A

CH07 ↔CH00

200

205 READ- Digital Input

Channel Register B

CH31 ↔CH24

READ- Digital Input

Channel Register B

CH23 ↔CH16

204

209 R/W -Digital Output

Channel Register A

CH15 ↔CH08

R/W -Digital Output

Channel Register A

CH07 ↔CH00

208

20D R/W - Digital Output

Channel Register B

CH31 ↔CH24

R/W -Digital Output

Channel Register B

CH23 ↔CH16

20C

211

NOT DRIVEN

1

R/W - Interrupt

Enable Register

1

CH07 ↔CH00

210

215

NOT DRIVEN

1

R/W -Interrupt Type

Config. Register

1

CH07 ↔CH00

214

219

NOT DRIVEN

1

R/W - Interrupt

Polarity Register

1

CH07 ↔CH00

218

21D

NOT DRIVEN

1

R/W - Interrupt

Status Register

1

CH07 ↔CH00

21C

221

NOT DRIVEN

1

NOT USED

2

220

225

↓

2FD

NOT USED

2

224

↓

2FC

Notes (Table 3.2):

1. Bits 15-8 of these registers are not used. Bits 15-8 will be driven

high (1’s).

2. The PMC408 will respond to addresses that are "Not Used".

Interrupt Register, (Read/Write) - (Base + 000H)

This read/write register is used to: enable board interrupt,

determine the pending status of interrupts, and release an interrupt.

The function of each of the interrupt register bits are described

in Table 3.3. This register can be read or written with either 8-bit,

16-bit, or 32-bit data transfers. A power-up or system reset sets all

interrupt register bits to 0.

Table 3.3: Interupt Register

BIT FUNCTION

0 Board Interrupt Enable Bit. This bit must be set to

logic “1” to enable generation of interrupts from the

PMC module. Setting this bit to logic “0” will disable

board interrupts. (Read/Write Bit)

1 Interrupt Pending Status Bit. This bit can be read to

determine the interrupt pending status of the PMC

module. When this bit is logic “1” an interrupt is

pending and will cause an interrupt request if bit-0 of

the register is set. When this bit is a logic “0” an

interrupt is not being requested.

7 to 2 Not Used

1

8 Software Reset

Writing a logic “1” to this bit will cause a reset of PMC

module. Bit-0 of this register will not be affected.

15 to 9 Not Used

1

Notes (Table 3.3):

1. All bits labeled “Not Used” will return logic “0” when read.

Digital Input Registers A & B (Read Only)

When the Digital Input Channel Data Registers are read, the

value read corresponds to the actual state of the input channels at

the time of the read. If the channel’s tandem output mosfet is being

controlled and its drain is loaded, then reading the digital input

channel data register will return the state of the output (it is directly

connected to the drain). This is an efficient method of

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 7 -

accomplishing “loopback” control of the output. A “0” bit means that

the corresponding input signal is below the threshold value (or the

tandem output mosfet is ON), a “1” bit means that the corresponding

input signal is at or above the threshold value (or the tandem mosfet

is OFF and pulled up).

Thirty-two possible input channels numbered 0 through 31 may

be read. Channel read operations use 8-bit (LSB or MSB), or 16-bit

data transfers with the lower ordered bits corresponding to the lower-

numbered channels for the register of interest (see below). Register

A monitors input channels 0 through 15. Register B monitors input

channels 16 through 31.

It is recommended that unused inputs not be left floating, but

pulled low by turning on the corresponding tandem output (see PMC

Digital Output Registers).

