ACS contsys SAT User manual

Technical manual BA 1118

Filling level

SAT

Electrode probe

for conductive limit level detection

in electrical conductive liquids

Detects up to six limit values simultaneously

Useable

for leakage or overflow protection in container

for minimum, maximum resp. multilevel detection in container

as pump protection, resp. dry run protection in pipelines

for two-position-control of pumps

Wide application range

for conductivities higher than 1 µS/cm

for process temperatures from -15 °C to +150 °C

for process pressures from -1 bar to +10 bar

materials also for aggressive filling material

ATEX II 1 G Ex ia IIB/IIC T6…T1 Ga

Certification for the use in explosion hazardous areas

Integrated wire break monitoring

L a u t e r b a c h s t r . 5 7 –8 4 3 0 7 E g g e n f e l d e n –G e r m a n y

T e l : + 4 9 8 7 2 1 / 9 6 6 8 - 0 –F a x : + 4 9 8 7 2 1 / 9 6 6 8 - 30

info@acs-controlsystem.de –www.acs-controlsystem.de

SAT

page 2 of 9

Index

Application field ........................................................................................................... 3

Function ........................................................................................................................ 3

Safety notes ..............................................................................................................3

Installation ..................................................................................................................... 4

Maintenance ................................................................................................................. 4

Repair ............................................................................................................................ 5

Electrical connection ..................................................................................................... 5

SAT

page 3 of 9

Application field

The electrode probe SAT, in combination with a suitable evaluation device, is used for conductive limit value

detection in electrically conductive filling materials.

Depending on the application, the electrode rods can have a length of up to 3 m.

With up to four contact electrodes multiple tasks can be fulfilled simultaneously. Among these tasks are e.g.

leakage and overflow protection, minimum / maximum protection resp. multilevel detection in container, pump

protection in pipelines and also the two-position-control of pumps.

The electrode probes are designed for a wide application range.

The conductivity also of aggressive filling materials, with 1 µS/cm and higher can be detected, at process

temperatures from -40 °C to +150 °C, at pressures from -1 bar to +20 bar.

The electrode probes are certificated for the use in explosion hazardous areas acc. to ATEX II 1 G in zone 0.

Function

The electrode probe is mounted directly in the wall of the container or of the pipe by using the respective process

connection or installed over the filling material by using a suitable mount.

The alternating voltage, that is generated by a suitable evaluation electronic is applied either between the

electrode rods or between the electrode rods and the metallic wall of the container resp. pipe that is connected

to the metallic process connection.

As soon as the electrically conductive filling material makes a connection between the electrodes resp. between

the electrode and the metallic wall of the container resp. pipe, an measurable current flows, that causes a

reaction of the connected evaluation device.

Due to the use of a alternating voltage the corrosion at the electrode and the electrolytic decomposition of the

filling material is avoided.

At the electrode probes an additional module (diode module LBM) for the wire supervision can be installed inside

the housing.

In the case of a wire break between electrode probe and a suitable evaluation device, the evaluation device can

output a corresponding warning signal.

SAT

page 4 of 9

Safety notes

Operational safety

The device is safely built and tested according to state-of-the-art technology and has left the factory in perfect

condition as regards technical safety.

The device meets the legal requirements of all relevant EC directives. This is confirmed by attaching the CE

mark.

Installation, connection, commissioning, operation

Installation, electrical connection, commissioning and operation of the device must be made by a qualified and

authorized expert according to the information’s in this technical manual and the relevant standards and rules.

This expert must have read and understood this technical manual and especially the safety notes.

The device may only be used within the permitted operation limits that are listed in this technical manual. Every

use besides these limits as agreed can lead to serious dangers.

The materials of the device must be checked for compatibility with the respective application requirements

(contacting materials, process temperature) before use. An unsuitable material can lead to damage, abnormal

behavior or destruction of the device and to the resulting dangers.

The sensors may not be used as sole device for prevention of dangerous conditions in machines and plants.

Using the device in a manner that does not fall within the scope of its intended use, disregarding this

instruction, using under-qualified personnel, or making unauthorized alterations releases the manufacturer from

liability for any resulting damage. This renders the manufacturer‘s warranty null and void.

Safety notes for electrical operating supplies

for explosive hazardous areas

If a device is installed and operated in explosive hazardous areas, the general Ex construction standards

(EN/IEC 60079-14, VDE 0165), these safety notes and the enclosed EC conformity certificate must be

observed.

The installation of explosive hazardous systems must be carried out principally by specialist staff.

