ACS-CONTROL-SYSTEM

GmbH

l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 3Index

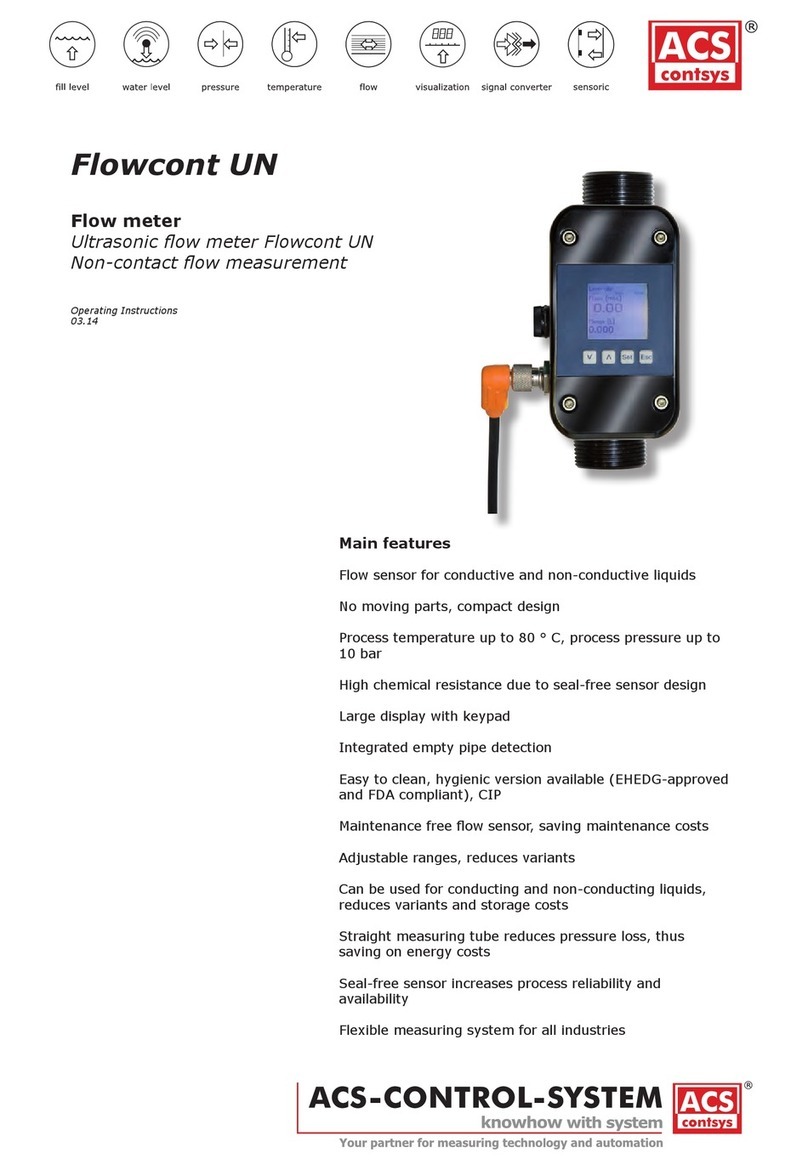

1 Systemdescription................................................4

1.1 Intended use ................................................... 4

1.2 Field of application ........................................... 4

1.3 System components ......................................... 4

1.4 Function ......................................................... 5

2 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 Operational safety ............................................ 6

2.2 Installation, connection, commissioning, operation6

3 Installation......................................................7

3.1 Installation place ............................................. 7

3.2 Installation notes ............................................. 9

4 Electricalconnection .............................................11

4.1 Potential equalization - earthing ......................... 11

4.2 Connection cable ............................................. 11

4.3 Supply voltage ................................................ 11

4.4 Switch output .................................................. 11

4.5 Analogue output .............................................. 12

4.6 Connection scheme .......................................... 12

5 Operation......................................................14

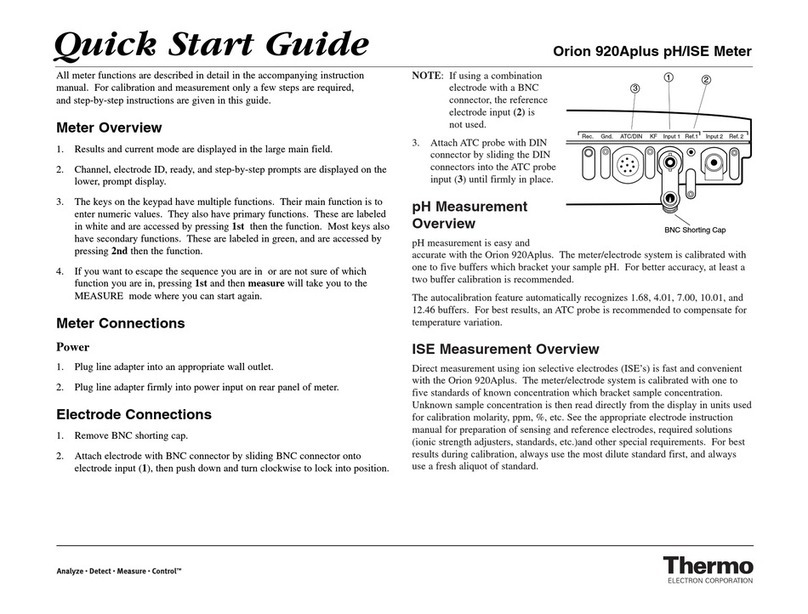

5.1 Operation and display parts ............................... 14

5.2 Function scheme .............................................. 14

5.3 Menu structure ................................................ 16

5.4 Navigation ...................................................... 17

5.5 Output ........................................................... 18

5.6 Basic setting ................................................... 25

5.7 Display ........................................................... 31

5.8 Simulation – E ................................................. 37

5.9 Diagnosis ........................................................ 38

5.10 Data .............................................................. 41

5.11 Start-up procedure ........................................... 45

5.12 Software history .............................................. 48

6 Service........................................................49

6.1 Maintenance .................................................... 49

6.2 Dismounting.................................................... 49

6.3 Repair ............................................................ 49

6.4 Return ............................................................ 49

6.5 Disposal ......................................................... 49

7 TechnicalData..................................................50

7.1 Auxiliary power supply ...................................... 50

7.2 Input.............................................................. 50

7.3 Output ........................................................... 51

7.4 Measuring accuracy .......................................... 51

7.5 Interface Bluetooth .......................................... 52

7.6 Data memory .................................................. 52

7.7 Clock .............................................................. 52

7.8 Process conditions ............................................ 52

7.9 Environmental conditions .................................. 52

7.10 Materials - process wetted ................................ 52

7.11 Materials - not process wetted ........................... 52

8 Dimensiondrawings..............................................53

8.1 Terminal enclosure ........................................... 53

8.2 Process connection ........................................... 53

9 Orderinginformation.............................................56

9.1 Order code ...................................................... 56

9.2 Additional options ............................................ 57

9.3 Accessories ..................................................... 57