REGISTER A (INPUT CHANNELS 0 THROUGH 15):

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CH15.....................................CH8 CH7....................................CH0

REGISTER B (INPUT CHANNELS 16 THROUGH 31):

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CH31..................................CH24 CH23.................................CH16

Digital Output Registers A & B (Read/Write)

When theDigital Output Channel Data Registers are written to,

the value written is represented at the corresponding output

channels. A “0” bit means that the corresponding output switch is

OPEN (OFF). Writing a “1” bit CLOSES the corresponding output

switch (turns it ON). There are two ways to accomplish an output

read. Reading the digital output channel register returns the state

configuration of this register (which is equivalent to the output

mosfet gate signal). Since input channels operate in tandem with

the output channels, reading the digital input channel register will

return the actual state of the output (it returns the level of the output

mosfet drain). That is, writing a ‘1’ to an output turns the switch ON

(gate signal high). In turn, this drives the drain low (mosfet is

conducting). As such, a read of the input channel register will be the

inverse of a read of the output channel register for a loaded output

channel.

Read/Write Control for 32 output channels numbered 0 through

31 is provided. Channel state Read/Write operations use 8-bit, 16-

bit, or 32-bit datatransfers with the lower ordered bits corresponding

to the lower-numbered channels for the register of interest (see

below). Register A controls output channels 0 through 15. Register

B controls output channels 16 through 31.

REGISTER A (OUTPUT SWITCHES 0 THROUGH 15):

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CH15...................................CH08 CH7....................................CH0

REGISTER B (OUTPUT SWITCHES 16 THROUGH 31):

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CH31...................................CH24 CH23.................................CH16

Each output channel register can be conveniently read back for

verification purposes. However, for critical control applications, it is

recommended that outputs be directly fed back to input points and

the input points monitored (loopback I/O). By design, input channels

are tied to the drains of the tandem output mosfet and a read of the

input channel register will return the inverse of a read of the output

channel register (a read of the input returns the drain level, a read of

the output returns the gate level). This is an efficient method of

accomplishing loopback output control without requiring additional

channels. However, this only applies for a loaded drain (a pullup or

other load connected to the drain).

All outputs are OFF (switch OPEN) following a power-on reset,

and are immediatelycleared following a system reset. It is

recommended that unused outputs be turned on so that the

corresponding unused inputs are pulled low, rather than floating.

Interrupt Enable Register (R/W)

The digital input channel Interrupt Enable Registers provide a

mask bit for each of the 8 possible interrupt channels (channels 0-7

only). A “0” bit will prevent the corresponding input channel from

generating an external interrupt. A “1” bit will allow the

corresponding input channel to generate an interrupt. The unused

upper 8 bits of these 16-bit registers are “Don’t Care” and will always

read high (1’s).

INTERRUPT ENABLE REGISTER:

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

X X X X X X X X CH7....................................CH0

All input channel interrupts are masked (“0”) following a reset.

Interrupt Type (COS or H/L) Configuration Register (R/W)

The Interrupt Type Configuration Registers determine the type

of input channel transition that will generate an interrupt for each of

the 8 possible interrupt channels (channels 0-7 only). A “0” bit

means that an interrupt will be generated when the input channel

level specified by the Interrupt Polarity Register occurs (i.e. Low or

High level transition interrupt). A “1” bit means the interrupt will

occur when a Change-Of-State (COS) occurs at the corresponding

input channel (i.e. any state transition). The unused upper 8 bits of

these 16-bit registers are “Don’t Care” and will always read high

(1’s). Note that interrupts will not occur unless they are enabled.

INTERRUPT TYPE (COS or H/L) CONFIGURATION REGISTER:

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

X X X X X X X X CH7....................................CH0

All bits are set to “0” following a reset which means that the

inputs will cause interrupts for the levels specified by the digital input

channel Interrupt Polarity Register.

Interrupt Polarity Register (R/W)

The Interrupt Polarity Register determines the level that will

cause a channel interrupt to occur for each of the 8 possible

interrupt channels (channels 0-7 only). A “0” bit specifies that an

interrupt will occur when the corresponding input channel is BELOW

TTL threshold (i.e. a “0” in the digital input channel data register). A

“1” bit means that an interrupt will occur when the input channel is

ABOVE TTL threshold (i.e. a “1” in the digital input channel data

register). Note that no interrupts will occur unless they are enabled

by the Interrupt Enable Register. Further, the Interrupt Polarity

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 8 -

Register will have no effect if the Change-of-State (COS) interrupt

type is configured by the Interrupt Type Configuration Register.