The device meets the classification

II 1 G Ex ia IIB/IIC T6...T1 Ga resp.

II 1/2 G Ex ia IIB/IIC T6...T1 Ga/Gb resp.

II 2 G Ex ib IIB/IIC T6…T1 Gb

The devices are conceived for detection of limit values in explosive hazardous areas.

The measured medium may also be combustible liquids.

The permitted operating temperatures and pressures are type and variant dependent and can be found in this

technical manual.

For applications, which require devices of category 1 or category 1/2, the process pressure and temperature

range of the media has to be between 0,8 bar and 1,1 bar and between -20 °C and 60 °C.

If a device is mounted in the separation wall to the hazardous area that requires devices of category 1, the

process connections have to be designed in such a way, that they are sufficiently tight according to

EN/IEC 60079-14 section 4.6.

The operating device may only remain in the zone when connected to an evaluation device and connected to

the potential compensation.

The device is earthen for safe technical function. Provide sufficient potential compensation along the complete

cable way. Install the intrinsically safe circuit earth free.

At variants of the devices with chargeable plastic parts (e.g. connection housing, isolation), a warning marking

points out to the safety measures, that must be applied because of the electrostatic charging in operation and

especially in the case of maintenance activities.

avoid friction

no dry cleaning

no assembling in pneumatic conveying stream

protect the electrode rods against pendular movements

SAT

page 5 of 9

Installation

The isolation of the electrode rod may not be damaged resp. removed excepted at the electrode tip.

The electrode rods can be cut arbitrarily by a tong or a saw. After cutting the electrode rod, remove 10 mm of

the isolation. The electrode may not be mechanically forced at the cutting, to avoid damaging the isolation.

Installation notes

Drive the system pressure free prior installation resp. deinstallation of the device and avoid high temperatures

to avoid injuries.

Consider enough installation space outside the container, to insert the electrode probe into the plant without the

use of force.

Install the device if necessary into a bypass if dense heavy foam, wild turbulences or foamed liquids can occur.

Install the electrode probe in such a position in the container, where no strong forces to the side, like e.g. by

mixer or near fill-in openings, can have an effect to the electrode rods.

This is especially important for especially long electrode rods.

The non-isolated electrode tips, when mounted, may not make a contact to the wall of the container, if this is

made of metal or electrically conductive plastic.

Electrode rods longer than 0,5 m must be stabilized among each other or against the wall of the container,

especially if the filling material is strongly fluctuating.

Use for the stabilization suitable isolating spacers.

The distance between the spaces should be not more than 0,5 m.

At horizontal side mounting into a container or also into a pipe for stability reasons the length

of the electrode rods should be not more than 200 mm.

At wider electrode rods (8 mm) the length can be longer.

At a horizontal mounting the electrode rods should be installed at an angel with the

electrode rod tip below (approx. 20°), to allow an easier flow-off of filling material

residues and by this to avoid the coat-forming.

At horizontal pipelines the length of the electrodes is limited by that way, that in a empty

pipe, also in the case of liquid residues, the electrically conductive liquid connection

between the two electrode rods can disconnect.

Otherwise and empty pipe can be detected as filled.

The tightening of the process connection may only be done at the hexagon by a suitable spanner. The

maximum permitted torque strength is 100 Nm.

The screw in of the process connection by using the connection housing is not permitted.

Maintenance

The device is free of maintenance.

The isolation of the electrodes should be checked regularly and also a possible coating at the electrode tips

should be removed.

A non-conductive coating at the metallic electrode tip can effect error behaviour because no current can flow

although the electrically conductive filling material makes a connection.

SAT

page 6 of 9

Repair

A repair may only be carried out by the manufacturer.

If the device must be sent back for repair, the following informations must be enclosed:

An exact description of the application.

The chemical and physical characteristics of the product.

A short description of the occurred error.

Before returning the device for repair, the following measures must be proceeded:

All stick product residues must be removed. This is especially important, if the product is unhealthily,

e.g. caustic, toxic, carcinogenic, radioactive etc.

A returning must be refrained, if it is not possible by 100% to remove the unhealthily product

completely, because e.g. it is penetrate into cracks or is diffused through plastic.

Electrical connection

The electrical connection of the device must be carried out according to the respective country specific

standards. Incorrect installation or adjustment could cause applicationally conditioned risks.

Use only suitable cables with max. 25 per wire, that fulfills the requirements e.g. regarding temperature,

resistance or laying at the place of installation.

