v

Table of Contents

CHAPTER 1:!SAFETY..............................................................VII!

1-1!How to Use This Manual ............................................................................................vii!

Safety Symbols Used in this Manual....................................................................vii!

1-2!Warnings and Precautions ..........................................................................................ix!

1-3!Responsibility .............................................................................................................. x!

General Responsibility .......................................................................................... x!

Operator Responsibility......................................................................................... x!

Maintenance Responsibility .................................................................................xii!

Reporting a Safety Defect ....................................................................................xii!

CHAPTER 2:!GENERAL INFORMATION ................................ 13!

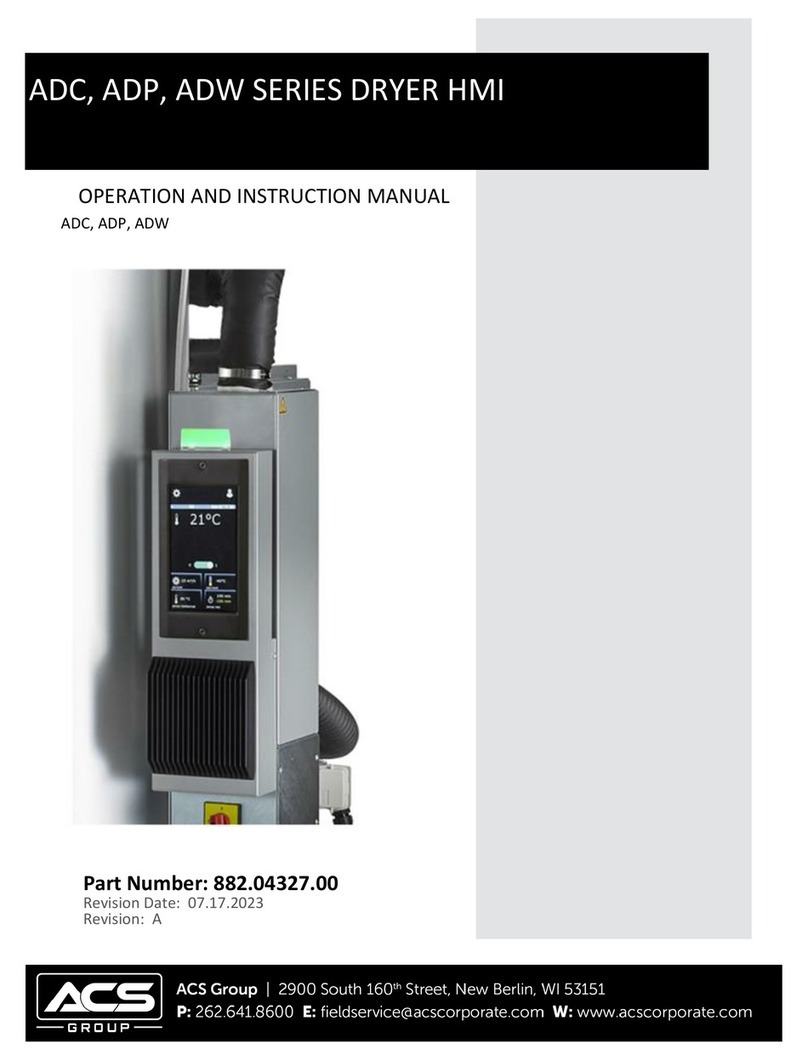

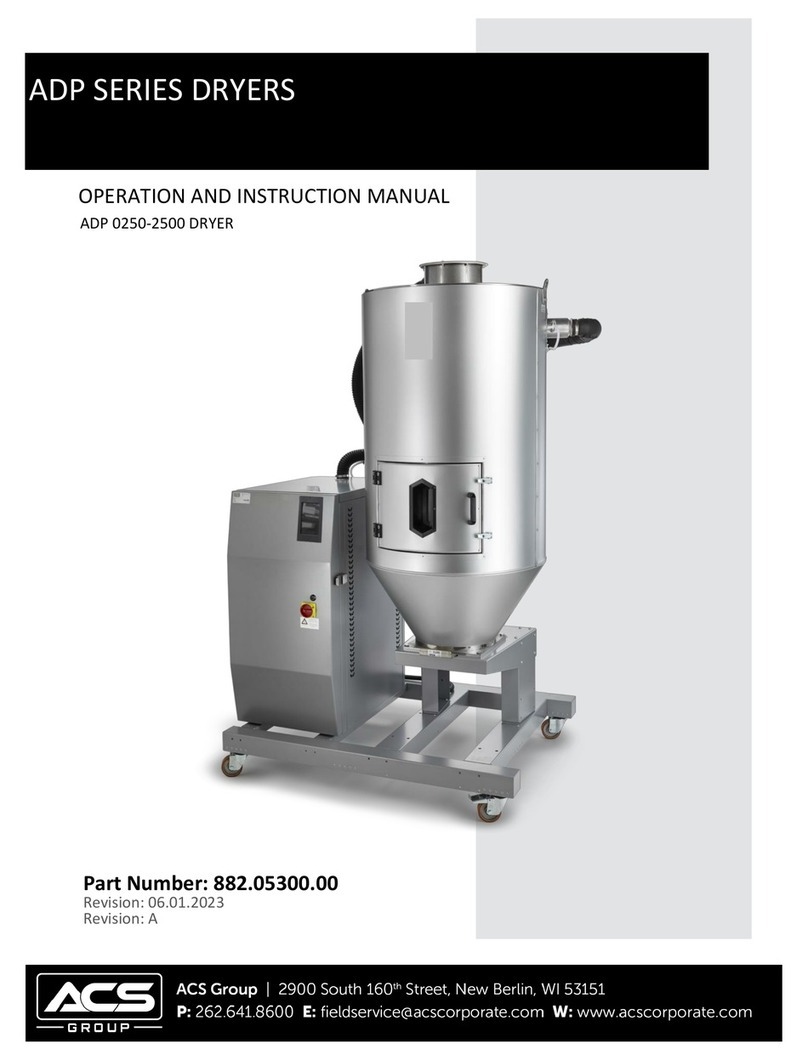

2-1!Models Covered in This Manual................................................................................ 13!

2-2!Necessary Documents .............................................................................................. 13!

2-3!General Description .................................................................................................. 13!

The Process/Regeneration Cycle ....................................................................... 15!

Material Overdrying Protection (DryPro Control Only) ........................................ 15!

2-4!Central Drying System Options................................................................................. 17!

Mechanical Options............................................................................................. 17!

CHAPTER 3:!INSTALLATION.................................................. 18!

3-1!Positioning Your Dryer .............................................................................................. 18!

3-2!Connecting the Process and Return Air Hoses......................................................... 18!

3-3!Drying Hopper ........................................................................................................... 21!

Removing the Rust Inhibitor.................................................................................... 21!

Air Trap Considerations ......................................................................................... 21!

3-4!Positioning Your Hopper ........................................................................................... 21!

3-5!Optional Damper Valve ............................................................................................. 21!

3-6!Optional Pressure Orifice (Required with Damper Valve)......................................... 22!

3-7!Optional Bypass Valve ............................................................................................. 23!

CHAPTER 4:!OPERATION....................................................... 24!

4-1!Pre-Startup Checks................................................................................................... 24!

4-2!Using the Optional Isolation Valves .......................................................................... 24!

CHAPTER 5:!MAINTENANCE ................................................. 25!

5-1!Work Rules................................................................................................................ 25!

5-2!Optional Damper Valve Maintenance ....................................................................... 25!

5-3!Optional Bypass Valve Maintenance ........................................................................ 26!

5-4!Replacing the Process Heaters................................................................................. 27!

5-5!Preventative Maintenance Checklist......................................................................... 28!

CHAPTER 6:!TROUBLESHOOTING ....................................... 29!

Determining Temperature Controller Errors or Sensor Errors................................... 32!