INTERRUPT POLARITY (HIGH/LOW) REGISTER:

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

X X X X X X X X CH7....................................CH0

The unused upper 8 bits of these 16-bit registers are “Don’t

Care” and will always read high (1’s). All bits are set to “0” following

a reset which means that the inputs will cause interrupts when they

are below TTL threshold.

Interrupt Status Register (R/W)

The Interrupt Status Register reflects the status of the 8

possible interrupt channels (channels 0-7 only). A “1” bit indicates

that an interrupt is pending for the corresponding channel. A

channel that does not have interrupts enabled will never set its

interrupt status flag. A channel’s interrupt can be cleared by writing

a “1” to its bit position in the Interrupt Status Register (writing a “1”

acts as a reset signal to clear the set state). However, if the

condition which caused the interrupt to occur remains, the interrupt

will be generated again (unless disabled via the Interrupt Enable

Register).

Note that the input channel bandwidth should be limited to

reduce the possibility of missing channel interrupts. For a specific

input channel, this could happen if multiple changes occur before

the channel’s interrupt is serviced.

INTERRUPT STATUS REGISTER:

MSB _ _ _ _ _ _ _ _ _ _ _ _ _ _ LSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

X X X X X X X X CH7....................................CH0

All interrupts are cleared following a reset.

PMC408 PROGRAMMING CONSIDERATIONS

To make programming and communicating with the board

easier, Acromag provides a software product (sold separately)

consisting of PMC module VxWorks®libraries. This software

(Model PMCSW-API-VXW, MSDOS format) is composed of

VxWorks®(real time operating system) libraries for all Acromag

PMC modules. The software is implemented as a library of “C”

functions which link with existing user code to make possible simple

control of all Acromag PMC modules.

Acromag, also provides a software product (sold separately)

consisting of PMC module ActiveX (Object Linking and Embedding)

controls for Windows 98, 95®, ME, 2000 and Windows NT®

compatible application programs (Model PMCSW- ATX, MSDOS

format) to program and communicate with the board.

The following sections give some pointers for programming

interrupts.

Programming Interrupts

Digital input channels can be programmed to generate interrupts

for the following conditions (channels 0-7 only):

•Change-of-State (COS) at selected channels.

•Input level (polarity) match at selected input channels.

Interrupts generated by the PMC408 use interrupt request line

INTA#. The interrupt release mechanism employed is the Release

On Register Access (RORA) type. This means that the interrupter

will release the interrupt request line (INTA#) after the interrupt has

been cleared by writing a “1” to the appropriate bit position in the

input channel Interrupt Status Register.

When using interrupts, input channel bandwidth should be

limited to reduce the possiblity of missing channel interrupts. For a

given input channel, this could happen if multiple changes occur

before the channel’s interrupt is serviced. The response time of the

input channels should also be considered when figuring this

bandwidth. The total response time is the sum of the input buffer

response time, plus the interrupt logic circuit response time, and this

time must pass before another interrupt condition will be recognized.

PMC Programming Example for Change-of-State Interrupts:

1. Enable PMC408 board interrupt by writing a “1” to bit 0 of the

Interrupt Register at Base Address + 000H.

2. Select channel Change-of-State interrupts by writing a “1” to

each channel’s respective bit in the Interrupt Type Register at

Base Address + 214H. Note that Change-Of-State interrupts

(specified with “1”) may be mixed with polarity match interrupts

(specified with “0”).

3. Enable individual input channel interrupts by writing a “1” to

each channel’s respective bit in the Interrupt Enable Register at

Base Address + 210H.

4. Clear pending interrupts by writing a “1” to each channel’s

respective bit in the Interrupt Status Register at Base Address

+ 21CH.

Change-of-State Interrupts may now be generated by the input

channels programmed above for any Change-Of-State

transition.