The cable gland is suitable for cable diameters from 3,5 to 8 mm. After installation of the cable the cable gland

must be fix screwed to ensure the tightness of the connection housing.

Use only shielded signal and measurement wires and install these wires separated from power leading wires.

At strong electromagnetic irradiation use principally a cable with shield. Connect the cable shield only at one

side to earth.

A suitable evaluation device must by connected by the connection cable with the electrode rods inside the

connection housing.

The connection of the cable to the electrode rods is made by terminals for wire cross-cuts up to 2,5 mm2or by

screw connections inside the connection housing. For the connection use isolated thimbles.

At electrode probes an additional module (diode module LBM) for the wire supervision can be installed inside

the housing. This must always be connected between the shortest rod and the longest rod.

A connection polarity is not relevant. When using evaluation devices resp. transmitter, that does not support a

wire supervision, this module may not be installed.

For inauguration it is suggested to switch off all connected control devices to avoid unintended control actions.

Two-position-control

For a two-position-control, an electrode probe with three

rods must be used, where the longest rod represents the

reference electrode.

The evaluation device with a function for two-position-control keeps the

filling material level between the upper and the lower limit level.

Four-level-detection

For a four-level-detection an electrode probe with five rods must be

used, where the longest rod represents the reference electrode.

For the evaluation two two-channel-evaluation-devices are used,

whose both reference connection must be connected with the longest

electrode.

SAT

page 7 of 9

Technical data

Materials

Electrode rod: Steel 1.4404 (AISI316L) resp. 1.4571 (AISI316Ti) / Hastelloy C22

(medium contact)

Electrode rod isolation: PA / ETFE resp. E-CTFE

(medium contact)

Process connection: POM / PP / PTFE

(medium contact)

Terminal enclosure: POM / PP / PTFE

Cable gland: Enclosure PA / gaskets CR, NBR

Gaskets: Medium contact:

Electrode isolation PA

NBR

Electrode isolation E-CTFE

FPM

Others: NBR, FPM

Environmental conditions

Environmental temperature: maximum –15°C...+100°C, observe limitations

Limitation by variant

Environmental temperature range

ATEX zone 0

-15...+60°C

ATEX T6

-15...+80°C

ATEX T5…T1

-15...+95°C

Limitation by material

Environmental temperature range

Terminal enclosure PP

+5...+100°C

Process temperature: maximum –15°C...+150°C, observe limitations

Limitation by variant

Process temperature range

ATEX zone 0

-15...+60°C

ATEX T6

-15...+80°C

ATEX T5

-15...+ 95°C

ATEX T4

-15...+ 130°C

ATEX T3...T1

-15...+ 130°C

Electrode isolation PA

-10...+ 100°C

Electrode isolation ETFE resp. E-CTFE

-15...+ 150°C

Limitation by material

Process temperature range

Process connection POM

-15...+110°C

Process connection PP

+5...+100°C

Process pressure: Standard -1 bar...+10 bar

ATEX zone 0 +0,8 bar... +1,1 bar

Conductivity: 1 Mresp. 1 µS/cm, depends on connected evaluation device

Protection classification: IP65 EN/IEC 60529

Weight: Depends on:

- material / size of connection housing resp.

- style of process connection resp.

- material / diameter / number / length of the electrodes

SAT

page 8 of 9

Dimension drawings

Process connection

G15 –G 1 ½“

Process connection

G20 –G 2“

Process connection

G10 –G 1“

Process connection

G12 –G ½“

Terminal enclosure

60mm (only with material POM)

Terminal enclosure

40mm

with terminal enclosure 40mm or 60mm (only with material POM)

SAT

page 9 of 9

Order code overview

Type

0 Standard

Ex ATEX 1 G Ex ia IIB/IIC T6…T1 Ga

Electrode number

1 1 electrode rod

2 2 electrode rods

3 3 electrode rods

4 4 electrode rods

5 5 electrode rods

7 7 electrode rods

Process connection

G12 Thread ISO 228-1 –G ½“ – 1-rod

G10 Thread ISO 228-1 –G 1“ – 1…3-rod

G15 Thread ISO 228-1 –G 1 ½“ – 1…5-rod

G20 Thread ISO 228-1 –G 2“ – 1…7-rod

Material electrode rod (medium contact)