PMC Programming Example for Level (Polarity) Match

Interrupts:

1. Enable PMC408 board interrupt by writing a “1” to bit 0 of the

Interrupt Register at Base Address + 000H.

2. Select channel polarity match interrupts by writing a “0” to each

channel’s respective bit in the Interrupt Type Register at Base

Address + 214H. Note that Change-Of-State interrupts

(specified with “1”) may be mixed with polarity match interrupts

(specified with “0”).

3. Select the desired polarity (High/Low) level for interrupts by

writing a “0” (Low), or “1” (High) level toeach channel’s

respective bit in the Interrupt Polarity Registers at Base Address

+ 218H.

4. Enable individual input channel interrupts by writing a “1” to

each channel’s respective bit in the Interrupt Enable Registers

at Base Address + 210H.

5. Clear pending interrupts by writing a “1” to each channel’s

respective bit in the Interrupt Status Register at Base Address

+ 21CH.

Interrupts can now be generated by matching the input level with

the selected polarity for programmed interrupt channels.

General Sequence of Events for Processing an Interrupt

1. The PMC408 asserts the Interrupt Request Line (INTA#) in

response to an interrupt condition.

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 9 -

2. Determine the IRQ line assigned to the PMC408 during system

configuration (read configuration register number 15).

3. Set up the system interrupt vector for the appropriate interrupt.

4. Unmask the IRQ in the system interrupt controller.

5. The interrupt service routine pointed to by the vector set up in

step 3 starts.

6. Interrupt service routine determines if the PMC408 has a

pending interrupt request by reading the Interrupt pending bit-1

of the Interrupt Register.

7. Example of Generic Interrupt Handler Actions:

A. Disable the interrupting channel(s) by writing a “0” to the

appropriate bits in the PMC408 Interrupt Enable Register.

B. Clear the interrupting channel(s) by writing a “1” to the

appropriate bits in the PMC408 Interrupt Status Register.

C. Enable the interrupting channel(s) by writing a “1” to the

appropriate bits in the PMC408 Interrupt Enable Registers

at Base Address + 210H. Also, write a “1” to bit-0 of the

Interrupt Register at Base Address + 000H.

8. Write “End-Of-Interrupt” command to systems interrupt

controller.

9. If the PMC408’s interrupt stimulus has been removed, the

interrupt cycle is completed and the board holds the INTA#

inactive.

4.0 THEORY OF OPERATION

This section describes the basic functionality of the circuitry

used on the board. Refer to the Block Diagram shown in Drawing

4501-866 as you review this material.

INPUT/OUTPUT

The field I/O interface to the carrier board is provided through

connector P1 (refer to Table 2.1). Field I/O points are NON-

ISOLATED. This means that the field return and logic common

have a direct electrical connection to each other. As such, care

must be taken to avoid ground loops (see Section 2 for connection

recommendations). Ignoring this effect may cause operation errors,

and with extreme abuse, possible circuit damage. Refer to

Drawings 4501-867 & 4501-868 for example I/O and grounding

connections.

A Field Programmable Gate Array (FPGA) is used to generate

all the logic necessary to operate the board. With respect to input

acquisition, the interrupt channels drivethe FPGA through 8

individual buffers (channels 0-7 only). The input buffers of the other

24 channels are selectively enabled and drive the data bus directly.

The field input signals are tied to the inputs of these buffers via a

100KΩseries connected resistor which limits the input current (but

raises the tandem output’s off-state drain current). Additionally, the

buffer inputs are clamped to +4.7V (generated from the +12V supply

to minimize+5V loading). The input signal threshold is TTL

compatible. The typical threshold is 1.5V DC with 200mV of

hysteresis.

For output control, 32 open-drain outputs are connected in

tandem with 32 input buffers to each I/O channel. The outputs are

the open drains of individual mosfets. The gates of the mosfets are

driven by the FPGA. The sources of these mosfets are connected

in common. This configuration provides up to 32 low-side switches

for digital control. Writing a ‘1’ to the output will turn the switch ON

(closed-circuit), a ‘0’ will turn it OFF (open-circuit). Since the input

buffers are connected in tandem with the output mosfets, efficient

loopback monitoring of the output state can be accomplished by

reading the input channel registers.

With respect to output control, the 100KΩinput buffer resistors

in combination with +4.7V voltage clamps will tend to increase the

off-state drain current with increased drain voltage (up to 0.5mA at

60V). This is due to the fact that the input buffer circuitry and output

mosfet drain circuitry are connected in tandem to the same I/O pin.

If this presents a problem for your application, then you should

consider separating the inputs and outputs by using multiple boards.

Output operation is considered ‘Fail-safe’. That is, the outputs

are always OFF upon power-up reset, and are automatically cleared

following a system software reset. This is done for safety reasons to

ensure reliable control of the output state under all conditions.

Further, unlike some competitive units, output gate pulldowns are

included to ensure that the outputs do not turn on momentarily when

output load power is applied with no power to the PMC module.

The output mosfets employed are rated for a much higher

current than specified. However, the field connector and cabling

used are only rated to 1A per pin (limiting a single channel to 1A).

For compatibility with other PMC models, 10 pins have been

reserved for ground return (hence; the 10A total current limitation

placed on this module). The low R

dsON

of the output mosfets will

ensure TTL-level compatible logic-low output signals even at high

(1A) output currents.

The output mosfets include an integrated zener diode between

the drain and the source. This provides output voltage clamp

protection to 60V. The tandem input channel is also rated to 60V.

However, when driving inductive loads such as relay coils, you

should always place a shunt diode across the load to shunt the

reverse EMF that develops across the coil when the current through

it is turned off (refer to Section 2 and see Drawing 4501-867 for an

example of this type of protection).

Since the input buffer and output mosfet circuitry share an I/O

pin, inputs and outputs may be intermixed in any combination.

Further, by providing an input channel for each output, efficient

loopback monitoring of the output state can be easily accomplished

(see Drawing 4501-868).

Digital input channels of this model can be configured to

generate interrupts for Change-Of-State (COS) and input level

(polarity) match conditions at selected input channels (channels 0-7

only). The interrupt release mechanism employed is RORA

(Release On Register Access).

PCI INTERFACE LOGIC

The PCI bus interface logic is imbedded within the FPGA. This

logic includes support for PCI commands, including: configuration

read/write, and memory read/write. In addition, the PCI target

interface performs parity error detection, uses a single 4K base

address register, and implements target abort, retry, and disconnect.

The PMC408 logic also implements interrupt requests via interrupt

line INTA#. J1 and J2 connectors also provide ±12V and +5V to

power the module (-12V is not used).

A PCI bus read of the PMC module will initially terminate with a

retry. While the read data is moved to the read register (typically

1000ns), continued retries will result in retry terminations. The retry

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 10 -

termination allows the PCI bus to be free for other system

operations while the data is moved to the read register.

A PCI bus write to the PMC module will result in 1)

immmediately accepting the write data and normal cycle termination

or 2) issue of a retry termination. A retry termination will be issued if

the previous write cycle has not completed on the PMC module. It

will typicallytake the PMC module 1000ns to write the data to the

required internal register. Thus if another write cycle is initiated on

the PCI bus before the typical 1000ns has lapsed, the write cycle will

be terminated with a retry.

A programmable logic device provides the control signals

required to operate the board. It decodes the selected addresses,

control signals, and interrupt handling. It also returns the

acknowledgement signal required by the carrier/CPU board per the

PMC specification. The program for the gate array is stored in

separate PROM memory and loaded upon power-up.