A4 CrNi-steel, rod diameter 4mm

A8 CrNi-steel, rod diameter 8mm

D Hastelloy C22, rod diameter 4mm

Y others on request

Material process connection / terminal enclosure

D POM 40mm for G ½“ / G 1“ resp. 80mm for G 1 ½“/ G 2“

E POM 60mm for G ½“ / G 1“

P PP 40mm for process connection G ½“/ G 1“

M PP 80mm for process connection G 1 ½“/ G 2“

T PTFE 40mm for process connection G ½“ / G 1“

L PTFE 80mm for process connection G 1 ½“/ G 2“

Material electrode isolation (medium contact)

R PA not for material process connection T / L –PFTE

H4 ETFE resp. E-CTFE, rod diameter 4mm

H8 ETFE resp. E-CTFE, rod diameter 8mm

Wire break monitoring

A without

B Diode module LBM only for terminal enclosure 80mm

Diameter electrode rod

0 4 mm (L1 max. 2000mm)

W 8 mm (L1 max. 3000mm)

Length L1 electrode rod in mm

Length L2 electrode isolation in mm

SAT __________

Table of contents

Other ACS contsys Measuring Instrument manuals

ACS contsys

ACS contsys RCE 300 User manual

ACS contsys

ACS contsys DAL-311x0x0S User manual

ACS contsys

ACS contsys DAL-311x3x0S User manual

ACS contsys

ACS contsys DAL-311 5 0S Series User manual

ACS contsys

ACS contsys DAL-311-2 Series User manual

ACS contsys

ACS contsys DAP-311 0 0S Series User manual

ACS contsys

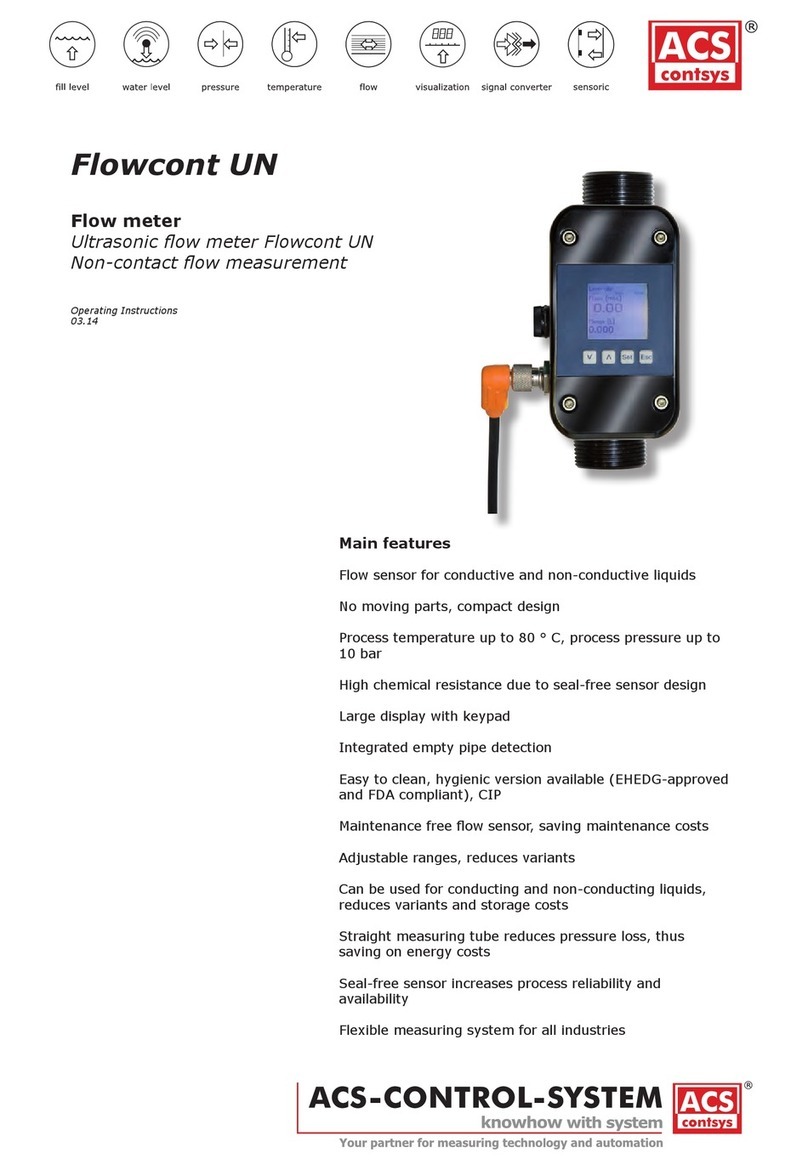

ACS contsys Flowcont UN User manual

ACS contsys

ACS contsys Sonicont USN4SP User manual