PMC Module Software

Acromag also provides a software product (sold separately)

consisting of PMC module ActiveX (Object Linking and Embedding)

controls for Windows 98, 95®, ME, 2000 and Windows NT®

compatible application programs (Model PMCSW- ATX, MSDOS

format). This software provides individual controls that allow

Acromag PMC modules to be easily integrated into Windows®

application programs, such as Visual C++™, Visual Basic®,

Microsoft®Office®97 applications and others. The ActiveX

controls provide a high-level interface to PMC modules, eliminating

the need to perform low-level reads/writes of registers, and the

writing of interrupt handlers—all the complicated details of

programming are handled by the ActiveX controls. These functions

consist of ActiveX control for each Acromag PMC module.

In addition, Acromag provides a software product (sold

separately) consisting of PMC module VxWorks®libraries. This

software(Model PMCSW-API-VXW, MSDOS format) is composed

of VxWorks®(real time operating system) libraries for all Acromag

PMC modules. The software is implemented as a library of “C”

functions which link with existing user code to make possible simple

control of all Acromag PMC modules.

5.0 SERVICE AND REPAIR

SERVICE AND REPAIR ASSISTANCE

Surface-Mounted Technology (SMT) boards are generally

difficult to repair. It is highly recommended that a non-functioning

board be returned to Acromag for repair. The board can be easily

damaged unless special SMT repair and service tools are used.

Further, Acromag has automated test equipment that thoroughly

checks the performance of each board. When a board is first

produced and when any repair is made, it is tested, placed in a burn-

in room at elevated temperature, and retested before shipment.

Please refer to Acromag's Service Policy Bulletin or contact

Acromag for complete details on how to obtain parts and repair.

PRELIMINARY SERVICE PROCEDURE

Before beginning repair, be sure that all of the procedures in

Section 2, Preparation For Use, have been followed. Also, refer to

the documentation of your carrier board to verify that it is correctly

configured. Replacement of the module with one that is known to

work correctly is a good technique to isolate a faulty module.

CAUTION: POWER MUST BE TURNED OFF BEFORE

REMOVING OR INSERTING BOARDS

Acromag’s Applications Engineers can provide further technical

assistance if required. When needed, complete repair services are

also available from Acromag.

6.0 SPECIFICATIONS

PHYSICAL

Physical Configuration…….... Single PMC Module.

Height.............................… 15.11 mm (0.595 in).

(See Drawing 4501-859)

Stacking Height………….. 10.0 mm (0.394 in).

Length.............................

…

149.0 mm (5.866 in).

Width............................….

.

74.0 mm (2.913 in).

Board Thickness...........….

.

1.59 mm (0.062 in).

Connectors:

PCI Local Bus Interface..... Two 64-pin female receptacle header

(AMP 120527-1 or equivalent).

Field I/O…….................…. 50-pin, SCSI-2, female receptacle

header (AMP 787082-5 or

equivalent).

Power Requirements PMC408(E)

5V

1

Typical 65 mA

(±5%) Max. 90 mA

+12V Typical 8 mA

(±5%) Max. 12 mA

-12V Typical Not Used

(±5%) Max.

1. Maximum rise time of 100 milliseconds

ENVIRONMENTAL

Operating Temperature.......…… 0 to +70°C.

-40 to +85°C (E Versions)

Relative Humidity…....................

.

5-95% Non-Condensing.

Storage Temperature.…............. -55 to 105°C.

Non-Isolated....................…...…. Logic and field commons have a

direct electrical connection.

Radiated Field Immunity (RFI).. Designed tocomply with IEC1000-

4-3 Level 3 (10V/m, 80 to

1000MHz AM & 900MHz. Keyed)

and European Norm EN50082-1

with no data upsets.

Electromagnetic Interference

Immunity (EMI)…...…..……......

No data upsets occur under the

influence of EMI from switching

solenoids, commutator motors,

and drill motors.

Surge Immunity……………….… Not required for signal I/O per

European Norm EN50082-1.

ESD Protection……..........…....

Complies with IEC1000-2 Level 1

(2KV direct contact discharge at

input/output terminals) and

European Standard

EN50082-1.

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 11 -

Electric Fast Transient

Immunity (EFT)……………..…..

Complies with IEC1000-4-4 Level

2 (0.5KV at field input and output

terminals) and European Norm

EN50082-1.

Radiated Emissions ………....... Meets or exceeds European Norm

EN50081-1 for class A equipment.

Warning: This is a class A product. In a domestic environment

this product maycause radio interference in which the

user may be required to take adequate measures.

Reliability Prediction

Mean Time Between Failure…... MTBF = TBD hours (not available

at time of printing) @ 25°C,

Using MIL-HDBK-217F, Notice 2.

DIGITAL INPUTS

Input Channel Configuration.........32 non-inverting buffered inputs

with a common connection. For

DC voltage applications only,

observe proper polarity.

Input Signal Voltage Range...........0 to +60V DC, Maximum.

Input Signal Threshold..................TTL compatible. 1.5V DC with

200mV of hysteresis, typical.

Thus, Low-to-High threshold is

1.6VDC, High-to-Low is 1.4VDC,

typical. Limited to TTL levels of

0.8VDC (Max LOW level) and

2.0VDC (Min HIGH level).

Input Resistance...........................100KΩ, Typical.

Input Hysteresis............................200mVDC centered at a 1.5VDC

threshold, Typical.

Input Current.................................560uA, Typical at 60VDC.

Interrupt Input Response Time......250nS minimum to 375nS

maximum, depending on when

the input transition occurs with

respect to the 8MHz clock.

Measured from input transition to

INTA# line assertion.

DIGITAL OUTPUTS

Output Channel Configuration.......32 open-drain DMOS Mosfets

with common source connection.

For DC voltage applications only,

observe proper polarity.

Output “OFF” Voltage Range.........0 to +60V DC, Maximum.

Output “OFF” Leakage Current......25uA Maximum (Mosfet Only,

55°C, 48V). Does not include

tandem input bias current.

NOTE: The 100KΩinput buffer

resistors in combination with

+4.7V voltage clamps will tend to

increase the off-state drain

current with increased drain

voltage (up to 0.5mA at 60V).

This is due to the fact that the

input buffer circuitry and output

mosfet drain circuitry are

connected in tandem to the same

I/O pin.

Output “ON” Current Range...........0 to+1A DC, continuous (up to

10A total for all channels

combined), or 300mA DC,

continuous (all channels ON).

No deration required at elevated

ambients.

Output R

ds

ON Resistance.............0.2Ω, Maximum (25°C).

Turn-ON Time................................Varies with load, 620ns Typical,

with 330Ωpull-up to +5V and

12-inch ribbon cable. Measured

from FRAME# line assertion to

output drain state transfer to TTL

0.8V level.

Turn-OFF Time..............................Varies with load, 800ns Typical,

with 330Ωpull-up to +5V and

12-inch ribbon cable. Measured

from FRAME# line assertion to

output drain state transfer to TTL

2.0V level.

OUTPUT MOSFETS

(These specifications are included for reference and apply to

the output driver only. See DIGITAL OUTPUTS above for

module specifications).

Manufacturer/Part Number............National NDS9945,

Siliconix Si9945DY.

Voltage V

DSS

..................................60V DC, Maximum.

Current I

D

.......................................3.5A, Continuous (25°C),

2.8A, Continuous (70°C).

ON Resistance R

DS

.......................0.2Ω(VGS=4.5V, 25°C).

Power Dissipation P

D

....................2W (25°C).

Output “OFF” Leakage Current....25uA Maximum (55°C, 48V).

PCI Local Bus Interface

Compatibility......................…..... Conforms to PCI Local Bus

Specification, Revision 2.2 and

PMC Specification, P1386.1/Draft

2.4. (See Note 2)

Electrical/Mechanical Interface... Single-Width PMC Module.

PCI Target ……………………… Implemented by Altera FPGA.

4K Memory Space Required……One Base Address Register.

PCI commands Supported…….. Configuration Read/Write,

Memory Read/Write, 32,16, and 8-

bit data transfer types supported.

Signaling………………………… 5V Compliant, 3.3V Tolerant

PCI bus Write Cycle Time

1

…… 150 nS Typical measured from

falling edge of FRAME# to the

falling edge of TRDY#.

PCI bus Read Cycle Time

1

…… 150 nS Typical.

Notes (PCI Local Bus Interface):

1. Although the typical read or write PCI bus cycle time is only

150nS the actual read or write implemented on the PMC

Module will be typically 1000 nS. Thus, the PMC Module will

issue a RETRY when a new read or write cycle is implemented

before the PMC modules 1000 nS read or write has completed.

When the PMC Module issues a RETRY this frees the PCI

bus while the previous read or write operation is completed.

2. Due to the unique modular nature of the PMC408 assembly, it

is impossible to comply with the solder side component height

per the PMC Mechanical Standand. Refer to Mechanical

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 12 -

Assembly Drawing 4501-859 for details. You must determine

whether there will be adequate clearance for your application.

APPENDIX

CABLE: MODEL 5028-187 (SCSI-2 to Flat Ribbon, Shielded)

Type: Round shielded cable, 50-wires (SCSI-2 male connector at

one end and a flat female ribbon connector at the other end).

The cable length is 2 meters (6.56 feet). This shielded cable is

recommended for all I/O applications (both digital I/O and

precision analog I/O).

Application: Used to connect Model 5025-552 termination panel to

the PMC Module.

Length: Standard lenght is 2 meters (6.56 feet). Consult factory for

other lenghts. It is recommended that this length be kept to a

minimum to reduce noise and power loss.

Cable: 50 conductors, 28 AWG on 0.050 inch centers (permits

mass termination for IDC connectors), foil/braided shield inside

a PVC jacket.

Connectors: (One End): SCSI-2, 50-pin male connector with

backshell and spring latch hardware.

(Other End): IDC, 50-pin female connector with strain

relief.

Keying: The SCSI-2 connector has a “D Shell” and the IDC

connector has a polarizing key to prevent improper installation.

Schematic and Physical Attributes: See Drawing 4501-758.

Electrical Specifications: 30 VAC per UL and CSA (SCSI-2

connector spec.’s). 1 Amp maximum at 50% energized

(SCSI-2 connector spec.’s).

Operating Temperature: -20°C to +80°C.

Storage Temperature: -40°C to +85°C.

Shipping Weight: 1.0 pound (0.5Kg), packed.

TERMINATION PANEL: MODEL 5025-552

Type: Termination Panel For PMC Module Boards

Application: To connect field I/O signals to the PMC Module.

Termination Panel: Acromag Part 4001-040 (Phoenix Contact

Type FLKM 50). The 5025-552 termination panel facilitates the

connection of up to 50 field I/O signals and connects to the

PMC Module via a flat ribbon cable (Model 5025-551-x). Field

signals are accessed via screw terminal strips. The terminal

strip markings on the termination panel (1-50) correspond to

field I/O (pins 1-50) on the PMC module. Each PMC module

has its own unique pin assignments. Refer to the PMC module

manual for correct wiring connections to the termination panel.

Schematic and Physical Attributes: See Drawing 4501-464.

Field Wiring: 50-position terminal blocks with screw clamps. Wire

range 12 to 26 AWG.

Mounting: Termination panel is snapped on the DIN mounting rail.

Printed Circuit Board: Military grade FR-4 epoxy glass circuit board,

0.063 inches thick.

Operating Temperature: -40°C to +100°C.

Storage Temperature: -40°C to +100°C.

Shipping Weight: 1.25 pounds (0.6kg) packaged.

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 13 -

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 14 -

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 15 -

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 16 -

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 17 -

SERIES PMC408 PCI MEZZANINE CARD 32-CHANNEL DIGITAL I/O MODULE

___________________________________________________________________________________________

- 18 -

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

This manual suits for next models

2

Table of contents

Other Acromag PCI Card manuals